Professional Documents

Culture Documents

MN4046 - 0522 (W)

MN4046 - 0522 (W)

Uploaded by

Dênis Dáyol0 ratings0% found this document useful (0 votes)

8 views2 pagesOriginal Title

MN4046_0522 (W)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views2 pagesMN4046 - 0522 (W)

MN4046 - 0522 (W)

Uploaded by

Dênis DáyolCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

®

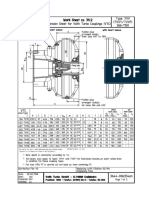

Moment Couplings: Sizes DM50–DM2100

Instruction Manual

These instructions must be read thoroughly before installation or operation. This instruction manual was accurate at the time of

printing. Please see dodgeindustrial.com for updated instruction manuals.

WARNING: To ensure the drive is not unexpectedly started, turn off and WARNING: All products over 25 kg (55 lbs) are noted on the shipping

lock-out or tag power source before proceeding. Failure to observe these package. Proper lifting practices are required for these products.

precautions could result in bodily injury.

STEP 1: PRE-ASSEMBLY INSPECTION

All parts should be examined for any damage during the shipping open flame. When using an open flame, be sure to apply

and handling process. Measurements should be taken to ensure heat evenly over the entire hub to avoid uneven heating and

parts meet application requirements, such as hub and shaft fits, distortion. It is recommended that temperature sensitive

shaft separation, etc. All parts must be clean and free of any crayons or stickers are used to ensure the hub reaches the

foreign material before attempting installation. Ensure that the proper temperature for installation.

shafts are free of burrs, grease, and other foreign material before 4. In some cases it might be necessary to shrink the shaft by

installing hubs. using dry ice.

STEP 2: INSTALLATION OF KEYS 5. Install each hub so that it is flush with the end of the shaft.

Also ensure that there is full length through bore engagement

Install keys in respective shafts. Keys should be made from with the key and shaft. Allow each hub time to cool to room

quenched and tempered alloy steel or similar material to ensure temperature before assembling the halves together.

the same strength as that of the Moment Coupling hub. Keys

Flush

should fit in the key seat with a tight fit on the sides and slight Driver Hub Driven Hub

clearance over the key. Ensure key is free of burrs and break all

edges.

STEP 3: MOUNTING HUBS

NOTE: PPE (Personal Protective Equipment) must be used

due to the high temperature of the hub.

1. Moment couplings are designed for tight interference fits.

Recommendations for shaft tolerances is as follows: shaft

Figure 1 - Hub Installation

diameter +0.00”/-0.001”. It is important to achieve the proper

fit as this coupling not only transmits the torque but must also STEP 4: COUPLING ASSEMBLY

provide support for the drive system.

2. Clean hubs and shafts and inspect for any nicks, burrs or 1. Moment couplings are not designed to accommodate

dents. Address issues as needed. any misalignment. They are intended to be used for shaft-

mounted gear drives where the assembly is free to move with

3. Heat the coupling hub to between 350°F (177°C) to 450°F the eccentricities in the driven equipment.

(232°C). Depending upon availability of equipment and safety

of processes, the following heating methods can be used 2. Move the drive assembly into position using properly sized

(in order of preference): oven, induction heater, oil bath, and lifting equipment. The output shaft of the reducer should

be parallel and in line with the driven shaft. Apply medium

WARNING: Because of the possible danger to person(s) or property

strength thread locker on each bolt prior to installation. Align

from accidents which may result from the improper use of products,

fastener holes and loosely tighten bolts.

it is important that correct procedures be followed. Products must be ISO GRADE 10.9 BOLTS

used in accordance with the engineering information specified in the DRIVER HUB

DRIVEN HUB

catalog. Proper installation, maintenance and operation procedures

must be observed. The instructions in the instruction manuals must

be followed. Inspections should be made as necessary to assure

safe operation under prevailing conditions. Proper guards and other

MOUNTS TO MOUNTS TO

suitable safety devices or procedures as may be desirable or as may REDUCER DRIVEN

be specified in safety codes should be provided, and are neither SHAFT EQUIPEMENT

provided by Dodge® nor are the responsibility of Dodge. This unit and SHAFT

its associated equipment must be installed, adjusted and maintained

by qualified personnel who are familiar with the construction and

operation of all equipment in the system and the potential hazards

involved. When risk to persons or property may be involved, a holding

device must be an integral part of the driven equipment beyond the

speed reducer output shaft. Figure 2 - Coupling Assembly

1

3. Tighten bolts gradually and evenly in an alternating star STEP 5: REMOVAL

pattern to the recommended tightening torques displayed in

Table 1 using a calibrated torque wrench. It is best to tighten 1. Use appropriate lifting equipment to remove the weight of the

each bolt to 50% of the tightening torque and then tighten to drive assembly from the Moment coupling and driven shaft.

100% of the tightening torque. Recheck each bolt to ensure Ensure the swing base is properly balanced to prevent the

that they have all maintained their torque value. load from swinging once the fasteners are removed.

4. Fasten the torque arm to the frame per the reducer 2. Remove all fasteners from the Moment coupling flange.

manufacturer’s instructions and remove lifting equipment. 3. Follow the manufacturer’s instructions for removing the tie

rod and torque arm. Once the tie rod is removed lower the

Table 1–Tightening Torque

swing base to the ground.

Moment Tightening Torque Hardware 4. Coupling Hub Removal – Standard Keyed Interference Fit

Coupling Bolt Size Kit Part

Size N-m ft-lbs Numbers a. Clean coupling hubs of any debris or grease that might

have accumulated during operation.

DM 50 M20-2.5 x 90MM ISO 10.9 610 450 001561

b. Connect a coupling hub puller or other removal tool to the

DM 75 M20-2.5 x 90MM ISO 10.9 610 450 001562 flange and ensure both the puller and coupling hub are

DM 100 M20-2.5 x 90MM ISO 10.9 610 450 001563 properly supported.

c. Heat the coupling hub evenly with an acetylene torch

DM 150 M20-2.5 x 90MM ISO 10.9 610 450 001564

to between 350°F (177°C) to 450°F (232°C). Use

DM 210 M24-3.0 x 120MM ISO 10.9 1055 778 001565 temperature sensitive crayons to prevent overheating

DM 285 M24-3.0 x 120MM ISO 10.9 1055 778 001566 the hub. Be sure to keep the torch away from the shaft to

insure that only the coupling hub is expanding.

DM 390 M30-3.5 x 140MM ISO 10.9 2095 1545 001567

d. Remove the hub from the shaft using the coupling hub

DM 525 M30-3.5 x 140MM ISO 10.9 2095 1545 001568 puller or other removal tool.

DM 700 M30-3.5 x 140MM ISO 10.9 2095 1545 001569

DM 920 M30-3.5 x 140MM ISO 10.9 2095 1545 001570

DM 1400 M36-4.0 x 160MM ISO 10.9 3662 2701 001571

DM 2100 M36-4.0 x 160MM ISO 10.9 3662 2701 001572

Dodge Industrial, Inc.

1061 Holland Road

Simpsonville, SC 29681

+1 864 297 4800 *4046-0522*

© DODGE INDUSTRIAL, INC. All Rights Reserved. Printed in USA.

AN RBC BEARINGS COMPANY MN4046 05/22

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- SEW Compact Constant Speed Reducer MC SeriesDocument195 pagesSEW Compact Constant Speed Reducer MC SeriesDênis DáyolNo ratings yet

- Dodge Couplings BR4004-minDocument16 pagesDodge Couplings BR4004-minDênis DáyolNo ratings yet

- PDF Catalogo Acoplamento Elasticos HDF Henfel - CompressDocument18 pagesPDF Catalogo Acoplamento Elasticos HDF Henfel - CompressDênis DáyolNo ratings yet

- Voith Fluid Couplings - End in XGDocument18 pagesVoith Fluid Couplings - End in XGDênis DáyolNo ratings yet

- PDF Catalogo Henfel Henfluid NG PT - CompressDocument2 pagesPDF Catalogo Henfel Henfluid NG PT - CompressDênis DáyolNo ratings yet

- MN4033 - 0322 (W)Document4 pagesMN4033 - 0322 (W)Dênis DáyolNo ratings yet

- MN1623 1623-213Document4 pagesMN1623 1623-213Dênis DáyolNo ratings yet

- RaptorDocument32 pagesRaptorDênis DáyolNo ratings yet

- Power Transmission - RINGSPANNDocument12 pagesPower Transmission - RINGSPANNDênis DáyolNo ratings yet

- Voith Fluid CoDocument32 pagesVoith Fluid CoDênis DáyolNo ratings yet

- Voith TVVSDocument14 pagesVoith TVVSDênis DáyolNo ratings yet

- Shrink Discs RLK 606 - RINGSPANNDocument3 pagesShrink Discs RLK 606 - RINGSPANNDênis DáyolNo ratings yet

- RENK Curved Too enDocument27 pagesRENK Curved Too enDênis Dáyol100% (1)

- Dge TXT ReducersDocument18 pagesDge TXT ReducersDênis DáyolNo ratings yet

- Installatitions FRHNDocument12 pagesInstallatitions FRHNDênis DáyolNo ratings yet

- Voith TVVDocument18 pagesVoith TVVDênis DáyolNo ratings yet

- Ringspanncatalog85 1343107463Document16 pagesRingspanncatalog85 1343107463Dênis DáyolNo ratings yet

- Rexnord Neptune Orion Saturn Titan Owners Manual GP PgomnDocument28 pagesRexnord Neptune Orion Saturn Titan Owners Manual GP PgomnDênis DáyolNo ratings yet

- GFR..F2F3 GFR..FDocument2 pagesGFR..F2F3 GFR..FDênis DáyolNo ratings yet

- FITTING OPERATION and MAINTENANCE - Flexible Unit PWM SeriesDocument9 pagesFITTING OPERATION and MAINTENANCE - Flexible Unit PWM SeriesDênis DáyolNo ratings yet

- HDP Motors - Manual - Update 08-2021 - MLDocument128 pagesHDP Motors - Manual - Update 08-2021 - MLDênis DáyolNo ratings yet

- MN4051 0322Document8 pagesMN4051 0322Dênis DáyolNo ratings yet

- 2000 MA4 CatalogDocument52 pages2000 MA4 CatalogDênis DáyolNo ratings yet

- IOM - H-ME High Performance Coplanar CouplingsDocument10 pagesIOM - H-ME High Performance Coplanar CouplingsDênis DáyolNo ratings yet

- Iom 5840 4PG BW Oct2015Document4 pagesIom 5840 4PG BW Oct2015Dênis DáyolNo ratings yet

- Instruccionesaacoples KTRDocument16 pagesInstruccionesaacoples KTRDênis DáyolNo ratings yet

- B TsdeDocument8 pagesB TsdeDênis DáyolNo ratings yet

- Type GFR / GFRN / GFR..F1F2 / GFR..F2F7 / GFRN..F5F6 GFR..F2F3 / GFR..F3F4Document30 pagesType GFR / GFRN / GFR..F1F2 / GFR..F2F7 / GFRN..F5F6 GFR..F2F3 / GFR..F3F4Dênis DáyolNo ratings yet

- PLWWDocument16 pagesPLWWDênis DáyolNo ratings yet

- LLH (Long Life Holdbacks) : Backstopping Technology Sprag DesignDocument16 pagesLLH (Long Life Holdbacks) : Backstopping Technology Sprag DesignDênis DáyolNo ratings yet