Professional Documents

Culture Documents

Januszewska Anna

Januszewska Anna

Uploaded by

मोहित नायकOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Januszewska Anna

Januszewska Anna

Uploaded by

मोहित नायकCopyright:

Available Formats

DETERMINATION OF OIL CONTENT IN RAPESEEDS USING TWO

METHODS – SOXHLET EXTRACTION AND PULSED NUCLEAR

MAGNETIC RESONANCE SPECTROMETRY

Anna Januszewska, Ewa Maria Siedlecka, Piotr Glamowski,

Izabela Tomasiak

University of Gdansk, Department of Environmental Engineering, Faculty of Chemistry,

ul. Sobieskiego 18, 80–952 Gdansk 6, Poland tel. (0 58) 53 25 437

Introduction

After cereals, oil crops are the second most important source of edible calories for

human societies. They are also sources of many industrial products, and have the potential

to provide raw materials for many more. The four major global traded oil crops are

soybean, oil palm, rapeseed and sunflower, respectively. Together, these four crops

account for 72% of worldwide vegetable-oil production [1]. Therefore an accurate and fast

determination of oil content is important to breeders, growers and buyers.

The traditional method of oil determination in oilseeds is based on solvent

extraction (Soxhlet). This method is laborious, time consuming and uses large volumes of

organic solvents, moreover results depends on operator attention. Currently, the alternative

techniques to solvent extraction are supercritical fluid extraction [2], NIR spectroscopy [3]

and pulsed nuclear magnetic resonance spectrometry [4].

In this article the Soxhlet method was compared with the pulsed nuclear magnetic

resonance spectrometry (pulsed NMR).

Materials and methods

Samples of rapeseeds were taken in accordance with current international methods

of sampling described in ISO standards: PN-EN ISO 542:1997 [5] and PN-EN ISO

664:1997 [6]. In the first instance increment samples ware taken from tracks. The number

of sampling points, where the increment samples are taken, was defined according to lot

size. The sampling points should have been uniformly distributed throughout the lot

volume, according to the principles described in PN-EN ISO 542:1997 (Fig. 1) [5].

Lot size: > 15 tonnes

Number of incremental samples:

5 sampling points

Lot size: 15 – 30 tonnes

Number of incremental samples:

8 sampling points

Lot size: 30 – 50 tonnes

Number of incremental samples:

11 sampling points

Fig. 1. The number of sampling points [5].

The increment samples were combined and mixed thoroughly to form bulk samples,

which were used to create laboratory samples. Part of laboratory samples were collected

and combined together. The final analytical samples were selected from this mixture [6].

In this paper the analytical samples were marked 1, 2, 3, 4, 5, 6. The total oil

content in rapeseeds was determined in the test samples (5 g), which were obtained from

representative and homogenous analytical samples. Four test samples were taken from

each analytical samples.

The rapeseeds used in the study were acquired from different growers in Poland.

Soxhlet extraction. The solvent extraction was conducted according to official methods

PN-EN ISO 659:1999 [7] and PN-73/R-66164 [8] with petroleum ether (boiling point

40-60ºC) as the extraction solvent. The oil was extracted from 5 g samples in Soxhlet

apparatus. These samples were prepared by drying rapeseed at 103 ±2ºC. The water

contents in all seeds should have been less than 10 % (m/m). For each test sample it was

necessary to carry out three extraction cycles (4 + 2 + 2 hours) to achieve complete oil

recovery from seeds. The oil extraction was repeated for each test sample three times to

ensure full oil recovery. After each extraction cycle seeds were grounded carefully in the

mortar.

The oil percentage of the collected oil in the seeds was determined gravimetrically

and expressed as a weight percent relative to initial weight of the raw oilseeds.

Pulsed nuclear magnetic resonance spectrometry. The total oil content was analyzed

directly on Bruker minispec Pulsed NMR analyzer (operating at 10 MHz) in accordance

with international standard PN-EN ISO 10565:1999 [9]. Five grams of rapeseed were used

for each test. Oilseeds shouldn’t have been cleaned and prepared in any way. The water

contents of all seeds should have been less than 10 % (m/m).

The calibration prior to each series of measurements was checked using three

verification samples of known oil contents [9].

Four analysis were carried out on test samples taken from the same homogenous

analytical sample.

Statistical analysis. In this study standard deviation (SR) was estimated by range (R) and

coefficient kn according to the following formula [10]:

SR = kn · R

The range is the largest value minus the smallest value in a data set. This formula can be

used when the number of determinations (n) is less than 7 [10].

All extraction and analyses were carried out four times. In this paper kn = 0,4857

where n = 4 [10].

Results and Discussion

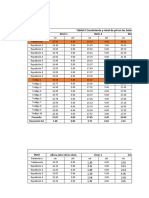

The oil content in rapeseed was determined using two methods Soxhlet extraction

and pulsed NMR and results are listed in Table 1.

The NMR results are not comparable with Soxhlet solvent extraction data. The

mean values of oil content determined by this method (~ 42,5 %) were lower then the the

Soxhlet extraction (~ 45,7 %).

Table 1. Determination of oil content in rapeseed using two methods – Soxhlet extraction

and pulsed nuclear magnetic resonance spectrometry.

Number Soxhlet method pulsed NMR method

of

analytical

C CM SDR RDS C CM SDR RDS

samples

45,69 35,90

46,21 39,40

1 46,04 0,25 0,54 41,60 6,90 16,60

46,18 41,00

46,09 50,00

45,66 48,80

46,07 43,00 41,50 5,20 12,50

2 45,95 0,19 0,41

46,06 35,90

46,03 38,00

44,59 31,10

44,59 52,60 43,50 10,40 23,90

3 44,59 0,01 0,02

44,60 40,20

44,59 50,20

45,80 39,40

45,78 40,00 38,00 2,30 6,00

4 45,79 0,01 0,02

45,79 37,00

45,80 35,40

46,69 48,00

45,88 44,90 46,90 2,10 4,40

5 46,13 0,39 0,85

45,90 49,30

46,08 45,40

45,20 42,30

46,00 50,10 43,70 6,10 13,90

6 45,47 0,48 0,01

45,01 44,30

45,70 37,60

C – the oil content in test samples, which were taken from the same homogenous

analytical sample [% of dry mass],

CM – mean value of the oil content in test samples [% of dry mass],

SDR – Standard deviation [10],

RDS – Relative standard deviation [%].

The Soxhlet system is repeatable technique for determination of oil content in

rapeseed. The values of standard deviation varied from 0,01 to 0,48. For comparison, SD

and RSD values obtained for NMR analysis are higher and range between 2,10-10,40 and

4,40-23,90 %, respectively. The Soxhlet method has excellent precission with less than 1%

relative standard deviation.

In the case of NMR, data distribution was very high and some statistical errors

occured.

The calibrate procedure cannot be ignored when using this methods. Pulsary NMR is

difficult to calibrate. The calibration curve shall be obtained by measuring the signal from

the three calibration samples with known oil content (Procedure A) [7] or the one standard

of known oil content (Procedure B) [7]. In this study the working calibration curve was

obtained according to Procedure A. The series of standards was prepared in a concentration

range near to the expected unknown concetration (test sample). All samples were measured

in the working range of calibration curve. The correlation coefficient for this linear

regression is high (0,98). It means that the calibration model works properly. There could

be other couses that could affect final results (sample presentation, water content, different

nature of calibration standards then samples, slope of the curve).

In conclusion, the proposed pulsary NMR method is relativelly simple, convenient,

rapid and non-destructive, without sample preparation. This technique offers considerable

savings of solvent disposal costs and analysis time (time of measurments is not more then

2 min.) also eliminates the exposure of laboratory staff to toxic and flammable solvents.

The results in Table 1 suggest that the pulsed NMR tehnique can be used for estimation of

oil assay in rapeseed. The best results, in respect of precision are obtained using the

conventional Soxhlet extraction. Therefore this method can be useful for the determination

of oil content in rapeseed.

Acknowledgements

This study was supported by University of Gdansk (DS/8270-4-0093-6). The authors

would like to thank Ms Izabela Tomasiak for her help with experimental work and Elstar

Oils S.A. for giving us an opportunity to use NMR analyser.

References

[1] Murphy D. J., TIBTECH, 14 (1996) 206

[2] Taylor S. L., King J. W., List G. R., J. Am. Oil Chem. Soc, 70 (4) (1993) 437

[3] Robertson J. R., Barton F.E. Ibid, 61(1984) 543

[4] Gambhir P. N., Ararwala A. K., Ibid, 62 (1985) 103

[5] PN-EN ISO 542:1997, Oilseeds – Sampling, PKN, Warsaw, 1997

[6] PN-EN ISO 664:1997, Oilseeds – Reduction of laboratory sample to test sample,

PKN, Warsaw 1997

[7] PN-EN ISO 659:1999, Oilseeds – Determination of oil content (Reference method),

PKN, Warsaw 1999

[8] PN-73/R-66164, Determination of the oil contents in the oilseeds and oil seed

extraction meals, PKN, Warsaw 1973

[9] PN-EN ISO 10565:1999, Oilseeds – Simultaneous determination of oil and water

contents – Method using pulsed nuclear magnetic resonance spectrometry, PKN,

Warsaw 1999

[10] Eckschlager K., in: Errors in Chemical Analysis, PWN,Warsaw 1974, 138

You might also like

- Radiographic Imaging and Exposure 4th Edition Fauber Test BankDocument25 pagesRadiographic Imaging and Exposure 4th Edition Fauber Test BankAngelaPhillipsbeomf100% (46)

- Soap Manufacturing TechnologyFrom EverandSoap Manufacturing TechnologyLuis SpitzRating: 4 out of 5 stars4/5 (6)

- Lab Report 2 Group1Document7 pagesLab Report 2 Group1azamatNo ratings yet

- Subhash Palekar Natural FarmingDocument11 pagesSubhash Palekar Natural Farmingमोहित नायकNo ratings yet

- Lab Report 4 Ash and SaltsDocument11 pagesLab Report 4 Ash and Saltsnikhil reddyNo ratings yet

- MOCK STATS TEST - Solutions Dec 2021Document10 pagesMOCK STATS TEST - Solutions Dec 2021Riddhi LalpuriaNo ratings yet

- 41.1.30 AOAC of Fi Cial Method 991.39 Fatty Acids in en Cap Su Lated Fish Oils and Fish Oil Methyl and Ethyl Es TersDocument2 pages41.1.30 AOAC of Fi Cial Method 991.39 Fatty Acids in en Cap Su Lated Fish Oils and Fish Oil Methyl and Ethyl Es TersAlex SaenzNo ratings yet

- Iliade-143 Ethanol Gc-FidDocument7 pagesIliade-143 Ethanol Gc-FidAlma Pusta100% (1)

- LAB 5 - Pineapple CordialsDocument17 pagesLAB 5 - Pineapple Cordialsghostly_form416995% (21)

- CPB30303 Oil and Fat Process Technology UniKL MICET Experiment 4: Lab Scale Soap Production Full Lab ReportDocument15 pagesCPB30303 Oil and Fat Process Technology UniKL MICET Experiment 4: Lab Scale Soap Production Full Lab ReportSiti Hajar MohamedNo ratings yet

- Elements of X Ray Diffraction by B D Cullity PDFDocument2 pagesElements of X Ray Diffraction by B D Cullity PDFKumar Bd40% (5)

- JWS 2011 - Poster A New Concept For The Performance of Inter-Laboratory Method Validation StudiesDocument1 pageJWS 2011 - Poster A New Concept For The Performance of Inter-Laboratory Method Validation StudiesScribd ScribdxNo ratings yet

- Metode Validasi ScreeningDocument24 pagesMetode Validasi ScreeningIqbalInsaniNo ratings yet

- COMESASession4 Aflas MethDocument46 pagesCOMESASession4 Aflas MethMike ChipunguNo ratings yet

- Influence of Temperature and Duration of The Process On The Degree of Nickel ExtractionDocument5 pagesInfluence of Temperature and Duration of The Process On The Degree of Nickel ExtractionResearch ParkNo ratings yet

- Fat ODocument2 pagesFat OaljammalhaythamNo ratings yet

- TSWJ2014 523120Document10 pagesTSWJ2014 523120saprifarmasiNo ratings yet

- Technique of Sample PreparationDocument7 pagesTechnique of Sample Preparationviko MendozaNo ratings yet

- CPB30503 Petrochemicals & Petroleum Refining Technology Experiment 5: Oil Distillation According To ASTM Method Full Lab ReportDocument11 pagesCPB30503 Petrochemicals & Petroleum Refining Technology Experiment 5: Oil Distillation According To ASTM Method Full Lab ReportSiti Hajar Mohamed100% (4)

- 2008 Overmeire Egg PCB DioxinDocument4 pages2008 Overmeire Egg PCB DioxinTammy BoavidaNo ratings yet

- Technique of Sample Preparation (1) - 1 PDFDocument7 pagesTechnique of Sample Preparation (1) - 1 PDFHamed HamidpourNo ratings yet

- Evaluation of Metabolic Responses of Artemia SalinDocument9 pagesEvaluation of Metabolic Responses of Artemia SalincolombinavalenzuelavNo ratings yet

- ProblemsDocument31 pagesProblemsAhmed Adham100% (1)

- EkstrakcijaDocument10 pagesEkstrakcijabazapodatakax_590173No ratings yet

- Part D - Proceedings Articles Theme 3 - Chemical, Food, Petroleum and Mining - FinalDocument276 pagesPart D - Proceedings Articles Theme 3 - Chemical, Food, Petroleum and Mining - FinalCEG BangladeshNo ratings yet

- FC-4102LAB - Ash and Salt ContentDocument8 pagesFC-4102LAB - Ash and Salt ContentharrygulatiNo ratings yet

- Determination of Oil and Water Content in Olive Pomace Using Near Infrared and Raman Spectrometry. A Comparative StudyDocument7 pagesDetermination of Oil and Water Content in Olive Pomace Using Near Infrared and Raman Spectrometry. A Comparative StudyPpiSpanyolNo ratings yet

- NicardipineeeDocument8 pagesNicardipineeekevin100% (1)

- Nicar PDFDocument8 pagesNicar PDFkevinNo ratings yet

- Nicar PDFDocument8 pagesNicar PDFkevinNo ratings yet

- Fennel GC ReportDocument5 pagesFennel GC ReportVijay JoshiNo ratings yet

- Tuk - Návody - AnglickyDocument7 pagesTuk - Návody - AnglickyBlessing HarvestNo ratings yet

- Chm432 Expt 5Document11 pagesChm432 Expt 5Ievana InsyirahNo ratings yet

- Lab Report #1: Plastic Particle Size Analysis of SoilsDocument10 pagesLab Report #1: Plastic Particle Size Analysis of SoilsKhryz AbadNo ratings yet

- Seven QC Tool and MoreDocument83 pagesSeven QC Tool and MorewllohNo ratings yet

- National Corn-to-Ethanol Research Center Laboratory Research DivisionDocument7 pagesNational Corn-to-Ethanol Research Center Laboratory Research DivisionShai VillalbaNo ratings yet

- Lampiran 3Document4 pagesLampiran 3Vita IlupzNo ratings yet

- ASHRAE 52-2 ExplainedDocument2 pagesASHRAE 52-2 ExplainedVenkatesan RamalingamNo ratings yet

- Nitration of α-methoxy-β-chloroethylbenzeneDocument2 pagesNitration of α-methoxy-β-chloroethylbenzenejavasoloNo ratings yet

- Dosis Support MWBB (Rev 1.1)Document5 pagesDosis Support MWBB (Rev 1.1)Anonymous Mp3EqzPNo ratings yet

- Dosis Support MWBB (Rev)Document4 pagesDosis Support MWBB (Rev)kucingmeong1922No ratings yet

- Progress Seminar 02Document32 pagesProgress Seminar 02Saifudeen KmNo ratings yet

- Articulo Obed GonzalezDocument8 pagesArticulo Obed GonzalezJuan Manuel TeranNo ratings yet

- Modeling of Organosolv Pulping Process Using Wavelet Neural NetworksDocument6 pagesModeling of Organosolv Pulping Process Using Wavelet Neural Networkswanrosli4898No ratings yet

- Wax Test MethodsDocument10 pagesWax Test MethodsJrg Trjlo100% (1)

- Exp 2-Dry FractionationDocument14 pagesExp 2-Dry FractionationFfmohamad NAdNo ratings yet

- Criteria C - Lab ReportDocument10 pagesCriteria C - Lab ReportNishtha KaushalNo ratings yet

- Development of A Method For Quantitative Determination of - Oryzanol Using Near Infrared SpectrosDocument9 pagesDevelopment of A Method For Quantitative Determination of - Oryzanol Using Near Infrared SpectrosramcatNo ratings yet

- Tabla de Datos Procesados EVI Biología FinalDocument20 pagesTabla de Datos Procesados EVI Biología FinalYovanni SanchézNo ratings yet

- Su AlbuDocument7 pagesSu AlbuLama SalahatNo ratings yet

- Operations Management 6th Edition Reid Solutions Manual DownloadDocument16 pagesOperations Management 6th Edition Reid Solutions Manual DownloadNancy Payton100% (20)

- 7 Stream Gauging-2Document54 pages7 Stream Gauging-2ChampNo ratings yet

- FULL REPORT Flow Over WeirDocument18 pagesFULL REPORT Flow Over WeirShahrul Ikram0% (1)

- Differentiation of Black Teas by Volatile Profile Analysis Using Hs-Spme/Gc-MsDocument11 pagesDifferentiation of Black Teas by Volatile Profile Analysis Using Hs-Spme/Gc-MsetikaNo ratings yet

- 6710x1781 (1) Clorofila Paper MetodoDocument7 pages6710x1781 (1) Clorofila Paper MetodoNathaly ComettantNo ratings yet

- Experiment 2 UV-VIS - Ilyas Fikri B. Mohd SaidDocument17 pagesExperiment 2 UV-VIS - Ilyas Fikri B. Mohd Saidnn bbNo ratings yet

- Work Sheet Evaluasi Sistem Irigasi TertutupDocument14 pagesWork Sheet Evaluasi Sistem Irigasi TertutuparyauniversitasNo ratings yet

- Anaerobic Respiration in YeastDocument4 pagesAnaerobic Respiration in Yeastakeisha kingNo ratings yet

- RAMANDocument28 pagesRAMANKiruthick DonNo ratings yet

- Chapter 1Document5 pagesChapter 1Christian EduardoNo ratings yet

- Estimation of Active IngredientDocument5 pagesEstimation of Active IngredientSuleman QaiserNo ratings yet

- Experiment No: 2 Experiment Name: Measurement of Anthropometric Data and AnalysisDocument7 pagesExperiment No: 2 Experiment Name: Measurement of Anthropometric Data and AnalysisSakline MinarNo ratings yet

- Lec 24Document4 pagesLec 24मोहित नायकNo ratings yet

- Notice-Ph DDocument1 pageNotice-Ph Dमोहित नायकNo ratings yet

- Topics: Single and Double Beam SpectrophotometreDocument1 pageTopics: Single and Double Beam Spectrophotometreमोहित नायकNo ratings yet

- 111938632Document1 page111938632मोहित नायकNo ratings yet

- BM Ijas 2014Document7 pagesBM Ijas 2014मोहित नायकNo ratings yet

- ADO PhY Edu Press Note 1Document2 pagesADO PhY Edu Press Note 1मोहित नायकNo ratings yet

- New Bitmap ImageDocument1 pageNew Bitmap Imageमोहित नायकNo ratings yet

- DR SandeepDocument1 pageDR Sandeepमोहित नायकNo ratings yet

- WEF Artificial Intelligence For Agriculture Innovation 2021Document32 pagesWEF Artificial Intelligence For Agriculture Innovation 2021मोहित नायकNo ratings yet

- QuickStartGuide AspxDocument51 pagesQuickStartGuide Aspxमोहित नायकNo ratings yet

- Physics NewDocument17 pagesPhysics Newdnyanadakulkarni125No ratings yet

- Solutions - Medical (Vats-7 Arjuna Test-07 (22!03!2024) - Neet-2024Document15 pagesSolutions - Medical (Vats-7 Arjuna Test-07 (22!03!2024) - Neet-2024level15659No ratings yet

- Particle: Conceptual PropertiesDocument5 pagesParticle: Conceptual PropertieskirolosseNo ratings yet

- 5olasa 2022Document11 pages5olasa 2022volcano netNo ratings yet

- Cambridge O Level: Combined Science 5129/21Document20 pagesCambridge O Level: Combined Science 5129/21Ibrahim NagraNo ratings yet

- Karl's Study Guide For PhysicsDocument79 pagesKarl's Study Guide For PhysicsDeepika DevarajNo ratings yet

- Chemistry Formula SheetDocument18 pagesChemistry Formula Sheetannuj vermaNo ratings yet

- UntitledfccccfffDocument3 pagesUntitledfccccfffABNo ratings yet

- Thermal-Hydraulic Analysis of A Nuclear Research Reactor Core Channel PDFDocument12 pagesThermal-Hydraulic Analysis of A Nuclear Research Reactor Core Channel PDFAli AliNo ratings yet

- Compilation Objectives - ESAS 2005 To 2008Document24 pagesCompilation Objectives - ESAS 2005 To 2008John Henry OcampoNo ratings yet

- Neet 20 SolvedDocument10 pagesNeet 20 Solvedsyed sulthanNo ratings yet

- Diagnostic Test in Science 9Document3 pagesDiagnostic Test in Science 9Pepito Rosario Baniqued, JrNo ratings yet

- B.SC Physics 2016-17Document75 pagesB.SC Physics 2016-17Vinay NelasNo ratings yet

- SCIENCE 9 EXAM (2nd Quarter) QuestionsDocument3 pagesSCIENCE 9 EXAM (2nd Quarter) QuestionsKert Cyrel RomeroNo ratings yet

- Hydrogen: 2. Spin Isomers of H MoleculeDocument11 pagesHydrogen: 2. Spin Isomers of H MoleculeNehal GautamNo ratings yet

- JEE Main Previous Year Questions On Isomerism: 1. Monocarboxylic Acids Are Functional Isomers ofDocument5 pagesJEE Main Previous Year Questions On Isomerism: 1. Monocarboxylic Acids Are Functional Isomers ofsaralaNo ratings yet

- FULL SUMMARY - IB SL Chemistry (Imaginfinity)Document16 pagesFULL SUMMARY - IB SL Chemistry (Imaginfinity)Suju SonNo ratings yet

- 2-Phenylethanol Mass Spectrum InterpretationDocument3 pages2-Phenylethanol Mass Spectrum InterpretationPAOLO GAMBACORTANo ratings yet

- ExerciseDocument26 pagesExercisemurugan NishanthNo ratings yet

- Atomic Structure WorksheetDocument3 pagesAtomic Structure Worksheetmaryum.gaming48No ratings yet

- 16-17-SERINI DavideDocument133 pages16-17-SERINI DavidesandroNo ratings yet

- Super 100 - SET - BDocument16 pagesSuper 100 - SET - BAnshuman TiwariNo ratings yet

- 11.chemical Bonding in A NutshellDocument24 pages11.chemical Bonding in A Nutshellmary ann leddaNo ratings yet

- Chemistry Handbook Part 1Document247 pagesChemistry Handbook Part 1Bezimeni BezimenovicNo ratings yet

- Ebook Chemistry For Today General Organic and Biochemistry 8Th Edition Seager Test Bank Full Chapter PDFDocument34 pagesEbook Chemistry For Today General Organic and Biochemistry 8Th Edition Seager Test Bank Full Chapter PDFhaogwyneth050p96100% (11)

- Human Anatomy and Physiology 9th Edition Marieb Solutions ManualDocument26 pagesHuman Anatomy and Physiology 9th Edition Marieb Solutions ManualWilliamCartersafg100% (57)

- lsc11 01 MSC 20200123Document22 pageslsc11 01 MSC 20200123Ahmad Syueb 0No ratings yet

- Atoms PYQDocument8 pagesAtoms PYQAyaanNo ratings yet