Professional Documents

Culture Documents

A Novel Approach of Ceramic Tile Crack Detection Using Morphological Operations

Uploaded by

Aayan ShahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Novel Approach of Ceramic Tile Crack Detection Using Morphological Operations

Uploaded by

Aayan ShahCopyright:

Available Formats

Mehran University Research Journal of Engineering and Technology

https://doi.org/10.22581/muet1982.2202.14

2022, 41(2) 146-154

A novel approach of ceramic tile crack detection using morphological operations

Mahzaib Younas a, Qamar Nawaz a, Isma Hamid b,*

, Syed Mushhad Mustuzhar Gilani c, M. Javed

Iqbal d.

a

Department of Computer Science, University of Agriculture, Faisalabad Pakistan

b

Department of Computer Science, National Textile University, Faisalabad Pakistan

c

University Institute of Information Technology, PMAS, Arid Agriculture University, Rawalpindi Pakistan

d

Department of Software Engineering, University of Engineering and Technology Taxila, Pakistan

*

Corresponding author: Isma Hamid, Email: ismahamid@ntu.edu.pk

Received: 09 October 2020, Accepted: 05 May 2021, Published: 01 April 2022

KEYWORDS ABSTRACT

Edge Detection In ceramic tiles manufacturing industry, tiles are manufactured at large scale

which makes it more challenging to ensure the quality of each tile according to

Quality Control

the set standards. Mostly, Statistical Process Control (SPC) is used by tile

Morphological Operators manufacturers at each step to monitor various processing parameters. SPC

Defect Detection procedures are implemented manually that requires sufficient number of

experienced human resource to identify defected tiles from a batch of tiles. The

Pattern Recognition manual inspection also gives low accuracy of defect detection due to human

errors and hard environment. Considering these drawbacks, in this paper an

automated defect detection method is proposed which is based on image

processing and morphological operation to ensure the quality and standard of

tiles. The proposed method resizes and converts the input RGB image into

grayscale image and removes any possible noisy artifacts. An edge detection

algorithm is applied on grayscale image to enhance the edges representing the

cracks. Afterwards, morphological erosion and dilation operations are applied,

one at a time, to get two intermediate images. Finally, edges are detected by

subtracting eroded intermediate image from dilated intermediate image. For

detection, the proposed algorithm does not require any separate reference image.

The algorithm is tested on an image set of sixty different defected tile images

and attained 92% average detection accuracy.

1. Introduction deployed for quality control. The manual procedure for

quality check is somewhat slow and results could be

Previously, in ceramic tiles manufacturing industry,

different regarding same object because of experience,

Statical Process Control (SPC) [1] was a widely used

level of concentration, and tiredness of the person [2].

method to monitor the build quality of tiles. The SPC is

a manual procedure, and its successful implementation For last couple of decades, the field of digital image

depends on the knowledge and training of the person processing and computer vision has turned into

© Mehran University of Engineering and Technology 2022 146

exceedingly onerous unit of information Technology in A fairly simple defect detection algorithm that is

automating industrial processes. Digital images are based on Laplacian of Gaussian operator is proposed by

processed by means of digital computer to extract Rajashri et al. [4]. This algorithm converts input RGB

important information, also called features, from images image into a grayscale image and then applies Gaussian

using simple to complex mathematical procedures [3]. Filter to remove noise and smoothen the image then

Defect identification of tiles through digital images is edges are detected using Laplacian of Gaussian Operator

widely used application of digital image processing to [7]. To identify cracks, this algorithm performs pixel by

enforce computerized quality control process in pixel comparison of edge detected image with a

manufacturing industry. reference image of a perfect tile. This algorithm is

simple to understand and easy to implement but, it can

For defect identification in tiles images, researchers

only be used to identify defects in a flat or single-color

have proposed many different algorithms depending on

tile.

the types, sizes, and textures of tiles [4]. Traditionally,

defect detection algorithms perform resizing, noise In [8], the authors presented a real time defect

removal, and edge detection procedures to identify detection system to identify cracks based on Erosion

operator [9]. The accuracy of the algorithm depends on

manufacturing defects in tiles through digital images [5].

threshold value as this value is not constant for different

Based on the functionality, most of the defect detection

types of defects as well as images of plain and textured

algorithms can be viewed as a two-stage process i.e.,

tiles.

low-level stage and high-level stage. At low-level stage,

the algorithm extracts feature like colours, texture, Another technique for defect detection proposed in

edges, and patterns. At high-level stage, the algorithm [10] is based on Prewitt algorithm [11]. This algorithm

uses adaptive histogram equalization technique for

utilizes low level information to extract semantic

contrast enhancement. Afterwards, noise is removed

meanings to identify defects like corner break, cracks,

using median filter and edges are detected using Prewitt

and faded textures.

algorithm. Finally, defects are detected using

Another defect detection algorithm proposed by morphological operation i.e. union, intersection, and

Elbehiery et al. [2], works in two stages. At first stage, inclusion. This algorithm only works for images of

the algorithm converts RGB image into grayscale to having size range between 600 x 600 and 800 x 800.

adjust the intensity of the image. Afterwards, intensity To address the main drawbacks discussed above, in

adjusted image is converted into binary image. At this study, we propose an algorithm for defect detection

second stage, different morphological operations are that is easy to implement, requires less processing time

performed to identify various types of defects like spot, and power, and is able to identify defects in plain and

pinhole, and long crack. This algorithm is not textured tile images without requiring any additional

completely automated as user must select morphological reference image.

operation according to the detection problem. The rest of the paper is organized as follows: In

In [3], the authors proposed a gradient based Section 2, details of the proposed algorithm are given.

Section 3 contains results of the proposed algorithm and

algorithm to detect defect in Ceramic tiles. This

its comparison with some of the existing algorithm in the

algorithm performs scale-down operation to reduce

same domain. Section 4 summarizes the paper.

image size and then converts it into grayscale. Edge

detection is performed by using an edge detection 2. Proposed Methodology for Defect Detection

operator [6] fixing the threshold value 0.13. In the next System

step, they applied a morphological operator on test The proposed algorithm is a three-step process. At first

image as well as on reference image. To detect the step, input image is converted into grayscale and pre-

defects in the image, the algorithm counts white pixels processing is performed to enhance the quality of the

of both of test image and compares their values with grayscale image. At second step, edge detection

reference image. Main drawback of this algorithm is its methodology is implemented on enhanced image. At

huge processing time as it performs pixel by pixel third step, enhanced grayscale image produced at first

comparison of test and reference image. step and edge detected image at second step are

converted into binary and defects are detected after

© Mehran University of Engineering and Technology 2022 147

subtracting magnitude of both images. Complete and erosion operations for highlight cracks and edges.

procedure of the proposed algorithm is shown in Fig. 1. These operations are natively robust for noise and are

Details of each steps are given in the following sub- able to correct imperfections in structure by connecting

sections. any disjoint pixels [17]. These operation uses a small

Get RGB Tile Image matrix structure, called structuring element [18]. The

important properties of structuring element are its origin,

Image Resize

shape, and size. Origin represents a pixel whose value is

Grayscale Conversion going to be updated after applying the operations, shape

defines the pattern of 0 and 1 for pixels falling within a

Apply Morphological Apply Morphological window, and size represents a window used to process

Eorsion Operation Dilation Operation

number of neighbourhood pixels at a time. Structuring

Convert Eroded image in Convert Dilated image in element can be used with different shapes such as line,

Doouble Perscision Double Percision

disk, square, diamond, pair, and rectangle. In the

proposed algorithm, we used disk shape structuring

Subtract dilated image from eroded image

element with the radius 2 [19], as shown in Fig. 2.

Edge detected image

Preform Binarization on Preform Binarization on

Grayscale image edge highlighted image

Get the magnitude of Get the magnitude of

matrix name as MR matrix name as MC

Fig. 2. Disk shape structuring element of size 2

After defining the structuring element, the algorithm

MC == performs dilatation and erosion operation on grayscale

MR

image. The dilation operator [18] is used to expand the

Yes No

foreground of image up to the extent to the maximum

Perfect Tile Defective Tile neighbourhood value in structuring element. The

implementation of Dilation process is just like spatial

Fig. 1. Proposed Algorithm convolution. Mathematical procedure of dilation

2.1 Pre-Processing operation is represented in Eqs. (1) and (2).

Image pre-processing is an important step to remove any (𝑄 ⊕ 𝑆𝐸)(𝑖, 𝑗) = max{𝑄(𝑖 − 𝑖`, 𝑗 − 𝑗`)| (𝑖`, 𝑗`)𝜖𝐷𝑆𝐸 }

unwanted artifact from the input image. At this step, we …(1)

resized input image it its size is greater than 500 x 500

𝑑 = 𝑄 ⊕ 𝑆𝐸 (2)

to reduce the overall processing time of the algorithm.

After resizing, we converted resized image into where SE is the structuring element, DSE is domain of

grayscale because colour features do not play any role in structuring element, Q is the enhanced grayscale image,

identification of defects like cracks, holes, and broken Q(i,j) is supposed the -∞ outside the image domain,

edges. (i`,j`) are domain of SE which belongs to DSE, this

symbol ⊕ represent the dilation operation, and d is the

2.2 Edge Detection

eroded image.

The boundary between two dissimilar regions of an

The Erosion Morphological operation is used to

image is known as an edge. Usually, the boundaries

shrink the foreground of image [20]. In other words,

form due to the different surfaces of objects or due to the

erosion operation is the complement of dilation Process.

light and shadow falling on a single surface [12]. In

The erosion operation also works like dilation operation,

literature, different edge detection algorithms have been

but it changes the value of origin pixel with minimum

proposed which are being used to detect cracks in tiles.

value found in neighbourhood window. Mathematical

Some of the widely used methods are based on gradients

procedure of erosion is represented in Eqs. 3 and 4.

that use predefine kernel for convolution, for example,

Prewitt [13], Canny [14], Sobel [15], and Robert [16]. In (𝑄 ⊝ 𝑆𝐸)(𝑖, 𝑗) = min{𝑄(𝑖 + 𝑖`, 𝑗 + 𝑗`)| (𝑖`, 𝑗`)𝜖𝐷𝑆𝐸 }

our proposed algorithm, we used morphological dilation …(3)

© Mehran University of Engineering and Technology 2022 148

𝑒 = 𝑄 ⊝ 𝑆𝐸 (4) 3. Results and Discussion

where SE is the structuring element, DSE is domain of To test the performance of the proposed algorithm, we

structuring element, Q is the enhanced grayscale image, perform a series of experiments on dataset containing

Q(i,j) is supposed the +∞ outside the image domain, sixty images of different tiles. The dataset we used is

(i`,j`) are the domain of SE which belongs to DSE, this not available publicly and so we collected images from

symbol ⊝ represent the erosion operation, and e is the multiple locations [21-22] because of the need of a

eroded image. dataset containing colour tile images. Some datasets are

available publicly that contain pre-processed black &

In Eq. 5, d is intermediate dilated image and e

white images which are not suitable to test the proposed

intermediate eroded image and N is the final edge

algorithm. The dataset used to test the algorithm is

highlighted image.

categorised in two categories, as shown in Table 1.

𝑁 = [𝑑𝑜𝑢𝑏𝑙𝑒(𝑑)] − [𝑑𝑜𝑢𝑏𝑙𝑒(𝑒)] (5) Category 1 contains 29 perfect images i.e. images of

2.3 Crack Detection faultless tiles and category 2 contains 31 images of

defected tiles containing cracks, missing patterns, and

For crack detection, the proposed algorithm binarization surface scratches. Images in category 1 and category 2

is perform on both grayscale image and edge detected are shown in Fig. 3 and Fig. 4 respectively.

image because of its ability of detecting the different

type of defect, object separation, pattern recognition, Table 1

and reduce the computation complexity. Afterwards, Categories of dataset used to test the algorithm

the algorithm calculates the magnitude of binary images

Category Number of Tiles

individually. If magnitude of binary grayscale image

equals to the binary edge detected image, then the tile is Category 1 (Faultless Images) 29

a perfect tile. Category 2 (Faulty Images) 31

Fig. 3. Category 1, faultless images in dataset

© Mehran University of Engineering and Technology 2022 149

Fig. 4. Category 2, faulty images in dataset

(a) (b) (c)

(d) (e) (f)

Fig. 5. Visual result of proposed algorithm applied on perfect tile image of category 1 (a) Input image (b) Pre-process image (c)

Noisy image, (d) Eroded image, (e) Dilated image, (f) Final edge detected image

© Mehran University of Engineering and Technology 2022 150

(a) (b) (c)

(d) (e) (f)

Fig. 6. Visual result of proposed algorithm applied on defective tile image of category 2 (a) Input image (b) Pre-process image

(c) Noisy image, (d) Eroded image, (e) Dilated image (f) Final edge detected image

For the purpose of demonstration and to save the algorithms we selected for comparison includes Prewitt

space, only one experimental detail for each category is [23], Sobel [15], canny [24], Roberts [15], Kirsch [25],

presented in this section. The visual results of each stage and Robinson [25]. Fig. 7 represents visual results of

produced by the proposed algorithm are shown in Fig. 5 edge detection after applying existing and proposed

and Fig. 6 for image no. 6 from category 1 and image algorithm on tile 15 of category 2. It can be observed

no. 9 from category 2, respectively. The details of that the edge detected image produced by the proposed

complete experimental outputs are given in Table 2. algorithm is clearer, sharper, and provides smooth and

noiseless visual information that helps in clearly

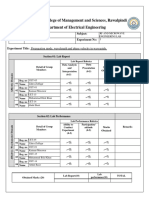

Table 2

identifying cracks and tile texture. Normally, visual

Details of experimental results of the proposed algorithm results of any defect detection algorithms are not

Total number of tested tiles 60 important as humans are not involved in the process of

Total number of perfect tiles 29 identifying defects. The software, implementing the

Total number of defected tiles 31 algorithm, is responsible of detecting and highlighting

Number of perfect tiles detected as defected 2 defects in underlying images. Edge detected image

Number of defective tiles detected as perfect 3 provides the base for detecting defects therefore, for the

Total number of correct outcomes 55 sake of comparison, we also compared the visual quality

of the edge detected image of the proposed algorithm

Total number of wrong outcomes 5

with existing algorithms. During the experiments, we

From the results, it is found that the accuracy of the observed that if defect detection algorithm produces

proposed algorithm is almost 92% and total processing good quality edge detected image, it ultimately provides

time to process whole dataset is approximately 30sec. better accuracy in defect detection stage. Visually, the

To find the accuracy of the proposed algorithm, proposed algorithm produces better edge detected image

following equation is used. but, visual comparison is just one aspect. Sometimes,

𝑁𝑢𝑚𝑏𝑒𝑟 𝑜𝑓 𝑐𝑜𝑟𝑟𝑒𝑐𝑡 𝑜𝑢𝑡𝑐𝑜𝑚𝑒𝑠 visual comparison alone is not enough as different

𝐴𝑐𝑐𝑢𝑟𝑎𝑐𝑦 𝑅𝑎𝑡𝑒 = × 100

𝑇𝑜𝑡𝑎𝑙 𝑛𝑢𝑚𝑏𝑒𝑟 𝑜𝑓 𝑡𝑖𝑙𝑒 persons may have different opinions regarding

…(6) information available in the same image. Therefore, to

validate our claim, we also compared objectively the

3.1 Comparison with Existing Algorithm edge detected images produced by the proposed

We compared our proposed algorithm with six existing algorithm and existing algorithms using three widely

and widely used algorithms in the same domain. The used image quality assessment matrices, i.e. RMSE [26],

© Mehran University of Engineering and Technology 2022 151

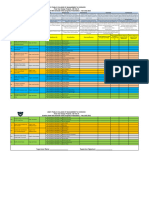

PSNR [27] and SSIM [28]. The mathematical equations Table 3

and output results of RMSE, PSNR, and SSIM are given

Comparison of Edge Detection Algorithm

in Eqs. 7-10 and Table 3, respectively. Accuracy and

processing time comparison of the proposed defect Algorithm RMSE PSNR SSIM

detection algorithm with existing defect detection Name

algorithms are given in Table 4, respectively. Prewitt 120.3038 6.73 0.0514

∑[𝑂(𝑖,𝑗)−𝑒(𝑖,𝑗)] Sobel 133.6235 5.89 0.0334

𝑀𝑆𝐸 = 𝑖∗𝑗

(7) Canny 129.3551 7.19 0.0382

Robert 123.2008 5.71 0.0366

𝑅𝑀𝑆𝐸 = √𝑀𝑆𝐸 (8)

Kirsch 89.1963 9 0.0111

where i and j are number of rows and columns of an Robinsion 114.9114 6.9 0.0430

image O is consider as an original image and e is edge Proposed 88.97 8.89 0.213

detected which is also called the compressed image. Algorithm

And, root mean square error, RMSE, is actually the

Table 4

square root of the mean square error, MSE.

𝑅2 Comparison Using Existing Defect Detection Process

𝑃𝑆𝑁𝑅 = 10𝑙𝑜𝑔10 ( ) (9)

𝑀𝑆𝐸

Algorithm Correct Incorrect Accuracy Time

where R is maximal value of input image. Result result

SSIM (i , j) = [𝑙(𝑖, 𝑗)]𝛼 . [𝑐(𝑖, 𝑗)]𝛽 . [𝑠(𝑖, 𝑗)]𝛾 (10) Prewitt 37 23 63% 27sec

Canny 44 16 74% 29sec

where l is luminous used to compare the brightness

factor, c is contrast used to compare the brightness and Sobel 38 22 65% 29sec

darkness region, and s is structure used to compare the Roberts 41 19 70% 28sec

pattern. α, β and γ are the positive constants. Kirsch 46 14 76% 33sec

As shown in Fig. 11, the proposed edge detection Robinson 50 10 87% 35sec

algorithm is given the high accuracy rate. The Proposed Proposed 55 5 92% 30sec

Defect Detection process give the 92% accuracy which Algorithm

is an achievement of our proposed system.

(a) (b) (c)

(d) (e) (f)

(g)

Fig. 7. Comparison of edge detected images. (a) Prewitt (b) Sobel (c) Canny (d) Robert (e) Kirsch (f) Robinson (g) proposed

© Mehran University of Engineering and Technology 2022 152

4. Conclusion

By attaining 92% accuracy and taking 0.5 to 1 sec to

process a single tile image, the proposed algorithm

proven to be a better alternative to the existing defected

detection algorithms. The reason of better accuracy rate

is dependent on sequence of procedural steps, quality of

input image, and quality of edge detected image. The

less processing time makes the proposed algorithm very

practical for implementation in real time defect

Fig. 8. Graphical representation of RMSE value in Table 3

detection systems. However, the proposed algorithm

attained less accuracy in detecting hair line cracks and

colour fading present in some of the tile images. Our

future work will focus on making the proposed

algorithm more efficient by adding the ability to detect

small cracks, defects, and colour fading.

5. References

[1] “What is statistical process control? SPC quality

Fig. 9. Graphical representation of PSNR value in Table 3 tools | ASQ”, Available from

https://asq.org/quality-resources/statistical-

process-control, [29 Jan 2021].

[2] H. Elbehiery, A Hefnawy, and M Elewa.

“Surface defects detection for ceramic tiles using

image processing and morphological

techniques”, Proceedings of 3rd World

Enformatika Conference (WEC), 2005 vol. 5,

no. 5, pp. 158–162.

Fig. 10. Graphical representation of SSIM value in Table 3 [3] Y.C. Samarawickrama, and D.W. Chamira,

“Matlab based automated surface defect

detection system for ceremic tiles using image

processing”, 6th National Conference on

Technology and Management (NCTM), Malabe,

Sri Lanka, IEEE, 2017, pp. 34–39.

[4] N.A. Shire, M.M. Khanapurkar, and S.M.

Rajashri, “Plain ceramic tiles surface defect

detection using image processing”, 4th

International Conference on Emerging Trends in

Engineering and Technology, Port Louis,

Fig. 11. Graphical representation of accuracy rate in Table 4

Mauritius, IEEE, 2011, pp. 215–220.

[5] P. Kumari and S. Kumar Gupta, “Morphological

image processing GUI using MATLAB”, Trends

Journal of Sciences Research, vol. 2, no. 3,

pp. 90–94, 2015,

[6] R. M. Yousaf, H. A. Habib, H. Dawood, and S.

Shafiq, "A comparative study of various edge

detection methods", 14th International

Conference on Computational Intelligence and

Fig. 12. Graphical representation of SSIM value in Table 4 Security, 2018 ,pp. 96–99.

© Mehran University of Engineering and Technology 2022 153

[7] P. Ganesan, and G. Sajiv, "A comprehensive [18] R. Srisha and A. Khan, “Morphological

study of edge detection for image processing operations for image processing : understanding

applications", International Conference on and its applications”, NCVSComs-13, December

Innovations in Information, Embedded and 2013, no. 13, pp. 17–19.

Communication Systems, Janua, 2018, pp. 1–6.

[19] P. Kumari and S. Kumar Gupta, “Morphological

[8] B. R. K and S. A. Angadi, “Crack detection in image processing GUI using MATLAB”, Trends

ceramic tiles using zoning and edge detection Journal of Sciences Research, vol. 2, no. 3, pp.

methods”, Int. J. Trend Sci. Res. Dev., vol. 2, 90–94, 2015,

no. 4, pp. 2844–2847, 2018.

[20] C. Shagf, “Image edges detection using

[9] W. S. AlAzawee, I. Abdel-Qader, and J. bdel- morphological operations”, J. Kerbala Univ.,

Qader, "Using morphological operations; vol. 6, no. 4, 2008

Erosion based algorithm for edge detection",

[21] "Cracked tiles high res stock images |

IEEE Int. Conf. Electro Inf. Technol. June 2015,

shutterstock", Available

pp. 521–525.

https://www.shutterstock.com/search/cracked+ti

[10] B. Mohammad, S. Naidu, T. Ravikanth, P. Siva, les, [11 Feb 2021].

"Identification and rejection of defective ceramic

[22] "Perfect ceramic tile images, stock photos &

tile using image processing and Arduino",

vectors | shutterstock", Available from

International Journal for Modern Trends in

https://www.shutterstock.com/search/perfect+ce

Science and Technology, vol. 2, no. 4 ,pp. 57–

ramic+tile, [11 Feb 2021].

60, 2015.

[23] P. Topno, and G. Murmu, "An improved edge

[11] J. Li, and N. Wang, " A study of crack detection

detection method based on median filter", Proc.

algorithm", Proc. - 5th Int. Conf. Instrum. Meas.

3rd Int. Conf. 2019 Devices Integr. Circuit

Comput. Commun. Control, 2016, pp. 1184–

DevIC, 2019, pp. 378–381.

1187.

[24] P. P. Acharjya, R. Das, and D. Ghoshal, "A study

[12] P. Selvakumar, and S. Hariganesh, "The

on image edge detection using the gradients", Int.

performance analysis of edge detection

J. Sci. Res. Publ., vol. 2, no. 12, pp. 2–6, 2012.

algorithms for image processing", International

Conference on Computing Technologies and [25] A. Abdullah, M. Ali, and H. Jawad, "Evaluation

Intelligent Data Engineering, 2016, pp. 1–5. of the performance of kirsch and robinson

methods on different color spaces", International

[13] J. Li and N. Wang, “A study of crack detection

Journal of Simulation: Systems, Science and

algorithm”, 5th International Conference on

Technology. vol. 20, no. 3, pp. 1-9, 2019.

Instrumentation and Measurement, Computer,

Communication and Control, Qinhuangdao, [26] U. Sara, M. Akter, and M. S. Uddin, “Image

China, 2015, pp. 1184–1187. quality assessment through FSIM, SSIM, MSE

and PSNR—a comparative study”, JCC, vol. 07,

[14] P. P. Acharjya, R. Das, and D. Ghoshal, "A study

no. 03, pp. 8–18, 2019.

on image edge detection using the gradients", Int.

J. Sci. Res. Publ., vol. 2, no. 12, pp. 2–6, 2012. [27] D. Sadykova and A. P. James, “Quality

assessment metrics for edge detection and edge-

[15] G. N. Chaple, R. D. Daruwala, and M. S. Gofane,

aware filtering: A tutorial review”, International

"Comparisons of robert, prewitt, sobel operator

Conference on Advances in Computing,

based edge detection methods for real time uses

Communications and Informatics, Udupi, 2017,

on FPGA", International Conference on

pp. 2366–2369.

Technologies for Sustainable Development,

2017, no.1 , pp.1–4. [28] G.H. Chen, C.L. Yang, L.M. Po, and S.L. Xie,

[16] G. N. Chaple, R. D. Daruwala, and M. S. Gofane, “Edge-based structural similarity for image

"Comparisons of robert, prewitt, sobel operator quality assessment”, IEEE International

based edge detection methods for real time uses Conference on Acoustics Speed and Signal

on FPGA", International Conference on Processing Proceedings, Toulouse, France,

Technologies for Sustainable Development, 2006, vol. 2, pp. 933-936.

2017, no.1, pp.1–4.

[17] C. Rafael et al., “Digital image processing,”

Second Edition, Prentice Hall, 2004, pp. 519-560

and 617-621.

© Mehran University of Engineering and Technology 2022 154

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- RF Lab 5 Tasks (1)_mergedDocument4 pagesRF Lab 5 Tasks (1)_mergedAayan ShahNo ratings yet

- final4Document1 pagefinal4Aayan ShahNo ratings yet

- PctDocument3 pagesPctAayan ShahNo ratings yet

- g6Wjk5DYSQY6jUTOkQTFDocument1 pageg6Wjk5DYSQY6jUTOkQTFAayan ShahNo ratings yet

- cst RF lab 1Document9 pagescst RF lab 1Aayan ShahNo ratings yet

- Result BSc (EE)-21 (Fall-2019)Document1 pageResult BSc (EE)-21 (Fall-2019)Aayan ShahNo ratings yet

- Assignment 01 EEDocument1 pageAssignment 01 EEAayan ShahNo ratings yet

- Time Table, BSc EE, Spring 23Document2 pagesTime Table, BSc EE, Spring 23Aayan ShahNo ratings yet

- I&M Lab 1 fileDocument15 pagesI&M Lab 1 fileAayan ShahNo ratings yet

- BSc (EE)-(Fall-2019)Document3 pagesBSc (EE)-(Fall-2019)Aayan ShahNo ratings yet

- Experiment 02Document5 pagesExperiment 02Aayan ShahNo ratings yet

- radio frequency lab task lab 1Document2 pagesradio frequency lab task lab 1Aayan ShahNo ratings yet

- Project ProposalDocument4 pagesProject ProposalAayan ShahNo ratings yet

- Brig Asghar new design2Document5 pagesBrig Asghar new design2Aayan ShahNo ratings yet

- Experiment 01Document6 pagesExperiment 01Aayan ShahNo ratings yet

- Experiment 06Document3 pagesExperiment 06Aayan ShahNo ratings yet

- Assignment 3 - CEPDocument1 pageAssignment 3 - CEPAayan ShahNo ratings yet

- Experiment 03Document2 pagesExperiment 03Aayan ShahNo ratings yet

- DisposalDocument6 pagesDisposalAayan ShahNo ratings yet

- GENDERDocument6 pagesGENDERAayan ShahNo ratings yet

- SDP As CEPDocument2 pagesSDP As CEPAayan ShahNo ratings yet

- Lean101 Train The Trainer Slides tcm36-68577Document66 pagesLean101 Train The Trainer Slides tcm36-68577zakari100% (1)

- What Is A StereotypeDocument4 pagesWhat Is A StereotypeAayan ShahNo ratings yet

- Course PackDocument4 pagesCourse PackAayan ShahNo ratings yet

- Speech Recognition Using Correlation TecDocument8 pagesSpeech Recognition Using Correlation TecAayan ShahNo ratings yet

- DSP Lab#05Document6 pagesDSP Lab#05Aayan ShahNo ratings yet

- Hazard ClassificationDocument6 pagesHazard ClassificationAayan ShahNo ratings yet

- Lab 03 Properties of Signals and Various SystemsDocument7 pagesLab 03 Properties of Signals and Various SystemsAayan ShahNo ratings yet

- Automatic Defect Detection and Classification of Ceramic TilesDocument7 pagesAutomatic Defect Detection and Classification of Ceramic TilesAayan ShahNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- SUP 2053 - Assignment - 1 FinalDocument11 pagesSUP 2053 - Assignment - 1 FinalShravanNo ratings yet

- Model and Part Numbers: Desktop, Desk-Edge and Flush-Mount StationsDocument2 pagesModel and Part Numbers: Desktop, Desk-Edge and Flush-Mount StationsDavid AlvaradoNo ratings yet

- Build Contractor Marketing App for Hardware StoreDocument67 pagesBuild Contractor Marketing App for Hardware StorenaimNo ratings yet

- Topic 1 UBD2012 Introduction To Digital TalentDocument8 pagesTopic 1 UBD2012 Introduction To Digital TalentEcah HyraaNo ratings yet

- Introduction To Java: Class 10 - Logix Kips Icse Computer Applications With BluejDocument9 pagesIntroduction To Java: Class 10 - Logix Kips Icse Computer Applications With BluejKaushik ChoudhuryNo ratings yet

- Technology Plan and Infrastruture Support System Journalize TransactionsDocument5 pagesTechnology Plan and Infrastruture Support System Journalize TransactionskrizylNo ratings yet

- Fake Review Detection Iee PaperDocument4 pagesFake Review Detection Iee Paperapeksha SiddramNo ratings yet

- Asm2 1670 GCH0718 Le Trung HaiDocument22 pagesAsm2 1670 GCH0718 Le Trung Hai27ducanhNo ratings yet

- Information Technology Law AssignmentDocument25 pagesInformation Technology Law Assignmentarul279324No ratings yet

- Maximizing Machine Shop Profits with Branch and BoundDocument16 pagesMaximizing Machine Shop Profits with Branch and BoundMariki BelajarNo ratings yet

- Step by Step JINGLING Traffic SoftwareDocument5 pagesStep by Step JINGLING Traffic SoftwareRockin StonezNo ratings yet

- MH3511Document8 pagesMH3511Alex0% (1)

- Cópias de Programas - MozardDocument6 pagesCópias de Programas - MozardTânia RodriguesNo ratings yet

- Uninterupted Power Supply Owner ManualDocument24 pagesUninterupted Power Supply Owner ManualCurtis CampbellNo ratings yet

- ETI MicroprojectDocument13 pagesETI MicroprojectVedant Deepak JadhavNo ratings yet

- MBIT Genus FlowDocument52 pagesMBIT Genus FlowSHANKAR PNo ratings yet

- ANSYS Autodyn Users ManualDocument502 pagesANSYS Autodyn Users Manualcimen.ozgur7416100% (3)

- MHT - CET Application Form DemoDocument11 pagesMHT - CET Application Form DemoAniruddha BalbudheNo ratings yet

- IDC Update Installation Notes M2096Document3 pagesIDC Update Installation Notes M2096Eduardo Vallejos AlfaroNo ratings yet

- Scanner Quickview: Pfu Imaging Solutions Europe Limited Pfu Imaging Solutions GMBHDocument23 pagesScanner Quickview: Pfu Imaging Solutions Europe Limited Pfu Imaging Solutions GMBHgvaxNo ratings yet

- Oracle® MRP: User's Guide Release 12.2Document544 pagesOracle® MRP: User's Guide Release 12.2yadavdevenderNo ratings yet

- Laptops and PCs from TIENDA LUZ under 40 charactersDocument158 pagesLaptops and PCs from TIENDA LUZ under 40 charactersIgnacio Ocacio CabreraNo ratings yet

- Bug Bounty Hunters Extension Guidelines 12062022Document13 pagesBug Bounty Hunters Extension Guidelines 12062022StellaNo ratings yet

- Front Office Tools, Equipment and ParaphernaliaDocument20 pagesFront Office Tools, Equipment and ParaphernaliaMiKiNo ratings yet

- Ae21-It Application Tools and BusinessDocument8 pagesAe21-It Application Tools and BusinessResty Pedrialva LugmaoNo ratings yet

- Overall Previous Year QuestionDocument3,231 pagesOverall Previous Year QuestionMUJA ICSNo ratings yet

- Access Control in BACnet PDFDocument6 pagesAccess Control in BACnet PDFSyed Rohail AhmedNo ratings yet

- Series 3 Electrical Minicargador CASEDocument15 pagesSeries 3 Electrical Minicargador CASEMauricio DuranNo ratings yet

- LB STYLE GUIDE ESMX Mexican SpanishDocument32 pagesLB STYLE GUIDE ESMX Mexican SpanishCarla PeriaNo ratings yet

- Binary Tree and BSTDocument48 pagesBinary Tree and BSTsri aknthNo ratings yet