Professional Documents

Culture Documents

Krohne WPX 1017 New

Uploaded by

HazopsilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Krohne WPX 1017 New

Uploaded by

HazopsilCopyright:

Available Formats

KROHNE, Inc.

Steam Flow Measurement Technology White Paper

Ultrasonic vs. Differential Pressure Flowmeters for High Pressure Steam Service

Renewable energy poses well-publicized opportunities in the quest to reduce fossil fuel

consumption and global warming. However rarely mentioned are the new challenges

associated with increasingly more frequent startups, shutdowns and load changes on

conventional power plants. An increasingly variable production rate is necessary to balance the

dynamic nature of renewable energy production which can be influenced each day by the

availability of sunlight or wind, for example.

One specific new challenge is the measurement of steam flow during these dramatic power

boiler load changes. This challenge will grow as the amount of renewable electrical energy in

the grid increases in relation to the amount of electricity generated by power boilers using

traditional fuels.

High Pressure Steam Flow Measurement Requirements

Steam flow measurement in an environment of increasingly faster and more frequent load

changes and startups/shutdowns necessitates flowmeters that can operate accurately in a

stable manner at increasingly lower flow rates when steam demand for conventional energy

production is low and at high flow rates when demand for conventional energy is high. Stated

differently, these flowmeters must measure accurately over a wider turndown and be capable

of a more dynamic response than would otherwise be required without renewable electrical

energy generation sources. In addition, these flowmeters must be reliable, safe to operate and

easy to maintain.

Benefits of more accurate steam flow measurements include the ability to better monitor the

process and identify problems sooner. In particular, these steam measurements can be used to

determine whether or not equipment is functioning properly and efficiently --- enabling

corrective action well before there is a major problem or economic impact. Accurate steam

flow measurements also contribute to the ability of power boilers to reach steady state

operation faster and better follow demand so as to provide more stable and more economical

operation. In addition, better monitoring and control results in a safer operation.

Typical applications where steam flow is measured in power plants include steam production

from the boiler or heat recovery steam generator and steam used for injection, turbines, heat

exchangers and other auxiliary equipment.

Differential pressure, mechanical, vortex shedding and ultrasonic flowmeters are often applied

in high pressure steam service. The extreme operating conditions to which these flowmeters

are exposed make their maintenance an important factor in selecting which flowmeter to

apply.

Improved high pressure steam flow measurement can be used in conjunction with feed water,

condensate, and/or fuel flowmeters to more precisely monitor power boiler performance and

T: 1-800 FLOWING E: info@krohne.com W: http://ca.krohne.com 1

KROHNE, Inc. Steam Flow Measurement Technology White Paper

enable more efficient operation under startup conditions and at loads below their rated

minimum capacity. This wider operational capability can yield substantial energy savings and

potentially reduce the number of startup and shutdowns required during operation. Reducing

the number of startups and shutdowns not only reduces operator activity but also tends to

reduce overall equipment maintenance requirements.

Therefore existing flow measurement systems based on old measurement techniques should

be considered for upgrade or replacement when maintenance becomes too costly or

cumbersome.

Differential Pressure Steam Flowmeters

Differential pressure flow measurement systems are estimated to represent approximately 90

percent of the population of flowmeters used to measure high pressure steam. This has been

the case historically because few other flowmeter technologies are sufficiently rugged to

withstand high steam pressures and high steam temperatures.

The primary differential pressure flow element is a physical restriction located in the pipe that

generates a pressure drop proportional to the square of the flow rate. Primary elements come

in many forms, but flow nozzles or orifice plates are the most common in steam service. The

pressure drop is measured using a differential pressure transmitter. Pressure and temperature

measurements are often added in applications where operating conditions vary significantly or

when the steam is superheated to more accurately calculate the mass flow.

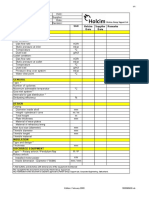

Figure 1 Differential pressure flow element installation in high pressure steam service (Image Courtesy of Spirax Sarco)

T: 1-800 FLOWING E: info@krohne.com W: http://ca.krohne.com 2

KROHNE, Inc. Steam Flow Measurement Technology White Paper

Despite having “worked” in power plants for decades, differential pressure flow measurement

systems have a number of significant constraints:

1. The relationship between flow and pressure drop is inherently non-linear whereby a

small differential pressure change at low flow results in a large flow change. In

particular, 0 and 1 percent of differential pressure correspond to 0 to 10 percent of

flow. As a result, a seemingly small differential pressure error at low flow can result in

relatively large flow errors that can significantly degrade flow measurement accuracy

and limit the turndown of the flow measurement system.

2. The uncertainty of the primary flow element must be considered to determine the

overall differential pressure flow measurement system performance. Improper

geometry and/or material selection can cause the primary flow element to wear and/or

become deformed over time. Some differential pressure flowmeter primary flow

elements (such as an orifice plates) can be installed with an offset from the center of the

pipe that can cause unnoticed but substantial flow measurement errors. Perhaps as

concerning is that many of these flowmeters cannot be removed from service to check

for wear or deformation without a 100% shutdown --- that may not come for decades

(literally). Any damage that can affect accuracy may only be discovered years or even

decades later. Even primary flow elements that can theoretically be isolated could be a

problem when steam shutoff valves do not seal properly.

3. The restriction in the pipe causes a non-recoverable pressure drop that reduces the

energy content of the stream and therefore reduces the amount of energy that can is

available to make electricity

4. Impulse tubes route the upstream and downstream pressures from the primary flow

element to a differential pressure transmitter and/or indicator. In older plants, these

devices were often located near the control room for convenience --- often 50+ meters

from the primary flow element. Any imbalance in the impulse lines caused by ambient

conditions, perhaps from poor insulation, may result in a bias error on the

measurement. Aside from the possibility of a leak, even short impulse tubes can cause

potentially unsafe conditions. For most fluids, removing the transmitter from service

involves opening a bypass valve and closing shutoff valves. In power plant steam

service, this procedure may cause the liquid seals to be drained and expose the

transmitter sensor to high temperature steam which may damage it. The more ominous

danger from an impulse tube fitting failure or valve mishandling is the potential for

serious or critical injury to the technician from the steam.

5. Differential pressure transmitter performance is affected by the ambient pressure and

temperature at which the transmitter operates. Pressure and temperature effect

specifications can often appear deceivingly small but may be actually be multiples of the

transmitter accuracy at high process pressures and at varying temperatures, especially

for older transmitters.

6. Differential pressure transmitter specifications are almost always directly or indirectly

based on a fixed differential pressure error at the optimal sensor range maximum--- not

a flow rate error. The significance of this differential pressure error becomes bigger as

T: 1-800 FLOWING E: info@krohne.com W: http://ca.krohne.com 3

KROHNE, Inc. Steam Flow Measurement Technology White Paper

flow is reduced. Further exacerbating the measurement error is the aforementioned

non-linear relationship between flow and differential pressure. The differential pressure

errors at low flow end up as even larger flow errors. In particular, consider an

application where measuring over a 10:1 turndown would be beneficial. Here, a

seemingly appropriate transmitter with a (differential pressure) turndown of 25:1

represents a flow turndown of only 5:1 (20-100 percent flow). This fixed differential

pressure error degrades performance significantly at low flow rates. In other words, the

desired flow turndown is not achieved.

7. Any available diagnostics are limited to the operation of the differential pressure

transmitter.

In summary, differential pressure flow measurement systems will “work” for a long time --- but

they do have issues of concern insofar as their maintenance and safety, performance,

turndown and overall accuracy.

Mechanical Steam Flowmeters

Mechanical steam flowmeters such as turbine and shunt flowmeters have been applied to

steam service for decades --- typically in smaller pipe sizes due to cost considerations. Insertion

turbine flowmeters can often be applied cost-effectively in large pipes, can be removed from

service while in service and exhibit little or no pressure drop. However, mechanical flowmeters

inherently contain moving parts and bearings that can make their long-term operation and

maintenance problematic due to wear and degradation. Also, insertion devices do not provide

substantial accuracies due to the uncertainties associated with mounting.

Figure 2 Insertion turbine flowmeter (Image Courtesy of Spirax Sarco)

Vortex Shedding Steam Flowmeters

Vortex shedding flowmeters are applied extensively to measure low pressure steam but their

application in high pressure steam service can be limited by the operating pressure, operating

temperature and pipe size. Pipe size limitations can often be mitigated using an insertion

vortex shedding flowmeter that also allows removal of the flowmeter while the pipe is in

T: 1-800 FLOWING E: info@krohne.com W: http://ca.krohne.com 4

KROHNE, Inc. Steam Flow Measurement Technology White Paper

service and exhibits little or no pressure drop. Because of their operating principle vortex

shedding flowmeters are limited by a low flow cutoff that results in zero flow measurement

below a minimum flowing velocity. This may pose operational problems in some applications.

Ultrasonic Steam Flowmeters

Ultrasonic flow measurement systems are relative newcomers to the market with sensors now

having overcome the challenges of operating at the extreme pressures and temperatures

encountered in high pressure steam service.

In a steam ultrasonic meter, the flow sensor consists of a spool piece with one or more pairs of

precisely positioned ultrasonic piezo transducers. Wetted sensor rods route the ultrasonic

energy to the correct location in the pipe while protecting the transducers which are located

external to the pipe where they can operate at lower temperature and with higher reliability

than if directly in contact with high temperature steam. For high pressure service, the spool

piece can be welded inline to reduce leak paths.

The flowing velocity of steam in the pipe is determined by the transit time difference between

the ultrasonic energy that alternately travels with the flow stream and against the stream

between the transducers. Pressure and temperature measurements are often incorporated to

more accurately infer mass flow in a manner similar to differential pressure volumetric flow

measurement systems.

Figure 3 Steam Ultrasonic Flow Sensor and Converter

Ultrasonic flowmeters address many of the disadvantages associated with differential pressure

flowmeters outlined earlier.

1. The spool piece does not have any flow restrictions so there is no pressure drop.

2. The spool piece is constructed of materials suitable for high pressure steam and

fabricated to exacting dimensions. The sensor geometry will not change over the life of

the flowmeter eliminating the need for inspection to ensure accuracy.

3. Spool piece construction ensures that the flow element and its sensors will be installed

in their proper location and examination or replacement of the sensor transducers does

T: 1-800 FLOWING E: info@krohne.com W: http://ca.krohne.com 5

KROHNE, Inc. Steam Flow Measurement Technology White Paper

not require that the pipe be completely shut down. Although designed for decades of

operation in high pressure steam service, the ultrasonic sensor transducers can be

removed or replaced if necessary while steam is flowing --- albeit using proper high

temperature safety precautions.

4. Ultrasonic flowmeters are linear so accuracy does not degrade at low flow and

accuracies are expressed as a percentage of the actual flow rate, and not of maximum

range, so their accuracy is dramatically better than that of differential pressure

flowmeter systems, especially at mid-range and lower flow rates.

5. Steam does not leave the spool piece so there are fewer opportunities for leaks as

compared to differential pressure flowmeters where impulse tubing can be long and

have many fittings.

6. The spool piece should be appropriately insulated for personnel safety typically at or

near the spool piece.

7. The ultrasonic flowmeter's velocity measurement is not affected by changes in steam

pressure and temperature. For clarity, since this is a volumetric flow measurement

device, pressure and temperature compensation is needed to infer mass flow from the

raw flowmeter measurement.

8. The flowmeter is wet-calibrated at the factory so the performance statement for

ultrasonic flowmeters includes the accuracy of the transmitter and its ultrasonic primary

flow element and the complete meter is calibrated against a known and traceable

measurement standard at the factory. A calibration certificate is provided for each

meter.

9. Since the sensor measurement is done electronically, a wide variety of on board

diagnostics are available to remotely evaluate the sensor and transmitter, as well as the

actual measurement quality, at any time..

Figure 4 Redundant Ultrasonic Meters in a Shared Flow Sensor Tube are possible for Critical Steam Measurements

Maintenance

Mechanical flowmeters with moving parts are subject to wear and bearing degradation.

Differential pressure flowmeters are applied extensively in high pressure steam service

but require frequent verification or recalibration to compensate for inherent drift and

sensors and impulse lines should be periodically inspected to ensure they are not

affecting measurement performance. Vortex shedding and ultrasonic flowmeters have

no moving parts and tend to retain their geometry so as to require fewer inspections to

ensure accuracy.

T: 1-800 FLOWING E: info@krohne.com W: http://ca.krohne.com 6

KROHNE, Inc. Steam Flow Measurement Technology White Paper

Summary

Power plant equipment is increasingly required to respond not only to changing electrical loads

but also to changing electrical supplies that include renewable power sources whose output can

vary rapidly depending upon natural phenomena such as wind, sun or clouds. These power

source variations require that power boilers react faster and to a greater extent to provide

reliable and stable electricity to consumers. These demands are expected to increase as

renewable power generation increases in relation to the amount of power generated. Utilizing

accurate and responsive high pressure steam flow measurements are important to meet this

challenge.

Differential pressure flowmeters used to measure high pressure steam flows have

disadvantages such as pressure loss, wear over time, offset installation, periodic inspection,

degraded accuracy at low flow rates, impulse lines with high pressure fluids, safety concerns

due to technician error, safety concerns due to burns, transmitter pressure and temperature

effects, and the accuracy of the primary flow element. In contrast to dp devices, ultrasonic and

vortex shedding flowmeters require less maintenance..

Utilizing ultrasonic flowmeters with wide turndowns and fast response can mitigate these

disadvantages in high pressure steam service and enable power boilers to respond in a stable

manner to the more extreme operating conditions and increasing numbers of startups and

shutdowns in their new operating circumstances. The ability of power boilers to operate over a

wider range in a stable manner can yield substantial energy savings under startup conditions

and at low load. It will also tend to reduce the number of startups and shutdowns that would

otherwise occur, thereby reducing operator activity reducing overall power boiler equipment

maintenance.

Other possible benefits include:

Power boiler efficiency (water and heat energy inputs/steam outputs) can be monitored more

precisely to gauge or optimize boiler performance and wider turndown can readily benefit

control optimization strategies during varying load conditions.

In some cases, by combining ultrasonic steam measurement with ultrasonic feed water,

condensate flows and ultrasonic gas or liquid fuel flow measurement, the resulting wider

operating range and accuracy improvements may allow a power generator to operate

efficiently well below its otherwise rated capacity. This can result in substantial ROI if that

avoids having to find a different way to efficiently generate that power, such as a lower

capacity boiler. New power generation installations with these flow technologies can operate

at greater efficiencies too.

If your plant uses older metering technology for steam or other flow measurements, consider

the latest available ultrasonic developments to help optimize your process operations.

T: 1-800 FLOWING E: info@krohne.com W: http://ca.krohne.com 7

You might also like

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- EI Regulator Station Handbook TDC UK - DesbloqueadoDocument39 pagesEI Regulator Station Handbook TDC UK - DesbloqueadoAlvaro Jhoel Quinteros RNo ratings yet

- Control Valve Sizing Guide for Optimal Plant PerformanceDocument7 pagesControl Valve Sizing Guide for Optimal Plant PerformanceJojolasNo ratings yet

- Module 05: Troubleshoot Centrifugal Compressors Efficiency IssuesDocument18 pagesModule 05: Troubleshoot Centrifugal Compressors Efficiency Issuessivagulf100% (1)

- GG 01 01 2017 26Document5 pagesGG 01 01 2017 26Shaban RabieNo ratings yet

- GG 01 01 2017 26Document5 pagesGG 01 01 2017 26Shaban RabieNo ratings yet

- EI Regulator Station Handbook TDC UKDocument32 pagesEI Regulator Station Handbook TDC UKupesddn2010No ratings yet

- Compressor Selection and SizingDocument32 pagesCompressor Selection and SizingbrainandspiritNo ratings yet

- Flowmeter HandbookDocument23 pagesFlowmeter HandbookClimaco Edwin100% (1)

- Troubleshooting FCC Circulation ProblemsDocument6 pagesTroubleshooting FCC Circulation ProblemsLefter RinaldoNo ratings yet

- Damages on Pumps and Systems: The Handbook for the Operation of Centrifugal PumpsFrom EverandDamages on Pumps and Systems: The Handbook for the Operation of Centrifugal PumpsRating: 4.5 out of 5 stars4.5/5 (2)

- How To Control SurgeDocument22 pagesHow To Control SurgeGlishna Peushan WidanapathiranaNo ratings yet

- Cooling System Keeps Engines from OverheatingDocument8 pagesCooling System Keeps Engines from OverheatingRâdển Mẳs SựryọỡNo ratings yet

- Steam Turbine: A Rotor of A Modern Steam Turbine, Used in ADocument13 pagesSteam Turbine: A Rotor of A Modern Steam Turbine, Used in AAnil Tandon100% (1)

- Graph Installed Flow and Gain PI Mag 03 21Document11 pagesGraph Installed Flow and Gain PI Mag 03 21FabioSalaNo ratings yet

- Controlling Anti-Surge Valves in Low Flow Load Balancing OperationDocument7 pagesControlling Anti-Surge Valves in Low Flow Load Balancing Operationmasimaha1379100% (1)

- Flowmeter Piping RequirementsDocument13 pagesFlowmeter Piping RequirementsVinodKumarNo ratings yet

- Carrier Chapter 3 Piping DesignDocument22 pagesCarrier Chapter 3 Piping DesignAhmad Al-rifaiNo ratings yet

- Reduce Pressure Drop and Lower Energy Costs in Vacuum SystemsDocument5 pagesReduce Pressure Drop and Lower Energy Costs in Vacuum SystemsnasirmuzaffarNo ratings yet

- Column Instrumentation BasicsDocument8 pagesColumn Instrumentation BasicsAmbuja SharmaNo ratings yet

- HP Surge ValveDocument4 pagesHP Surge ValveVee Balaji100% (1)

- Flowmeter HandbookDocument23 pagesFlowmeter HandbookDarkmatter DarkmatterrNo ratings yet

- Metering of GasDocument59 pagesMetering of GasSHOBHIT KUMAR100% (2)

- Liquid Measurement Station DesignDocument10 pagesLiquid Measurement Station Designsigit.kurniadiNo ratings yet

- Finding and Fixing Leakage Within Combined HPDocument34 pagesFinding and Fixing Leakage Within Combined HPsevero97No ratings yet

- Verifying Flowmeter AccuracyDocument8 pagesVerifying Flowmeter AccuracynokarajuNo ratings yet

- Flare Gas Flow Measurement-GEDocument2 pagesFlare Gas Flow Measurement-GEsaverrNo ratings yet

- Pipe Flow Fundamentals Rev 0Document81 pagesPipe Flow Fundamentals Rev 0junaediwendi100% (1)

- Basics of Flow Measurement With The Orifice Flow MeterDocument14 pagesBasics of Flow Measurement With The Orifice Flow MeterBEN ADEGBULUNo ratings yet

- BBS BBT BBTD Sales PresentationDocument34 pagesBBS BBT BBTD Sales PresentationJosé Luis Marcelino PérezNo ratings yet

- Parts List Book: CPA7.5-10-15-20 Screw Air CompressorsDocument15 pagesParts List Book: CPA7.5-10-15-20 Screw Air CompressorsFERNANDO GUAMANNo ratings yet

- How Custody Transfer Works: Accuracy Critical for Financial ExposureDocument4 pagesHow Custody Transfer Works: Accuracy Critical for Financial ExposureJoanna George - Joseph100% (1)

- Pipe Flow Fundamentals Rev 0Document81 pagesPipe Flow Fundamentals Rev 0junaediwendiNo ratings yet

- PROCESS GAS SOLUTIONS: AERZEN'S RELIABLE COMPRESSORS AND BLOWERSDocument26 pagesPROCESS GAS SOLUTIONS: AERZEN'S RELIABLE COMPRESSORS AND BLOWERSWesley andrade martins100% (1)

- CHE Facts 1211Document1 pageCHE Facts 1211kumar_chemicalNo ratings yet

- 83 Calibration Ultrasonic Flowmeters PDFDocument6 pages83 Calibration Ultrasonic Flowmeters PDFMalouk CheniouniNo ratings yet

- Flare SystemsDocument38 pagesFlare Systemsanu malikNo ratings yet

- Calibrating ultrasonic gas metersDocument11 pagesCalibrating ultrasonic gas metersMelina Sbh100% (1)

- Six Popular Flowmeter Technologies ComparedDocument70 pagesSix Popular Flowmeter Technologies ComparedFlor MarchitaNo ratings yet

- Cyclone SeparatorDocument1 pageCyclone SeparatordadNo ratings yet

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- API Plans PosterDocument1 pageAPI Plans Posterskdalalsin100% (1)

- Flow Measurement GuidelinesDocument13 pagesFlow Measurement GuidelinesalainNo ratings yet

- Measurement of LPG CEESIDocument7 pagesMeasurement of LPG CEESIpalebejoNo ratings yet

- GasFlowMeasurement 0508Document6 pagesGasFlowMeasurement 0508bub1ll4No ratings yet

- Technical Resource Library From Cole-Parmer PDFDocument9 pagesTechnical Resource Library From Cole-Parmer PDFshiv kr dubeyNo ratings yet

- 7th Pipeline Technology Conference 2012Document17 pages7th Pipeline Technology Conference 2012Gabo Montaño MendozaNo ratings yet

- Flow Meter Accuracy MattersDocument4 pagesFlow Meter Accuracy Mattersfawmer61No ratings yet

- Accuracy and RepeatablityDocument5 pagesAccuracy and RepeatablityWalid Ben HuseinNo ratings yet

- Onsite Proving of Gas Turbine Meters: Daniel J. Rudroff Flowline Meters IncDocument6 pagesOnsite Proving of Gas Turbine Meters: Daniel J. Rudroff Flowline Meters IncthotalnNo ratings yet

- Instr 2 Joseph SteinkeDocument7 pagesInstr 2 Joseph Steinkekselvan_1No ratings yet

- Steam Measurement ChallengesDocument13 pagesSteam Measurement ChallengesRajagopal ThekkemadamNo ratings yet

- The Real Reason Your Pumps Fail: HOMA Pump TechnologyDocument5 pagesThe Real Reason Your Pumps Fail: HOMA Pump TechnologyZainal Abidin AbRahmanNo ratings yet

- FC 1013 FCIPumpPaperDocument4 pagesFC 1013 FCIPumpPaperkresimir.mikoc9765No ratings yet

- Pipeline Sizing: Learning ObjectivesDocument7 pagesPipeline Sizing: Learning Objectivesbikas_sahaNo ratings yet

- Term Report 2Document9 pagesTerm Report 2Faizan FareedNo ratings yet

- The Final Valve Closure Is TH: To of at A PredeterminedDocument5 pagesThe Final Valve Closure Is TH: To of at A PredeterminedCitra Desiana ErinNo ratings yet

- Power Magazine EprintDocument4 pagesPower Magazine EprintArun BabuNo ratings yet

- Protect Your PumpDocument4 pagesProtect Your PumpAmar SheteNo ratings yet

- Measuring air flow quantities using test sectionsDocument1 pageMeasuring air flow quantities using test sectionsSanya PhilangamNo ratings yet

- Week 6-8Document3 pagesWeek 6-8Christian John Paul LijayanNo ratings yet

- Chapter Four Flow Measurement and ControlDocument35 pagesChapter Four Flow Measurement and ControlMoqeemNo ratings yet

- 2.3 ICR Aug 05 - Optimise Fan PerformanceDocument1 page2.3 ICR Aug 05 - Optimise Fan PerformanceKreshnik StratiNo ratings yet

- Flow Meters PDFDocument2 pagesFlow Meters PDFLyndsey Baker100% (1)

- NEL Best Practice - Impulse Lines For DP FTs PDFDocument8 pagesNEL Best Practice - Impulse Lines For DP FTs PDFnasirmuzaffar0% (1)

- Hydronic Balancing - A Necessity For Good ControlDocument4 pagesHydronic Balancing - A Necessity For Good ControlAntonio LebrunNo ratings yet

- Install PipingDocument5 pagesInstall PipingDan CosacNo ratings yet

- Application of Measuring Gas Flow in The DowncomerDocument4 pagesApplication of Measuring Gas Flow in The DowncomerAhmad NilNo ratings yet

- Diagnosis and Robust Control of Complex Building Central Chilling Systems for Enhanced Energy PerformanceFrom EverandDiagnosis and Robust Control of Complex Building Central Chilling Systems for Enhanced Energy PerformanceNo ratings yet

- Article Tuscon Electric Power Builds Award Winning Predictive Maintenance Ams en 38068Document3 pagesArticle Tuscon Electric Power Builds Award Winning Predictive Maintenance Ams en 38068HazopsilNo ratings yet

- A6510 A6510 T Sensor Input Card en 5087256Document2 pagesA6510 A6510 T Sensor Input Card en 5087256HazopsilNo ratings yet

- Brochure Csi 6500 Machinery Health Manager Ams en 39994Document2 pagesBrochure Csi 6500 Machinery Health Manager Ams en 39994HazopsilNo ratings yet

- LMS200 Launch Customer External-En A 20180618Document13 pagesLMS200 Launch Customer External-En A 20180618HazopsilNo ratings yet

- Case Study Multivariable Vortex Technology Improves Custody Transfer of Saturated Steam Rosemount en 74282Document2 pagesCase Study Multivariable Vortex Technology Improves Custody Transfer of Saturated Steam Rosemount en 74282HazopsilNo ratings yet

- Gilflo ILVA Flowmeters For Steam Liquids and Gases-SB-P337-07-EnDocument8 pagesGilflo ILVA Flowmeters For Steam Liquids and Gases-SB-P337-07-EnHazopsilNo ratings yet

- Thermodynamic Analysis of Rajby Industries Power and Boiler HouseDocument20 pagesThermodynamic Analysis of Rajby Industries Power and Boiler HouseSyed AhmedNo ratings yet

- M10 400 Corrosion ApparatusDocument33 pagesM10 400 Corrosion ApparatusDelfino Mayo AlorNo ratings yet

- BIOMAS TORREFACTION PROCESSDocument5 pagesBIOMAS TORREFACTION PROCESScristian grigorasenco100% (1)

- Case Studies in Thermal EngineeringDocument7 pagesCase Studies in Thermal EngineeringtöreNo ratings yet

- History N Development ICEDocument5 pagesHistory N Development ICEAneesh KumarNo ratings yet

- Comfort-Aire 2012 Full Line CatalogueDocument12 pagesComfort-Aire 2012 Full Line CatalogueRifki 'Okky' FauzyNo ratings yet

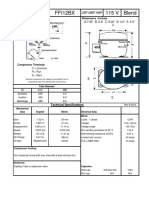

- Ffi12bx1 513200085Document2 pagesFfi12bx1 513200085Leonardo FernandesNo ratings yet

- Ppe AnswersDocument54 pagesPpe AnswersAditya SinghNo ratings yet

- What Is A Cooling Tower - SPX Cooling TechnologiesDocument6 pagesWhat Is A Cooling Tower - SPX Cooling Technologiesprabhanshu241991No ratings yet

- Chernobyl Disaster: "Historicizing" ManagementDocument12 pagesChernobyl Disaster: "Historicizing" Managementindranil biswasNo ratings yet

- Eaton Williams - RHR ManualDocument8 pagesEaton Williams - RHR ManualLuis DomdNo ratings yet

- Ejercicios Topico 3 Moreta HenryDocument6 pagesEjercicios Topico 3 Moreta HenrystearimofyNo ratings yet

- Energy Storage and Tranporation of EnergyDocument96 pagesEnergy Storage and Tranporation of EnergyAhmed khushalNo ratings yet

- Thermo 5th Chap10 P046Document23 pagesThermo 5th Chap10 P046IENCSNo ratings yet

- Piping & Pumping ArrangementDocument12 pagesPiping & Pumping ArrangementPiyus Kumar MazumdarNo ratings yet

- 2-GT IntroDocument70 pages2-GT Intropawan deep100% (1)

- Gasification: An overview of the process, history, reactions and applicationsDocument10 pagesGasification: An overview of the process, history, reactions and applicationsJu Naid MalikNo ratings yet

- NGS Ipg 0001 PDFDocument16 pagesNGS Ipg 0001 PDFRoderick WineNo ratings yet