Professional Documents

Culture Documents

NF FilmTec Prevention of Iron Manual Exc 45 D01575 en

Uploaded by

dpahomi1Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NF FilmTec Prevention of Iron Manual Exc 45 D01575 en

Uploaded by

dpahomi1Copyright:

Available Formats

Tech Manual Excerpt

Water Chemistry and Pretreatment

Fouling Prevention

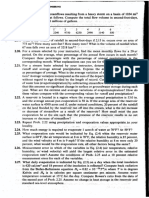

Prevention of Iron fouling is very common. Like any fouling, it causes a performance loss of the

Iron and membrane system, specifically flux loss. In addition, the presence of iron makes the

Manganese Fouling membrane more susceptible to oxidation damage. Fortunately, iron fouling can be

cleaned fairly easily; see Iron Fouling (Form No. 45-D01625-en). Some operators

deliberately accept iron fouling up to 10% flux loss and then clean the membranes

with a predetermined frequency.

Typical sources of iron fouling are

l Anoxic aquifers containing soluble divalent iron and/or manganese

l Hydroxide flocs of oxidized iron and/or manganese from raw water

l Natural organic matter (NOM) containing iron complexes

l Hydroxide flocs from coagulation process

l Corrosion products from piping materials used for the feedwater

l Silicates containing iron

The methods to prevent fouling with colloidal and particulate iron have been

described in Colloidal and Particulate (Form No. 45-D01559-en). Iron silicates have

been discussed in Silica Scale Prevention (Form No. 45-D01557-en). The pretreatment

of water containing ferrous (divalent) iron is described below.

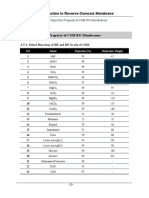

Anoxic waters typically contain divalent iron, manganese, or both. If water

containing iron or manganese has taken up more than 5 mg/L of oxygen, or has

been chlorinated, Fe2+ (ferrous) is converted into Fe3+ (ferric), which forms insoluble

colloidal hydroxide particles that may foul RO/NF membranes. The oxidation of iron

and manganese is given by:

4Fe(HCO3)2 + O2 + 2H2O → 4Fe(OH)3 + 8CO2

4Mn(HCO3)2 + O2 + 2H2O → 4Mn(OH)3 + 8CO2

Iron fouling occurs more frequently than manganese fouling because the oxidation

of iron occurs at a much lower pH. Thus, a fouling problem can be created even if

the SDI is below 5 and the level of iron in the RO feedwater is below 0.1 mg/L.

Waters with low alkalinity usually have higher iron concentrations than waters with

high alkalinity, because the Fe2+ concentration is usually limited by the solubility of

FeCO3.

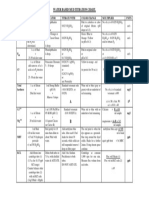

One approach to avoid membrane fouling is to prevent oxidation and precipitation

of iron and manganese by keeping the water in the reduced state. The exposure of

the water to air or to any oxidizing agent (e.g., chlorine) through the whole RO

process must be prevented. A low pH is favorable to retarding Fe2+ oxidation. At pH

< 6 and oxygen < 0.5 mg/L, the maximum permissible Fe2+ concentration is 4 mg/L.

Page 1 of 2 Form No. 45-D01575-en, Rev. 10

March 2022

Prevention of If the anoxic process is used, care must be taken to avoid:

l Oxygen leakage into the feedwater

Iron and

l Reaction of iron with silica to form insoluble iron silicate

Manganese Fouling

l Oxidation by iron reducing bacteria resulting in acceleration of biofilm

(Cont.)

growth and iron deposit

l Blending of ferrous iron containing water with water containing hydrogen

sulfide (H2S), since this could form an insoluble black ferrous sulfide, FeS

Regular iron cleaning (see Iron Fouling (Form No. 45-D01625-en) ) will be necessary

with the anoxic process.

The alternative method of handling anoxic waters is by oxidation-filtration as

described in Oxidation–Filtration (Form No. 45-D01561-en).

Excerpt from FilmTec™ Reverse Osmosis Membranes Technical Manual (Form No. 45-D01504-en), Chapter 2, "Water Chemistry and Pretreatment."

Have a question? Contact us at: All information set forth herein is for informational purposes only. This information is general information and may differ from that

based on actual conditions. Customer is responsible for determining whether products and the information in this document are

www.dupont.com/water/contact-us

appropriate for Customer's use and for ensuring that Customer's workplace and disposal practices are in compliance with

applicable laws and other government enactments. The product shown in this literature may not be available for sale and/or

available in all geographies where DuPont is represented. The claims made may not have been approved for use in all countries.

Please note that physical properties may vary depending on certain conditions and while operating conditions stated in this

document are intended to lengthen product lifespan and/or improve product performance, it will ultimately depend on actual

circumstances and is in no event a guarantee of achieving any specific results. DuPont assumes no obligation or liability for the

information in this document. References to “DuPont” or the “Company” mean the DuPont legal entity selling the products to

Customer unless otherwise expressly noted. NO WARRANTIES ARE GIVEN; ALL IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED. No freedom from

infringement of any patent or trademark owned by DuPont or others is to be inferred.

© 2022 DuPont. DuPont™, the DuPont Oval Logo, and all trademarks and service marks denoted with ™, ℠ or ® are owned

by affiliates of DuPont de Nemours Inc., unless otherwise noted.

Page 2 of 2 Form No. 45-D01575-en, Rev. 10

March 2022

You might also like

- HYDRANAUTICS - Technical Service BulletinDocument50 pagesHYDRANAUTICS - Technical Service Bulletindpahomi1No ratings yet

- Hydranautics TSB110 LDocument7 pagesHydranautics TSB110 Ldpahomi1No ratings yet

- Nanofiltration Hydracore NFDocument2 pagesNanofiltration Hydracore NFdpahomi1No ratings yet

- Solute RO RejectionDocument2 pagesSolute RO Rejectiondpahomi1No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Spec Disodium 5-RibonucleotidesDocument1 pageSpec Disodium 5-RibonucleotidesFerdian Iwank IriyantoNo ratings yet

- Problem Set 1Document3 pagesProblem Set 1supernerd4ever0% (1)

- 3-Iminobutanenitrile As Building Block For The Synthesis of Substituted Pyrazolo (1,5-A) Pyrimidines With Antitumor and Antioxidant ActivitiesDocument19 pages3-Iminobutanenitrile As Building Block For The Synthesis of Substituted Pyrazolo (1,5-A) Pyrimidines With Antitumor and Antioxidant ActivitiesWalid Ebid ElgammalNo ratings yet

- Experiment No 1Document6 pagesExperiment No 1John TacordaNo ratings yet

- Clean Coal TechnologiesDocument8 pagesClean Coal TechnologiesArunChandraBabuNo ratings yet

- 4 Classical Problems of Rigid Body MechanicsDocument2 pages4 Classical Problems of Rigid Body MechanicsPauMarCorNo ratings yet

- A Comprehensive Review of Asphaltene Deposition in Petroleum Reservoirs Theory, Challenges, and TipsDocument39 pagesA Comprehensive Review of Asphaltene Deposition in Petroleum Reservoirs Theory, Challenges, and TipsSoleiman ChatrsimabNo ratings yet

- 303-Stainless Steel-Annealed BarDocument2 pages303-Stainless Steel-Annealed BarARUNKANNANNo ratings yet

- Final Year Project (Thesis)Document197 pagesFinal Year Project (Thesis)Misgates100% (2)

- Inzapol CB 625Document2 pagesInzapol CB 625New EmailNo ratings yet

- Ficha Tecnica Cobre Pure CopperDocument4 pagesFicha Tecnica Cobre Pure CopperANDRES DOMINGUEZNo ratings yet

- Eng ApeelDocument9 pagesEng ApeelSouth AustralianNo ratings yet

- Bulk Density of BricksDocument1 pageBulk Density of BrickssuryakantameNo ratings yet

- 1 Sc-Plastic LimitDocument14 pages1 Sc-Plastic LimitNurul AmshahieraNo ratings yet

- Forces and MotionDocument3 pagesForces and MotionJulia Geonzon LabajoNo ratings yet

- Effect of Rare Earth Elements On Microstructure and Properties of High Chromium White IronDocument7 pagesEffect of Rare Earth Elements On Microstructure and Properties of High Chromium White IronMatheus BoligonNo ratings yet

- Bio-Spin 6 and 30 InstructionsDocument2 pagesBio-Spin 6 and 30 InstructionsdnajenNo ratings yet

- Extrusion Process and Die Design ConsiderationDocument62 pagesExtrusion Process and Die Design ConsiderationMun JiwonNo ratings yet

- CD 225 Revision 1 Design For New Pavement Foundations-WebDocument49 pagesCD 225 Revision 1 Design For New Pavement Foundations-WebJOENo ratings yet

- Water Based Mud Titration Chart.: Test Sample Indicator Titrate With Color Change Multiplier Units PF Cc'sDocument1 pageWater Based Mud Titration Chart.: Test Sample Indicator Titrate With Color Change Multiplier Units PF Cc'sjamesNo ratings yet

- PS - Q1 - Summative Test 1Document10 pagesPS - Q1 - Summative Test 1Rock Quel Sotto Daluz-PullosNo ratings yet

- Heat and Optics One Mark QuestionsDocument23 pagesHeat and Optics One Mark QuestionssaravanamoorthyNo ratings yet

- Primary Checkpoint - Science (0846) April 2016 Paper 1 MSDocument12 pagesPrimary Checkpoint - Science (0846) April 2016 Paper 1 MSpixelhobo94% (17)

- POGIL - ThermodynamicsDocument4 pagesPOGIL - ThermodynamicsMar0% (1)

- Water-Resources Engineering - Parte 3Document50 pagesWater-Resources Engineering - Parte 3Jose SuarezNo ratings yet

- Chemistry: Confidential InstructionsDocument8 pagesChemistry: Confidential InstructionsHubbak KhanNo ratings yet

- Chofu Commissioning Guide 1Document20 pagesChofu Commissioning Guide 1EmiljanoNo ratings yet

- Pieas 1 PlspotDocument13 pagesPieas 1 PlspotMuhammad Javed AkramNo ratings yet

- General Physics 2: Quarter 4 - Week 1Document21 pagesGeneral Physics 2: Quarter 4 - Week 1Ralph QuiambaoNo ratings yet

- Chapter 16Document9 pagesChapter 16Michelle HsiehNo ratings yet