Professional Documents

Culture Documents

Nanofiltration Hydracore NF

Uploaded by

dpahomi1Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nanofiltration Hydracore NF

Uploaded by

dpahomi1Copyright:

Available Formats

HYDRACoRe™ ESNA

Color Removal High Performance

Membrane Elements

Elements ● ESNA1-LF - Significantly

● HydraCoRe 50 - reduces operating costs

Chlorine tolerant, spiral and provides optimum

wound nanofiltration hardness rejection for

membrane elements for softening applications

effective color removal ● ESNA1-LF2 - Ideal for

Chlorine Tolerance of

removing organics that

HydraCoRe Membrane vs. CA Membrane form disinfection by-products

while providing partial water

Retention Rate of Rejection (%)

100

HydraCoRe softening

80 Membrane

(1000ppm)

Mass Transfer Coefficient, MTCw (GFD/PSI)

ESNA1-LF Performance on Feedwater

60

Containing High Organics

0.40

40 CA

Membrane 0.35

(100ppm) ESNA LF

20

0.30

0 0.25

0 10 20 30 40 50

0.20

Immersing Period (day) Membrane A

0.15

0 5 10 15 20 25 30 35 40 45 50 55

HYDRACoRe membranes are ideal for Run Time (Days)

potable applications requiring color Feedwater TOC: 12 ppm

reduction, and minimal removal of Test results courtesy of Dr. Curtis A. Kiefer,

“Optimizing New Low Fouling Nanofiltration Membrane

dissolved salts. HYDRACoRe’s Performance for Deerfield Beach.”

performance remains stable when used ESNA is a high performance nanofiltration

to treat chlorinated feedwater, or when membrane ideal for softening applications,

cleaned with a chlorine solution. and the removal of pesticides, bacteria or

HYDRACoRe technology has also proven viruses. It provides 50%-90% salt rejection

highly effective for industrial wastewater with ultra-low-pressure operation, increased

treatment, including highly colored streams energy savings, and significantly lower

from pulp and paper manufacturing, and installation and operating costs.

food applications for sugar fractation and

color removal.

Specifications

HYDRACoRe™ ESNA

Test Conditions Test Conditions

NaCl Solution, PPM . . . . . . . . . . . . . . . . . . . . . . . . . . .500 NaCl Solution, PPM . . . . . . . . . . . . . . . . . . . . . . . . . . .500

Applied Pressure, psig (MPa) . . . . . . . . . . . . . . . .75 (0.52) CaCl2 Solution ESNA1-LF, PPM . . . . . . . . . . . . . . . . . . .500

Operating Temperature, ˚F (˚C) . . . . . . . . . . . . .77˚ (25˚) Applied Pressure, psig (MPa) . . . . . . . . . . . . . . . .75 (0.52)

Permeate Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . .15% Operating Temperature, ˚F (˚C) . . . . . . . . . . . . .77˚ (25˚)

Feed pH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6.5 Permeate Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . .15%

pH Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6.5 - 7.0

Application Data

Maximum Applied Pressure, psig (MPa) . . . . . . 600 (4.14) Application Data

Maximum Feed Flow, GPM (m3/h) . . . . . . . . . . . . 75 (17.0) Maximum Applied Pressure, psig (MPa) . . . . . . 600 (4.14)

Maximum Operating Temperature, °F (°C) . . . . . .104° (40°) Maximum Feed Flow, GPM (m3/h) . . . . . . . . . . . . . . . . . . .

Feedwater pH Range . . . . . . . . . . . . . . . . . . . . .2.0 - 11.0 . . . . . . . . . . . . . . . . . . . . . .4040-16(3.6), 8-inch -75(17.0)

Maximum Feedwater Turbidity, NTU . . . . . . . . . . . . . . .1.0 Maximum Operating Temperature, °F (°C) . . . . . .113° (45°)

Maximum Feedwater SDI (15 mins) . . . . . . . . . . . . . . .5.0 Feedwater pH Range . . . . . . . . . . . . . . . . . . . . .3.0 - 10.0

Maximum Continuous Chlorine Concentration, PPM . . . .10 Maximum Feedwater Turbidity, NTU . . . . . . . . . . . . . . .1.0

Maximum Chlorine Concentration for Cleaning, PPM . .100 Maximum Feedwater SDI (15 mins) . . . . . . . . . . . . . . .5.0

Maximum Pressure Drop for Each Element, psig . . . . . . .10 Maximum Chlorine Concentration, PPM . . . . . . . . . . .<0.1

Maximum Ratio of Concentrate to Permeate Flow . . . . . . . . . .

Element Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .for Any Element, 5:1

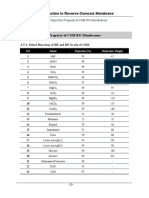

Min. Nom. Permeate Maximum Pressure Drop for Each Element, psig . . . . . . .10

Element Salt Salt MWCO*, Flow, Feed TOC, PPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<3

Type Rej.,% Rej.†,% Daltons** GPD (m3/d) Feed TOC ESNA1-LF, PPM . . . . . . . . . . . . . . . . . . . . .<30

HYDRACoRe 50 . . .50.0 . .35.0 . . .1,000 . . .8,200 . .(31.0)

† Typical rejection for brackish water Element Performance

* Molecular Weight Cut-Off measurement based on Cytochrome C Min. Nom. Typical Rej. Permeate

** Salt rejection of this membrane varies significantly depending on Element Salt Salt Brackish Flow,

concentration, pressure and ion species. Contact Hydranautics’ technical Type Rej.,% Rej.,% Water GPD (m3/d)

support for more information.

ESNA1-LF . . . .73.0 . . .80.0 . . .96.0 . . . . .7,500 (28.0)

Selected Project References for ESNA1-LF2 . . .70.0 . . .77.0 . . .93.0 . . . . .8,300 (30.9)

Hydranautics’ HydraCoRe Membranes

Irvine Ranch, . . . . . . . .7.35 MGD (27,800 m3/d) of potable

Selected Project References for

California water from a ground water source

Hydranautics’ ESNA Membranes

Hollywood, Florida . . . .18 MGD (68,000 m3/d) of potable

water from a well water source

Collier County, Florida . .12 MGD (45,500 m3/d) of potable

water from a well water source

City of Fort Myers, . . . .12 MGD (45,400 m3/d) of potable

Florida water from a well water source

Hydranautics Corporate: 401 Jones Road, Oceanside, CA 92054

Sales Offices Worldwide 1-800-CPA-PURE Phone: 760-901-2500 Fax: 760-901-2578

Hydranautics believes the information and data contained herein to be accurate and useful. The information and data are offered in good faith, but without guarantee, as conditions and methods

of use of our products are beyond our control. Hydranautics assumes no liability for results obtained or damages incurred through the application of the presented information and data. It is

the user’s responsibility to determine the appropriateness of Hydranautics’ products for the user’s specific end uses.

© Copyright 2002 Hydranautics All Rights Reserved For updated product information, contact Hydranautics. 0703/2M

You might also like

- Geotextiles and Geomembranes HandbookFrom EverandGeotextiles and Geomembranes HandbookT.S. IngoldRating: 5 out of 5 stars5/5 (1)

- Making The Grade On Safe Drinking Water For The City of Boca RatonDocument4 pagesMaking The Grade On Safe Drinking Water For The City of Boca RatonRamkiNo ratings yet

- Ucar Latex R-362 - Mielco PDFDocument3 pagesUcar Latex R-362 - Mielco PDFForever0% (1)

- MFUF Pre-Treatment ToDocument1 pageMFUF Pre-Treatment TorezaNo ratings yet

- TDS-975 Carbopol Clear PDFDocument2 pagesTDS-975 Carbopol Clear PDFRafat Kitaneh100% (1)

- CaseStudies PharmezZLDDocument2 pagesCaseStudies PharmezZLDYang SunmanNo ratings yet

- Tertiary Filtration: Pile Cloth Media FiltrationDocument8 pagesTertiary Filtration: Pile Cloth Media FiltrationBrian ThomasNo ratings yet

- Clarox FilterDocument2 pagesClarox FilterMike MichaelidesNo ratings yet

- Exterior White Paint 37% PVCDocument1 pageExterior White Paint 37% PVCAPEX SONNo ratings yet

- NanoPore VIPDocument2 pagesNanoPore VIPbooter_bewareNo ratings yet

- LF710F TDS Agcce 01-2020Document3 pagesLF710F TDS Agcce 01-2020Robert SkibaNo ratings yet

- Omega Air Product Data Sheet Filter Element HF-R v3.02Document2 pagesOmega Air Product Data Sheet Filter Element HF-R v3.02VictorNo ratings yet

- Silicon Carbide Membranes: P R O D U C T B U L L E T I NDocument2 pagesSilicon Carbide Membranes: P R O D U C T B U L L E T I NGabriel Montoya CorreaNo ratings yet

- Emflon PFR Sterilizing-Grade Filter Cartridge For Gas and VentDocument2 pagesEmflon PFR Sterilizing-Grade Filter Cartridge For Gas and VentTruong Anh TuanNo ratings yet

- Oil-X FabricatedDocument4 pagesOil-X FabricatedMohsen ParpinchiNo ratings yet

- Infro Red Sensor DataDocument3 pagesInfro Red Sensor DataSHANKARNo ratings yet

- GORE - Turbine - Filters - Conical-Cylindrical - DSH - US E-100818Document2 pagesGORE - Turbine - Filters - Conical-Cylindrical - DSH - US E-100818HudaFiHayyatNo ratings yet

- XM Filter ElementDocument2 pagesXM Filter ElementhafsakrknNo ratings yet

- HYDAC FilterElements AquamicronDocument2 pagesHYDAC FilterElements AquamicronalishahsavarNo ratings yet

- 3m FluosufactantDocument4 pages3m Fluosufactantuzzy2No ratings yet

- Molins: Technical Data SheetDocument2 pagesMolins: Technical Data SheetsasidharkanthetiNo ratings yet

- Serenacel Mitsubishi EngDocument6 pagesSerenacel Mitsubishi EngYoo BoyyooNo ratings yet

- DriPak - Prod - Mark - SHT - AFP 1 120F NewDocument2 pagesDriPak - Prod - Mark - SHT - AFP 1 120F NewsandroNo ratings yet

- Aquamicron - Filter Elements AM: Up To 10 Bar, Filtration Rating 40 MDocument2 pagesAquamicron - Filter Elements AM: Up To 10 Bar, Filtration Rating 40 MseyedAli TabatabaeeNo ratings yet

- India Crete RMC: A. Mix StipulationDocument2 pagesIndia Crete RMC: A. Mix StipulationAnil UdaleNo ratings yet

- Data Sheet: MBR2520CT MBR25150CTDocument4 pagesData Sheet: MBR2520CT MBR25150CTHaner Eleazar Marin RangelNo ratings yet

- OEM Diff Erential Pressure Transmitter: Type 401Document4 pagesOEM Diff Erential Pressure Transmitter: Type 401minh2305No ratings yet

- Disc FilterDocument2 pagesDisc Filterphool singhNo ratings yet

- UCAR™ Latex UCAR™ Latex UCAR™ Latex UCAR™ Latex UCAR™ Latex D 161Document4 pagesUCAR™ Latex UCAR™ Latex UCAR™ Latex UCAR™ Latex UCAR™ Latex D 161sriatul2006No ratings yet

- Loctite 415™: Technical Data SheetDocument3 pagesLoctite 415™: Technical Data SheettheoNo ratings yet

- Amberlite XAD1180: Industrial Grade Polymeric AdsorbentDocument4 pagesAmberlite XAD1180: Industrial Grade Polymeric AdsorbentAnonymous 6Nt20xKNo ratings yet

- Dowex Marathon C: Ion Exchange ResinDocument12 pagesDowex Marathon C: Ion Exchange ResinZeeshan TalibNo ratings yet

- Filtro Submicrônico AmhDocument1 pageFiltro Submicrônico AmhFilipe GuaranyNo ratings yet

- MBBR STP - WastreatDocument2 pagesMBBR STP - WastreatA3S ENVIRONo ratings yet

- Intercept 8000 LPP: TBT Free, Low Friction Linear Polishing PolymerDocument2 pagesIntercept 8000 LPP: TBT Free, Low Friction Linear Polishing PolymerLeo TvrdeNo ratings yet

- Nippon Muki Catalogue (Seperator Type, J-Model)Document20 pagesNippon Muki Catalogue (Seperator Type, J-Model)Hou HonNo ratings yet

- Datasheet Aqualine ALN05-60BDocument2 pagesDatasheet Aqualine ALN05-60BDian Purwa Dewa (Babeh)No ratings yet

- En Aquacarb207c12x30Document2 pagesEn Aquacarb207c12x30fenda2No ratings yet

- Acumer™: Scale Inhibitor and DispersantDocument3 pagesAcumer™: Scale Inhibitor and DispersantAndreia Frassini100% (1)

- AFM WT Brochure June 2022-Final UpdateDocument8 pagesAFM WT Brochure June 2022-Final UpdateMi doremiNo ratings yet

- DOW - ECOSURF LF Specialty SurfactantsDocument4 pagesDOW - ECOSURF LF Specialty SurfactantsCereliaNo ratings yet

- Transocean - C5-M Typical Coating SystemDocument2 pagesTransocean - C5-M Typical Coating SystemMuhammad Nu'manNo ratings yet

- OPTIMASTIC PU1K 50 Prod Tech InfoDocument2 pagesOPTIMASTIC PU1K 50 Prod Tech InfoMel GarciaNo ratings yet

- Design Basis R4Document2 pagesDesign Basis R4sunil patelNo ratings yet

- Product Information Sheet - OIL-X Compressed Air Filter Grades AO and AA - (English)Document4 pagesProduct Information Sheet - OIL-X Compressed Air Filter Grades AO and AA - (English)ademgsNo ratings yet

- DARAK For Flooded Batteries PDFDocument3 pagesDARAK For Flooded Batteries PDFJelenaNo ratings yet

- Carboxane 2000: Selection & Specification Data Substrates & Surface PreparationDocument2 pagesCarboxane 2000: Selection & Specification Data Substrates & Surface PreparationPurwanto ritzaNo ratings yet

- CROSSLINKEDHADocument10 pagesCROSSLINKEDHABrian BeeNo ratings yet

- Omega Air Product Data Sheet Filter Element HF-A v3.02Document2 pagesOmega Air Product Data Sheet Filter Element HF-A v3.02VictorNo ratings yet

- Xs Filter ElementDocument2 pagesXs Filter ElementhafsakrknNo ratings yet

- Series: Micro Mist SeparatorDocument49 pagesSeries: Micro Mist SeparatorRodrigoBurgosNo ratings yet

- F200AWD LF12x40Document2 pagesF200AWD LF12x40Herik AziziNo ratings yet

- Mipolam Troplan CardDocument4 pagesMipolam Troplan Cardsr2011glassNo ratings yet

- MRF-140CG Magneto-Rheological Fluid: Lord Technical Data Lord Technical DataDocument2 pagesMRF-140CG Magneto-Rheological Fluid: Lord Technical Data Lord Technical DataSoroush RahimiNo ratings yet

- BetaQua ASFDocument2 pagesBetaQua ASFbuattugasmetlitNo ratings yet

- Laser InatraDocument1 pageLaser InatraKleberBuñayNo ratings yet

- Axeon XE1 Membrane Spec SheetDocument1 pageAxeon XE1 Membrane Spec Sheetamanuel waleluNo ratings yet

- Bokela Dyno FilterDocument12 pagesBokela Dyno FilterAlanNo ratings yet

- Agilent 1260 Infinity Diode Array Detector: Features, Technical Details, Specifications and Ordering DetailsDocument6 pagesAgilent 1260 Infinity Diode Array Detector: Features, Technical Details, Specifications and Ordering DetailssaidvaretNo ratings yet

- Varicel 2hc Afp1243Document2 pagesVaricel 2hc Afp1243Pablo B.No ratings yet

- Filtration Case StudyDocument6 pagesFiltration Case Studywacsii ccasullaNo ratings yet

- HYDRANAUTICS - Technical Service BulletinDocument50 pagesHYDRANAUTICS - Technical Service Bulletindpahomi1No ratings yet

- Hydranautics TSB110 LDocument7 pagesHydranautics TSB110 Ldpahomi1No ratings yet

- Solute RO RejectionDocument2 pagesSolute RO Rejectiondpahomi1No ratings yet

- NF FilmTec Prevention of Iron Manual Exc 45 D01575 enDocument2 pagesNF FilmTec Prevention of Iron Manual Exc 45 D01575 endpahomi1No ratings yet

- Mem CalcDocument6 pagesMem CalcQruisedNo ratings yet

- Torts and Damages Lecture NotesDocument42 pagesTorts and Damages Lecture NotesMaeNo ratings yet

- Huanyang Inverter Instruction (Eng) .300dpi.67pages - OcrDocument70 pagesHuanyang Inverter Instruction (Eng) .300dpi.67pages - Ocrkyuwan kimNo ratings yet

- What Is Nursing?: What Exactly Do Nurses Do?Document3 pagesWhat Is Nursing?: What Exactly Do Nurses Do?mabel yapuraNo ratings yet

- A Grammar of Power in Psychotherapy Exploring The Dynamics of Privilege (Malin Fors)Document220 pagesA Grammar of Power in Psychotherapy Exploring The Dynamics of Privilege (Malin Fors)Andrea A. Ortiz Vázquez100% (1)

- Oedipus SummaryDocument1 pageOedipus SummaryReynold FrancoNo ratings yet

- Nutrition AssessmentDocument7 pagesNutrition AssessmentJoyce VitalNo ratings yet

- iSF EClassRecord - NewNormal AdviserDocument254 pagesiSF EClassRecord - NewNormal AdviserYanara Delarama DayapNo ratings yet

- Department of Civil Engineering Uttara University: LaboratoryDocument102 pagesDepartment of Civil Engineering Uttara University: LaboratorytaniaNo ratings yet

- Social Science Assignment Class 8 CBSEDocument3 pagesSocial Science Assignment Class 8 CBSEgurdeepsarora8738No ratings yet

- Hydraulic Seat Puller KitDocument2 pagesHydraulic Seat Puller KitPurwanto ritzaNo ratings yet

- (Nikolaj Wolfson, Alexander Lerner, Leonid Roshal (B-Ok - CC)Document589 pages(Nikolaj Wolfson, Alexander Lerner, Leonid Roshal (B-Ok - CC)Andi sutandi100% (1)

- Professional DevelopmentDocument1 pageProfessional Developmentapi-488745276No ratings yet

- Phaser 3250 Service Manual 0106 2010Document334 pagesPhaser 3250 Service Manual 0106 2010Terry BogardNo ratings yet

- ES 92.05 D1 Fire ProofingDocument18 pagesES 92.05 D1 Fire ProofingKanjana LeardrakNo ratings yet

- MBBS Cafeteria TEST 1Document7 pagesMBBS Cafeteria TEST 1aalishba6a2b9cNo ratings yet

- Metrel Mi 3290 Earth AnalyserDocument4 pagesMetrel Mi 3290 Earth AnalyserMarijan MustačNo ratings yet

- Operations Manual: Conical Burr Coffee GrinderDocument15 pagesOperations Manual: Conical Burr Coffee Grindercherrera73No ratings yet

- Siklus Biogeokimia - Retensi NutrienDocument24 pagesSiklus Biogeokimia - Retensi NutrienPutri Nur Fadhilah YasharNo ratings yet

- Imaging-Guided Chest Biopsies: Techniques and Clinical ResultsDocument10 pagesImaging-Guided Chest Biopsies: Techniques and Clinical Resultsweni kartika nugrohoNo ratings yet

- 12 29 11editionDocument27 pages12 29 11editionSan Mateo Daily JournalNo ratings yet

- Project PPT Spot WeldingDocument19 pagesProject PPT Spot WeldingMehul BariyaNo ratings yet

- Cognizin CDPCholine Caps 60vcaps by Life ExtensionnvyzqvhqimDocument2 pagesCognizin CDPCholine Caps 60vcaps by Life Extensionnvyzqvhqimcarollip2No ratings yet

- Odontektomi Bahan Diskusi Od KoasDocument51 pagesOdontektomi Bahan Diskusi Od Koaspanjidrg100% (1)

- Aerobic ActivitiesExercises PDFDocument14 pagesAerobic ActivitiesExercises PDFPalma, Arrabela M.No ratings yet

- 3 D7 QC Physical and Chemical Tests Ok For EmailDocument17 pages3 D7 QC Physical and Chemical Tests Ok For EmailUbaid KhanNo ratings yet

- Dr. Ashraf Sayeed: Department of OphthalmologyDocument49 pagesDr. Ashraf Sayeed: Department of Ophthalmologysaiful haque100% (1)

- DAFTARRUJUKANDocument4 pagesDAFTARRUJUKANIndahNo ratings yet

- WWW CDC Gov/malaria/about/biologyDocument2 pagesWWW CDC Gov/malaria/about/biologyFiik FiikNo ratings yet

- Is 228 (Part 1) : 1987 Methods For Chemical Analysis Of: (Reaffirmed 2008)Document5 pagesIs 228 (Part 1) : 1987 Methods For Chemical Analysis Of: (Reaffirmed 2008)Indira BanerjeeNo ratings yet