Professional Documents

Culture Documents

A320 Air

Uploaded by

HazemOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A320 Air

Uploaded by

HazemCopyright:

Available Formats

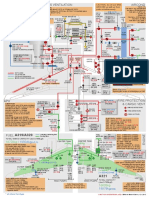

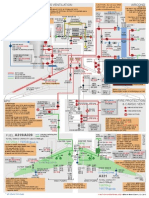

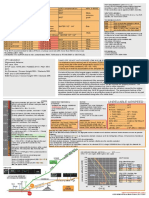

BLEED AVIONICS VENTILATION CAUTION, do not use GND AIRCOND

CONFIGURATIONS: AIRCOND air with air from *PACK CTL

Prim fail => reg. not optimized

CAUTION, do not use CLOSED, on GND (skin<9°-12°C), in FLT(skin<32°-35°C) packs simultaneously

Sec fail => ECAM sgnal lost

HP GND air with APU bleed INTERMEDIATE if (skin>32°-35°C) then EXTRACT VLV partially opens

(IOM, JLP-S) Both fail => 5-30°C in 6’

OPEN, on GND (skin>9°-12°C) PACK 1 AIR COND SYS 1 CTL by a/ice vlv

SMOKE CONFIG FLOW *ZONE CTL

Regulated pressure 45 +/- 5 psi Air from avionics bay CONTROL *ZONE CTL

CABIN Prim fail => 24°C by packs

Leak detection FANs SPD (-IOM,-JLP-S) SKIN EXCH VALVE Sec fail => no effect

SKIN HEAT AIR

- single loop for APU and pylon ducts HI if T > 40°C [DC ESS *PACK 1 CTL Both fail => 20°C pack 1

OUTLET EXCHANGER SKIN

- double loop for wing ducts LO if T < 35°C SHED] 10°C pack 2

BYPASS VLV EXCH FILTER

AEVC ISOL CAB FAN 1

[DC1] VLV [AC1]

[DC ESS PACK

BLOWER COCKPIT EXTRACT 1 COCKPIT

SHED]

ENG A/ICE VALVE FAN PANELS FAN SKIN AIR

ENG 1 [DC1] SKIN AIR [AC1] [AC2] EXTRACT HOT AIR FLAP

INLET VLV AVIONICS VLV

ENG 2 [DC2] PRESS VALVE

EQPMT TRIM

valve opens if unpowered REG VLV

AIR VALVES

FILTER FWD

AIRCOND SKIN CABIN

INLET MIXING

EXCH UNIT

VALVE INLET

FAN AIR VALVE EMER

ENG 1 [DC ESS SHED] 5th BYPASS

VLV RAM AIR AIRCOND TRIM

ENG 2 [DC2] HP VLV, maintain 36+/-4 psi [DC ESS] GND

cargo AIR VALVES

regulates BLEED temp at 200°C 9th ENG 1 [DC ESS SHED] CONNECT

under-floor PACK 2

ENG 2 [DC2] FLOW

CONTROL AFT

BLEED MONITORING BLEED VALVE (ENG 1 only)

VALVE [DC2] PACK CABIN

COMPUTER ENG 1 [DC ESS SHED] pressure

BMC 1 [DC ESS SHED] ENG 2 [DC2] HYD WATER 2 CAB FAN 2

indication LOOP A

BMC 1 [DC2] RES TANK [AC2]

OVERPRESS LOOP B FILTER

VALVE (85psi) FF SATCOM

STARTER VLV *PACK 2 CTL

FF CABIN AIR

FF IOM, JLP-S

*ZONE CTL (85% recycle air)

temperature AIR COND SYS CTL

B1 one lane fail => no effect

indication X-BLEED VLV (IOM, JLP-S)

AUTOCTL [DC2] B2 AIR COND SYS 2 CTL both lanes fail => PACK lost

HOT BLEED MANCTL [DC ESS SHED]

COLD FAN AIR

COLD AIR FROM PACK

MIXED CONDITIONNED AIR

SAFETY

VALVES

PRESSURIZATION

MOT 1 CPC 1

- 2 safety valves (max 8.6psi or -.25psi)

WING ANTI ICE VLV [DC ESS] [DC ESS]

HP GND - RAM AIR ON and ∂p<1psi, outfl. vlv 50% opens

[AC ESS SHED]

Valve closes if unpowered CONNECT

MAN - CAB PR EXCESS CAB ALT (>9550+/-350ft)

MAN V/S

MOT

SWITCH

[DC BAT]

only SLATS 3,4 & 5

are heated OUTFLOW RPCU (IOM, JLP-S)

VALVE MOT 2 CPC 2 Depressurizes in case of residual press on GND

[DC2] [DC2]

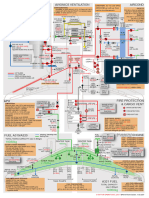

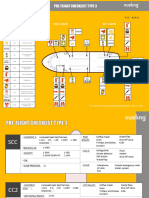

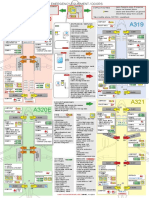

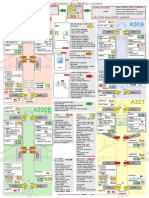

APU ELECTRONIC

FWD

CARGO

SDCU (others)

CH1 [DC ESS SHED]

FIRE PROTECTION

LIMITATIONS

RPM min 95%, max 107% (auto shut down)

CONTROL BOX

[BAT]

APU

BLEED

COMP

A321 only CH2 [DC2]

& CARGO VENT

running EGT max 682°C (5sec) or 700-742 VALVE OUTLET ISOL SMOKE DETECTORS

start EGT max 900°C > 25'000ft VALVE SQUIBS

B CIDS (IOM, JLP-S)

start EGT max 982°C < 25'000ft EXTRACT FAN B [DC BAT] F FIRE DETECTORS

LOW OIL LEVEL => 10 hrs APU ops APU FF [AC1]

CH1 [DC ESS]

CH2 [DC2]

start cycles: S 1min S 1min S 60min APU B FIREX BOTTLES

Enveloppe: STARTER AFT

START with AC pwr up to 39'000ft [BAT] CARGO

A321 only ELECTRICAL SUPPLY

START with EMER ELEC pwr up to 25'000ft COMP

APU LP VLV ENG 1 loop A [DC ESS], loop B [DC2]

BLEED ON 2packs max 15'000ft, 1 pack max 20'000ft [DC BAT]

BLEED ON for engine start max 20'000ft BULK ENG 2 loop A [DC2], loop B [DC ESS]

[HOT 1] APU loop A & B[DC BAT]

BLEED for WING A/ICE not permitted INLET CARGO

APU FUEL FLOW ~130 kg/hr APU PUMP ISOL ENG 1&2 BTL 1 squib A [HOT1] squib B [HOT2]

VENTILATION

[DC BAT] P VALVE ENG 1&2 BTL 2 squib A [DC2] squib B [DC2]

CONTROL

[AC ESS APU BTL squib A [HOT1] squib B [DC BAT]

[DC BAT]

SHED] CABIN AMBIENT AIR APU auto extinguish [DC BAT]

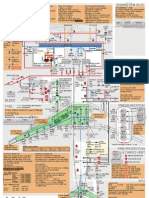

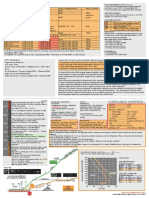

FUEL A319/A320 refueling / defueling lines

feeding lines

FUEL EIU

A319: CFM56-5B6/2 23'500lbs

NOZZLES ENG1 [DC BAT]

A320: CFM56-5B4/2 27'000lbs

ENGINE

ENG2 [DC ESS]

A320E: CFM56-5B4/P 27'000lbs

TOTAL TANKS CAPACITY (den 0.785kg/l)

FF A321: CFM56-5B1/2 30'000lbs

CENTER TANK

18728kg / 19004kg (JLP-S) CENTER TANK

6476kg 6437kg

HP VLV [DC ESS] N1 100% = 5000 rpm

N2 100% = 14460 rpm

OUTER to INNER TRANSFER X-FEED FUEL METERING VLV TOGA EGT max 950° (5’, 10’OEI)

- XFR valves open when INNER have ~750kg MOT 1 [DC ESS SHED] IDG OIL COOLER ENG cool-down time 3' (1' for ops)

- T/O only with Outer TK full LP VALVE START cycle 4x(St.2’/20”) then 15’

MOT 2 [DC1] SERVO FUEL

- Automatic XFR after landing MOT 1 [DC ESS] ENG

HEATER IGNITION

(to avoid, switch REFUEL panel PWR ON!) MOT 2 [DC2] PMP FADEC

or transfer via DEFUEL/XFR valve. jet pump FUEL/OIL HEAT ENG1&2 CH A [DC ESS] ENG1&2 A [AC ESS]

1 or [AC STAT INV]

LP VALVE ENG1 CHB [DC BAT] ENG1 B [AC1]

DEFUEL ENG2 CHB [DC2]

MOT 1 [DC ESS] ENG2 B [AC2]

FQI INNER TANKS 1 2 XFR 1 2 MOT 2 [DC2]

CH1 [DC ESS SHED] XFR VALVES VLV

1 [DC ESS SHED] 2 x 5435kg* CENTER to WING TRANSFER

CH2 [DC2]

2 [DC2] 2 x 5573kg (JLP-S) A320 -Valve opens until wing tank is full then wait

A319 A321 until 250kg are used and re-opens

PUMP PUMP PUMP PUMP PUMP

- Gravity transfer from CTR TK

OUTER TANKS LH 1 LH 2 CTR1 RH 1 RH 2

CTR XFR [AC1] [AC2] WING TANKS only possible if >2000kg in

2 x 691kg REFUEL VALVE [AC1] [AC2] [AC1] VLV center tank these

[DC2] refueling on [DC1] [DC2] [DC1] [DC1] [DC2] 2 x 6084kg* REFUEL

are trapped

[DC ESS] L[DC1] [DC ESS] VALVE

batteries with

PUMP R[DC2] 2 x 6221kg (IOM)

[HOT1]

REFUEL

COUPLING

CTR2

[AC2] A321

REFUEL

COUPLING VENT TANK

FUEL IMBALANCE A319/A320 [DC2]

INNER TK Full, max 1500kg TOTAL CAPACITY ~50kg

INNER TK 4300kg, max 1600kg

TANK PUMPS WING PUMPS

(den 0.785kg/l) A321 FUEL IMBALANCE

INNER TK 2250kg, max 2250kg FUEL TEMPERATURE

no limitations below 2250kg

OUTER TK max 530kg, if OUTER+INNER same

JET A1 min -43°C max +54°C 18605kg WING TK Full, max 1350kg

WING TK 4000kg, max 1500kg

JET A min -36°C max +54°C

or INNER of empty OUTER equal or higher (up to 3t) of

opposite INNER

(IOM)18879kg WING TK 2350kg, max 2350kg

no limitations below 2350kg

* all others from type !!! NOT FOR OPERATIONAL USE !!! ©Pierre-Michel Gasser, 12.1.2013

You might also like

- A320air - SysDocument1 pageA320air - SysNathaniel Alexander -No ratings yet

- A320 AirDocument1 pageA320 AirHazemNo ratings yet

- HP GND Air With APU Bleed AIRCOND Air With Air From Packs SimultaneouslyDocument1 pageHP GND Air With APU Bleed AIRCOND Air With Air From Packs SimultaneouslyAlex AlexNo ratings yet

- Esquema 320Document9 pagesEsquema 320Paco Iglesias CubilesNo ratings yet

- Airbus 320 Air ConditioningDocument1 pageAirbus 320 Air ConditioningRafaelNo ratings yet

- A320 Schematic at A Glance 1686986584Document4 pagesA320 Schematic at A Glance 1686986584Harsh PawarNo ratings yet

- A340 Air Fuel EngineDocument1 pageA340 Air Fuel EngineDAVID FAJARDO PUERTO100% (1)

- HP GND Air With APU Bleed: CAUTION, Do Not UseDocument1 pageHP GND Air With APU Bleed: CAUTION, Do Not UseElias Iruela100% (1)

- CB ResetDocument169 pagesCB ResetAmine Chabchoub100% (1)

- A320 AirDocument1 pageA320 AirEnrique Barberan100% (1)

- 7.airbus A320 Family CB List and ResetsDocument30 pages7.airbus A320 Family CB List and ResetsVu Nguyen TuanNo ratings yet

- Airbus A320 Family CB List and ResetsDocument30 pagesAirbus A320 Family CB List and Resetsaeozbay94% (17)

- A320 CB Resets PDFDocument30 pagesA320 CB Resets PDFFaiyaz DurweshNo ratings yet

- A320 Air PDFDocument1 pageA320 Air PDFStephanie Johnson100% (1)

- Reset BreakersDocument44 pagesReset BreakersX67% (6)

- A320 EACM Message RESET CB PDFDocument44 pagesA320 EACM Message RESET CB PDFbluesky_1976100% (5)

- Trening Klima Sistema - 7 (A)Document13 pagesTrening Klima Sistema - 7 (A)DraganNo ratings yet

- A320 CB + ResetsDocument30 pagesA320 CB + ResetsamroushararaNo ratings yet

- A320 Schematics PDFDocument4 pagesA320 Schematics PDFAlina Costica100% (2)

- Cockpit Panel Description: NavigateDocument47 pagesCockpit Panel Description: NavigateVu Nguyen TuanNo ratings yet

- ATR FCOM Fire ProtectionDocument4 pagesATR FCOM Fire ProtectionslsalescoNo ratings yet

- Type 2 Rev14Document2 pagesType 2 Rev14Andrea Berenguel GarciaNo ratings yet

- Checklists and Procedures A 319 CFM: 12.1 Basic Preparation Procedure (Aircraft in COLD DARK State)Document9 pagesChecklists and Procedures A 319 CFM: 12.1 Basic Preparation Procedure (Aircraft in COLD DARK State)Rodrigo LewandowskiNo ratings yet

- Crj200 Eicas Message ListDocument17 pagesCrj200 Eicas Message Listmonawar100% (2)

- Accumulator Specifications AIR Dryer Unit Air Dryer Unit Specifications (Working Weight) ConsumerDocument5 pagesAccumulator Specifications AIR Dryer Unit Air Dryer Unit Specifications (Working Weight) ConsumerBenyamin heidariNo ratings yet

- Description and Operation: Component Maintenance ManualDocument8 pagesDescription and Operation: Component Maintenance ManualLou Parker100% (1)

- ATR Flight ControlsDocument41 pagesATR Flight ControlsJavier100% (3)

- Ram Open DeactivateDocument5 pagesRam Open DeactivateRendi 911No ratings yet

- FENIX AIRBUS A320 FSCrew CHECKLISTDocument31 pagesFENIX AIRBUS A320 FSCrew CHECKLISTGilles MédaillonNo ratings yet

- Tips A320 ResetDocument82 pagesTips A320 Resetgarry pangkey100% (1)

- Type 3 Rev14Document2 pagesType 3 Rev14Andrea Berenguel GarciaNo ratings yet

- ATR-Ice and Rain ProtectionDocument38 pagesATR-Ice and Rain ProtectionJavierNo ratings yet

- Falcon 2000EX Expanded Normal Procedures: Do List Item ActionDocument7 pagesFalcon 2000EX Expanded Normal Procedures: Do List Item ActionTony NicholasNo ratings yet

- AMM - A318, A319, A320, A321 - Rev. Num - 39 - 01-Aug-2023 - Figure 36-10-00-11700-00-B (SHEET 1) - Pneumatic System - SchematicDocument1 pageAMM - A318, A319, A320, A321 - Rev. Num - 39 - 01-Aug-2023 - Figure 36-10-00-11700-00-B (SHEET 1) - Pneumatic System - SchematicMuhammad Luthfi FadhilahNo ratings yet

- BOOKLET ATR-600 Rev 01-1 (1) (001-025)Document25 pagesBOOKLET ATR-600 Rev 01-1 (1) (001-025)Juychardson ReisNo ratings yet

- BOOKLET ATR-600 Rev 01 PDFDocument161 pagesBOOKLET ATR-600 Rev 01 PDFcesar neira100% (3)

- Manual Checklist 3094Document2 pagesManual Checklist 3094MARTIN GONZALEZNo ratings yet

- B1435 Cool Air Bypass Damper Position SensorDocument4 pagesB1435 Cool Air Bypass Damper Position SensorVũ Nguyễn Minh100% (1)

- Warning: Do Not Reset C/B's Within 2 Min of Aircraft Power Up. (Self Test of FMGC)Document3 pagesWarning: Do Not Reset C/B's Within 2 Min of Aircraft Power Up. (Self Test of FMGC)anarko arsipelNo ratings yet

- 03 B737CL Anti Ice - and - Rain DesbloqueadoDocument13 pages03 B737CL Anti Ice - and - Rain DesbloqueadoJulio BorgesNo ratings yet

- C1741 PDFDocument4 pagesC1741 PDFbob loblawNo ratings yet

- A320 CB PanelsDocument67 pagesA320 CB PanelsMiklós Meixner100% (4)

- Type 1 Rev14Document2 pagesType 1 Rev14Andrea Berenguel GarciaNo ratings yet

- Bombardier CRJ 200-Environmental Control System PDFDocument39 pagesBombardier CRJ 200-Environmental Control System PDFmamon113No ratings yet

- CMOS General Purpose Timer: Description Pin ConfigurationDocument10 pagesCMOS General Purpose Timer: Description Pin ConfigurationNagappan NagaNo ratings yet

- Check List A320Document6 pagesCheck List A320Miguel Cayuela de PedroNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Unit 2Document36 pagesUnit 2HazemNo ratings yet

- Lecture 6Document20 pagesLecture 6HazemNo ratings yet

- Revision 1 For Midterm ExamDocument6 pagesRevision 1 For Midterm ExamHazemNo ratings yet

- Revision Problems For PracticeDocument37 pagesRevision Problems For PracticeHazemNo ratings yet

- MU123 - Week4 - Trade and CashDocument17 pagesMU123 - Week4 - Trade and CashHazemNo ratings yet

- Lecture 7Document26 pagesLecture 7HazemNo ratings yet

- B120 Important Topics To Be Focused 2Document20 pagesB120 Important Topics To Be Focused 2HazemNo ratings yet

- Final Exam Yona 1Document25 pagesFinal Exam Yona 1HazemNo ratings yet

- MU123 Week 2 Unite 2 3Document34 pagesMU123 Week 2 Unite 2 3HazemNo ratings yet

- Module Specification: Important Notes - Please Read Them Before Completing This FormDocument9 pagesModule Specification: Important Notes - Please Read Them Before Completing This FormHazemNo ratings yet

- MU123 Week 3 Unit 3Document13 pagesMU123 Week 3 Unit 3HazemNo ratings yet

- Notes On Book 5Document11 pagesNotes On Book 5HazemNo ratings yet

- MU123 Week 4 Unit 4 11Document35 pagesMU123 Week 4 Unit 4 11HazemNo ratings yet

- A320 TakeOffDocument1 pageA320 TakeOffHazemNo ratings yet

- A320 HydDocument1 pageA320 HydHazemNo ratings yet

- Book 3qDocument16 pagesBook 3qHazemNo ratings yet

- Fall 2016 MU123 Course Syllabus AOU-FBSDocument10 pagesFall 2016 MU123 Course Syllabus AOU-FBSHazemNo ratings yet

- Fall 2016 MU123 Take Home AssignemntDocument4 pagesFall 2016 MU123 Take Home AssignemntHazemNo ratings yet

- Sample MTA 1 - Copy AKDocument8 pagesSample MTA 1 - Copy AKHazemNo ratings yet

- B120 Course Syllabus TEMP AOU-FBS-Core - Fall 2016-2017-TentativeDocument5 pagesB120 Course Syllabus TEMP AOU-FBS-Core - Fall 2016-2017-TentativeHazemNo ratings yet

- A320 HydDocument1 pageA320 HydHazemNo ratings yet

- A320 TakeOffDocument1 pageA320 TakeOffHazemNo ratings yet

- A320 EmerDocument1 pageA320 EmerHazemNo ratings yet

- A320 EmerDocument1 pageA320 EmerHazemNo ratings yet

- A320 ElecDocument1 pageA320 ElecHazemNo ratings yet