Professional Documents

Culture Documents

A340 Air Fuel Engine

Uploaded by

DAVID FAJARDO PUERTOOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A340 Air Fuel Engine

Uploaded by

DAVID FAJARDO PUERTOCopyright:

Available Formats

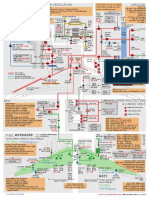

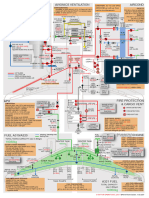

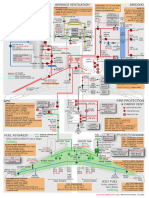

AIR SYSTEMS Regulated pressure 44 - 52 psi PACK CTL channels AIR CYCLE MACHINE failure ENGINE CFM 56-5C

1 failed => no effect Pack operates in heat exchanger Thrust 68000lbs = ~30.8t

Leak detection N1: FAN+4 Comp+5 Turb, 100%=5000rpm

Hot bleed air both failed => temp 1-15°C by cooling mode in-flight only

Single loop for APU and pylon ducts N2: 9 Comp + 1 Turb, 100%=14460rpm

Cold air from fan / outside anti-ice valve. no ECAM indication. HOT AIR VLV failure

Double loop for wing ducts 20 Fuel nozzles + 2 Igniters

Cold air from packs Flow 120% of NORM failed open => no effect

Mixed conditionned air Temperature control ZONE CTL channels 1 vlv failed closed => no effect (X-hot) Warm-up time 5’ before T/O thrust

Cabin recirculated air 200°C normal temperature 1 failed => no effect 2 vlvs failed closed => reg by PACKS Cool-down time 5' or 1' if required by ops

150°C if wing a/ice OFF and enough both failed => Packs deliver 20°C. TRIM AIR VLV failure

AVIONICS VENT for zone controller demand ECAM ind lost & display PACK REG 1 failed closed => half this zone lost

1 failed open => half each zone lost EIUs FADECs IGNITION

[DC BAT] CH A [AC ESS] A [AC ESS]

PANELS COCKPIT ch B ENG 1&3 [AC2-3] B ENG 1&3 [AC2-3]

FWD CABIN MID CABIN AFT CABIN ch B ENG 2&4 [AC2-4] B ENG 2&4 [AC1-2]

CABIN CABIN

RESTRICTOR AIR AIR

EQPMT

CABIN

AEVC RACKS

[AC1-2] FANs

other side HOT AIR 1 [AC1-2]

to avionic 2 [AC2-3]

X-VLV vent

EXTRACT FAN [AC1-2]

TRIM RECIRC

AIR VLVs VLVs

UNDERFLOOR 1 [AC1]

2 [AC2]

OVBD EXTRACT

EXTRACT VLV MIXER UNIT

VLV to FWD to FWD

cargo PACK 1 BY PASS cargo cooling

heating flow in by-pass VLV

on gnd engines PACK 2 HOT AIR 2

HOT AIR 1 mode

not running EMER LP GND VLV

VLV TEMP RAM AIR INLETS

[DC ESS]

CTL VLV

In-flight or PACK 1 CTL ZONE CTL PACK 2 CTL

Ditching ON ch 1 [AC1-2,DC1]

ch 2 [AC1-2,DC1]

CH1 [DC1]

CH2 [DC2]

ch 1[AC2-3,DC2]

ch 2[AC2-3,DC2]

CAUTION, do not use

Main Heat Primary Heat A/ICE Turbofan for pack HP GND air with APU bleed

WATER TK

Exchanger Exchanger VLV bay cooling

HYD RES

Extract OVRD

SMOKE EVAC PACK 1 CARGO EXT AIR APU CAUTION, do not use GND

FLOW PACK 2

HEAT AIRCOND air with air from

CTL VLV FLOW

closure CTL VLV closure packs simultaneously

[DC ESS] [DC ESS]

WING A/ICE VLVs

[DC ESS SHED]

X-BLEED VLV

ENG 2

FAN AIR

SLAT 4 VLVs FUEL INJECTORS MANUAL [DC ESS]

AUTO [DC2] EXTRACT OUTLET

ENG 2 & 4 [DC1] A/ICE VLVs 10/10 with BSV or

FAN ISOL VLV

ENG 1

ENG 1 & 3 [DC2] ENG 2 & 4 [DC1]

20 on /P ENG FWD [AC2] [AC2] BATTERY VENT

ENG 1 & 3 [DC2]

DISTRIBUTION VLV Forward

SLATS 5,6,7 CARGO by a venturi and an overboard vent

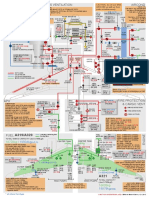

Outflow

STARTER FUEL FLOW COMP Bilge air

OVERPRESS HMU Valve

VLV HP VLV [DC ESS] LAV & GALLEY VENT

VLV (85psi) FF Cabin

air by an extraction fan and an exhaust

BLEED VLVs FF FUEL METERING through a venturi

BMC FF Cold air Hot air 1

ENG 1,2,3 & 4 [DC ESS]

HP VLV

2 & 3 [DC ESS]

1 & 4 [DC2] IP 5th COLD from Pack 2 TRIM

AIR VLV AIR VLV PACK BAY VENT

B1 FUEL by a NACA air inlet, a bleed air

HP VLVs Fuel/Eng Oil [AC2] [DC2, DC ESS SHED]

PUMP Cabin driventurbofan. Controlled by

Heat Exch air

BLEED ENG 2 & 4 [DC1]

ENG 1 & 3 [DC2] HP 9th B2 UNIT

LP X-FEED

INLET ISOL VLVs [AC2]

Bilge air

the AEVC

VLV 1,2,3,4

FUEL xfr / refueling / defueling lines

feeding lines ENG

MOTOR 1 [DC ESS]

MOTOR 2 [DC2] PRESSURIZATION

FWD APU MANUAL

LP VLV 1,2,3,4 ECAM

PUMP AFT XFR VLVs NEG BACKUP

TOTAL TANKS CAPACITY (den 0.785kg/l) MOT 1[HOT] [AC1-1] L [DC1]

MOT 1 CPC 1

MOT 2[DC2] R [DC2] RELIEF

110’402kg

[DC ESS] [DC ESS]

APU VALVE

MAIN CENTER TANK MAN MAN V/S

REFUELING FWD

STBY 2

Distribution trim TK 2400kg if more than 36.5t FOB 2 32’625kg OUT

MOT

[DC BAT]

SWITCH

CTR TK -FLOW

FCMC 1 FCMC 2 INNER TANKS MAIN INLET VLV MOT 2 CPC 2

MAIN [DC ESS SHED] MAIN [DC2 or HOT] (refuel on BAT)

STBY 1 VALVE

LVL Sensing[DC ESS SHED] LVL Sensing[DC ESS SHED] 2 X 33’578kg 1 1 2

[DC2, HOT] [DC2] [DC2]

- if RAM AIR ON

SPLIT APU TRIM PIPE AUX FWD and ∆p<1psi,

MOT 1

VLVs ISOL ISOL VLV XFR VLV [DC ESS] outflow valves

INNER VLV [DC ESS, HOT] [DC ESS]

[?] are 50% open

OUTER TANKS INLET [HOT] MAN

AFT (if not in

2 X 2’865kg VLV

L [DC 1] CTR TK XFR CTR TK XFR OUT

MOT MANUAL)

JETTISON R [DC ESS, HOT]

[DC BAT]

VLVs PUMP 1 PUMP 2 -FLOW

REFUEL [AC1-2, DC1] [AC2-3, DC2] MOT 2

OUTER MOTOR 1 [DC1] VALVE

VLV MOTOR 2 [DC1] [DC2]

OUTER XFR [DC BAT, HOT]

INLET VLV Cargo

VLVs [DC ESS] underfloor

[DC 1] EXTRACT OUTLET SAFETY VALVES( > 8.85 or < -1 ∆p)

VENT TANKS FAN ISOL VLV

INNER TANK PUMPS

accept 2% increase

FIRE PROTECTION

1 2 3 4 [AC2-4] [AC2-4]

of full tanks capacity MAIN [AC ESS, DC ESS] [AC1-2, DC1] [AC2-3, DC2] [AC2-4, DC2] AFT Cabin air

STBY [AC2-3, DC2] [AC2-4, DC2] [AC1-2, DC1] [DC1,AC ESS, DC ESS]

CARGO

OUTER TO INNER XFR CENTER TO INNER XFR

COMP

INLET ISOL VLV

Cabin air SDCU 1

[DC ESS SHED] & CARGO VENT

[AC2-4] JMK/JML only SDCU 2

Each Outer TK cycle its Inner TK between The center TK pumps run continously. [DC2] SMOKE DETECTORS

3500kg and 4000kg until it is empty. The Each inner TK inlet valve controls the tranfer B1

valves then close after 5min. If no AUTO by cycling its inner TK between FULL and 2000kg F FIRE DETECTORS

BTL 1, 60” discharge VENT CONT

XFR available, manual xfr via refueling pipe below full until it is empty.Then pmps & vlvs close. [DC2, DC ESS SHED]

BULK B2 B FIREX BOTTLES

and inlet valve possible.

CG CONTROL BTL 2, 4h 45’ discharge

LIMITATIONS ELECTRICAL SUPPLY

Take-off fuel: min 5400kg and AFT XFR starts if: Cabin air ENG loop A [DC ESS], loop B [DC2]

FUEL L(R) WING TK LO LVL Gear up, Slats in, Trim TK not full, Inner > 6250kg, INLET FAN ENG BTL 1 squib A [HOT2], squib B [DC2]

not displayed on ECAM above FL255 and CG not on target ISOL VLV HEATER ENG BTL 2 squib A [HOT1], squib B [DC2]

AFT XFR stops if: [AC2-4]

[AC1-1] APU loop A [DC ESS], loop B [DC BAT]

FUEL IMBALANCE CG = target CG - 0.5% or Trim TK full or Inner

INNER TK Full max 2300kg Aft outflow APU BTL squib A [HOT1] squib B [DC BAT]

<6250kg or FWD button pushed or MAN xfr EXTRACT OUTLET valve APU auto extinguish [HOT2]

Half max 3700kg outer-inner or center-inner.

6100kg max 6100kg FAN ISOL VLV CARGO squib A [HOT1], squib B [DC2]

FWD XFR starts if: stops if: [AC2-4] [AC2-4]

OUTER TK Full max 1300kg

1400kg max 1400kg

CG = target

inner = 4000kg

CG = target - 0.5%

inner = 5000kg

to LEFT

Bleed duct

APU

TRIM TK LIMITATIONS

FUEL TEMPERATURE - 35’ to dest or FL245 (or 75’ if XFR PUMP u/s)

ISOL VLV RPM min 95% max 107% (auto shut down)

Inner TK Outer TK - in EMER ELEC

[DC ESS] running EGT max 650°C

FWD XFR

JET A1 min -42°C min -47°C start EGT max 1250°C

PUMP

JET A min -35°C min -40°C F [AC2-3,DC2] Minimum oil level for start: ADD at APU level indicator

INLET VLV APU Cooling after 3 start attempts: 60min

[DC ESS, HOT] BLEED APU FUEL FLOW ~200 kg/hr

TRIM TANK VLV

A340

APU ENVELOPE

4’890kg LP VLV APU

[DC BAT, HOT] START with AC pwr up to 41'100ft

APU

ECB START with EMER ELEC pwr up to 25'000ft

AFT APU PUMP APU

[AC ESS, HOT] [APU BAT BLEED ON 2packs max 17'500ft, 1 pack max 22'500ft

STARTER DC ESS]

!!! NOT FOR OPERATIONAL USE !!! A340 ©Pierre-Michel Gasser , 1.7.2008 FF B [APU BAT, APU TR] BLEED ON for engine start max 20'000ft

You might also like

- Esquema 320Document9 pagesEsquema 320Paco Iglesias CubilesNo ratings yet

- A320 NeoDocument1 pageA320 NeoLawrence HNo ratings yet

- ATR 72-500 Systems Overview SyllabusDocument2 pagesATR 72-500 Systems Overview SyllabusBENoNo ratings yet

- PW 1100GAM maintenance document titleDocument16 pagesPW 1100GAM maintenance document titleGenaro RodriguezNo ratings yet

- CP Door TS Guide PDFDocument2 pagesCP Door TS Guide PDFnaziaNo ratings yet

- Operation With Minimum Fuel PDFDocument30 pagesOperation With Minimum Fuel PDFAlex SilvestreNo ratings yet

- Airbus Commercial Aircraft AC A320 PDFDocument399 pagesAirbus Commercial Aircraft AC A320 PDFTania AriasNo ratings yet

- FCTM A318 To A321Document510 pagesFCTM A318 To A321gaby82_pfNo ratings yet

- Weight and BalanceDocument2 pagesWeight and BalancePedro PalzaNo ratings yet

- Data MorichonDocument103 pagesData MorichonAndreeaAndreeaNo ratings yet

- Alteon Computer Based Training (CBT) Users Guide Installation and Launch InstructionsDocument15 pagesAlteon Computer Based Training (CBT) Users Guide Installation and Launch InstructionsSudheesh Sudhakaran Nair100% (1)

- A330-200 Panel Efisg2zDocument1 pageA330-200 Panel Efisg2zpontooNo ratings yet

- 00 ContentsDocument14 pages00 Contentsali4957270No ratings yet

- Erj 170-190 Mmel Faa Rev 9Document139 pagesErj 170-190 Mmel Faa Rev 9mh.hiliryNo ratings yet

- Airbus - A320 Engine StartDocument15 pagesAirbus - A320 Engine StartNutapol thungpaoNo ratings yet

- Atlas-Polar B747-400FCP Normal Checklist 01 APR 21Document2 pagesAtlas-Polar B747-400FCP Normal Checklist 01 APR 21Joel VitorNo ratings yet

- Speed TapeDocument1,852 pagesSpeed TapealeNo ratings yet

- Airbus A318/A319/A320/A321: Maintenance TrainingDocument1 pageAirbus A318/A319/A320/A321: Maintenance TrainingAnonymous QRVqOsa5100% (1)

- CPCP e PDFDocument263 pagesCPCP e PDFKarina Flores100% (1)

- How To Know Your Airbus From BoeingDocument31 pagesHow To Know Your Airbus From BoeingDaniel CampbellNo ratings yet

- ATR 42 Takeoff and Landing CardsDocument1 pageATR 42 Takeoff and Landing CardsAnonymous d8N4gqNo ratings yet

- Bombardier Dash 8 Q400 Fire - Protection PDFDocument21 pagesBombardier Dash 8 Q400 Fire - Protection PDFSwapnil kapadiaNo ratings yet

- Afm Airbus A 320 PDF FreeDocument706 pagesAfm Airbus A 320 PDF FreeewiontkoNo ratings yet

- Airbus Prologue TutorialDocument5 pagesAirbus Prologue TutorialHellovnAZNo ratings yet

- 787故障快速处理参考手册R2Document211 pages787故障快速处理参考手册R2Chen AndyNo ratings yet

- M.E.L of Crew Oxigen at A320 NeoDocument2 pagesM.E.L of Crew Oxigen at A320 NeobnmmauricioNo ratings yet

- Flight Reference Cards BulldogDocument34 pagesFlight Reference Cards BulldogGraham Waterfield100% (1)

- Stations Nacelles and PylonsDocument3 pagesStations Nacelles and PylonsPanagiotis Diakidis100% (1)

- Flight Ops MD80: July EditionDocument5 pagesFlight Ops MD80: July EditionPampus46No ratings yet

- Boeing 747 Overhead (Version 1)Document51 pagesBoeing 747 Overhead (Version 1)Giuliano LuzNo ratings yet

- Preflight After Takeoff: Normal ChecklistDocument1 pagePreflight After Takeoff: Normal ChecklistNeethNo ratings yet

- A318/A319/A320/A321 emergency proceduresDocument2 pagesA318/A319/A320/A321 emergency proceduresPhương Nguyễn100% (1)

- Pro Flight Rudder Pedals: User ManualDocument5 pagesPro Flight Rudder Pedals: User Manualtolin430No ratings yet

- A320 NEO Center PedestalDocument1 pageA320 NEO Center PedestalwenjukwaxNo ratings yet

- Airbus NotesDocument128 pagesAirbus NotesmartinbutlerNo ratings yet

- Airline Transport Pilot and Aircraft Type Rating Practical Test StandardsDocument87 pagesAirline Transport Pilot and Aircraft Type Rating Practical Test Standardsmustang12484No ratings yet

- DC 10 PDFDocument7 pagesDC 10 PDFraja89No ratings yet

- FEB 2006 Lights and Switches GuideDocument45 pagesFEB 2006 Lights and Switches GuideNeessttorNo ratings yet

- MEL R00 - Learjet 45 V02Document86 pagesMEL R00 - Learjet 45 V02Fabricio ValenteNo ratings yet

- SOPA OtterDocument21 pagesSOPA OtterFrancisco Javier Bandarra BandarraNo ratings yet

- Van's Aircraft RV-12 Pilot's Operating Handbook Rev5Document80 pagesVan's Aircraft RV-12 Pilot's Operating Handbook Rev5Geoff MohrNo ratings yet

- Aircraft Rescue and Firefighting Tips for 717 SeriesDocument8 pagesAircraft Rescue and Firefighting Tips for 717 SeriesTomeuNo ratings yet

- Airbus A300-600/A310 Landing Gear SystemsDocument190 pagesAirbus A300-600/A310 Landing Gear SystemsRaph 1123No ratings yet

- Cost-Effective, Off-the-Shelf Commercial Re-Engining: Turbofan EngineDocument2 pagesCost-Effective, Off-the-Shelf Commercial Re-Engining: Turbofan EngineStrawichDanielNo ratings yet

- Delta Airlines 747-400 ChecklistDocument2 pagesDelta Airlines 747-400 ChecklistBen Weston100% (1)

- CURSO DE ENTRENAMIENTO SOBRE AERONAVES BOEING 727 y 737-200Document103 pagesCURSO DE ENTRENAMIENTO SOBRE AERONAVES BOEING 727 y 737-200Nicolas PrietoNo ratings yet

- Fast27 PDFDocument32 pagesFast27 PDFsudarshan111990No ratings yet

- Fast 24Document20 pagesFast 24Quartermaster340No ratings yet

- Concorde: AFR F-BTSD GCLP - LemdDocument9 pagesConcorde: AFR F-BTSD GCLP - LemdCarlos LopezNo ratings yet

- 787 Walk 787-Walk 20120322 AllDocument91 pages787 Walk 787-Walk 20120322 Allapache9000No ratings yet

- Boeing 777 Fly-By-Wire Computer Design ConsiderationsDocument9 pagesBoeing 777 Fly-By-Wire Computer Design ConsiderationsMichael MarciniakNo ratings yet

- Abnormal Engine Start A300-600Document21 pagesAbnormal Engine Start A300-600Punthep PunnotokNo ratings yet

- Normal Checklist 1 Rev.5Document2 pagesNormal Checklist 1 Rev.5JoseNo ratings yet

- HP GND Air With APU Bleed AIRCOND Air With Air From Packs SimultaneouslyDocument1 pageHP GND Air With APU Bleed AIRCOND Air With Air From Packs SimultaneouslyAlex AlexNo ratings yet

- A320 AirDocument1 pageA320 AirHazemNo ratings yet

- A320air - SysDocument1 pageA320air - SysNathaniel Alexander -No ratings yet

- A320 AirDocument1 pageA320 AirHazemNo ratings yet

- Airbus 320 Air ConditioningDocument1 pageAirbus 320 Air ConditioningRafaelNo ratings yet

- A320 Schematic at A Glance 1686986584Document4 pagesA320 Schematic at A Glance 1686986584Harsh PawarNo ratings yet

- Instructions on how to apply for relocation supportDocument5 pagesInstructions on how to apply for relocation supportDAVID FAJARDO PUERTONo ratings yet

- Electrician, Aircraft Energy Systems - Job DescriptionDocument2 pagesElectrician, Aircraft Energy Systems - Job DescriptionDAVID FAJARDO PUERTONo ratings yet

- Helicopter Flight Training ManualDocument142 pagesHelicopter Flight Training Manualdodger202020No ratings yet

- EASA Part-66 Exam Questions of Module 05 Avionics - Part IIIDocument18 pagesEASA Part-66 Exam Questions of Module 05 Avionics - Part IIISteven J. SelcukNo ratings yet

- InstallationInstructionts FB FBFDocument1 pageInstallationInstructionts FB FBFDAVID FAJARDO PUERTONo ratings yet

- Type-Certificate Data SheetDocument11 pagesType-Certificate Data SheetDAVID FAJARDO PUERTONo ratings yet

- Teledyne Continental Tsio 360 Parts Manual GuideDocument1 pageTeledyne Continental Tsio 360 Parts Manual GuideDAVID FAJARDO PUERTO0% (1)

- Electrician, Aircraft Energy Systems - Job DescriptionDocument2 pagesElectrician, Aircraft Energy Systems - Job DescriptionDAVID FAJARDO PUERTONo ratings yet

- Cessna 1971 Super Skymaster 337 POH PDFDocument63 pagesCessna 1971 Super Skymaster 337 POH PDFDAVID FAJARDO PUERTONo ratings yet

- InstallationInstructionts FB FBFDocument1 pageInstallationInstructionts FB FBFDAVID FAJARDO PUERTONo ratings yet

- Continental C75 C85 C90 O 200 Parts Catalog Aug 2011 PDFDocument53 pagesContinental C75 C85 C90 O 200 Parts Catalog Aug 2011 PDFDAVID FAJARDO PUERTO100% (2)

- Installation & Operating Instruction For Complete FreewheelsDocument12 pagesInstallation & Operating Instruction For Complete Freewheelsadh3ckNo ratings yet

- Jeppesen Powerplant Textbook4Document728 pagesJeppesen Powerplant Textbook4sat011291% (11)

- InstallationInstructionts FB FBFDocument1 pageInstallationInstructionts FB FBFDAVID FAJARDO PUERTONo ratings yet

- Cover Letter PDFDocument4 pagesCover Letter PDFbrang123No ratings yet

- Instructions on how to apply for relocation supportDocument5 pagesInstructions on how to apply for relocation supportDAVID FAJARDO PUERTONo ratings yet

- X30617 PDFDocument104 pagesX30617 PDFDAVID FAJARDO PUERTONo ratings yet

- Engine SyllabusDocument4 pagesEngine SyllabusSyed BashaNo ratings yet

- Easa Part 66 Guide - Easa Part 66 - Digital QuestionDocument70 pagesEasa Part 66 Guide - Easa Part 66 - Digital QuestionnikhilNo ratings yet

- Cessna 1971 Super Skymaster 337 POH PDFDocument63 pagesCessna 1971 Super Skymaster 337 POH PDFDAVID FAJARDO PUERTONo ratings yet

- AviationDocument347 pagesAviationSyed Salman UddinNo ratings yet

- Exercise 1 Fill In: in / On / at / byDocument1 pageExercise 1 Fill In: in / On / at / byDAVID FAJARDO PUERTONo ratings yet

- Jeppesen 021 - 02 - ElectricsDocument196 pagesJeppesen 021 - 02 - ElectricsSadcat90% (20)

- Diccionario Tecnico en Ingles PDFDocument953 pagesDiccionario Tecnico en Ingles PDFDAVID FAJARDO PUERTO100% (10)

- RXG20L2V1B RXG25L2V1B RXG35L2V1B RXG50L2V1BDocument3 pagesRXG20L2V1B RXG25L2V1B RXG35L2V1B RXG50L2V1BDAVID FAJARDO PUERTONo ratings yet

- Module 10 Aviation LegislationDocument185 pagesModule 10 Aviation Legislationashinkoshy100% (2)

- P66 B1 M5 Lufthansa PDFDocument196 pagesP66 B1 M5 Lufthansa PDFDAVID FAJARDO PUERTO100% (1)

- 01 MM Bo105 (Maintenance Manual) Aeronaves PDFDocument2,535 pages01 MM Bo105 (Maintenance Manual) Aeronaves PDFDAVID FAJARDO PUERTO100% (19)

- Aircraft Wiring and Bonding-Completo PDFDocument416 pagesAircraft Wiring and Bonding-Completo PDFDAVID FAJARDO PUERTONo ratings yet

- Astm A501 PDFDocument2 pagesAstm A501 PDFgaminNo ratings yet

- 501 F Rotor OverhaulDocument3 pages501 F Rotor OverhaulmacrespoNo ratings yet

- Pilatus PC-12 Assembly Line: Industrialization, Manufacturing and Process ImprovementDocument8 pagesPilatus PC-12 Assembly Line: Industrialization, Manufacturing and Process ImprovementTGTrindadeNo ratings yet

- 5 Perfo Per Tof Bel NorDocument23 pages5 Perfo Per Tof Bel NorLuis HernandezNo ratings yet

- Stuck Pipe in High Dip SloughingDocument7 pagesStuck Pipe in High Dip SloughingAnnisa Rachmadani SastrodiwiryoNo ratings yet

- Seasons and pressureDocument2 pagesSeasons and pressureKyle100% (1)

- Structural Analysis ErrataDocument12 pagesStructural Analysis Errata陳宣芳No ratings yet

- History of Aeronautics Part1Document273 pagesHistory of Aeronautics Part1Israel CarvalhoNo ratings yet

- VL2018195000813 Ast04 PDFDocument1 pageVL2018195000813 Ast04 PDFYubraj JhaNo ratings yet

- An Rep0405engDocument125 pagesAn Rep0405engSudhir JyothulaNo ratings yet

- Seminar ReportDocument25 pagesSeminar ReportJosiah Prince100% (2)

- WWII Aircraft Recognition Guide PDFDocument17 pagesWWII Aircraft Recognition Guide PDFerik_x100% (2)

- 287 Planes - Imperative FormsDocument3 pages287 Planes - Imperative FormsRoberta TraspadiniNo ratings yet

- Aircraft Manual DGCA QuestionsDocument7 pagesAircraft Manual DGCA Questionsavijayakumar_1964100% (3)

- HydraulicCylinderTubeST52 ST52 3Document1 pageHydraulicCylinderTubeST52 ST52 3rjramanathanNo ratings yet

- Pacific Oceanic Group – Oceanic Endorsement SyllabusDocument19 pagesPacific Oceanic Group – Oceanic Endorsement SyllabusVincent RadityaNo ratings yet

- Design of A Supersonic NozzleDocument39 pagesDesign of A Supersonic NozzlePandel0% (1)

- ICCM 11v2Document899 pagesICCM 11v2Payel DuttaNo ratings yet

- VVNBDocument97 pagesVVNBAloha516No ratings yet

- Tutorial 2Document16 pagesTutorial 2amehbeeNo ratings yet

- Owner'S & Operator'S Guide: V2500Document22 pagesOwner'S & Operator'S Guide: V2500Robertas NegudinasNo ratings yet

- Vibration Analysis and Rotor Balancing GuideDocument84 pagesVibration Analysis and Rotor Balancing GuideLuis HernandezNo ratings yet

- Defence Public Sector Undertakings of IndiaDocument6 pagesDefence Public Sector Undertakings of IndiaWaqar Ahmed FahadNo ratings yet

- Aircraft Loads (1) - 1Document40 pagesAircraft Loads (1) - 1CABINGAN, Jacob Samuel U.No ratings yet

- AviTrader Monthly MRO E-Magazine 2019-01Document34 pagesAviTrader Monthly MRO E-Magazine 2019-01Victor MartinezNo ratings yet

- 270 seat Turkish Airlines A340-300 load and trim sheetDocument8 pages270 seat Turkish Airlines A340-300 load and trim sheetFilip Skultety100% (1)

- m8 83 KeyDocument18 pagesm8 83 KeyDuy Khanh NguyễnNo ratings yet

- Air India internship reportDocument46 pagesAir India internship reportanshita jainNo ratings yet

- Flight Crew Briefing ChecklistDocument2 pagesFlight Crew Briefing ChecklistRob McGarryNo ratings yet

- Advanced Aircraft Flight PerformancesDocument664 pagesAdvanced Aircraft Flight PerformancesMarcos Lopez100% (2)