Professional Documents

Culture Documents

Finite Element Analysis of Friction Welding Process For 2024al Alloy and AISI 1021 Steel

Uploaded by

Naser KhalidOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Finite Element Analysis of Friction Welding Process For 2024al Alloy and AISI 1021 Steel

Uploaded by

Naser KhalidCopyright:

Available Formats

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2013): 6.14 | Impact Factor (2013): 4.438

Finite Element Analysis of Friction Welding

Process for 2024Al Alloy and AISI 1021 Steel

T. Santhosh Kumar1, A. Chennakesava Reddy2

1

PG student, Department of Mechanical Engineering, JNTUH College of Engineering, Kukatpally, Hyderabad – 500 085, Telangana, India

2

Professor, Department of Mechanical Engineering, JNTUH College of Engineering, Kukatpally, Hyderabad – 500 085, Telangana, India

Abstract: The purpose of this work was to weld dissimilar metals of 2024Al and AISI 1021 steel by continuous drive friction welding.

The finite element analysis has been carried out to model the continuous drive friction welding. The process parameters have been opti-

mized using Taguchi techniques. The optimal process parameters for 2024Al and AISI 1021 steel are found to be frictional pressure of

35 MPa, frictional time of 3 sec, rotational speed of 1500 rpm and forging pressure of 37.5 MPa.

Keywords: 2024Al, AISI 1021 Steel, finite element analysis, Taguchi, continuous drive friction welding.

1. Introduction welding is dependent the force applied and the rotational

speed. If the applied force is too high or the rotational speed

Friction welding is a solid-state welding process that allows is too low, the fusion zone at the centre of the joint will be

material combinations to be joined than with any other weld- narrow as showed in figure 2a. On the other hand, if the ap-

ing process. In continuous drive friction welding, one of the plied force is too low or the rotational speed is too high, the

workpieces is attached to a motor driven unit while the other fusion zone at the centre of the joint will be wider as showed

is restrained from rotation as showed in figure 1a. The motor in figure 2b. In both the cases, the result is poor weld joint

driven workpiece is rotated at a predetermined constant strength.

speed. The workpieces to be welded are forced together and

then a friction force is applied as shown in figure 1b. Heat is

generated because of friction between the welding surfaces.

This is continued for a predetermined time as showed in fig-

ure 1c. The rotating workpiece is halted by the application of

a braking force. The friction force is preserved or increased

for a predetermined time after the rotation is ceased (fig-

ure1d). Figure1also illustrates the variation of welding speed,

friction force and forging force with time during various

stages of the friction welding process.

Figure 2: Effect of force and rotational speed in friction

welding

In the friction welding process, the developed heat at the

interface raises the temperature of work pieces rapidly to

values approaching the melting range of the material. Weld-

ing occurs under the influence of pressure that is applied

when heated zone is in the plastic range, as mentioned [3].

The foremost difference between the welding of similar ma-

terials and that of dissimilar materials is that the axial

movement is unequal in the latter case whilst the similar ma-

terials experience equal movement along the common axis.

Figure 1: Friction welding This problem arises not only from the different coefficients

of thermal expansion, but also from the distinct hardness

Even metal combinations not normally considered compati- values of the dissimilar materials to be joined. Joint and edge

ble can be joined by friction welding, such as aluminum to preparation is very important to produce distortion free

steel, copper to aluminum, titanium to copper and nickel welds. The solid-state diffusion is slow in the wider joints

alloys to steel. As a rule, all metallic engineering materials [4].The intermetallic compounds can change the micro hard-

which are forgeable can be friction welded, including auto- ness near the joint interface of dissimilar metals [5].

motive valve alloys, maraging steel, tool steel, alloy steels

and tantalum [1, 2]. With friction welding, joints are possible The difficulties in the welding of 2024 aluminum alloy with

between not only two solid materials or two hollow parts, but AISI 1021 steel by fusion welding processes have been a

also solid material/hollow part combinations can be reliably great challenge for engineering; because they result from

welded. However, the shape of a fusion zone in friction hard and brittle inter metallic phases that formed between

Volume 4 Issue 5, May 2015

www.ijsr.net

Paper ID: SUB154500 1679

Licensed Under Creative Commons Attribution CC BY

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2013): 6.14 | Impact Factor (2013): 4.438

aluminum and steel at evaluated temperatures. Therefore, parameters and their levels are given table-1. The orthogonal

friction welding of these materials needs to be eased by en- array (OA), L9 was selected for the present work. The para-

suring that both the workpieces deform similarly. In this con- meters were assigned to the various columns of O.A. The

text, this research work aims at finite element analysis of assignment of parameters along with the OA matrix is given

friction welding process for aluminum (2024Al) alloy and in Table 2.

AISI 1021 steel.

Table 2: Orthogonal Array (L9) and control parameters

2. Finite Element Modeling Treat No. No. A B C D

1 1 1 1 1

In this study, ANSYS workbench (15.0) software was used 2 1 2 2 2

3 1 3 3 3

in the coupled deformation and heat flow analysis during

4 2 1 2 3

friction welding of AISI 1021 Steel and aluminum (2024Al)

5 2 2 3 1

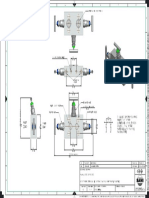

alloy. An axisymmetric 3D model [6] of aluminum (2024A) 6 2 3 1 2

- AISI 1021 Steel rods of 25.4 mm diameter and 100 mm 7 3 1 3 2

length was made using ANSYS workbench as shown in fig- 8 3 2 1 3

ure 3. Hexahedron elements [7] were used to mesh the alu- 9 3 3 2 1

minum and AISI 1021 Steel rods. The rotating part was mod-

eled with 3298 elements and 14904 nodes and the non- 3. Results and Discussion

rotating part was meshed with 16493 nodes and 3672 ele-

ments.

The temperature distribution from the transient thermal anal-

ysis; equivalent stress and directional deformation from the

structural analysis; penetration and sliding from the contact

analysis are discussed in the following sections.

Figure 3: Finite element modeling of friction welding Table 3: ANOVA summary of the temperature distribution

Source Sum 1 Sum 2 Sum 3 SS v V F P

A 2683 3192 3616 72708 2 36354.06 12800.73 32.97

B 2994 2729 3768 97198 2 48599.21 17112.4 44.07

C 2863 3330 3298 22709 2 11354.79 3998.16 10.29

D 2843 3406 3241 27907 4 6976.81 2456.62 12.65

e 20 7 2.84 1 0.02

T 11384 12658 13924 220543 17 100

Figure 4: The boundary conditions Note: SS is the sum of square, v is the degrees of freedom, V

is the variance, F is the Fisher’s ratio, P is the percentage of

The boundary conditions are mentioned in figure 4. First the contribution and T is the sum squares due to total variation.

transient thermal analysis was carried out keeping AISI 1021

Steel rod stationary and aluminum rod in rotation. The coef-

ficient of friction 0.2 was applied at the interface of AISI

1021 Steel rod and aluminum rods. The convection heat trans-

fer coefficient was applied on the surfaces of two rods. The

heat flux calculations were imported from ANSYS APDL

commands and applied at the interface. The temperature dis-

tribution was evaluated. The thermal analysis was coupled to

static structural analysis. For the structural analysis the rotat-

ing (aluminum) rod was brought to stationary and the forging

pressure was applied on the AISI 1021 Steel rod along the axis

of rod. The AISI 1021 Steel rod was allowed to move in the

axial direction. The structural analysis was carried out for the

equivalent stress and strain, total and directional deforma-

tion. The contact analysis was also carried out to estimate the Figure 5: Influence of frictional pressure on temperature.

depth of penetration and sliding of the material at the inter-

face. 3.1 Influence of parameters on temperature distribution

Table 1: Process parameters and levels Table – 3 gives the ANOVA (analysis of variation) summary

Factor Symbol Level–1 Level–2 Level–3 of raw data. The Fisher’s test column establishes all the pa-

Frictional Pressure, MPa A 25 30 35 rameters (A, B, C and D) accepted at 90% confidence level.

Frictional time, Sec B 3 4 5 The percent contribution indicates that the friction pressure,

Rotational speed C 1000 1250 1500 A contributes 32.97% of variation, B (friction time) aids

Forging pressure, MPa D 31.25 37.5 43.75 44.07% of variation, C (rotational speed) influences 10.29%

The analysis of friction welding was carried out as per the of variation and D (forging pressure) contributes 12.65% of

design of experiments using Taguchi techniques. The process

Volume 4 Issue 5, May 2015

www.ijsr.net

Paper ID: SUB154500 1680

Licensed Under Creative Commons Attribution CC BY

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2013): 6.14 | Impact Factor (2013): 4.438

variation on the temperature distribution. The effect of forg-

ing pressure is due to reaction of frictional pressure.

Figure 8: Influence of forging pressure on temperature.

Figure 6: Influence of frictional time on temperature.

Figure 7: Influence of rotational speed on temperature.

The temperature developed in the welding rods is directly

proportional to the frictional pressure, rotational speed and

Figure 9: Temperature distribution during different trials

forging pressure as shown in figure 5, 7 & 8. In fact this is

natural phenomena. The effect of frictional time on the gen-

eration of temperature is polynomial as shown in figure 6. 3.2 Influence of parameters on equivalent stress

Form figure 9 it is observed that the temperature is very high

The ANOVA summary of the elastic modulus is given in

at the interface. The trial 9 gives the highest temperature

Table 4. The Fisher’s test column ascertains all the parame-

generation and trial 1 gives the lowest temperature genera-

ters (A, B, C, D) accepted at 90% confidence level influen-

tion in the rods. Change of temperature field is generated by

cing the variation in the equivalent stress. The contribution

heat flux that depends on: frictional pressure on the contact

of friction pressure, frictional time, rotational speed and forg-

surface, relative velocity of the two faces, frictional time and

ing pressure are 43.74%, 26.21%, 12.97%, and 16.96% re-

coefficient of friction.

spectively towards variation in the effective stress.

Table 4: ANOVA summary of the equivalent stress

Source Sum 1 Sum 2 Sum 3 SS v V F P

A 957.578 1190.19 1369.03 14188.05 2 7094.025 3135.38 43.74

B 1314.43 999.43 1202.93 8503.4 2 4251.7 1879.14 26.21

C 1042.95 1227.47 1246.38 4210.46 2 2105.23 930.46 12.97

D 1028.25 1275.36 1213.19 5507.22 4 1376.80 608.51 16.96

e 15.84 7 2.26 1.00 0.12

T 4343.21 4692.45 5031.53 32424.97 17 100

The equivalent stress increases with an increase in the

frictional pressure, rotational speed and forging pressure

as shown in figure 10, 12 & 13. The effect of frictional time

is polynomial on the equivalent stress (figure 11). The

equivalent stress is low for the frictional time of 5 sec.

Volume 4 Issue 5, May 2015

www.ijsr.net

Paper ID: SUB154500 1681

Licensed Under Creative Commons Attribution CC BY

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2013): 6.14 | Impact Factor (2013): 4.438

ing stage any surface irregularities are removed, the tem-

perature increases in the vicinity of the welded surfaces,

and an interface of visco-plastic aluminum is formed. Dur-

ing forging pressure stage there is significant thermo-

plastic deformation of aluminum in the contact area. In

result of this is formation of a flange-like flash. The

process of welding takes place due to the plastic and dif-

fusion effects.

3.3 Influence of parameters on total deformation

Figure 10: Influence of frictional pressure on equivalent stress. The ANOVA summary of the directional deformation is giv-

en in Table 6. The Fisher’s test column ascertains all the pa-

rameters (A, B, C, D) accepted at 90% confidence level in-

fluencing the variation in the directional deformation. The

major contribution (38.18%) is of frictional pressure and

frictional time towards variation in the directional deforma-

tion. The influence of rotational speed and forging pressure

are 26.20% and 16.45% respectively.

Table 5: Equivalent stress values under different trials

At end of frictional heating At end of forging

1

Figure 11: Influence of frictional time on equivalent stress.

2

5

Figure 12: Influence of rotational speed on equivalent stress.

Figure 13: Influence of forging pressure on equivalent

stress. 9

It is observed from table 5 that the equivalent stress is

280.53 MPa for trail 7 at the end of frictional heating and is

154.27 MPa at the end of forging pressure. It is also ob-

served from table 5 that the equivalent stress is 138.16

MPa for trail 1 at the end of frictional heating and is 87.31

MPa at the end of forging pressure. During friction heat-

Volume 4 Issue 5, May 2015

www.ijsr.net

Paper ID: SUB154500 1682

Licensed Under Creative Commons Attribution CC BY

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2013): 6.14 | Impact Factor (2013): 4.438

Table 6: ANOVA summary of the directional deformation

Source Sum 1 Sum 2 Sum 3 SS v V F P

A 1.1096 1.37368 1.45283 0.01 2 0.005 12.30 12.61

B 1.0884 1.0814 1.76634 0.05 2 0.025 61.50 67.52

C 1.1571 1.41152 1.36744 0 2 0 0.00 -1.12

D 1.1946 1.38833 1.35314 0.01 4 0.0025 6.15 11.5

e 0.002845 7 0.000406 1.00 9.49

T 4.54973 5.25493 5.93975 0.072845 17 100

The total deformation increases with an increase in the fric-

tional pressure, frictional time and forging pressure as shown

in figure 14, 15 & 16. In the first numerical iteration (ther-

mal) the external load generates uniform pressure on the con-

tact surface and consequently linearly changing heat flux.

There is a gap between steel aluminum as seen from table 6.

In the next iteration (static) the forging pressure on the con-

tact surface forces the material to penetrate and slid. There is

no gap between steel aluminum. The extruded shape gradual-

ly forms near the welded joint during the welding process.

The extruded shape is asymmetric, as shown in table 6. It

results from non-uniform material properties along the radial

direction of the specimen during welding.

Figure 16: Influence of forging pressure on deformation

3.4 Influence of parameters on penetration and sliding

In friction welding of 2024Al and AISI 1021 Steel, only

2024Al is consumed in the form of flash due to softer and

high thermal conductive material as most of the heat gener-

ated at the interface is transferred to 2024Al. The deforma-

tion of AISI 1021 Steel is negligible due to its higher hard-

ness value, and higher melting point as shown in table 7. In

the case of trail 1 the interface layer has not produced a good

metallic bond between aluminum and AISI 1021 Steel. In the

case of trail 4 and 7 the interface layer has produced a good

Figure 14: Influence of frictional pressure on deformation metallic bond between aluminum and steel. The penetrations

of trails 4 and 7 are 0.0017 and 0.002 mm respectively. A

closer look at the penetration and sliding images shows that

the failure of good bonding has taken place largely by inter-

face separation. One factor may be the uneven rate of heat

generation. Due to this uneven rate of heat input, the amount

of melt-off for each cycle for welding this combination of

steel and aluminum.

Table 6: Directional deformation values under different trials

At end of frictional heating At end of forging

1

2

Figure 15: Influence of frictional time on deformation

Volume 4 Issue 5, May 2015

www.ijsr.net

Paper ID: SUB154500 1683

Licensed Under Creative Commons Attribution CC BY

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2013): 6.14 | Impact Factor (2013): 4.438

4

5

6

5

7

6

8

7

9

8

The optimal process parameters for 2024Al and AISI 1021

Steel are found to be frictional pressure of 35 MPa, frictional

time of 3 sec, rotational speed of 1500 rpm and forging

Figure 17: Welding 2024 Al alloy and AISI 1021 steel with

pressure of 37.5 MPa. For this dissimilar metals of

trial 7 conditions

aluminium and steel, the forging pressure should be higher

than the frictional pressure. The experimental fricitional

welding validateds the the seventh trial conditions as shown

5. Acknowledgements

in figure 17.

The author acknowledges with thanks University Grants

Commission (UGC) – New Delhi for sectioning R&D

4. Conclusions project.

This study shows that the 2024Al and AISI 1021 Steel is

good if the operating conditions: frictional pressure of 35

References

MPa, frictional time of 3 sec, rotational speed of 1500 rpm

[1] A. Chennakesava Reddy, Fatigue Life Evaluation of Joint

and forging pressure of 37.5 MPa. For friction welding of

Designs for Friction Welding of Mild Steel and Austenite

AISI 1021 Steel and aluminum the forging pressure should

Stainless Steel, International Journal of Science and Re-

be less than the frictional pressure or equal. For this condi-

search, vol.4, n0.2, pp. 1714-1719, 2015.

tion of welding there was good penetration and sliding of

[2] A. Chennakesava Reddy, Fatigue Life Prediction of Dif-

materials at the welding interface resulting a good mechani-

ferent Joint Designs for Friction Welding of 1050 Mild

cal bonding.

Steel and 1050 Aluminum, International Journal of Scien-

Table 7: Sliding and penetration values under different trials

tific & Engineering Research, vol.6, no.4, pp. 408-412,

Sliding Penetration 2015.

1 [3] B.S. Yibas, A.Z. Sahin, N. Kahrama, and A.Z. Al-Garni,

“Friction welding of St-A1 and A1-Cu materials”, Jour-

nal of Materials Processing Technology”, (49), pp.431-

443, 1995.

2

[4] A. Chennakesava Reddy, A. Ravaivarma, and V. Thiru-

pathi Reddy, in Proceedings of National Welding Semi-

nar, IIT-Madras, pp.51-55, 2002.

3 [5] W. Li and F. Wang, “Modeling of continuous drive fric-

tion welding of mild steel”, Materials Science and Engi-

neering A, (528), pp.5921-5926, 2011.

[6] Chennakesava, R. Alavala, “CAD/CAM: Concepts and

4

Applications,” PHI Learning Pvt. Ltd, 2008:

[7] Chennakesava R. Alavala, “Finite element methods: Ba-

sic Concepts and Applications, PHI Learning Pvt. Ltd.,

2009.

Volume 4 Issue 5, May 2015

www.ijsr.net

Paper ID: SUB154500 1684

Licensed Under Creative Commons Attribution CC BY

You might also like

- GEARS May 2015Document76 pagesGEARS May 2015Rodger Bland100% (1)

- Electrical Load ComputationDocument4 pagesElectrical Load ComputationAllen Velasquez Mangaoil87% (15)

- Welding of AluminiumDocument33 pagesWelding of Aluminiumemerson100% (1)

- Dissimilar Metal WeldingDocument37 pagesDissimilar Metal WeldingAlbar33% (3)

- 8th Sem Project ReportDocument55 pages8th Sem Project ReportPrathmeshBhokari100% (2)

- MK 1000 ADocument2 pagesMK 1000 AkhaiNo ratings yet

- Handbook de Diagnostico IndustrialDocument560 pagesHandbook de Diagnostico IndustrialDaVishur WthNo ratings yet

- Reasons, Regulations, and Rules: A Guide To The Validation Master Plan (VMP)Document6 pagesReasons, Regulations, and Rules: A Guide To The Validation Master Plan (VMP)carbouNo ratings yet

- Study of Transient Temperature Distribution in A Friction Welding Process and Its Effects On Its JointsDocument12 pagesStudy of Transient Temperature Distribution in A Friction Welding Process and Its Effects On Its JointsMuhammad Fatka FirmansyahNo ratings yet

- Taper Friction WeldingDocument19 pagesTaper Friction Weldingsenthil muruganNo ratings yet

- Friction AL CUDocument2 pagesFriction AL CUGaluh ArifNo ratings yet

- Welding Distortion Control in Thin Metal Plates by Altering Heat Input Through Weld ParametersDocument7 pagesWelding Distortion Control in Thin Metal Plates by Altering Heat Input Through Weld ParametersGanesh R NairNo ratings yet

- Joining of Stainless Steel and Copper Materials With Friction WeldingDocument6 pagesJoining of Stainless Steel and Copper Materials With Friction WeldingBosco BeloNo ratings yet

- Document 2 OHlj 03052016 PDFDocument5 pagesDocument 2 OHlj 03052016 PDFEgi SlankersbimaNo ratings yet

- Musonda 2018 IOP Conf. Ser. Mater. Sci. Eng. 423 012162Document7 pagesMusonda 2018 IOP Conf. Ser. Mater. Sci. Eng. 423 012162JUANNo ratings yet

- Analysis of The Friction Welding Process in Relation To The WeldingDocument10 pagesAnalysis of The Friction Welding Process in Relation To The WeldingTian YudhaNo ratings yet

- Effect of Heat Treatment On Corrosion Resistance of Friction Stir Welded AA 2024 Aluminum Alloy - Hani Aziz AmeenDocument10 pagesEffect of Heat Treatment On Corrosion Resistance of Friction Stir Welded AA 2024 Aluminum Alloy - Hani Aziz AmeenHani Aziz AmeenNo ratings yet

- ICEE097 - Full Length Paper PDFDocument4 pagesICEE097 - Full Length Paper PDFWeld TechNo ratings yet

- Mechanical Properties and Microstructures of Friction Welded Mild SteelDocument10 pagesMechanical Properties and Microstructures of Friction Welded Mild SteelM Khoirul AnamNo ratings yet

- FW 3 PDFDocument16 pagesFW 3 PDFdaniel 119360020No ratings yet

- A Review On Friction Stir Welding of Dissimilar Materials Between Aluminium Alloys To CopperDocument7 pagesA Review On Friction Stir Welding of Dissimilar Materials Between Aluminium Alloys To CopperInternational Journal of Latest Research in Engineering and TechnologyNo ratings yet

- Effects of Temperature On Tensile and Impact Behavior of Dissimilar Welds of Rotor SteelsDocument8 pagesEffects of Temperature On Tensile and Impact Behavior of Dissimilar Welds of Rotor SteelsRajneesh KumarNo ratings yet

- Trans NonferrousMet Soc China29201918241835Document13 pagesTrans NonferrousMet Soc China29201918241835omerNo ratings yet

- Fundamentals of Friction Stir Welding, Its Application, and AdvancementsDocument50 pagesFundamentals of Friction Stir Welding, Its Application, and Advancementsjose ramirez cruzNo ratings yet

- Materials and Design: I. Hajiannia, M. Shamanian, M. KasiriDocument8 pagesMaterials and Design: I. Hajiannia, M. Shamanian, M. KasiriBurhanuddin As-SirajNo ratings yet

- Metals 13 01301Document11 pagesMetals 13 01301iqbal haiderNo ratings yet

- Brahmin Belkessa - X52-2205 SMAWDocument9 pagesBrahmin Belkessa - X52-2205 SMAWWaris Nawaz KhanNo ratings yet

- 10.1515 - HTMP 2014 0201Document7 pages10.1515 - HTMP 2014 0201Wahyu Eko PrasetyoNo ratings yet

- Latest Developments in Friction Welding - A ReviewDocument6 pagesLatest Developments in Friction Welding - A ReviewIJRASETPublicationsNo ratings yet

- Experimental and Finite Element Studies of StretchDocument16 pagesExperimental and Finite Element Studies of Stretchorangeideas7No ratings yet

- Welding Characteristics of 304 306 316 SDocument3 pagesWelding Characteristics of 304 306 316 SHenry León HenaoNo ratings yet

- Constantin 2017 IOP Conf. Ser. Mater. Sci. Eng. 252 012038 PDFDocument9 pagesConstantin 2017 IOP Conf. Ser. Mater. Sci. Eng. 252 012038 PDFMeet PatelNo ratings yet

- A Study On Rotary Friction Welding of Titanium AllDocument10 pagesA Study On Rotary Friction Welding of Titanium AllmadhukarNo ratings yet

- Application of Taguchi Method For Resistance Spot Welding of Galvanized SteelDocument6 pagesApplication of Taguchi Method For Resistance Spot Welding of Galvanized Steelpradipta satrio wNo ratings yet

- Optimization of Spheroidized Annealing Process Parameters On AISI 10B21 Steel Wire Using Taguchi ApproachDocument4 pagesOptimization of Spheroidized Annealing Process Parameters On AISI 10B21 Steel Wire Using Taguchi ApproachTanzil ZaidiNo ratings yet

- NOV161840Document3 pagesNOV161840arge1No ratings yet

- Materials and Design: S. Gopalakrishnan, N. MuruganDocument6 pagesMaterials and Design: S. Gopalakrishnan, N. MuruganRahul SaraswatNo ratings yet

- 2023 Study of Resistant Spot Welding and Its Effect On The Metallurgical and Mechanical Properties - A ReviewDocument9 pages2023 Study of Resistant Spot Welding and Its Effect On The Metallurgical and Mechanical Properties - A Reviewguravshubham7777No ratings yet

- IEI Journal PaperDocument7 pagesIEI Journal PaperPearl IPNo ratings yet

- Metals: A Case Study For The Welding of Dissimilar EN AW 6082 and EN AW 5083 Aluminum Alloys by Friction Stir WeldingDocument9 pagesMetals: A Case Study For The Welding of Dissimilar EN AW 6082 and EN AW 5083 Aluminum Alloys by Friction Stir WeldingArvind ShuklaNo ratings yet

- Evaluation of Temperature and Properties at Interface of AISI 1040 Steels Joined by Friction WeldingDocument9 pagesEvaluation of Temperature and Properties at Interface of AISI 1040 Steels Joined by Friction WeldingBosco BeloNo ratings yet

- IJCRT2403994Document10 pagesIJCRT2403994sravankumar8634No ratings yet

- 1 s2.0 S2214785320358120 Main PDFDocument7 pages1 s2.0 S2214785320358120 Main PDFJohnny VillarroelNo ratings yet

- CompressedDocument10 pagesCompressedSIVA WAHYUNINo ratings yet

- Modeling and Simulation of Friction Stir Welding Process For AA6061-T6 Aluminum Alloy Using Finite Element MethodDocument14 pagesModeling and Simulation of Friction Stir Welding Process For AA6061-T6 Aluminum Alloy Using Finite Element MethodDr. Mahesh GopalNo ratings yet

- Rotary Friction Welding of Inconel 718 AISI 304 Stainless Steel Dissimilar JointDocument12 pagesRotary Friction Welding of Inconel 718 AISI 304 Stainless Steel Dissimilar Jointvamsi krishnaNo ratings yet

- 10 5923 J Jmea 20150501 05Document10 pages10 5923 J Jmea 20150501 05wajdiNo ratings yet

- Literature Survey: Weldability of MaterialsDocument15 pagesLiterature Survey: Weldability of MaterialsEng-Mohammed Abu NuktaNo ratings yet

- Welded Lap Joints of Thin Steel Sheets With DiffeDocument11 pagesWelded Lap Joints of Thin Steel Sheets With DiffeRicardo HernandezNo ratings yet

- CRITICAL REVIEW ON DESIGN OF ROLLING PROCESS Kondapalli Siva Prasad1Document16 pagesCRITICAL REVIEW ON DESIGN OF ROLLING PROCESS Kondapalli Siva Prasad1Samir BoseNo ratings yet

- Microstructure Analysis of Arc Welded Mild Steel Plates: IOP Conference Series: Materials Science and EngineeringDocument7 pagesMicrostructure Analysis of Arc Welded Mild Steel Plates: IOP Conference Series: Materials Science and EngineeringAniekanNo ratings yet

- A Fully Coupled Thermo-Mechanical Model of Friction Stir WeldingDocument16 pagesA Fully Coupled Thermo-Mechanical Model of Friction Stir WeldinglarryNo ratings yet

- Optimizing Tensile Strength of Low-Alloy Steel Joints in Upset WeldingDocument5 pagesOptimizing Tensile Strength of Low-Alloy Steel Joints in Upset Weldingabraham silva hernandezNo ratings yet

- Design and Simulation of A Spot Welding Process: February 2019Document7 pagesDesign and Simulation of A Spot Welding Process: February 2019Abdullah hussainNo ratings yet

- 50IJMPERDFEB201950Document8 pages50IJMPERDFEB201950TJPRC PublicationsNo ratings yet

- Research Paper FSWDocument10 pagesResearch Paper FSWsahith palikaNo ratings yet

- Tensile Properties of Friction Stir Welded Joints of 2024 Aluminum Alloys in Different Heat-Treated-StateDocument11 pagesTensile Properties of Friction Stir Welded Joints of 2024 Aluminum Alloys in Different Heat-Treated-StateRikko Putra YouliaNo ratings yet

- The Effect of Copper and Brass On Friction Stir Welded Dissimilar Aluminium Alloy When Used As in Thin Sheet FormDocument5 pagesThe Effect of Copper and Brass On Friction Stir Welded Dissimilar Aluminium Alloy When Used As in Thin Sheet FormVidyutNo ratings yet

- Materials Today: Proceedings: Sharda Pratap Shrivas, G.K. Agrawal, Shubhrata Nagpal, Amit Kumar KachhawahaDocument8 pagesMaterials Today: Proceedings: Sharda Pratap Shrivas, G.K. Agrawal, Shubhrata Nagpal, Amit Kumar KachhawahaMKM OfficialNo ratings yet

- A Review of Friction Stirs WeldingDocument6 pagesA Review of Friction Stirs WeldingEditor IJTSRDNo ratings yet

- Finite Element Simulation of Temperature and Strain Distribution in Al2024 Aluminum Alloy by Friction Stir WeldingDocument5 pagesFinite Element Simulation of Temperature and Strain Distribution in Al2024 Aluminum Alloy by Friction Stir Weldingabhilash sharanNo ratings yet

- (Elearnica) - Effect - of - Welding - Parameters - On - Mechanical - and - Microstructural - Properties - o PDFDocument8 pages(Elearnica) - Effect - of - Welding - Parameters - On - Mechanical - and - Microstructural - Properties - o PDFelmiraNo ratings yet

- X-Ray Diffraction JournalDocument9 pagesX-Ray Diffraction JournalSREEJITH S NAIRNo ratings yet

- Flexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsFrom EverandFlexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsSean M. GarnerNo ratings yet

- Friction Stir Welding of 2XXX Aluminum Alloys including Al-Li AlloysFrom EverandFriction Stir Welding of 2XXX Aluminum Alloys including Al-Li AlloysNo ratings yet

- FLUID I CH 5 Fluid Dynamics Analysis Control Volume Tut 5Document9 pagesFLUID I CH 5 Fluid Dynamics Analysis Control Volume Tut 5Naser KhalidNo ratings yet

- Fluid Kinematics: Fluid Mechanics I EMEC3309Document15 pagesFluid Kinematics: Fluid Mechanics I EMEC3309Naser KhalidNo ratings yet

- FLUID I CH 1 Fluid Statics Tut 2 ADocument5 pagesFLUID I CH 1 Fluid Statics Tut 2 ANaser KhalidNo ratings yet

- FLUID-I-CH 1 Introduction Properties Tut 1Document4 pagesFLUID-I-CH 1 Introduction Properties Tut 1Naser KhalidNo ratings yet

- FLUID I CH 2 Fluid Statics Tut 2 BDocument6 pagesFLUID I CH 2 Fluid Statics Tut 2 BNaser KhalidNo ratings yet

- 1 5152631097749668533Document9 pages1 5152631097749668533Naser KhalidNo ratings yet

- Tutorial 3 Fluid Kinematics (Chapter 3)Document5 pagesTutorial 3 Fluid Kinematics (Chapter 3)Naser KhalidNo ratings yet

- Islamic University of Gaza (IUG) Mechanical Engineering DepartmentDocument3 pagesIslamic University of Gaza (IUG) Mechanical Engineering DepartmentNaser KhalidNo ratings yet

- Manuscript R 1 FDocument30 pagesManuscript R 1 FNaser KhalidNo ratings yet

- Matecconf mms18 02036Document12 pagesMatecconf mms18 02036Naser KhalidNo ratings yet

- EX3Document1 pageEX3Naser KhalidNo ratings yet

- Plate BendingDocument5 pagesPlate Bendingnitesh2109No ratings yet

- Metrology in Chemistry - A Public Task: Gunther DubeDocument5 pagesMetrology in Chemistry - A Public Task: Gunther DuberubenNo ratings yet

- Very High Cycle Fatigue - Testing MethodsDocument17 pagesVery High Cycle Fatigue - Testing Methodsالحمد اللهNo ratings yet

- GE Ham News 813 GG ArticleDocument31 pagesGE Ham News 813 GG ArticleMichael HodappNo ratings yet

- Bakerlux SHOP - Pro Installation and Maintenance ManualDocument32 pagesBakerlux SHOP - Pro Installation and Maintenance ManualTurnor Store ASNo ratings yet

- THE AND Office Companion: Reliable CompactDocument4 pagesTHE AND Office Companion: Reliable CompactYaser HamdyNo ratings yet

- Application Program For PCO5Document36 pagesApplication Program For PCO5elshan_asgarovNo ratings yet

- Programme PDFDocument22 pagesProgramme PDFSominath HarneNo ratings yet

- PKCS#11 Wrapper For Java PKCS#11 Wrapper For Java: Programmer's ManualDocument7 pagesPKCS#11 Wrapper For Java PKCS#11 Wrapper For Java: Programmer's Manualbog495No ratings yet

- ACRP Grant Approval Fact SheetDocument2 pagesACRP Grant Approval Fact SheetCTV CalgaryNo ratings yet

- New JFrame 1Document8 pagesNew JFrame 1jayesh30sikchiNo ratings yet

- Info Iec60245-6 (Ed2.0) en D.imgDocument5 pagesInfo Iec60245-6 (Ed2.0) en D.imgRonald Rey SotoNo ratings yet

- Resume Sukhchain SidhuDocument2 pagesResume Sukhchain SidhuShaun SidhuNo ratings yet

- Ships Operating in Ice Covered WatersDocument4 pagesShips Operating in Ice Covered WatersRogerNo ratings yet

- Assignment 1Document2 pagesAssignment 1Borhan ShaikatNo ratings yet

- DTS Notes 1Document58 pagesDTS Notes 1Karthi SanNo ratings yet

- Sanskruti Brochure - Updated (1) 2Document10 pagesSanskruti Brochure - Updated (1) 2Gaurav RaghuvanshiNo ratings yet

- Principles of Heat Flow Modelling Stuewe08Document15 pagesPrinciples of Heat Flow Modelling Stuewe08Fahmi BajryNo ratings yet

- How To Photograph Scale Models PDFDocument7 pagesHow To Photograph Scale Models PDFcraigwilliamthomasNo ratings yet

- Battery Charger Profitec 2000 S 216 V/120 A: Management Documents 81504209.EN0 BFU, enDocument9 pagesBattery Charger Profitec 2000 S 216 V/120 A: Management Documents 81504209.EN0 BFU, endinkoheNo ratings yet

- Review of Cooling Load Calculation Methods: Ala HasanDocument15 pagesReview of Cooling Load Calculation Methods: Ala Hasanhermez19100% (1)

- Gujarat Technological University: Telecommunication Switching Systems and Networks B.E. 6 SemesterDocument3 pagesGujarat Technological University: Telecommunication Switching Systems and Networks B.E. 6 SemesterRAMSHI CHETARIYANo ratings yet

- Fpga Implementation of Ofdm Transceiver For A 60Ghz Wireless Mobile Radio SystemDocument5 pagesFpga Implementation of Ofdm Transceiver For A 60Ghz Wireless Mobile Radio SystemBoualem ZouggariNo ratings yet

- Energy Method PDFDocument43 pagesEnergy Method PDFSenthil KumarNo ratings yet

- 3150cdahhbaa YokogawaDocument1 page3150cdahhbaa YokogawaAlberto Fernández MarínNo ratings yet