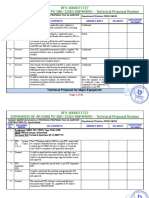

1) QA/QC Manager Approval

Contract Award

2) Project Quality Plan (PQP),

3) Inspection Test & Plan (ITP) with

Checklists

4) Quality Procedure (QP),

5) Audit Schedule

6) Quality Personnel Approvals:

• PQCS

• Quality Auditor

• Quality Supervisors

• Quality Inspectors

Designate and Submit

QA/QC Manager CV Submit CV’s of Quality Personnel (PQCS, • IFC Drawings

(SCH. Q. Section 5.2) Quality Auditor, Quality Supervisors, Quality • PQD for Vendors

(within 7 cal. days of the Inspectors) (SCH. Q. Section 7.5 & 7.3) • Batch Plant (BP) Mix Design

effective date of contract) (within 30 cal. days of the effective date of • Material Approval (MAT)

contract or before commencing activities) • Method Statement (MS)

Prepare & Submit

• Project Quality Plan (includes Quality Procedures, QA/QC Org.

Chart, Audit Schedule)

(SCH. Q. Section 9.3.3 & 7.11 ,5.3)

(within 30 cal. days of the effective date of contract)

• Inspection & Test Plans with Checklists (SCH. Q. Section C1.1,

RACI 4.2)

(1 Month prior to start of applicable work)

Preliminary Reviews

• Preliminary Assess Competencies of PQCS, Review and

• QA/QC Manager (SCH. Q. Section 5.2, RACI 1.4) Quality Auditor Review PQD for approve IFC, PQD,

Vendors BP Mix

• Project Quality Plan (includes Quality Procedures, • Assess competency and approve Supervisors, Design, MAT, MS

QA/QC Org. Chart, Audit Schedule) (SCH. Q. Section Quality Inspectors

7.11 & 5.3) (SCH. Q. Section 7.5 & 7.3, RACI 1.4 & 1.3)

• Inspection & Test Plans with Checklists (SCH. Q.

Section C1.1, RACI 4.2)

No No No

No Approved? Approved? Approved?

Approved?

Yes Yes Yes

Yes

Assess Competency of

• QA/QC Manager (SCH. Q. Section 5.2, RACI Final approval of PQCS and

1.4) Review Quality Auditor Final approval

(SCH. Q. Section 9.3.6 ,7.5 ,7.3, of PQD

• Project Quality Plan (includes Quality RACI 1.4 & 1.3)

Procedures, QA/QC Org. Chart, Audit Schedule)

(SCH. Q. Section 7.11 & 5.3, RACI 4.1)

• Inspection & Test Plans with Checklists (SCH.

Q. Section C1.1, RACI 4.3)

No

Approved? Approved?

No

Approved?

Yes

Yes Yes

Quality Personnel Documents Approved:

1) QA/QC Manager Approval

Approvals:

2) Project Quality Plan (PQP), • IFC Drawings

3) Inspection Test & Plan (ITP) with Checklists • PQCS • PQD for Vendors

4) Quality Procedure (QP), • Quality Auditor • Batch Plant (BP) Mix Design

5) Audit Schedule • Quality Supervisors • Material Approval (MAT)

• Quality Inspectors • Method Statement (MS)

1

� Documents Approved:

Invitation of

Walkthrough

• IFC Drawings

• PQD for Vendors

• Batch Plant (BP) Mix Design

• Material Approval (MAT)

• Method Statement (MS)

Raise WIR/MIR Addressing NEOM Raise WIR/

Submit

(SCH. Q. Appendix Raised NCRs (SCH. notification

Walkthrough

C1.2.4, RACI 3.3 & Q. Section 9.5.4, to close Punchlist

Request (RACI 4.7)

3.4 ) RACI 3.2) (SCH. Q. Section

8.4.3, RACI 4.7)

• Inspect and approve MIR (level 1,2

material) (RACI 3.4)

Root Cause,

• Verify MIR (level 3 material) (RACI No Corrective No Verified No

3.5 & 3.4) Action Plan & Approved?

and accepted?

Implementation

• Verify WIR (witness and hold points) Approved?

(RACI 3.3)

Yes Yes

No

Approved? Invite All Parties Communicate

Yes (Proponent, NEOM to ETSD (RACI 4.7

ETSD, PMC/EPM,

etc) for

Walkthrough

(RACI 4.7)

Yes

Conduct

• Inspect and approve MIR (level 3 Walkthrough and No

material) (RACI 3.5) Root Cause, Generate Punchlist Approved?

Corrective then upload in BIM

• Inspect and approve WIR (witness No Action Plan & 360 (RACI 4.7)

and hold points) (RACI 3.3) Implementation

Verified

and accepted? Yes

Originators Close

No Inspected &

Approved? Accepted Punchlist

items in BIM 360

Yes (RACI 4.7)

Yes

Closed NCR with TOC Approval

Approved

Supporting (once all Major

MIR & WIR

Document Punchlist Items are

closed in BIM 360)