Professional Documents

Culture Documents

Hazard Identification 3. Risk Control

Uploaded by

Re: AlChemist Brotherhood0 ratings0% found this document useful (0 votes)

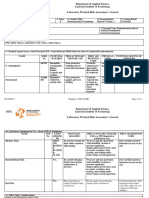

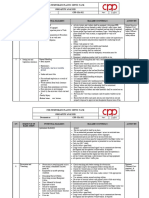

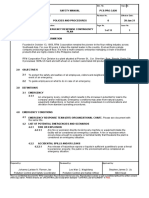

9 views1 pageThe document is an experiment-based risk assessment form for abrasive sand blasting in a physics lab located in room S7 #01-01. There are five potential hazards identified: fine dust and silica particles from abrasive blasting media which can cause silicosis; flying debris from abrasive blasting equipment that could cause injuries; high noise levels that could damage hearing; vibration from equipment that could cause hand injuries; and high-pressure particulate matter that could injure eyes or skin if the nozzle is misdirected. Controls listed include proper ventilation, protective equipment, maintenance of equipment, isolation of hazards, training personnel, and designating responsibilities.

Original Description:

Original Title

GXqOJYhoppclMrBUNa1Dtx6VfZ9Jb713WRvAUUzMJsKRZ9CO88gaLwHKjdypPHzFA3niMSa4YgZvww5kB2-Hh8XVVvoSrs6d6Fda_JFPn37FRhz6ZwtBNbl-nnDjN8NudwWbegdpN2GFDw9xM8rOoq1Yfv20

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document is an experiment-based risk assessment form for abrasive sand blasting in a physics lab located in room S7 #01-01. There are five potential hazards identified: fine dust and silica particles from abrasive blasting media which can cause silicosis; flying debris from abrasive blasting equipment that could cause injuries; high noise levels that could damage hearing; vibration from equipment that could cause hand injuries; and high-pressure particulate matter that could injure eyes or skin if the nozzle is misdirected. Controls listed include proper ventilation, protective equipment, maintenance of equipment, isolation of hazards, training personnel, and designating responsibilities.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views1 pageHazard Identification 3. Risk Control

Uploaded by

Re: AlChemist BrotherhoodThe document is an experiment-based risk assessment form for abrasive sand blasting in a physics lab located in room S7 #01-01. There are five potential hazards identified: fine dust and silica particles from abrasive blasting media which can cause silicosis; flying debris from abrasive blasting equipment that could cause injuries; high noise levels that could damage hearing; vibration from equipment that could cause hand injuries; and high-pressure particulate matter that could injure eyes or skin if the nozzle is misdirected. Controls listed include proper ventilation, protective equipment, maintenance of equipment, isolation of hazards, training personnel, and designating responsibilities.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

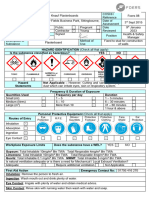

Experiment-Based Risk Assessment Form

Name of Department Physics Location of Lab S7 #01-01

Name of Laboratory Physics Workshop Name of PI Tan Choon Wah

Name of Researcher/LO Mansor Name of Activity/Experiment Abrasive Sand Blasting

1. Hazard Identification 3. Risk Control

No Description/Details of Steps in Activity Hazards Possible Accident / Ill Health & Existing Risk Control (Mitigation) Severity Likelihood Risk Level Additional Risk Control Person Responsible By (Date)

Persons-at-Risk (Probability)

1 Abrasive Blasting Media (e.g., coal slag, Fine dust and powder Silica can couse silicossis, a stiffening Extera vantilation should be consider in work 2 2 8 check vantilation is working before start USER ON GOING

copper slag, nical slag, glass, aluminium slag, and scarring of the lang,which is a area.Wear Personal protective equipment (PPE)

stell grit, garnet, silica sand) permanent and generative illness which Helmet, protective suits or clothing to keep out dust

may result in death.Breathing in silica and abrasive girds,respirators,chemically resistance

may also leadto development of form of gloves, safety booths and aprons, barrier cream (for

cancer short term protection).

2 Abrasive blasting plant and equipment(Air Flying stone/minarel particles. High pressure air Explosion,toxic air contaminants.Other Checking and inspection, common example plan 2 1 2 service regularly,should keep log books USER ON GOING

compressor and blas pot, nozel, blas hoses, workers and persons in vicinity of works equipment and machinery used. and inspection check sheets containing a

hose whips and couplings, blasting cabinates, full history of service and repairs.

eye and skin protection).

3 Noise internal injured (e.g Noise ) each person's susceptibility to hearing relocating or enclosing noisy equipment in acoustic 2 2 4 Check the impact on noise level of USER ON GOING

damage.Expose to noise in our work enclosures.Wear personal hearing protector.Design location of work area,check the

envioroment course a number of plan to eliminate or control noise emission where is transmission of noise through structures

physiological responses e.g heart risk to a person's hearing. and dust

disease, reduced immune respond and

sleep disturbance.

4 Vibration physically injured(e.g Vibration) Prolong use blasting equipment may The lengh of time an operator is required to operate 1 1 1 The use of vibration reduced equipment USER ON GOING

lead to condition know as white finger or a blast nozzle should keep to minimum,through job such as vibratin isolating handle

dead finger.It result persistent rotation or more frequence break.Use hand incorporated into blasting nozzles my

microscopic

p damage g to nurve and blood g , g y mainteinance the equipment.

glove,regularly q p g

decrease the incidence of dead finger.

capillaries

5 Particulate matter Physically injured Serious injured or dead can result from Isolation(e.g blasting cabinates,blasting chamber, 2 2 4 When blasting, the nozzle should only USER ON GOING

being stuck by particulate matter temporary enclosures and exclusion zones). Self- pointed at the work,never pointed at any

discharge under pressure(e.g eye actuating cut-off device must be fitted under the person.Blast hose should be uncoiled

damage, severe lacerations burn and direct control of nozzle operator.Wear personel when use.Blasting personnel shuold be

skin penetration. protective equipment (e.g respiratory adequately trained in the use and

equipment,eyes protective, protective clothing and maintenance of equipment.

protective foot wear)

6 0

0

0

0

10 0

Conducted By Approved By

Name Dr Murray Barrett

Signature

Approval date Next Revision date

(Maximum 3 years)

You might also like

- JSA-010 Excavation Sampling PDFDocument5 pagesJSA-010 Excavation Sampling PDFArgaYurIstiawanNo ratings yet

- Cutting DrillingDocument2 pagesCutting DrillingKoneti JanardhanaraoNo ratings yet

- Jsa Grinding W Angle GrinderDocument2 pagesJsa Grinding W Angle GrinderMichael Angelo SanteNo ratings yet

- Apds-Ra-011 Filtration Operation of Apds Filtration System Rev BDocument4 pagesApds-Ra-011 Filtration Operation of Apds Filtration System Rev BHua Tien DungNo ratings yet

- Clearing Brush With Weed Trimmer: Job Safety AnalysisDocument2 pagesClearing Brush With Weed Trimmer: Job Safety AnalysisRetselisitsoe100% (1)

- Asbestos Risk Assessment TemplateDocument3 pagesAsbestos Risk Assessment Templatedeonstuurman777No ratings yet

- 09052019K6EKJ42CRiskAssessment UploadDocument26 pages09052019K6EKJ42CRiskAssessment UploadAhmed IbrahimNo ratings yet

- JSA-009a Drilling and Mon Well Construction-Sonic - 2Document4 pagesJSA-009a Drilling and Mon Well Construction-Sonic - 2sudarmanNo ratings yet

- Assignment 1Document4 pagesAssignment 1Ahmed IsahNo ratings yet

- Sterilization of Explosive Delivery Systems Entering Normet WorkshopsDocument4 pagesSterilization of Explosive Delivery Systems Entering Normet WorkshopsPEDRONo ratings yet

- Pre-Job Safety Assessment MCGPI ISMDocument3 pagesPre-Job Safety Assessment MCGPI ISMRayyan ramosNo ratings yet

- Job Safety AnalysisDocument3 pagesJob Safety AnalysisAndhy DhannyNo ratings yet

- JSA Hydro ExcavateDocument3 pagesJSA Hydro Excavatearnel_ado4412100% (3)

- Job Safety Analysis Worksheet: JGC Penthouse Extension BLDGDocument2 pagesJob Safety Analysis Worksheet: JGC Penthouse Extension BLDGCherry BetonioNo ratings yet

- HIRA WORK SHEET Blasting and Painting.Document10 pagesHIRA WORK SHEET Blasting and Painting.Madhu Electricals & Engineering100% (2)

- Industrial HygieneDocument34 pagesIndustrial HygieneJohn Paulo TacudNo ratings yet

- Risk Assessment: Job:Control Blasting For Wagon TipplerDocument1 pageRisk Assessment: Job:Control Blasting For Wagon Tipplerali rezaNo ratings yet

- JSA - Sand Blasting and PaintngDocument8 pagesJSA - Sand Blasting and PaintngJohn100% (1)

- Report FDP - Safety Health and EnvironmentDocument26 pagesReport FDP - Safety Health and EnvironmentJss Aircond & ElectricalNo ratings yet

- Report FDP - Safety Health and EnvironmentDocument26 pagesReport FDP - Safety Health and EnvironmentJss Aircond & ElectricalNo ratings yet

- 08 Knauf PlasterboardsDocument2 pages08 Knauf Plasterboardsphil.jacksonNo ratings yet

- HIRA WaterproofingDocument16 pagesHIRA WaterproofingPRIYESH . K. PRIYANNo ratings yet

- Hirac TableDocument6 pagesHirac TableNor Syazwani Sharudin100% (1)

- JSA GrinderAngleDocument2 pagesJSA GrinderAngleslamet_rNo ratings yet

- 1-JHA - ExcavationDocument2 pages1-JHA - ExcavationAnna Marie Filipinas RajilNo ratings yet

- Risk Assessmnet RecrystallizationDocument3 pagesRisk Assessmnet Recrystallizationh9g886qdnpNo ratings yet

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument4 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDTigor GurningNo ratings yet

- Ewrc SHP Gen Hse Jsa 00040Document12 pagesEwrc SHP Gen Hse Jsa 00040Rickz CabaloNo ratings yet

- Capil's - ABS - HSE Risk Assessment 24.11.2023Document48 pagesCapil's - ABS - HSE Risk Assessment 24.11.2023Shannon MooreNo ratings yet

- 4. job-safety Housekeeping 清理工作安全分析Document8 pages4. job-safety Housekeeping 清理工作安全分析ADEN LIUNo ratings yet

- Risk Assessment For VA MenlynDocument6 pagesRisk Assessment For VA MenlynVictor Thembinkosi MakhubeleNo ratings yet

- Pre-Job Hazard AnalysisDocument3 pagesPre-Job Hazard AnalysisFiras HamanNo ratings yet

- JSA 37-Rev.01 - RADIOGRAPHY TESTDocument1 pageJSA 37-Rev.01 - RADIOGRAPHY TESTgolusinghdataNo ratings yet

- JSA DrillingDocument12 pagesJSA DrillingAbdus SamadNo ratings yet

- SWMS2 Confined Space EntryDocument9 pagesSWMS2 Confined Space EntryIslam Sarhan100% (1)

- Soil Compaction With Plate Compactor JSA HSE ProfessionalsDocument1 pageSoil Compaction With Plate Compactor JSA HSE ProfessionalsSamadov 13No ratings yet

- Soil CompactionDocument1 pageSoil CompactionLebohang ChakaNo ratings yet

- JSA 20-Rev.02 - Finish PaintingDocument2 pagesJSA 20-Rev.02 - Finish PaintinggolusinghdataNo ratings yet

- Using Grinder Jsa Fsanglgrndr.06Document2 pagesUsing Grinder Jsa Fsanglgrndr.06IAnNo ratings yet

- Firefly EXsolvo 1.0 EN-2Document9 pagesFirefly EXsolvo 1.0 EN-2Mostafa SayedNo ratings yet

- FPO MTI1011C Dust Collector Basics FG110112Document31 pagesFPO MTI1011C Dust Collector Basics FG110112jeannotkabNo ratings yet

- Job Safety Analysis: Confined Space: Health, Safety Environmental Management System (SMS)Document5 pagesJob Safety Analysis: Confined Space: Health, Safety Environmental Management System (SMS)ADEN LIUNo ratings yet

- JHSA For Temporary Plastic Septic TankDocument4 pagesJHSA For Temporary Plastic Septic TankAnna JisabaNo ratings yet

- BP Oil - Toledo Refinery: Procedure SAF 116Document10 pagesBP Oil - Toledo Refinery: Procedure SAF 116Rahul KrishnaNo ratings yet

- Risk Assessment Recrystallization 1.1Document3 pagesRisk Assessment Recrystallization 1.1h9g886qdnpNo ratings yet

- TEIPL-JSA-045 Housekeeping Waste ManagementDocument3 pagesTEIPL-JSA-045 Housekeeping Waste Managementba ratnaparkhe100% (1)

- Ijstev1i12005 PDFDocument2 pagesIjstev1i12005 PDFSreejith S NairNo ratings yet

- JOB SAFETY ANALYSIS - Idler Frame StencilingDocument1 pageJOB SAFETY ANALYSIS - Idler Frame StencilingSajith C PauloseNo ratings yet

- JSA New Line Installation 2012Document2 pagesJSA New Line Installation 2012Deshbandhu Aman PandeyNo ratings yet

- 006 Oper. Control - Incoming WarehousingDocument2 pages006 Oper. Control - Incoming WarehousingRobert UlatanNo ratings yet

- JSA 02-Rev.01 - Blinding & DeblindingDocument1 pageJSA 02-Rev.01 - Blinding & DeblindinggolusinghdataNo ratings yet

- Risk AssessmentDocument5 pagesRisk Assessmentelswefeyam.1980No ratings yet

- COSHH Assessment - C48i ACHDocument6 pagesCOSHH Assessment - C48i ACHalexNo ratings yet

- Risk AssesmentDocument2 pagesRisk AssesmentTarget AssistanceNo ratings yet

- Job Hazards AnalysisDocument1 pageJob Hazards AnalysisJane RoNo ratings yet

- Lecture 6 - Chemical SafetyDocument37 pagesLecture 6 - Chemical SafetyAlquien Engaling CapuyanNo ratings yet

- PCS-EMP-5.001 Emergency Response Contingency PlanDocument23 pagesPCS-EMP-5.001 Emergency Response Contingency PlanRFM Corporation Flour DivisionNo ratings yet

- PMLS BiosafetyDocument11 pagesPMLS BiosafetyseaynNo ratings yet

- Termites and Borers: A Home-Owner's Guide to their Detection, Prevention and ControlFrom EverandTermites and Borers: A Home-Owner's Guide to their Detection, Prevention and ControlNo ratings yet

- Sponsor Trial ErrorDocument13 pagesSponsor Trial ErrorRe: AlChemist BrotherhoodNo ratings yet

- Ardi LukmanDocument30 pagesArdi LukmanRe: AlChemist BrotherhoodNo ratings yet

- Review Article The Major Pathways of Lipids (Triglyceride and Cholesterol) and Lipoprotein MetabolismDocument12 pagesReview Article The Major Pathways of Lipids (Triglyceride and Cholesterol) and Lipoprotein MetabolismRe: AlChemist BrotherhoodNo ratings yet

- ID NoneDocument19 pagesID NoneRe: AlChemist BrotherhoodNo ratings yet

- Vernacular Names of HylocereusDocument6 pagesVernacular Names of HylocereusRe: AlChemist BrotherhoodNo ratings yet

- CFOT SlidesDocument24 pagesCFOT SlidesShariff Oluoch OdiwuorNo ratings yet

- Outpatient Appointment Systems in Healthcare - A Review of Optimization StudiesDocument32 pagesOutpatient Appointment Systems in Healthcare - A Review of Optimization Studiesgabrieelcrazy100% (1)

- Legprof Updated Full Text CasesDocument242 pagesLegprof Updated Full Text CasesKarmaranthNo ratings yet

- (Notes) Financial Management FundamentalsDocument65 pages(Notes) Financial Management FundamentalsJoanna Danielle AngNo ratings yet

- C - Library - SignalDocument2 pagesC - Library - SignaltrgyklNo ratings yet

- Codigos TV SMK SAM UniversalDocument16 pagesCodigos TV SMK SAM UniversalJeff KbreraNo ratings yet

- Form 4 PF WithdrawlDocument2 pagesForm 4 PF WithdrawlRajshree DubeyNo ratings yet

- Family Managed Business Vs Non Family BusinessDocument4 pagesFamily Managed Business Vs Non Family BusinessKARISHMA RAJ0% (1)

- SM-T587P (Phonelumi Com)Document81 pagesSM-T587P (Phonelumi Com)Tomaso SulisNo ratings yet

- Evraz Highveld SteelDocument6 pagesEvraz Highveld SteelCaio VaccariNo ratings yet

- Beijing Review - August 06, 2020 PDFDocument54 pagesBeijing Review - August 06, 2020 PDFAnanya SaikiaNo ratings yet

- Reyes Vs HRET GR 221103Document20 pagesReyes Vs HRET GR 221103Di JoyaNo ratings yet

- Slack Operations Management 6e Chapter1Document7 pagesSlack Operations Management 6e Chapter1dorislianNo ratings yet

- 2017 - Janjuhah Et Al., - Carbonates and Evaporites1Document19 pages2017 - Janjuhah Et Al., - Carbonates and Evaporites1Waleed HassanNo ratings yet

- Nuclie PDFDocument34 pagesNuclie PDFlvnarsingaraoNo ratings yet

- Upa 150CDocument40 pagesUpa 150CRené Sebastián Sabando Varas0% (1)

- Valves Q.S For Fire Pump Room - Eng Ahmed HassanDocument1 pageValves Q.S For Fire Pump Room - Eng Ahmed Hassanmujassam noorNo ratings yet

- HD 114 Jumbo Water Curtain NozzleDocument2 pagesHD 114 Jumbo Water Curtain Nozzlesun rockNo ratings yet

- Foreign LiteratureDocument3 pagesForeign LiteratureAngeline HermosoNo ratings yet

- Eun8e CH 006 TomDocument41 pagesEun8e CH 006 TomCarter JayanNo ratings yet

- Oshkosh M AtvDocument28 pagesOshkosh M AtvUsNdaomanu100% (1)

- List of Publishers - Scholarly Open AccessDocument22 pagesList of Publishers - Scholarly Open AccessHerman SjahruddinNo ratings yet

- Bow LsplanDocument4 pagesBow Lsplanapi-641176937No ratings yet

- Nutolts 201205 DLDocument84 pagesNutolts 201205 DLYvoSteentjes100% (1)

- Project Cost Management With 5D Bim: SciencedirectDocument8 pagesProject Cost Management With 5D Bim: Sciencedirectcrises7No ratings yet

- Mobile Digital NursingDocument12 pagesMobile Digital NursingyunitaNo ratings yet

- Data Communication Computer Networks Notes BCA PDFDocument20 pagesData Communication Computer Networks Notes BCA PDFHemalatha S Chinnu100% (2)

- Grade Thresholds - June 2022: Cambridge IGCSE First Language English (Oral Endorsement) (0500)Document2 pagesGrade Thresholds - June 2022: Cambridge IGCSE First Language English (Oral Endorsement) (0500)Sufiyan ShahidNo ratings yet

- AADocument238 pagesAAmarnekibNo ratings yet

- BDocument80 pagesBNovan Ediwibowo100% (1)