Professional Documents

Culture Documents

JSA 20-Rev.02 - Finish Painting

Uploaded by

golusinghdata0 ratings0% found this document useful (0 votes)

3 views2 pagesCopyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views2 pagesJSA 20-Rev.02 - Finish Painting

Uploaded by

golusinghdataCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

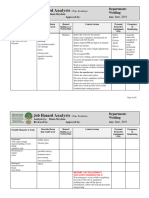

Metal Crafts Constructors Pvt Ltd

HPCL-Mittal Energy Ltd, GGSR, Bathinda

Job Safety Analysis Sheet

Permit No: Location: CPP

Main Activity: Finish Painting JSA No: MCCPL/HME/JSA-20.Rev.01

Sub Activities

(List the tasks required to Hazards (Both Existing as well as potential)

Control Measures. (List

Sl.no perform the activity in the Against each task list the hazards that could cause

the control measures required to eliminate or minimize the risk of injury

sequence they are carried out injury/damage to people, equipment or the

arising from the identified hazard.)

environment

Strain, while working Maintain correct posture, while carrying out the job.

Injury to eyes due to splash of paint , dust, rust etc. Use of mandatory PPEs & dust mask.

Clean the spilled paint immediately.

Slip injury due to spillage of paint in the nearby Barricade the area where painting is in progress

area Ensure housekeeping in the area.

Store painting material at appropriate place.

Surface cleaning & application Fire due to spillage of paint on hot surface or Covering the nearby hot surfaces, where painting job is not taking place,

1 assisted with sparks. with the fire resistant cloth. Ensure fire extinguishers

of paint

Ensure proper scaffolding and avoid transfer of load on to scaffold

Use only certified and validated scaffolding

Fall of person/Collapse of scaffolding due to Ensure appropriate PPE's and usage of the same.

improper loading Provide life line wherever possible.

Ensure/encourage use of fall arrestors, safety nets.etc.

Provide ladders for better approach to the working platforms

Name Designation Signature Date

Approver-1 (Manager or above both issuer &

requester)

Note:

1. JSA to be done by issuer and accepter of work permit, in case required, representative from other discipline can also join the team for JSA

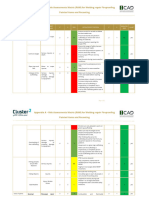

JOB SAFETY ANALYSIS FORM

JSA Sheet No._______________

Checklist of common Hazards

This should be used as an aid to identifying hazard. This is the list for the most common hazards but is not a definite list.

Mechanical/Equipment Thermal Ignition sources Electrical

Entanglement Hot surface Electricity Electrical shock

Shearing Steam Static electricity Static electricity

Crushing Refrigerants Hot work Power failure

Striking Stored Energy Lightening Pressure

Cutting Falling material Sparks Release of energy

Mechanical failure (e.g. by overloading) Springs under tension/compression Frictions Implosion

Chemical Counterweights Flames Compressed air

Flammable Radiations Auto ignition Steam

Toxic e.g. ionizing radiation (X-rays) Pyrophoric material Hydraulics

Harmful Place of work Vehicles Process

Irritant Obstructions Fork lift Wrong material

Oxidising Access/egress Tankers Missed steps

Pyrophoric Work at height Reversing vehicles Instrument failure

Corrosive Falling objects Speed Interlocks

Dangerous to environment Slip/trip/fall People Control system failure

Dust explosions Housekeeping Unsafe behavior Alarms

Gases Temperature Human errors Nature

Fumes Ventilation Training/competence Weather

Vapours Confined space Method of work Winds/Storms/lightening

Dusts Hazards of other tasks being done Manual handling (lifting, carrying, pushing

Asphyxiants Simultaneously. and pulling)

Stress/workload

Biological (e.g. legionella) Noise/Vibrations/Hot work

Name Designation Signature Date

Approver-1 (Manager or above both Issuer

& requestor)

(Note: 1. JSA to be done by issuer and acceptor of work permit. In case required, representative from other discipline can also join the team for JSA.

2. JSA to have approvals for Hot Jobs, confined space entry & Work on equipment in service

You might also like

- Jsa For Scaffolding Erection & DismentlingDocument7 pagesJsa For Scaffolding Erection & Dismentlingsanath adhikary100% (5)

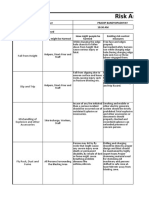

- 015 Risk Assessment - Painting WorksDocument5 pages015 Risk Assessment - Painting WorksVipul Shankar91% (11)

- Jsa PaintingDocument1 pageJsa Paintingclynne despiNo ratings yet

- Risk Assessment For Curtain Wall & Glazing InstallationDocument4 pagesRisk Assessment For Curtain Wall & Glazing InstallationChristos Loutrakis50% (2)

- Safe Work Method Statement: (See Below)Document6 pagesSafe Work Method Statement: (See Below)Siddharth P100% (1)

- Job Safety Analysis (Jsa) - Water Proofing WorkDocument6 pagesJob Safety Analysis (Jsa) - Water Proofing Worknitish tiwariNo ratings yet

- Hearing Conservation Program-RevDocument16 pagesHearing Conservation Program-RevBonnie M PahlavieNo ratings yet

- 38 Chipping Work at HeightDocument2 pages38 Chipping Work at HeightKoneti JanardhanaraoNo ratings yet

- JSA 01-Rev.02 - Blasting & PaintingDocument2 pagesJSA 01-Rev.02 - Blasting & PaintinggolusinghdataNo ratings yet

- JSA 02-Rev.01 - Blinding & DeblindingDocument1 pageJSA 02-Rev.01 - Blinding & DeblindinggolusinghdataNo ratings yet

- Risk Assessment - Elie SabDocument8 pagesRisk Assessment - Elie SabMuhammad FaizalNo ratings yet

- JSA 03-Rev.02 - BlindingDebliding Under Nitrogen PurgingDocument2 pagesJSA 03-Rev.02 - BlindingDebliding Under Nitrogen PurginggolusinghdataNo ratings yet

- JSA 03-Rev.01 - Buffing (Surface Cleaning)Document1 pageJSA 03-Rev.01 - Buffing (Surface Cleaning)golusinghdataNo ratings yet

- JSA 18-Rev.02 - GroutingDocument2 pagesJSA 18-Rev.02 - GroutinggolusinghdataNo ratings yet

- JLA WeldingDocument3 pagesJLA WeldingFaisal KhanNo ratings yet

- JSA - 0026 Chipping & Granite Cutting and Lying Work at PB-19Document2 pagesJSA - 0026 Chipping & Granite Cutting and Lying Work at PB-19Koneti JanardhanaraoNo ratings yet

- JHA Welding Pipe BenderDocument2 pagesJHA Welding Pipe Bendermohammad arshadNo ratings yet

- Risk Assessment-Instllation & Fabrication of Steel Structural WorkDocument3 pagesRisk Assessment-Instllation & Fabrication of Steel Structural WorkKono Nor AtanNo ratings yet

- Jsa Brick ShiftingDocument4 pagesJsa Brick ShiftingRavi thokalNo ratings yet

- Jha Lighting ArrestorDocument3 pagesJha Lighting ArrestorRavi thokalNo ratings yet

- JSA Replace Exsisting Strainer at FGD 8Document8 pagesJSA Replace Exsisting Strainer at FGD 8MarhendraNo ratings yet

- Copy (2) of JSA For Welding, Cutting and Grinding (Alam Engineering)Document5 pagesCopy (2) of JSA For Welding, Cutting and Grinding (Alam Engineering)Viron BaxhiaNo ratings yet

- Cutting DrillingDocument2 pagesCutting DrillingKoneti JanardhanaraoNo ratings yet

- Cutting & Grinding & WeldingDocument2 pagesCutting & Grinding & Weldingghazi kallelNo ratings yet

- Hse Risk Assessment For Civil Works, Isolators and Duct InstallationDocument6 pagesHse Risk Assessment For Civil Works, Isolators and Duct Installationvenkatesh snkNo ratings yet

- Job Safety Analysis Worksheet: JGC Penthouse Extension BLDGDocument2 pagesJob Safety Analysis Worksheet: JGC Penthouse Extension BLDGCherry BetonioNo ratings yet

- JSA For Errection of Batching PlantDocument4 pagesJSA For Errection of Batching Plantasamrat582No ratings yet

- Rme-Ms-Ee-0008 (Mos For Earthing & LPS) - Part20Document1 pageRme-Ms-Ee-0008 (Mos For Earthing & LPS) - Part20nanthan06No ratings yet

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument4 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDTigor GurningNo ratings yet

- JSA New Line Installation 2012Document2 pagesJSA New Line Installation 2012Deshbandhu Aman PandeyNo ratings yet

- 0017 JS A Hot Job (Welding, Grinding & Cutting)Document4 pages0017 JS A Hot Job (Welding, Grinding & Cutting)Positivesolution100% (2)

- Job Safety Analysis (Jsa) : CONTRACT N° .Document1 pageJob Safety Analysis (Jsa) : CONTRACT N° .ghazi kallelNo ratings yet

- 5.19.3 Job Safety Practices Installation of Cable TrayDocument3 pages5.19.3 Job Safety Practices Installation of Cable TrayBarkat UllahNo ratings yet

- 5.19.3 Job Safety Practices Installation of Fire Alarm Detection and ProtectionDocument3 pages5.19.3 Job Safety Practices Installation of Fire Alarm Detection and ProtectionBarkat UllahNo ratings yet

- JSA Column Errection, Shuttering, Casting, Deshuttering Raw Material Ware HouseDocument9 pagesJSA Column Errection, Shuttering, Casting, Deshuttering Raw Material Ware Houseradeep100% (1)

- Soil CompactionDocument1 pageSoil CompactionLebohang ChakaNo ratings yet

- Soil Compaction With Plate Compactor JSA HSE ProfessionalsDocument1 pageSoil Compaction With Plate Compactor JSA HSE ProfessionalsSamadov 13No ratings yet

- JSA Machinal PipingDocument7 pagesJSA Machinal PipingNaitik Desai48100% (1)

- JSA - Blooming Mill T-U-V Bay Axis 42 To 48Document6 pagesJSA - Blooming Mill T-U-V Bay Axis 42 To 48mohanNo ratings yet

- RISK ASSESSMENT Cleaning Tank in Waha CPFDocument8 pagesRISK ASSESSMENT Cleaning Tank in Waha CPFYoussef HdiaNo ratings yet

- Jsa For Scaffolding ErectionDocument7 pagesJsa For Scaffolding Erectionnoorul IslamNo ratings yet

- 0017 JS A Hot Job (Welding, Grinding & Cutting)Document4 pages0017 JS A Hot Job (Welding, Grinding & Cutting)midozotyNo ratings yet

- Risk - Assessments For Welding Repair Fireproofing and RecoatingDocument9 pagesRisk - Assessments For Welding Repair Fireproofing and Recoatingmjunaid7721No ratings yet

- HEI JHA Leakage RectificationDocument7 pagesHEI JHA Leakage RectificationJavid AaqibNo ratings yet

- Job Safety Analysis: (Risk Assessment)Document9 pagesJob Safety Analysis: (Risk Assessment)MarhendraNo ratings yet

- Expansion Joints in Columns JSA HSE ProfessionalsDocument1 pageExpansion Joints in Columns JSA HSE ProfessionalsSamadov 13No ratings yet

- Welding Works JSA HSE ProfessionalsDocument1 pageWelding Works JSA HSE ProfessionalsViron BaxhiaNo ratings yet

- Welding Works JSA HSE ProfessionalsDocument1 pageWelding Works JSA HSE ProfessionalsAli Kazi100% (1)

- Masonary Pitching Works JSA HSE ProfessionalsDocument2 pagesMasonary Pitching Works JSA HSE ProfessionalsSamadov 13No ratings yet

- Risk Assessment Form: Fall From HeightDocument24 pagesRisk Assessment Form: Fall From HeightRanjan SinghNo ratings yet

- JSA - FlowBackLoop - Choke ChangeDocument2 pagesJSA - FlowBackLoop - Choke ChangeAmur Al-rumhiNo ratings yet

- JSA - Transit Mixer & Boom PumpDocument4 pagesJSA - Transit Mixer & Boom PumpKrishVy KumærNo ratings yet

- Job Safety & Environmental Analysis WorksheetDocument2 pagesJob Safety & Environmental Analysis WorksheetCherry BetonioNo ratings yet

- Jsa For Gypsum Fixing & DismentlingDocument5 pagesJsa For Gypsum Fixing & DismentlingSushil Kumar YadavNo ratings yet

- TilingDocument6 pagesTilingrenovobuilders1820No ratings yet

- ISC-JSA Grouting Works For Shared FenceDocument4 pagesISC-JSA Grouting Works For Shared FenceSameer AlmahboubNo ratings yet

- Shuttering WorksDocument5 pagesShuttering Worksprasanna okNo ratings yet

- Concrete Placing by Using Mobile Crane Through Concrete Bucket JSA HSE ProfessionalsDocument1 pageConcrete Placing by Using Mobile Crane Through Concrete Bucket JSA HSE ProfessionalsViron BaxhiaNo ratings yet

- Packing Pumps New - FO-GL-HAL-HSE-0103FDocument4 pagesPacking Pumps New - FO-GL-HAL-HSE-0103FMohamed El-SawahNo ratings yet

- JSA 43 - Tightening of Water LineDocument1 pageJSA 43 - Tightening of Water LinegolusinghdataNo ratings yet

- JSA 26 - Magnetic Particle Inspection (MPI)Document1 pageJSA 26 - Magnetic Particle Inspection (MPI)golusinghdataNo ratings yet

- JSA 49-Rev.01Erection of Spool Using by Rope PulleyDocument2 pagesJSA 49-Rev.01Erection of Spool Using by Rope PulleygolusinghdataNo ratings yet

- JSA 45 - Valve BoxupDocument18 pagesJSA 45 - Valve BoxupgolusinghdataNo ratings yet

- JSA 37-Rev.01 - RADIOGRAPHY TESTDocument1 pageJSA 37-Rev.01 - RADIOGRAPHY TESTgolusinghdataNo ratings yet

- JSA 48-Man Basket Lifting and MovingDocument3 pagesJSA 48-Man Basket Lifting and MovinggolusinghdataNo ratings yet

- JSA 03-Rev.01 - Buffing (Surface Cleaning)Document1 pageJSA 03-Rev.01 - Buffing (Surface Cleaning)golusinghdataNo ratings yet

- JSA 18-Rev.02 - GroutingDocument2 pagesJSA 18-Rev.02 - GroutinggolusinghdataNo ratings yet

- Jsa 36 - Ppu ShedDocument2 pagesJsa 36 - Ppu ShedgolusinghdataNo ratings yet

- JSA 15-Rev.02 - Fabrication (OSBL)Document3 pagesJSA 15-Rev.02 - Fabrication (OSBL)golusinghdataNo ratings yet

- JSA 17-Rev.01 - Flange Tightening JobDocument2 pagesJSA 17-Rev.01 - Flange Tightening JobgolusinghdataNo ratings yet

- Safety Flash 10 - Crane Hoist Wire Rope Dead End FailedDocument1 pageSafety Flash 10 - Crane Hoist Wire Rope Dead End FailedgolusinghdataNo ratings yet

- JSA 03-Rev.02 - BlindingDebliding Under Nitrogen PurgingDocument2 pagesJSA 03-Rev.02 - BlindingDebliding Under Nitrogen PurginggolusinghdataNo ratings yet

- JSA 03-Rev.01 - Buffing (Surface Cleaning)Document1 pageJSA 03-Rev.01 - Buffing (Surface Cleaning)golusinghdataNo ratings yet

- What Can You Do To Prevent AccidentsDocument1 pageWhat Can You Do To Prevent AccidentsgolusinghdataNo ratings yet

- Averia PowerPoint Template DarkDocument45 pagesAveria PowerPoint Template DarkNikhilesh KarriNo ratings yet

- F-INO-05 Training Evaluation SheetDocument3 pagesF-INO-05 Training Evaluation SheetgolusinghdataNo ratings yet

- F-INO-04 Records of Training ImpartedDocument2 pagesF-INO-04 Records of Training ImpartedgolusinghdataNo ratings yet

- WRENCHESDocument1 pageWRENCHESgolusinghdataNo ratings yet

- F-INO-03 Training Need IdentificationDocument1 pageF-INO-03 Training Need IdentificationgolusinghdataNo ratings yet

- Safety Flash 35 Man Basket Fell From HeightDocument1 pageSafety Flash 35 Man Basket Fell From HeightgolusinghdataNo ratings yet

- Construction Fall Protection QuizDocument1 pageConstruction Fall Protection QuizgolusinghdataNo ratings yet

- Bypass Management PracticeDocument2 pagesBypass Management PracticeSyed Mustafa Hussain100% (1)

- Tuv Sud Lifts and EscalatorsDocument2 pagesTuv Sud Lifts and EscalatorsJazonNo ratings yet

- F-037 AUDIT Legal RequirementsDocument18 pagesF-037 AUDIT Legal Requirementsneo_chemistNo ratings yet

- Artistic Warning Sign Poster About Fire PreventionDocument3 pagesArtistic Warning Sign Poster About Fire PreventionMaria Felicity FabularNo ratings yet

- Ehss ProgramDocument8 pagesEhss ProgramsrisetNo ratings yet

- Eo BDRRMCDocument6 pagesEo BDRRMCAgustin MharieNo ratings yet

- Class1 Group DDocument1 pageClass1 Group DSam ChoiNo ratings yet

- C-10 Ce ManualDocument193 pagesC-10 Ce ManualKrunoslav75% (4)

- 6 Appendix C HazMat Group Equipment ListDocument5 pages6 Appendix C HazMat Group Equipment ListShiro IshiiNo ratings yet

- Rotary and Handling Tools Catalog PDFDocument190 pagesRotary and Handling Tools Catalog PDFjinyuan74100% (3)

- Pressure Equipment FailureDocument9 pagesPressure Equipment Failurevijayachidu100% (1)

- RRC Risk Assessment Dec 2010Document14 pagesRRC Risk Assessment Dec 2010Li ChenNo ratings yet

- Guia Rapida L7 PDFDocument225 pagesGuia Rapida L7 PDFjuanNo ratings yet

- Atlas Copco - Roto Xtend Duty Fluid - SDSDocument14 pagesAtlas Copco - Roto Xtend Duty Fluid - SDSEloany Batista da SilvaNo ratings yet

- Guidelines For Certification of Safety Management Systems: Department BSMDocument23 pagesGuidelines For Certification of Safety Management Systems: Department BSMMarc FazioliNo ratings yet

- PRC 2017 Annual Report ENDocument88 pagesPRC 2017 Annual Report ENmuhammad suryadiNo ratings yet

- Kurebwa and Mushiri 1-S2.0-S2351978919309795-MainDocument15 pagesKurebwa and Mushiri 1-S2.0-S2351978919309795-MainJoseph KurebwaNo ratings yet

- Business EthicsDocument29 pagesBusiness EthicsOm Communication Satationery100% (1)

- Dabsa SDSDocument13 pagesDabsa SDSKC Lakshmi NarayananNo ratings yet

- Airport Operations Diploma Program (AODP)Document2 pagesAirport Operations Diploma Program (AODP)MOUSSA Mamane RabiouNo ratings yet

- Arcol PPG 425Document2 pagesArcol PPG 425ahmed samyNo ratings yet

- BES 105 Safety OfficerDocument3 pagesBES 105 Safety OfficerFranz Owen Morada N.0% (1)

- SDS Condat Sen 60Document4 pagesSDS Condat Sen 60Ninh ChinhNo ratings yet

- Apply Problem Solving Edited For StudentsDocument27 pagesApply Problem Solving Edited For StudentsFelekePhiliphosNo ratings yet

- Road Asphalt Works-Epc10-Ra-74-R0Document5 pagesRoad Asphalt Works-Epc10-Ra-74-R0tariq1987100% (1)

- Fire Risk Assessment Guidance and TemplatesDocument20 pagesFire Risk Assessment Guidance and TemplatesKakira Lions ClubNo ratings yet

- Hospital Admission and DischargeDocument5 pagesHospital Admission and DischargeRenuga SureshNo ratings yet

- Mitigation StrategiesDocument51 pagesMitigation StrategiesAbdullah Alhatami50% (2)

- CraneDocument760 pagesCraneDave CamposNo ratings yet