Professional Documents

Culture Documents

Shuttering Works

Uploaded by

prasanna ok0 ratings0% found this document useful (0 votes)

91 views5 pagesThis document provides a safe work method statement for shuttering works. It outlines 3 key procedures: 1) preparation and fixing of shuttering, 2) footing, column and slab shuttering, and 3) cutting wood to required size. Potential hazards are identified for each procedure such as boards falling, eye injuries from flying nails, and falls from height. Control measures are specified to minimize risks, including barricading work areas, using proper PPE, installing fall protection, and deploying trained workers.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides a safe work method statement for shuttering works. It outlines 3 key procedures: 1) preparation and fixing of shuttering, 2) footing, column and slab shuttering, and 3) cutting wood to required size. Potential hazards are identified for each procedure such as boards falling, eye injuries from flying nails, and falls from height. Control measures are specified to minimize risks, including barricading work areas, using proper PPE, installing fall protection, and deploying trained workers.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

91 views5 pagesShuttering Works

Uploaded by

prasanna okThis document provides a safe work method statement for shuttering works. It outlines 3 key procedures: 1) preparation and fixing of shuttering, 2) footing, column and slab shuttering, and 3) cutting wood to required size. Potential hazards are identified for each procedure such as boards falling, eye injuries from flying nails, and falls from height. Control measures are specified to minimize risks, including barricading work areas, using proper PPE, installing fall protection, and deploying trained workers.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 5

Safe Work Method Statement

Project Name: OLA Cell technologies private limited DATE:18.07.2023

Company Name

Address:

Office Contact No:

Project Manager Name Contact No:

ACIVITY : SHUTTERING WORKS

The person who

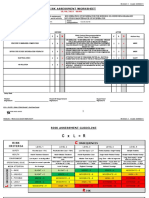

Procedure (in steps) Possible Hazards Risk Control Measures will ensure this

Rating (Describe what action or procedure will be happens

(Break the job down into steps. Each step (Identify the hazards associated with (See taken to eliminate or minimize the risk of injury

should accomplish some major task and each step. Examine each to find below) or damage. Use the Hierarchy of Controls

be in logical sequence.) possibilities that could lead to an accident below as a guide

or potential harm arising.) 1. Eliminate the Hazard

2. Substitute the material or equipment

3. Isolate the hazard

4. Implement Engineering control

5. Implement Administrative control

6. PPE

1. Preparation and fixing of Boards may fall. Area should be barricaded.

shuttering . Eye injury. All persons should be medically fit.

Flying nails while hammering. Wear safety goggles.

Use of loose hammer. Ensure that hammer handle is

properly wedged and hammer is in

good condition.

Document Name: Version Correct as at:

SWMS for brickwork and plastering 01 11.01.2023

Safe Work Method Statement

The person who

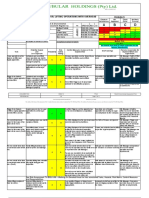

Procedure (in steps) Possible Hazards Risk Control Measures will ensure this

Rating (Describe what action or procedure will be happens

(Break the job down into steps. Each step (Identify the hazards associated with (See taken to eliminate or minimize the risk of injury

should accomplish some major task and each step. Examine each to find below) or damage. Use the Hierarchy of Controls

be in logical sequence.) possibilities that could lead to an accident below as a guide

or potential harm arising.) 1. Eliminate the Hazard

2. Substitute the material or equipment

3. Isolate the hazard

4. Implement Engineering control

5. Implement Administrative control

6. PPE

2. Footing,Coulmn and slab Personal Injury. Avoid using of sub- standard tools

Shuttering. Fall of Material. & tackles.

Ensure the use of required PPE like-

helmet, safety shoes, goggles, hand

gloves Reflective jacket & dust

mask.

Ensure proper cleaning (removal of

nails, small wooden pieces etc.)

Life line to be ensured.

Ensure to use the full body harness.

Ensure to check the height phobia

test.

Document Name: Version Correct as at:

SWMS for brickwork and plastering 01 11.01.2023

Safe Work Method Statement

The person who

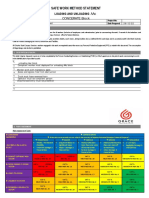

Procedure (in steps) Possible Hazards Risk Control Measures will ensure this

Rating (Describe what action or procedure will be happens

(Break the job down into steps. Each step (Identify the hazards associated with (See taken to eliminate or minimize the risk of injury

should accomplish some major task and each step. Examine each to find below) or damage. Use the Hierarchy of Controls

be in logical sequence.) possibilities that could lead to an accident below as a guide

or potential harm arising.) 1. Eliminate the Hazard

2. Substitute the material or equipment

3. Isolate the hazard

4. Implement Engineering control

5. Implement Administrative control

6. PPE

Misuse of cutting device. Deploy trained carpenter.

Fall of tools & wood from height. Proper supervision is required.

Need to protect fall of material.

3. Cutting wood to required size.

Document Name: Version Correct as at:

SWMS for brickwork and plastering 01 11.01.2023

Safe Work Method Statement

The person who

Procedure (in steps) Possible Hazards Risk Control Measures will ensure this

Rating (Describe what action or procedure will be happens

(Break the job down into steps. Each step (Identify the hazards associated with (See taken to eliminate or minimize the risk of injury

should accomplish some major task and each step. Examine each to find below) or damage. Use the Hierarchy of Controls

be in logical sequence.) possibilities that could lead to an accident below as a guide

or potential harm arising.) 1. Eliminate the Hazard

2. Substitute the material or equipment

3. Isolate the hazard

4. Implement Engineering control

5. Implement Administrative control

6. PPE

4. De-shuttering. Fall of shuttering. Deploy experience workers.

Protruding nails. Remove nails and stack shuttering

Loose nails on floor. materials properly.

Maintain good housekeeping.

5. Cleaning of site Personal Injury Ensure proper cleaning (removal of

nails, small wooden pieces etc.)

immediately after completion of the

work.

All materials were stocked in their

designated places

Document Name: Version Correct as at:

SWMS for brickwork and plastering 01 11.01.2023

Safe Work Method Statement

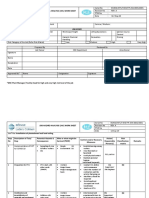

Personnel Summary

SUPERVISOR’S DETAILS

Supervisors Name & Qualifications: Name:

Experience:

Qualifications:

Prepared by: Signature: Date:

(Principle Contractor HSE Manager)

Reviewed by : Signature: Date:

(Principle Contractor Project Manager)

Reviewed by Signature Date:

(JLLSafety Manager)

Approved by

(JLL Project Manager) Signature Date:

Document Name: Version Correct as at:

SWMS for Brick work and plastering 01 11.01.2023

You might also like

- SWMS - Glass PartitionDocument11 pagesSWMS - Glass PartitionParasNo ratings yet

- Job Hazard Analysis Form Stripping Forms: ReferenceDocument2 pagesJob Hazard Analysis Form Stripping Forms: ReferenceReden Mejico PedernalNo ratings yet

- Ultimate Frisbee DraftDocument3 pagesUltimate Frisbee Draftapi-526745820No ratings yet

- Reinforcement WorksDocument5 pagesReinforcement Worksprasanna okNo ratings yet

- ExcavationDocument3 pagesExcavationprasanna ok100% (1)

- Unloading Method StatementDocument3 pagesUnloading Method Statementprasanna okNo ratings yet

- Safe Work Method Statement: One World Place Manila, 32nd ST, Taguig, Metro ManilaDocument6 pagesSafe Work Method Statement: One World Place Manila, 32nd ST, Taguig, Metro Manilanani ferrerNo ratings yet

- Safe Work Method StatementDocument12 pagesSafe Work Method StatementJanakiramanNo ratings yet

- 3.gypsum CeilingDocument5 pages3.gypsum Ceilingmohammed sohailNo ratings yet

- SWMS-Pipe Instalation Work at Utility 25.01.21Document10 pagesSWMS-Pipe Instalation Work at Utility 25.01.21Ansari FaisalNo ratings yet

- Risk Assessment WorksheetDocument2 pagesRisk Assessment WorksheetHergheligiu VasileNo ratings yet

- P111-Rsme-Tra-007 - Tra For Cold Tie inDocument5 pagesP111-Rsme-Tra-007 - Tra For Cold Tie inDarius DsouzaNo ratings yet

- Risk Cooling TowerDocument4 pagesRisk Cooling TowerHariharan MuthukrishananNo ratings yet

- Risk Assessment-Maintance of Tanks, VesselsDocument5 pagesRisk Assessment-Maintance of Tanks, VesselsKono Nor AtanNo ratings yet

- Dismantling of StagingDocument1 pageDismantling of StagingChandruNo ratings yet

- Job Safety Analysis - Tbl-Jsa: STEP 4: Hazard Risk AssessmentDocument6 pagesJob Safety Analysis - Tbl-Jsa: STEP 4: Hazard Risk AssessmentMoaatazz Nouisri100% (1)

- Chaliyama Steel Plant-Rungta Mines Limited Hazard Identification & Risk AssessmentDocument4 pagesChaliyama Steel Plant-Rungta Mines Limited Hazard Identification & Risk AssessmentCPP EI DSpNo ratings yet

- Risk Assessment Maintenance: L - Likelihood S - Severity RL - Risk LevelDocument3 pagesRisk Assessment Maintenance: L - Likelihood S - Severity RL - Risk LevelMohamed ElnagdyNo ratings yet

- A B C D: Risk & Environmental Assessment For: Lifting Operations With Overhead CranesDocument11 pagesA B C D: Risk & Environmental Assessment For: Lifting Operations With Overhead CranesMohammed Ali QaziNo ratings yet

- Demolition Risk AssessmentsDocument9 pagesDemolition Risk Assessmentssamar0% (1)

- SWP 5 Excavations Shoring and Trenches PDFDocument4 pagesSWP 5 Excavations Shoring and Trenches PDFThanesh ManogaranNo ratings yet

- Risk Assessment:: Corresponding Permit To Work NoDocument4 pagesRisk Assessment:: Corresponding Permit To Work NoNaseemandson TeamNo ratings yet

- Retaining Structure Vs EmbankmentDocument2 pagesRetaining Structure Vs EmbankmentCesar CabreraNo ratings yet

- Work at Height: Prepared: Ansar Ali (Am Hse)Document1 pageWork at Height: Prepared: Ansar Ali (Am Hse)Ansar AliNo ratings yet

- XX - PTW 575283 Doc1Document46 pagesXX - PTW 575283 Doc1JeffersonDeGuiaNo ratings yet

- Steel Shield Temporary Fencing Risk Assessment and Method Statement For ErectionDocument7 pagesSteel Shield Temporary Fencing Risk Assessment and Method Statement For ErectionIrfan Prima AldiNo ratings yet

- Risk Assessment/Management Form: Section / Dept: ActivityDocument2 pagesRisk Assessment/Management Form: Section / Dept: ActivityJack PNo ratings yet

- Environmental, Health and Safety Risks AnalysisDocument2 pagesEnvironmental, Health and Safety Risks AnalysisKrishna Patil100% (1)

- CTRA-23-STM-146 - TK - 11-995 - HotWorkDocument3 pagesCTRA-23-STM-146 - TK - 11-995 - HotWorkMohamed RizwanNo ratings yet

- Hazard Identification Risk Assessment and Control WorksheetDocument8 pagesHazard Identification Risk Assessment and Control WorksheetMERWIN ALDOVINONo ratings yet

- SWMS Loading and Unloading Vehicles WHS.127 V002.1Document18 pagesSWMS Loading and Unloading Vehicles WHS.127 V002.1Amit BhattNo ratings yet

- Explanatory and Illustrative Purposes Only: Appendix 6 - HSE Hazards & Effects Management ProcessDocument7 pagesExplanatory and Illustrative Purposes Only: Appendix 6 - HSE Hazards & Effects Management ProcessRonald AranhaNo ratings yet

- Near Miss - Identification Made Simple en & HI - PDF-1 - 12Document1 pageNear Miss - Identification Made Simple en & HI - PDF-1 - 12karpanaiNo ratings yet

- Risk Assessment-Workplace TransportDocument7 pagesRisk Assessment-Workplace TransportStelaNo ratings yet

- RA For HydrotestDocument26 pagesRA For HydrotestSandeep kumarNo ratings yet

- Brazing (Oxygen and Acetylene)Document6 pagesBrazing (Oxygen and Acetylene)My Zain100% (1)

- Jha Clarke Engine PumpDocument4 pagesJha Clarke Engine Pumpperquino oasanNo ratings yet

- Chemical SpillDocument27 pagesChemical SpillDaren BauiNo ratings yet

- PipingDocument9 pagesPipingshamierrul shahliNo ratings yet

- Risk Assessment - Usage of Overhead Crane - Ben Ching Engineering (1) .Rev.1Document3 pagesRisk Assessment - Usage of Overhead Crane - Ben Ching Engineering (1) .Rev.1Kono Nor AtanNo ratings yet

- Welding Procedure: PurposeDocument14 pagesWelding Procedure: Purposeinfos2magi856No ratings yet

- Al-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetDocument3 pagesAl-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetMustafa hse JafferNo ratings yet

- Job Safety Analysis (Jsa) : Fabrication Works, Welding Works Using Power Tools, Hand Tools, Welding Machine WapstechDocument3 pagesJob Safety Analysis (Jsa) : Fabrication Works, Welding Works Using Power Tools, Hand Tools, Welding Machine WapstechMohamedSaidNo ratings yet

- Z - MP-EHS-01 IRA - 03 Install HDPE Pipe Sleeve (1aug2023)Document3 pagesZ - MP-EHS-01 IRA - 03 Install HDPE Pipe Sleeve (1aug2023)Din JalilNo ratings yet

- ISLA JHA Removal of BarricadeDocument3 pagesISLA JHA Removal of Barricadeaasafety06No ratings yet

- Safety Data Sheet Conbextra Gp2: Revision Date: 01/01/2020 Revision: 0ADocument8 pagesSafety Data Sheet Conbextra Gp2: Revision Date: 01/01/2020 Revision: 0AAnonymous kRIjqBLkNo ratings yet

- JSA - Batching Plant OperationDocument3 pagesJSA - Batching Plant OperationNisith SahooNo ratings yet

- Vibration Risk Assessment: (Site/ Building/ Room)Document3 pagesVibration Risk Assessment: (Site/ Building/ Room)Him SiwakotiNo ratings yet

- Risk Assessment Carpentry Works For Dismantling Wooden BoxesDocument10 pagesRisk Assessment Carpentry Works For Dismantling Wooden BoxesSinaNo ratings yet

- Fan InstallationDocument2 pagesFan InstallationKrishna PatilNo ratings yet

- Risk Assesment Form For ScaffoldingDocument1 pageRisk Assesment Form For Scaffoldingchandanprakash30No ratings yet

- Safe Work ProcedureDocument5 pagesSafe Work ProcedureSurya Narayan MahapatraNo ratings yet

- Use of Power ToolsDocument3 pagesUse of Power ToolsNisanth ThulasidasNo ratings yet

- 9.risk Assessment - Working in PantryDocument2 pages9.risk Assessment - Working in PantryManzur AhmadNo ratings yet

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSDocument2 pagesProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSJohn100% (2)

- 50 MW Artistic Wind Power Project: Job Safety Analysis Worksheet (Equipment Lifting)Document3 pages50 MW Artistic Wind Power Project: Job Safety Analysis Worksheet (Equipment Lifting)Raza Muhammad SoomroNo ratings yet

- Civ 2 CasesDocument290 pagesCiv 2 CasesBediones JANo ratings yet

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Document3 pagesKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNo ratings yet

- Jsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007Document30 pagesJsa 07 (G) # Steel Structure Erection & Miscellaneous Steel-Ptj - S-007elmsm14No ratings yet

- Jsa No: 00 - Piling WorksDocument4 pagesJsa No: 00 - Piling WorksUMUTNo ratings yet

- PCC & ConcDocument4 pagesPCC & Concprasanna okNo ratings yet

- Adult Friends Diaper (Thought Process)Document2 pagesAdult Friends Diaper (Thought Process)Rohan HiremathNo ratings yet

- Disorders of Children and AdolescentsDocument13 pagesDisorders of Children and AdolescentsJay Mark Samson CabreraNo ratings yet

- Icd 10 Rajal Poli SarafDocument3 pagesIcd 10 Rajal Poli Sarafgrace efiliaNo ratings yet

- Outreach Service in Selected Local in Lagos NigeriaDocument48 pagesOutreach Service in Selected Local in Lagos NigeriaDOYINSOLA ADENUGANo ratings yet

- Confirmation of Degree Form PDFDocument2 pagesConfirmation of Degree Form PDFlouis0% (2)

- Dr. Ma. Florecilla C. Cinches Dr. Teresita T. TumaponDocument5 pagesDr. Ma. Florecilla C. Cinches Dr. Teresita T. TumaponTim ArroyoNo ratings yet

- Literature Review On OgiDocument7 pagesLiterature Review On Ogiafdtaeczo100% (1)

- FibranserinaDocument13 pagesFibranserinaLaura PadillaNo ratings yet

- Helium MsdsDocument7 pagesHelium MsdssalcabesNo ratings yet

- Effects of PollutionDocument1 pageEffects of PollutionSieben HerzenNo ratings yet

- Neonatal Antiepileptic Medication Treatment Patterns A Decade of ChangeDocument8 pagesNeonatal Antiepileptic Medication Treatment Patterns A Decade of ChangeEduardo Rios DuboisNo ratings yet

- POCKIT Central Nucleic Acid Analyzer (CE-IVD)Document2 pagesPOCKIT Central Nucleic Acid Analyzer (CE-IVD)Fadli AmbaraNo ratings yet

- Reading Comprehension 1 (SBP Trial 2016) Matching Vocabulary EnrichmentDocument8 pagesReading Comprehension 1 (SBP Trial 2016) Matching Vocabulary Enrichmentnik anisNo ratings yet

- Dry Acide Dessolution Unit FreesenuisDocument59 pagesDry Acide Dessolution Unit FreesenuisokboNo ratings yet

- Mu 31Document4 pagesMu 31Lovkesh GoyalNo ratings yet

- Rule: Pesticide Tolerance: ProthioconazoleDocument6 pagesRule: Pesticide Tolerance: ProthioconazoleJustia.comNo ratings yet

- DRUG StudyDocument43 pagesDRUG StudyNathalie Faith CotengNo ratings yet

- SOP For Training of Employees - Pharmaceutical GuidelinesDocument14 pagesSOP For Training of Employees - Pharmaceutical GuidelinesAli50% (2)

- Coxa PlanaDocument9 pagesCoxa PlanaRegine BlanzaNo ratings yet

- A Rapid Filtration Method For Harvesting Cell Cultture Grown in Cellbag Bio ReactorsDocument4 pagesA Rapid Filtration Method For Harvesting Cell Cultture Grown in Cellbag Bio ReactorsfreefreederNo ratings yet

- Aseptic TechniqueDocument34 pagesAseptic TechniqueJessa Adenig100% (1)

- The Role of The Nurse in Health Promotion PDFDocument1 pageThe Role of The Nurse in Health Promotion PDFCie Ladd0% (1)

- Tcs - Cong Van Gui DDKDocument337 pagesTcs - Cong Van Gui DDKSHIPMANAGEMENT PIONEERNo ratings yet

- Draft Visual Analysis EssayDocument5 pagesDraft Visual Analysis Essayapi-322143619No ratings yet

- Commrev - Insurance - Loti NotesDocument99 pagesCommrev - Insurance - Loti NotesCarlota Nicolas VillaromanNo ratings yet

- Memorize BiologyDocument79 pagesMemorize BiologyprthrNo ratings yet

- Natural Hygiene MagazineDocument33 pagesNatural Hygiene MagazineColm Rooney100% (1)

- Aubf Lab 4Document4 pagesAubf Lab 4Regina SalazarNo ratings yet

- Innovation at 3M - Group 3 - B2BDocument21 pagesInnovation at 3M - Group 3 - B2BRituraj BaruahNo ratings yet