Professional Documents

Culture Documents

Risk Assessment - Usage of Overhead Crane - Ben Ching Engineering (1) .Rev.1

Uploaded by

Kono Nor AtanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk Assessment - Usage of Overhead Crane - Ben Ching Engineering (1) .Rev.1

Uploaded by

Kono Nor AtanCopyright:

Available Formats

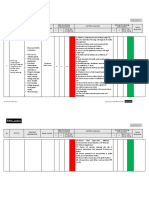

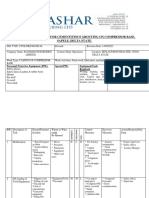

RISK ASSESSMENT FORM

Company: Ben Ching Engineering Pte Ltd

Location: Work site

Conducted by: K. Raji Reddy and Team; Wong SH, BV

Usage of Overhead Crane in

Activity : (Names, designations) Consultant.

Fabrication Workshop

Approved by:

(Name, designation) Sei Gim Hong 17 Nov 2006 As when

(Date) Last Review Date: Next Review Date: needed

1. Hazard Identification 2. Risk Evaluation 3. Risk Control

Potential Action Officer,

Existing Risk Control

No. Work Activity Hazard Consequences / S L RR Additional Risk Control Designation

Accidents (if any)

(Follow-up date)

1. Lifting of material a) Falling object Fatal, Serious a) Sound on movement of 3 1 M 1. Rule on No suspended Operator, Rigger,

in fabrication injuries. Damages to crane. load over people. Worker

workshop with equipment b) Trained workers for 2. Workers to stop work

Overhead Crane rigging. and move off area of

c) Loose objects to be load path.

bundled together before 3. PPE – helmet area.

lifting.

3 1 M

b) Lifting object Fatal or serious a) Regular maintenance of Check for abnormal noise

came down due to injuries. Damages to brake drum – yearly. and conditions during

brake drum equipment Check for wear and tear. operation by operator.

failures. b) Overhead Crane

certificate.

3 1 M

c) Failure due to As above a) Same as above. As above

lifting gears failure 1. Rigger to check slings

b) Lifting gear certificates. and gears lifting

capacities at various

configurations prior to

lifting.

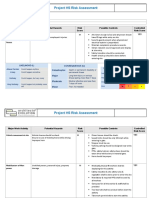

Risk Assessment Register - Draft

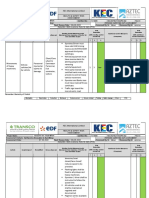

RISK ASSESSMENT FORM

Company: Ben Ching Engineering Pte Ltd

Location: Work site

Conducted by: K. Raji Reddy and Team; Wong SH, BV

Usage of Overhead Crane in

Activity : (Names, designations) Consultant.

Fabrication Workshop

Approved by:

(Name, designation) Sei Gim Hong 17 Nov 2006 As when

(Date) Last Review Date: Next Review Date: needed

1. Hazard Identification 2. Risk Evaluation 3. Risk Control

Potential Action Officer,

Existing Risk Control

No. Work Activity Hazard Consequences / S L RR Additional Risk Control Designation

Accidents (if any)

(Follow-up date)

2. Ensure all lifting gears

are certified / tested

3. Regular inspection every

3 months

4. Colour code lifting gears

5. Damaged or uncertified

lifting gear and tackle

found on site to be

removed/ disposed

immediately

As above Yearly load tested of 3 1 M Check for abnormal noise

d) Failure of crane overhead crane. and conditions during

structure. operation by operator

e) Hit by Swing As above a) Trained crane operators 2 1 L

object b) Tag lines to prevent

excessive swing.

f) Electrocution due Fatal or serious Regular maintenance of 3 1 M Report any sign of cable

to electrical faults. electric shock electrical motor – yearly by damages by operators.

LEW

Risk Assessment Register - Draft

RISK ASSESSMENT FORM

Company: Ben Ching Engineering Pte Ltd

Location: Work site

Conducted by: K. Raji Reddy and Team; Wong SH, BV

Usage of Overhead Crane in

Activity : (Names, designations) Consultant.

Fabrication Workshop

Approved by:

(Name, designation) Sei Gim Hong 17 Nov 2006 As when

(Date) Last Review Date: Next Review Date: needed

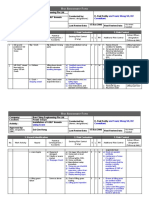

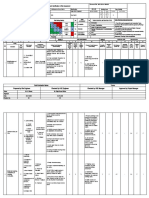

1. Hazard Identification 2. Risk Evaluation 3. Risk Control

Potential Action Officer,

Existing Risk Control

No. Work Activity Hazard Consequences / S L RR Additional Risk Control Designation

Accidents (if any)

(Follow-up date)

Likelihood Remote Occasional Frequent

Severity (1) (2) (3)

Major (3) M H H

Moderate (2) L M H

Minor (1) L L M

Risk Assessment Register - Draft

You might also like

- Job Safety Analysis Roof Plumbing - Working On Roofs Construction & RepairDocument14 pagesJob Safety Analysis Roof Plumbing - Working On Roofs Construction & RepairLokesh AravindanNo ratings yet

- Risk Assessment for Overhead Line Relocation ProjectDocument5 pagesRisk Assessment for Overhead Line Relocation Projectghada gattouchNo ratings yet

- Risk Assesment Form ScaffoldDocument10 pagesRisk Assesment Form ScaffoldRejin PradeepNo ratings yet

- Ra For Hot Work (Welding & Cutting Works)Document3 pagesRa For Hot Work (Welding & Cutting Works)Abrar AhmedNo ratings yet

- Block Work (Unit Masonary) RISK ASSESSMENTDocument8 pagesBlock Work (Unit Masonary) RISK ASSESSMENTVimal ViswanathNo ratings yet

- AHA Roofing SystemDocument8 pagesAHA Roofing SystemLawrence adeleke Omisakin100% (1)

- 002 Excavation & TrenchingpdfDocument3 pages002 Excavation & Trenchingpdfghada gattouch100% (1)

- Scaffolding Erection and DismantlingDocument14 pagesScaffolding Erection and DismantlingDylan GreyNo ratings yet

- Risk Assessment Steel FixingDocument1 pageRisk Assessment Steel Fixingmohamed ghalyNo ratings yet

- Risk Assessment FOR: Over Head Crane ErectionDocument9 pagesRisk Assessment FOR: Over Head Crane ErectionZameer AhmedNo ratings yet

- Chipping Work by MCDocument1 pageChipping Work by MCChandruNo ratings yet

- Plant and Traffic Movement: L S Risk Score Risk Rating L S Risk Score Risk RatingDocument11 pagesPlant and Traffic Movement: L S Risk Score Risk Rating L S Risk Score Risk RatingRAMANo ratings yet

- PTW272 - Asphalt Paving 17-01-2023Document22 pagesPTW272 - Asphalt Paving 17-01-2023Shah Muzzamil0% (1)

- Risk Assessment-Instllation & Fabrication of Steel Structural WorkDocument3 pagesRisk Assessment-Instllation & Fabrication of Steel Structural WorkKono Nor AtanNo ratings yet

- Risk Assessment-Instllation & Fabrication of Steel Structural WorkDocument3 pagesRisk Assessment-Instllation & Fabrication of Steel Structural WorkKono Nor AtanNo ratings yet

- Risk Assessment Cutting Plates Oxygen-Di AcetyleneDocument2 pagesRisk Assessment Cutting Plates Oxygen-Di AcetyleneandreNo ratings yet

- Lesson 4 Laws On Partnership and CorporationDocument34 pagesLesson 4 Laws On Partnership and CorporationGerstene Reynoso MaurNo ratings yet

- Risk Assessment Ground Collapse 8Document5 pagesRisk Assessment Ground Collapse 8Ali Almarshad100% (1)

- Risk Assessment Distribution Board DB Junction Box Junction Box InstallationDocument6 pagesRisk Assessment Distribution Board DB Junction Box Junction Box InstallationAnonymous HeA9HEbtDmNo ratings yet

- Block Work and PlasteringDocument7 pagesBlock Work and Plasteringmohammed sohailNo ratings yet

- Demurrer Draft 5Document4 pagesDemurrer Draft 5AJ of SB19No ratings yet

- Job Safety Analysis Worksheet: JGC Penthouse Extension BLDGDocument2 pagesJob Safety Analysis Worksheet: JGC Penthouse Extension BLDGCherry BetonioNo ratings yet

- Risk Assessment Carpentry Works For Dismantling Wooden BoxesDocument10 pagesRisk Assessment Carpentry Works For Dismantling Wooden BoxesSinaNo ratings yet

- 31.HIRA - Boom Placer OperationDocument3 pages31.HIRA - Boom Placer OperationMMRDACA07 SAFETYNo ratings yet

- Risk Assessment: Method Statement Painting ActivitiesDocument11 pagesRisk Assessment: Method Statement Painting ActivitiesWalid Amdouni100% (1)

- Plant and Equipment Risk Assessment Fgoc - NewDocument13 pagesPlant and Equipment Risk Assessment Fgoc - Newmajid khanNo ratings yet

- RA-for Glass Installation 30-04-2022Document6 pagesRA-for Glass Installation 30-04-2022Muideen Oyedele100% (2)

- Construction Safety: Page 1 of 4Document4 pagesConstruction Safety: Page 1 of 4ryan.aniceteNo ratings yet

- Qrc-Ra-001-00-Road and Footpath Modification WorksDocument27 pagesQrc-Ra-001-00-Road and Footpath Modification WorksKallem RajashekarNo ratings yet

- Job Safety Analysis For Civil WorkDocument9 pagesJob Safety Analysis For Civil Worksakthi venkatNo ratings yet

- RA 02 - Earth WorkDocument38 pagesRA 02 - Earth WorkAnonymous kWfNFb100% (2)

- Risk Assessment of Block Works and Plastering WorksDocument7 pagesRisk Assessment of Block Works and Plastering Worksfaizan khanNo ratings yet

- Samsung Scaffold Risk Assesment 2Document7 pagesSamsung Scaffold Risk Assesment 2Saleem AkhtarNo ratings yet

- Risk Assessment Lifting Operations PDFDocument6 pagesRisk Assessment Lifting Operations PDFkim alfonsoNo ratings yet

- Deshuttering WorkDocument1 pageDeshuttering WorkAhmed AbdulfatahNo ratings yet

- Daily JSA - Diesel FillingDocument3 pagesDaily JSA - Diesel Fillingshoaib akhtarNo ratings yet

- Basic Principles of Contract Drafting - ULapland 2015Document50 pagesBasic Principles of Contract Drafting - ULapland 2015Aditi MehtaNo ratings yet

- Installation of Diesel GeneratorDocument12 pagesInstallation of Diesel Generatoramal100% (1)

- Risk Assessment - Site Establishment - 2021Document6 pagesRisk Assessment - Site Establishment - 2021Asakundwi Mukhwa100% (1)

- Risk Assessment - Vessel InstallationDocument5 pagesRisk Assessment - Vessel InstallationKono Nor AtanNo ratings yet

- Hazard Risk Assessment and Control at Godrej Project SiteDocument11 pagesHazard Risk Assessment and Control at Godrej Project SiteRajput AmitNo ratings yet

- Risk Assessment-Maintance of Tanks, VesselsDocument5 pagesRisk Assessment-Maintance of Tanks, VesselsKono Nor AtanNo ratings yet

- Risk Assessment-Maintance of Tanks, VesselsDocument5 pagesRisk Assessment-Maintance of Tanks, VesselsKono Nor AtanNo ratings yet

- Risk Assessment What Work Excavation Work With Help of JCB Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDDocument2 pagesRisk Assessment What Work Excavation Work With Help of JCB Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDhemant yadav0% (1)

- Ra For Night PDFDocument23 pagesRa For Night PDFsoliman fathyNo ratings yet

- JHA FOR CEMENTITIOUS GROUTING ON COMPRESSOR BASEDocument8 pagesJHA FOR CEMENTITIOUS GROUTING ON COMPRESSOR BASEaloysius akpanNo ratings yet

- HIRA - Fixed Scaffold and Wall BreakingDocument6 pagesHIRA - Fixed Scaffold and Wall BreakingSujan Augustin100% (2)

- Paz Reyes Aguam Vs CADocument1 pagePaz Reyes Aguam Vs CARaiza SunggayNo ratings yet

- Project HS Risk AssessmentDocument8 pagesProject HS Risk AssessmentParasNo ratings yet

- Risk Assessment Sheet For Installation of Wooden DoorsDocument3 pagesRisk Assessment Sheet For Installation of Wooden Doorsrajat100% (1)

- Risk Assessment-Pnuematic Test. DraftDocument3 pagesRisk Assessment-Pnuematic Test. DraftKono Nor AtanNo ratings yet

- Risk Assessment-Pnuematic Test. DraftDocument3 pagesRisk Assessment-Pnuematic Test. DraftKono Nor AtanNo ratings yet

- C/M or P Excavation SafetyDocument1 pageC/M or P Excavation SafetyHafiz SabriNo ratings yet

- P111-Rsme-Tra-007 - Tra For Cold Tie inDocument5 pagesP111-Rsme-Tra-007 - Tra For Cold Tie inDarius DsouzaNo ratings yet

- (Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)Document3 pages(Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)krisNo ratings yet

- CCBPI v. Menez G.R. 209906 Nov. 22 2017Document2 pagesCCBPI v. Menez G.R. 209906 Nov. 22 2017V CruzNo ratings yet

- Article 1822, 1823, and 1824Document3 pagesArticle 1822, 1823, and 1824maria cruzNo ratings yet

- Class Action Suit: Derivative or Representative SuitDocument17 pagesClass Action Suit: Derivative or Representative Suitrahul bhaskarNo ratings yet

- Job Safety Analysis: 10.06.2017 Page 1 of 7Document7 pagesJob Safety Analysis: 10.06.2017 Page 1 of 7Raghava RichhuNo ratings yet

- Risk Assessment Erection of Precast Concrete ElementsDocument2 pagesRisk Assessment Erection of Precast Concrete ElementsBunyamin Selimoglu100% (1)

- HAZARD IDENTIFICATION AND RISK ASSESSMENT FOR SUSPENDED CEILING WORKSDocument4 pagesHAZARD IDENTIFICATION AND RISK ASSESSMENT FOR SUSPENDED CEILING WORKSfaizan khanNo ratings yet

- Brief History Criminology Philippines covers founding schools lawsDocument1 pageBrief History Criminology Philippines covers founding schools lawsJohn Alcher Enricoso75% (4)

- 23 JSA For Block WorkDocument2 pages23 JSA For Block WorkWakil AhmadNo ratings yet

- Risk Assessment:: Corresponding Permit To Work NoDocument4 pagesRisk Assessment:: Corresponding Permit To Work NoNaseemandson TeamNo ratings yet

- Hira RCC Cement MillDocument2 pagesHira RCC Cement MillRajuNo ratings yet

- Job Safe Practices for Overhead Crane Operation (JSP 08Document4 pagesJob Safe Practices for Overhead Crane Operation (JSP 08Farooq MohammadNo ratings yet

- Environmental, Health and Safety Risks AnalysisDocument3 pagesEnvironmental, Health and Safety Risks AnalysisKrishna PatilNo ratings yet

- HIRA For Waterproofing Work at B-Hub ProjectDocument8 pagesHIRA For Waterproofing Work at B-Hub ProjectRajat Kumar MishraNo ratings yet

- HAZARD IDENTIFICATION AND RISK ASSESSMENTDocument31 pagesHAZARD IDENTIFICATION AND RISK ASSESSMENTNikhil ManjrekarNo ratings yet

- Shifting of Materials by Double HydraDocument1 pageShifting of Materials by Double HydraShahid RazaNo ratings yet

- Environmental, Health and Safety Risks AnalysisDocument2 pagesEnvironmental, Health and Safety Risks AnalysisKrishna Patil100% (1)

- Risk assessment and control measures for concreting activityDocument2 pagesRisk assessment and control measures for concreting activityHSE1 SHAMNET0% (1)

- JSA Gathering Tent: Basic Job Step Potential Hazards Controls Action PartyDocument4 pagesJSA Gathering Tent: Basic Job Step Potential Hazards Controls Action PartyMuhammad TariqNo ratings yet

- Installation of Seismic Stoppers and Elastomeric BearingsDocument51 pagesInstallation of Seismic Stoppers and Elastomeric BearingsPlanning C7100% (1)

- Amity Law School, Amity University Lucknow SESSION-2021-2024 NTCC Assignment (Report)Document31 pagesAmity Law School, Amity University Lucknow SESSION-2021-2024 NTCC Assignment (Report)Tanya SinghNo ratings yet

- Argumentative Essay AbortionDocument2 pagesArgumentative Essay Abortion• •ZaraYtMeteor• •No ratings yet

- Noriega v. Sison, A.C. No. 2266, 27 October 1983-Public Officials and The Practice of LawDocument1 pageNoriega v. Sison, A.C. No. 2266, 27 October 1983-Public Officials and The Practice of LawJosal PusoNo ratings yet

- The Parties Met Twice On 2/28/18, and 3/4/18Document11 pagesThe Parties Met Twice On 2/28/18, and 3/4/18court filingsNo ratings yet

- DUW10022 & DUW 10012: CHAPTER 3: Incident PreventionDocument35 pagesDUW10022 & DUW 10012: CHAPTER 3: Incident PreventionDanial Azhad YusreyzalNo ratings yet

- Sison Vs Atty ValdezDocument4 pagesSison Vs Atty ValdezCaleb Josh PacanaNo ratings yet

- Grade 7/8 Caregiving and Dressmaking Home Economics CourseDocument2 pagesGrade 7/8 Caregiving and Dressmaking Home Economics CourseEdilbert Bonifacio Gayo0% (1)

- Rescissible Contracts ExplainedDocument8 pagesRescissible Contracts ExplainedIvan Ruzzel PesinoNo ratings yet

- Problem TreeDocument3 pagesProblem TreeScribdTranslationsNo ratings yet

- Deles Vs AragonaDocument13 pagesDeles Vs AragonaJan BeulahNo ratings yet

- 07f5c Indias Third Gender - From Recognition To EmancipationDocument11 pages07f5c Indias Third Gender - From Recognition To EmancipationRAHUL HEERADASNo ratings yet

- ADR Criminal Cases BangladeshDocument18 pagesADR Criminal Cases BangladeshMH MOHSINNo ratings yet

- QUESTIONNAIRE 2 As of 1116 November 16Document15 pagesQUESTIONNAIRE 2 As of 1116 November 16Jale Ann A. EspañolNo ratings yet

- Risk Acknowledgement and Consent FormDocument2 pagesRisk Acknowledgement and Consent FormheunjuNo ratings yet

- Section 366, 366A, 366BDocument2 pagesSection 366, 366A, 366BAnkit KumarNo ratings yet

- Benami Property TransactionDocument27 pagesBenami Property TransactionBalaji KondaNo ratings yet

- FIA Act MCQs by Study River Institute of Competitive ExamsDocument18 pagesFIA Act MCQs by Study River Institute of Competitive ExamsNATIONAL JOBS OFFICIAL100% (1)

- GalaDocument2 pagesGalaMaeve AguerroNo ratings yet

- Conditions Restraining Alienation NotesDocument7 pagesConditions Restraining Alienation NotessunidhiNo ratings yet

- Trends_Q2_Module2-DECEMBER-11Document18 pagesTrends_Q2_Module2-DECEMBER-11magnothea2005No ratings yet

- JESUS D. CARBAJOSA vs. JUDGE HANNIBAL R. PATRICIODocument2 pagesJESUS D. CARBAJOSA vs. JUDGE HANNIBAL R. PATRICIOkristian datinguinooNo ratings yet

- Criminal Law 1 NotesDocument7 pagesCriminal Law 1 NotesMaki CabuenaNo ratings yet