Professional Documents

Culture Documents

Tenside Phosphate Ester

Uploaded by

Dr Pinklesh AroraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tenside Phosphate Ester

Uploaded by

Dr Pinklesh AroraCopyright:

Available Formats

REVIEW ARTICLE

y Pinklesh Arora, Rakhi Singh, Geetha Seshadri and Ajay Kumar Tyagi

Synthesis, Properties and Applications

of Anionic Phosphate Ester Surfactants:

A Review

This paper reviews the various technologies involved in the syn- several factors such as the type of alcohols used as raw ma-

thesis of anionic phosphate ester surfactants. Use of base mate- terial, phosphating agents, degree of ethoxylation of alco-

rial such as alcohol ethoxylates, alkyl phenol ethoxylates, fatty hols, synthesis process and mono/diester ratio. In this pa-

acid ethoxylates and phosphating reagents plays a key role on per, the effect of base materials (alcohols), phosphating

Tenside Surfactants Detergents downloaded from www.hanser-elibrary.com by Hanser - Library on July 31, 2018

the applications and properties of phosphate ester surfactants. agents, and synthesis procedure on the properties of phos-

Also roles are played by the reaction conditions maintained phate esters and their applications has been discussed and

and charging conditions on the mono-diester ratio. In this paper correlations are established.

attempt has been made to review the base materials used for

the synthesis of phosphate esters, synthesis processes and their 2 Base Materials

effect on the properties of phosphate esters, applications and

global scenario of phosphate ester surfactants. Phosphate esters are anionic surfactants which are produced

by phosphation of aliphatic or aromatic (ethoxylated) alco-

Key words: Phosphate esters, surfactants, alcohol ethoxylates, hols [4]. The reaction of alcohols with phosphating agents

phosphation is depicted in Fig. 1. The properties of phosphate esters can

be altered by the type of alcohol used as raw material and

degree of ethoxylation of the alcohol [5].

For personal use only.

Synthese, Eigenschaften und Anwendungen von anioni- The most common base materials, which are used for

schen Phosphatestertensiden: Ein Übersichtsbeitrag. In synthesizing phosphate esters, include fatty alcohol ethoxy-

diesem Artikel werden die verschiedenen Technologien, die bei lates, alkyl phenol ethoxylates, sorbitan ester ethoxylates,

der Synthese anionischer Phosphatester-Tenside eine Rolle spie- fatty amine ethoxylates and ethylene oxide-propylene oxide

len, dargestellt. Die Verwendung der Ausgangsmaterialien wie copolymers [3]. The hydroxy functional hydrophobe typically

Alkoholethoxylate, Alkylphenolethoxylate, Fettsäureethoxylate consists of from 1 to 30 carbons of linear or branched, ali-

und Phosphatierungsreagenzien spielt eine Schlüsselrolle bei phatic, olefinic, or aromatic hydrocarbon. They are ethoxy-

den Anwendungen und Eigenschaften von Phosphatestertensi- lated with the degree of ethoxylation ranging from 0 to 50

den. Auch spielen die beibehaltenen Reaktionsbedingungen ethylene oxide units [6] responsible for hydrophilicity.

und Aufladungsbedingungen auf das Mono-Diester-Verhältnis

eine Rolle. In dieser Arbeit wurde versucht, die für die Synthese 2.1 Alcohol Ethoxylates

von Phosphatestern verwendeten Ausgangsmaterialien, Synthe-

seprozesse und ihre Wirkung auf die Eigenschaften von Phos- Alcohol ethoxylates are based on either synthetic or natural

phatestern, Anwendungen und das globale Szenario von Phos- fatty alcohols. Synthetic alcohol ethoxylates are produced by

phatestertensiden zu überprüfen. direct ethoxylation of alcohols, whereas natural fatty alcohols

are first reduced to make them saturated before going for

Stichwörter: Phosphatester, Tenside, Alkoholethoxylate, Phos- ethoxylation. Both synthetic and natural alcohol ethoxylates

phatierung are used as nonionic surfactants in many industries [7]. Al-

cohol ethoxylates having a degree of ethoxylation or ethylene

oxide moles (EO moles) of 6 – 10 are used as surfactants in

detergents, ethoxylation greater than 10 is used in lime soap

1 Introduction

as dispersants, wetting agents and emulsifiers. The fatty al-

cohol ethoxylates are non-ionic surfactants which are widely

Phosphate esters are highly versatile anionic surfactants

used in washing detergents both domestic and industrial.

with a useful combination of multifunctional properties.

These are used as wetting and cleaning agents in cosmetics,

Compared to other anionic surfactants, phosphate esters of-

agriculture, textile, paper, oil and various other process in-

fer specific advantages including stability over a broad pH

dustries. The examples of fatty alcohol ethoxylates are lauryl

range, good solubility and corrosion inhibiting properties.

Phosphate esters are highly suitable for use as emulsifying

agents, wetting agents, anti-static agents, corrosion inhibi-

tors, lubricants, fire retardants, hydraulic fluids, paints and

coatings, emulsifiers, plasticizers and hydrotropes in clean-

ing formulations [1].

Phosphate esters are known for exhibiting mild and non-

irritating properties [2]. Phosphate esters are widely used as

lubricants and hydraulic fluids because of high performance

and safety advantage over others due to their high thermal

stability [3]. The properties of phosphate esters depend on Figure 1 Reaction scheme of alcohol with phosphating agent

266 ª Carl Hanser Publisher, Munich Tenside Surf. Det. 55 (2018) 4

Pinklesh Arora et al.: Synthesis, Properties and applications of anionic phosphate ester surfactants: a review

alcohol ethoxylate, stearyl alcohol ethoxylate, behenyl alcohol synthesis of phosphate esters are phosphoric anhydride

ethoxylate etc. All of these ethoxylated products vary in phys- (P2O5), polyphosphoric acid (H4P2O7), phosphorus oxychlor-

ical appearance and have different properties like pour ide [P(O)Cl3], orthophosphoric acid (H3POˇ4) and pyrophos-

point, cloud point, density, viscosity, and flash point depend- phoric acid which are summarized in Table 1.

ing on the level of ethoxylation process from which they are

formed [8]. The chemical structures of alcohol ethoxylates 3.1 Phosphoric Anhydride

present in household cleaning products are presented in

Fig. 2. Phosphoric anhydride is a thermally stable, white, free-flow-

ing powder. It is very hygroscopic, acting as powerful desic-

2.2 Fatty Acid Ethoxylates cating agent. Addition of phosphorus anhydride to alcohol

can results in a vigorous, potentially uncontrollable and ha-

Fatty acid ethoxylates are synthesized through ethoxylation zardous reaction. With primary alcohols, phosphoric anhy-

of fatty acids. These are extensively used in formulations of dride reacts preferentially. Secondary alcohols are prone to

emulsifying softeners, wetting agents, cleansing agents and undergo undesirable side reactions such as dehydration.

dispersants. The most popular application of acid ethoxy- When using P2O5 as the phosphating agent, the reaction

lates is in textile industry. The ethoxylates based on stearic yields equimolar amounts of di and monoesters with no

acid are applied in cosmetic industrial sectors as emulsifiers phosphoric acid [11]. It is possible to obtain a desirable inter-

Tenside Surfactants Detergents downloaded from www.hanser-elibrary.com by Hanser - Library on July 31, 2018

in oil-in-water type creams and lotions. Some other exam- mediate product mixture by certain multi staged reaction se-

ples of fatty acid ethoxylates are coconut fatty acid ethoxy- quences [12, 13]. The reaction of alcohol and phosphorus an-

late, lauric acid ethoxylate, oleic acid ethoxylate and myristic hydride is given in Fig. 5.

acid ethoxylates [9]. The chemical structure of fatty acid

ethoxylate is shown in Fig. 3. 3.2 Polyphosphoric Acid

2.3 Alkyl Phenol Ethoxylates Polyphosphoric acid is the concentrated grade of phosphoric

acid (H3PO4) above 95 %. It is a highly viscous colorless li-

Alkyl phenol ethoxylates are prepared by the reaction of quid. Polyphosphoric acid consists of a mixture of linear, oli-

ethylene oxide with the appropriate alkyl phenol. The most gomeric chains having alternating phosphorus and oxygen

common phosphate esters are based on nonyl phenol atoms [14]. The strength of polyphosphoric acid is com-

ethoxylate. Owing to their properties of solubility in aqueous monly expressed as a percentage of phosphoric anhydride

For personal use only.

and non-aqueous media, good emulsification and dispersion (P2O5). As the corresponding percentage of phosphoric acid

properties play an important role in making number of in- increases, the material becomes progressively more viscous.

dustrial products such as pulp and paper, textiles, coatings, Most frequently, polyphosphoric acid of about 83 – 84 %

agricultural pesticides, lubricating oils and fuels, metals and P2O5 is used. The linear polymeric structure of poly-

plastics. Alkyl phenol ethoxylates are most effectively used phosphoric acid makes it less reactive than the phosphoric

in commercial cleaning products. [4]. Most common com- anhydride. Polyphosphoric acid reacts with alcohols to pro-

mercially used products are octyl, nonyl, and dodecylphenol

with a degree of ethoxylation ranging from 4 to 40. Octyl

and nonylphenols with 8 – 12 ethylene oxide moles are used

in detergents. Compounds having ethylene oxide moles < 5

are applied in antifoaming agents or detergent in non-aque-

ous media. Ethoxylates with ethylene oxide moles ranging

from 12 to 20, are wetting agents and O/W emulsifiers.

More than 20 ethylene oxide moles exhibit detergents prop-

erties at high temperature and high salinity. The chemical Figure 3 Chemical structure of fatty acid ethoxylates

structure of alkyl phenol ethoxylates is given as Fig. 4.

3 Phosphating Agents

Phosphating agent is one important reactant for the synthe-

sis of the phosphate ester. The structure of phosphating

agent affects its reactivity and selectivity, resulting in vari-

ation in the monoester, diester, and triester product dis-

tribution [10]. The main phosphating agents used for the Figure 4 Chemical structure of alkyl phenol ethoxylates

Figure 2 Chemical structure of alcohol ethoxy-

lates

Tenside Surf. Det. 55 (2018) 4 267

Pinklesh Arora et al.: Synthesis, Properties and applications of anionic phosphate ester surfactants: a review

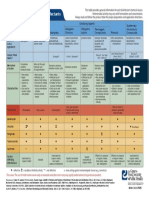

Sample No. Name Molecular Formula Structure

1 Phosphoric anhydride P2O5

2 Polyphosphoric acid (H)n+2 · (P)n · (O)3n+1

3 Phosphorus Oxychloride POCl3

Tenside Surfactants Detergents downloaded from www.hanser-elibrary.com by Hanser - Library on July 31, 2018

4 Orthophosphoric acid H3PO4

5 Pyrophosphoric acid H4P2O7

For personal use only.

Table 1 Phosphating agents for synthesis of phosphate esters

rosive. It also produces undesirable alkyl chloride, so that it

is difficult to enhance the phosphoric monoester content of

the reaction product [18].

3.4 Orthophosphoric Acid

Figure 5 Reaction of phosphoric anhydride with alcohol for synthesis of Pure orthophosphoric acid corresponds theoretically to a

phosphate esters mixture of H2O and P2O5 in the ratio of 3 moles of water to

1 mole of P2O5 and is expressed as phosphoric acid contain-

ing 72.4 % P2O5 [19]. It is a white solid that melts at 42.35 8C

duce a mixture of high monoalkyl phosphate, low dialkyl

to form a colorless, viscous liquid. Phosphoric acid is a very

phosphate and high residual phosphoric acid [15]. Reaction

polar molecule; therefore it is highly soluble in water. Phos-

of polyphosphoric acid (Fig. 6) with an alcohol results in the

phoric acid molecule can form a monoalkyl, a dialkyl, or a

cleavage of the polyphosphoric acid chain. In this reaction a

trialkyl ester by reaction with one, two, or three molecules

large amount of residual phosphoric acid is formed because

of an alcohol.

each chain produces one mole of phosphoric acid. One mole

of phosphoric acid would theoretically be produced from the

tail end of each chain, or alternatively, the amount of phos- 3.5 Pyrophosphoric Acid

phorus remaining, as H3PO4 would be equal to 1/n where n

equals the average polymer chain length. The monoalkyl to Pyrophosphoric acid is colorless, odorless, hygroscopic and

dialkyl ratio increases with increasing reaction temperature soluble in water, diethyl ether, and ethyl alcohol. It is pro-

and decreasing strength of the polyphosphoric acid [16]. duced from phosphoric acid by dehydration. Pyrophosphoric

acid and phosphoric anhydride (P2O5) are generally two dif-

3.3 Phosphorus Oxychloride ferent types of commercially used phosphating agents. The

selection of the phosphating reagent has an effect on the ra-

Phosphorus oxychloride is a highly reactive, colorless, low- tio of the components and on the functional properties of

viscosity liquid and hydrolyses in moist air to phosphoric the final product [20].

acid to release fumes of hydrogen chloride. Phosphorus oxy-

chloride is tetrahedral in shape, featuring three P–Cl bonds 4 Synthesis of Phosphate Esters

and one very strong P=O double bond. The reaction of phos-

phorous oxychloride with alcohol gives phosphate ester en- Phosphate esters are the reaction products of phosphating

rich in triester (Fig. 7). Phosphorus oxychloride is the only agent and alcohol. Typically, phosphate ester surfactants are

phosphating agent, which gives a high content of triesters produced by the reaction of alcohols with an activated phos-

[17]. It produces three moles of HCl that makes it highly cor- phorous derivative. Phosphate ester products are a mixture

268 Tenside Surf. Det. 55 (2018) 4

Pinklesh Arora et al.: Synthesis, Properties and applications of anionic phosphate ester surfactants: a review

Figure 6 Reaction of polyphosphoric acid with

alcohol for synthesis of phosphate esters

Figure 7 Reaction of phosphorus oxychloride

with alcohol for synthesis of phosphate esters

Tenside Surfactants Detergents downloaded from www.hanser-elibrary.com by Hanser - Library on July 31, 2018

Figure 8 Reaction of orthophosphoric acid with

alcohol for synthesis of phosphate esters

of monoalkyl phosphate (monoester), dialkyl phosphate (die- of ethoxylated alcohols with 115 % to 116 % polyphosphoric

For personal use only.

ster), residual alcohol and residual phosphoric acid [21]. acid at ambient temperature [25].

There can be a range of phosphate esters depending upon The phosphate esters with high monoalkyl content are

the base material used. For example, if the base material is generally made by reacting the base alcohol or alcohol ethox-

ethoxylated tridecyl alcohol, several products can be of vary- ylates with polyphosphoric acid [19]. In this method the pro-

ing the number of moles of ethylene oxide attached to the duct has a higher amount of residual phosphoric acid which

alcohol. A series of products with a wide range of properties is undesirable in the use of personal care applications [18].

can be obtained. The quality and properties of phosphate es- The presence of high level of residual phosphoric acid may

ters can be altered by selection of base materials, phosphat- cause the phase separation problem in formulation [12].

ing agents and reaction conditions [22]. Phosphate ester with a high amount of monoester can be

There are various patented methods available for the syn- prepared by the esterification of the alcohol with a two-step

thesis of phosphate ester surfactants. Mostly, application reaction. In the first step, the organic hydroxy compound is

based methodology has been followed to develop the product esterified in the presence of an excess amount of one or

mixture of the targeted ratio of the monoester, diester, residu- more phosphating agents selected from the group consist-

al phosphoric acid and ethoxylates i. e. the base materials can ing of phosphorus pentoxide, phosphoric acid and poly-

be adjusted to get the desired applicability of the final pro- phosphoric acids. In the second step, a further portion of

duct. the same organic hydroxy compound is added to the reac-

For personal care applications, high content of monoalkyl tion mixture of the first step. The reaction product on the

ester, low level of residual phosphoric acid and residual alco- analysis shows the 80.5 % monoalkyl phosphate, 7.8 % of

hol formulations are most preferred. Monesters are also pre- dialkyl phosphate and 11.7 % of orthophosphoric acid [21].

ferred over diesters due to their excellent detergency, foam In an industrial process of phosphate ester preparation

formation, stability, low surface tension and skin irritation using the P2O5 method, a reaction product has an enriched

[4]. The presence of high content of diesters causes poor de- amount of monoalkyl phosphate and a reduced amount of

tergency, low water solubility and foaming. Many mono- orthophosphoric acid depending on product. In this method

esters with relatively high percentage diesters, display in- the base material (alcohol ethoxylate) is added in two steps,

creased surface tension in aqueous solution and reduces so that the reaction product has an enhanced ratio of

their cleansing effectiveness [23]. Furthermore, a large monoester to the diester. The phosphating agent, P2O5 is

amount of residual alcohol causes low solubility, skin irrita- added to one mole of alcohol and the reaction was carried

tion and haziness to formulation, while the presence of re- out at 80 8C for one hour [19].

sidual phosphoric acid increases the viscosity of solution The typical phosphation processes do not produce pro-

making it unmanageable for formulations. Hence, it is ne- ducts with the high monoalkyl phosphate together with the

cessary to remove the excess alcohol and phosphoric acid low dialkyl phosphate, low phosphoric acid and residual al-

from the product [24]. A composition containing a high con- cohol contents. In the reaction process a phosphating agent

tent of monoester of at least 95 % is so effective in solubiliz- is selected to use in a single step, solventless process having

ing that they do not require the presence of additional compositions with high level of monoalkyl phosphate, low

hydrotropes to prevent precipitation of other active ingredi- levels of free phosphoric acid and residual alcohol. The

ents and have high chemical stability. The desired ester is phosphating reagent is prepared by blending of phosphoric

obtained by mixing stoichiometric equivalents of a mixture anhydride with phosphoric acid to form a slurry or paste. It

Tenside Surf. Det. 55 (2018) 4 269

Pinklesh Arora et al.: Synthesis, Properties and applications of anionic phosphate ester surfactants: a review

dissolves more easily than phosphoric anhydride and can be group is adhesion enhancement. Phosphate esters are used

added to alcohol to reduce the exothermic reaction problems as anti-wear, anti-corrosion and adhesion promoting addi-

and black chunks, which are formed during the addition of tives in metal lubricants and coatings and as anti-stripping

phosphorus anhydride [18]. This phosphating agent when agents for the aggregates in asphalt. Higher MAP content

reacted with alcohols under optimized reaction conditions contributes to higher performance in these applications [6].

yields a product having monoalkyl phosphate to diakyl phos- These high monoalkyl phosphate surfactants exhibit a un-

phate ratio greater than 80:20 with low level of residual ique combination of good detergency and low skin irritancy,

phosphoric acid and alcohol [26 – 28]. especially in comparison to alkyl sulphate or alkyl sulpho-

A process was developed for the preparation of a phospho- nate surfactant [35].

ric monoester with high purity and a lower residual ortho- Phosphate esters have an unique range of properties,

phosphoric acid content, which does not give any product which are exploited in the production of specialized chemi-

of high-viscosity gel and has good odor. In this process, reac- cal processing aids for industry [36]. They are especially use-

tion was carried out in two steps. In the first step an organic ful in household and maintenance cleaning products. Phos-

hydroxyl compound was reacted with polyphosphoric acid at phate esters are extremely soluble in alkaline solutions and

60 8C to 100 8C for 5 h. In the second step phosphorus pen- have excellent heat and chemical stability. They are very effi-

taoxide is added and the reaction was kept at 60 8C to 100 8C cient emulsifiers and provide excellent wetting properties at

for 5 – 15 h. The reaction product contains a compound hav- temperature above 50 8C. Phosphate esters have a greater

Tenside Surfactants Detergents downloaded from www.hanser-elibrary.com by Hanser - Library on July 31, 2018

ing a pyrophosphate bond, if in a large amount it increases solubility and compatibility than the nonionic surfactants

the viscosity of the product. In order to hydrolyze the pyro- from which they are derived. Applications include uses as

phosphates, water is added. The unreacted organic hydroxyl cleansing agents, emulsifiers, wetting agents and disper-

compound is removed by steam distillation [29]. sants. The choice of a phosphate ester for a specific applica-

A mixture of monoalkyl phosphate and dialkyl phosphate tion is highly dependent upon the monoalkyl to dialkyl

esters was synthesized and the structure of hexadecyl phos- phosphate ratio. Other important performance parameters

phate ester with a low mono/dimole ratio was confirmed by include the amount of residual alcohol and phosphoric acid

FTIR and NMR. The surface tensions of these alkyl phos- present in the surfactant [37, 38].

phate esters were analyzed using a surface tensiometer. The Phosphate esters have been used as fire resistant hydrau-

results showed that the critical micelle concentration (CMC) lic fluids in a wide variety of industrial processes and they

and critical surface tension of phosphate esters with a high have made a significant contribution to a safe working envi-

mono/di ratio decreases with the increase of alkyl chain ronment for operating personnel [39]. Phosphate esters are

length [30]. During the synthesis of phosphate esters, diox- used as lubricants due to good thermal stability, high film

For personal use only.

anes are formed. 1,4-dioxane is carcinogenic and has a low strength, lack of flammability, non-corrosiveness, excellent

rate of biodegradability, hence it is desirable to reduce the boundary lubrication properties, low volatility and fair hy-

formation of this material during phosphation. 1,4-Dioxane drolytic stability [28].

is produced as a by-product in the processes in which poly- Phosphate ester surfactants are also applied as surface ac-

ethylene glycol chains are in contact with even catalytic tive agents [40, 41], flame retarding agents [42 – 45], anti-

amounts of strong acid. To control the formation of 1,4-diox- freeze liquids [46], emulsifiers [47, 48], special fertilizers

ane, the phosphation reaction was carried out in two steps. [49 – 52] and in emulsion polymerization [53]. The important

In the first step the phosphoric anhydride was blended with application of aryl phosphates is in the field of hydraulic

polyphosphoric acid to form a slurry or paste under mild fluid and lubricants [54 – 56]. The aryl phosphates are also

conditions. In the second step this phosphating reagent was used as rust and corrosion inhibitors [57, 58]. The use of

mixed with alcohol ethoxylate and the reaction mixture was phosphate ester surfactants is also reported in pigment ink

kept at 100 8C for 5 h to conduct the reaction. The 1,4-diox- for jet printing [59, 60], water based ink compositions con-

ane level was found to be reduced to less than 15 ppm based taining water-soluble and water insoluble resins [61]. Other

on the total weight of the active ingredient [31, 32]. significant applications are as environmentally degradable

An amphoteric phosphate ester surfactant was synthe- pesticides due to their toxicity to a wide range of insects

sized by using polyphosphoric acid as phosphorylation re- and their relatively short residence time in the environment

agent at 80 8C and 5.5 hour reaction time. The monoalkyl [62].

phosphate content and the conversion rate was found to be

89.3 % and 97.2 % respectively [33]. 6 Global Market and Manufacturers of Phosphate Esters

5 Applications of Phosphate Esters The global phosphate ester market was valued at USD 843.9

Million in 2017 and is expected at USD 1,179.8 Million by

Phosphate esters have industrial applications due to their 2022, at a CAGR (Compound Annual Growth Rate) of

overall stability, especially in the presence of oxygen [34]. 6.9 % from 2017 to 2022. The market will grow due to high

Phosphate esters are distinguished within their class of sur- demand for phosphate esters from the Asia-Pacific region

factants because of the additional unique characteristic of and technological advancements in lubricants, surfactants,

the phosphate group. They have the broad range of applica- pesticides, fire retardants, hydraulic fluids, plasticizers, and

tions because of the versatility in structure and properties. paints and coatings for application-based end-use industries

They are excellent hydrotropes and effective coupling agents, [63]. Phosphate esters have been manufacturing worldwide

which give outstanding wetting, emulsification and deter- with different carbon chain length and ethylene oxide mo-

gency. They are widely used in emulsion polymerization, les. Asia pacific is the major manufacture of the phosphate

textile auxiliaries, maintenance chemicals, metal finishing ester. North America and Europe have stringent regulations

and many other applications. Phosphate esters of organic regarding manufacturing as well as usage of phosphate es-

hydroxyl compounds are used in a wide field as detergent, ter. Thus owing to the presence of few manufacturers in

textile treating agent, emulsifying agent, rust preventive North American and Europe, there is low production in this

and liquid ion exchanger [19]. In addition to the surfactant region [64]. The major manufacturers of phosphate esters

properties, a significant benefit provided by the phosphate are summarized in Table 2.

270 Tenside Surf. Det. 55 (2018) 4

Pinklesh Arora et al.: Synthesis, Properties and applications of anionic phosphate ester surfactants: a review

S. No. Manufactur- Location Trade Name HPTLC and GC has to be explored for the structure activity

er correlation.

1 Rhodia France Rhodafac

References

2 Akzo Nobel USA Phospholan

1. http://www.elementisspecialties.com/esweb/esweb.nsf/pages/

3 Cognis Korea Agnique surfactants-anionicsurfactants

2. Williamson, S. C.: Cleansing compositions comprising ethoxylated alcohol

4 Ashland USA Dextrol, Strodex, Zenix monoesters of phosphoric acid, U.S. Patent 4493782 (1985).

3. Report on \North America Phosphate Esters Market: By Type (Tri Aryl/Alkyl Aryl

5 Clariant Germany Hordaphos Phosphate Esters, Tri Alkyl Phosphate Ester and Bisphosphates); By Application

(Lubricants, Surfactants, Pesticides, Fire Retardants, Hydraulic Fluids, Plastici-

6 Dow Midland-USA Triton zers, Paints & Coatings, and Others); By Geography (U.S., Canada, and Mexico)

– Forecasts till 2020", 2016, Report Code-PH1001.

7 Ethox USA Ethfac 4. Derian, P. J., Tao, G., Herve, P. J. C. and Reierson, R. L.: High solids, pumpable

aqueous compositions of high monoalkyl phosphate ester salt content, U.S.

8 Chemcor USA Phoschem Patent 6262130 (2001).

5. http://www.elementisspecialties.com/esweb/esweb.nsf/pages/surfactants-

9 BASF USA Maphos anionicsurfactants.

6. Reierson, R. L., Crooks, R., Gabbianelli, A. and Warburton, S.: Phosphate Esters:

10 Librachem USA Libraphos

A natural for personal care and cosmetic applications, Cosmetic Science Tech-

11 Croda USA Crodaphos nology, T4 International, Hertfordshire (2006) 267 – 274.

Tenside Surfactants Detergents downloaded from www.hanser-elibrary.com by Hanser - Library on July 31, 2018

7. https://biokhimact.com.ua/images/catalogs/Surfactants.pdf.

12 De-forest USA Dephos 8. http://www.rimpro-india.com/articles1/surfactants-widely-used-in-industrial-

processes-fatty-alcohol-ethoxylate,-fatty-acid-ethoxylate.html.

13 Stepan USA Stepfac 9. https://sites.google.com/site/demulsifiers/home/fatty-alcohol-ethoxylate-

fatty-acid-ethoxylate-surfactants-for-industries.

14 Uniqema USA Monafax 10. Tracy, D. J. and Reierson, R. L.: Phosphate ester surfactants, Handbook of De-

tergents Part F: Production, Surfactant Science Series, edited by U. Zoller and

15 Lubrizol USA Lubrizol P. Sosis, CRC Press, Boca Raton, Florida, USA, 142 (2009) 183 – 199.

DOI:10.1201/9781420014655

16 Ilcochem Germany Ilcophos 11. Tadashi, H., Method for producing copolymerizable compound containing

functional group of phosphoric acid, US 3686371 A, 1972.

17 Lankem UK Lanphos 12. Reierson, R. L.: Phosphation reagent, US 6136221 A, 2000.

13. Thilo, V. E. and Sauer, R.: On the chemistry of condensed phosphates and ar-

18 MFG Chemicals USA Ultaphos senates. XVII. The course and products of dehydration of monophosphoric acid

H3PO4, J. Prakl. Chem. 4 (1957) 324 – 348. DOI:10.1002/prac.19570040512

19 Lakeland UK Lakeland PA 14. Clarke, F. and Lyons, J.: The alcoholysis of polyphosphoric acid, J. Am. Chem.

Soc., 88 (1966) 4401 – 4405. DOI:10.1021/ja00971a018

For personal use only.

15. Nelson, A. K. and Toy, A. D. F.: The preparation of long-chain monoalkyl phos-

Table 2 Main manufacturers of phosphate esters phates from pyrophosphoric acid and alcohols, Inorganic Chemistry 2 (1963)

775 – 777. DOI:10.1021/ic50008a026

16. Tracy, D. J. and Reierson, R. L.: Commercial synthesis of monoalkyl phosphate,

J. Surfactants and Detergents 5 (2) (2002) 169 – 172.

7 Conclusions DOI:10.1007/s11743-002-0218-9

17. P. E. Slade: Handbook of Fiber Finish Technology, Gulf Research Associate 295

(1997).

Phosphate esters are highly versatile, multifunctional anion- 18. Kurosaki, T. and Manb, A.: Method for producing a phosphoric monoester, US

ic surfactants with a useful combination of multifunctional Patent 4350645, (1982).

properties. The properties of phosphate esters depend on 19. Akira M.,, Akira, F. Shinji, T., Toshio, N. and Masayuki U.: Process for the pre-

paration of phosphoric monoester, US Patent 6034261 A, 2000.

several factors such as the type of alcohols used as raw ma- 20. http://infohouse.p2ric.org/ref/33/32804.pdf.

terial, phosphating agents, degree of ethoxylation of alco- 21. Leslie R. Rudnick: Lubricant Additives: Chemistry and applications, CRC Press,

USA; 2003, 45 – 71. DOI:10.1201/9780824747404

hols, synthesis process and mono/diester ratio of phosphate 22. Bocnig, I. A., Crutchfield, M. M. and Heitch C. W.: Phosphoric acid and Phos-

esters. Using different phosphating materials and alcohols, phates, Kirk-Othmer Encyclopedia of Chemical Technology, 3rd edn. John Wiley

a range of phosphate esters can be synthesized. Phosphate & Sons, New York, 17 (1982) 518.

DOI:10.1002/0471238961.1608151907011804.a01

esters are distinguished within their surfactant class because 23. Williamson, S. C.: Cleansing compositions comprising ethoxylated alcohol

of the additional, unique properties of the phosphate group. monoesters of phosphoric acid, US Patent 4493782, 1985.

24. Loraine, C. P., Alvino, G. and Reierson, R. L.: Aqueous surfactant compositions

They have the broad range of applications because of the of monoalkyl phosphate ester salts and amphoteric surfactants, US Patent-

versatility in structure and properties. High content of 6566408 B1, (2003).

monoalkyl ester, low level of residual phosphoric acid and 25. Katz, M. M., Hashem, M. M. and Talley, C. P.: Method of removing dioxane

from phosphate ester surfactants, US Patent 4375437 A (1983).

residual alcohol, the formulations are preferred in personal 26. Reierson, R. L.: Phosphorylation agent, process and use, EP 0675076 A2

care applications. The monoesters have excellent detergency, (2002).

27. Reierson, R. L.: Monoalkyl phosphonic acid ester production process, US

foam formation, stability, low surface tension and skin irrita- Patent US 5554781 A (1996).

tion. The presence of high content of diesters causes poor 28. Reierson, R. L.: In-situ phosphation reagent process, US Patent 5550274 A

detergency, low water solubility and foaming. Large amount (1996).

29. Reierson, R. L.: Phosphation reagent, process and use, EP 1207135 B1 (2008).

of residual alcohol causes low solubility, skin irritation and 30. Hanping Li, Yong Jin, Baozhu Fan, Rui Qi, Xinfeng Cheng and Shaojun Peng:

haziness during formulation, while the presence of residual Journal of Dispersion Science & Technology 38 (5) (2017).

DOI:10.1080/01932691.2016.1192041

phosphoric acid increases the viscosity of solution making it 31. Shinji T., Kengo, S. and Kiyoshi, A.: Process for the preparation of phosphoric

unmanageable for formulations. Phosphate esters have been monoester, US Patent 5883280 A (1999).

manufactured worldwide with different carbon chain length 32. Reierson, Robert L.: Process of making low dioxane alkoxylate phosphate es-

ters, US Patent 5463101 A (1995).

and EO moles as per their respective applications. Asia paci- 33. Ren, L. F., Wang, X. C., Qiang, T. T. and An, H. R.: Synthesis of amphoteric

fic is the major manufacturer of the phosphate ester. phosphate ester surfactant by polyphosphoric acid and its application in free-

chrome collagen fiber, Advanced Materials Research, 129 – 131(2010) 271 –

Although phosphate ester surfactants are the most pre- 275. DOI:10.4028/www.scientific.net/AMR.129-131.271

ferred materials in many areas of application not much in- 34. Johnson, D. W. and Hils, J. E.: Phosphate esters, thiophosphate esters and

formation is available on the structure-activity correlation of metal thiophosphates as lubricant additives, Lubricants 1(4) (2013) 132 – 148.

DOI:10.3390/lubricants1040132

phosphate esters. A sophisticated technique such as NMR 35. Imokawa, G.: Study on skin-irritating and biological properties of monoalkyl

has been the most commonly used technique, based on phosphate anionic surfactants, J. Am. Oil Chem. Soc. 56 (1979) 604 – 609.

PMid:479492; DOI:10.1007/bf02660246

which structure activity correlations have been established. 36. Witt W. J. D.: Four corners, J. Am. Oil Chem. Soc. 49 (1972) 362 – 370.

The use of other techniques such as viscosity, HPLC, DOI:10.1007/BF02628902

Tenside Surf. Det. 55 (2018) 4 271

Pinklesh Arora et al.: Synthesis, Properties and applications of anionic phosphate ester surfactants: a review

37. http://surchem.pl/pl/kosmetyki/pdf/ Bibliography

Lieferprogramm_Phosphate%20Esters.pdf

38. Ghesner, I. and Horton, D. P.: Gelled hydrocarbons for oilfield processes, DOI 10.3139/113.110570

phosphate ester compounds useful in gellation of hydrocarbons and methods Tenside Surf. Det.

for production and use thereof, US Patent-7972996 B2, (2011). 55 (2018) 4; page 266 – 272

39. Phillips, W. D.: Phosphate ester hydraulic fluids, Handbook of Hydraulic Fluid ª Carl Hanser Verlag GmbH & Co. KG

Technology, IInd Edition, CRC Press, 833 – 891 (2011). PMid:22128728; ISSN 0932-3414

DOI:10.1201/b11225 – 20

40. Fogel, A. W.: Neutralization of phosphate esters, compositions based upon and

methods using same, US Patent-6417238 B1 (2002).

y Correspondence address

41. Fogel, A. W.: Neutralization of phosphate esters, compositions based upon and

methods using same, US Patent-6828352 B2 (2004). Dr. Pinklesh Arora

42. Hall, S. A. and Jacobson, M.: Hexaethyl tetraphosphate and tetraethyl pyro- Shriram Institute for Industrial Research,

phosphate, Ind. Eng. Chem., 40 (1948) 694 – 699. 19 University Road

DOI:10.1021/ie50460a024 Delhi – 110007

43. Cefn, B. and Antonie, W. J.: Fog reduction in polyurethane foam using phos- India

phate esters, US Patent-5958993 (1999). Tel.: +91112766 7267

44. Magendie, Franke: Weidnann Ulrich, Flame-proofing agents, US Patent- Fax: +91112766 76 76

7053138 B2 (2006). E-Mail: pinklesh@shriraminstitute.org

45. Paul, M.: Aryl phosphate ester fire-retardant additive for low-smoke vinyl appli-

cations, J. Vinyl and Additive Technology 10 (2004) 187 – 192.

DOI:10.1002/vnl.20028 The authors of this paper

46. Haak, J. L. and Mohr, P. H.: Organophosphate-containing antifreeze, US Patent-

4613445 (1986).

Tenside Surfactants Detergents downloaded from www.hanser-elibrary.com by Hanser - Library on July 31, 2018

47. Pereira, A. G., Obukowho, P., Garcia, M. G. and King, N.: Fatty alcohol phos- Dr. Pinklesh Arora, has done her Ph. D. in 2009 from C.C.S. University, Meerut, In-

phate ester emulsifier compositions, US Patent-6117915 A (2000). dia. She has 11 years experience in Shriram Institute for Industrial Research, Delhi,

48. John, I. and John H.: Alkoxylated silicone phosphate esters as emulsifiers, US India in the field of surfactants, polymers, polymer nanocomposites and adhesives.

Patent-5382381 A (1995). She has been worked on various national and international R & D projects. She has

49. Spencer, V. E. and Stewart, R.: Phosphate studies: I. soil penetration of some authored one book, five research papers and five conference papers in her credit.

organic and inorganic phosphates, Soil Sci. 38 (1) (1934) 65 – 79.

DOI:10.1097/00010694-193407000-00005 Dr. Rakhi Singh has done her Ph. D. from B.R. Ambedkar University, Agra, India in

50. Bancroft, W. D., Rutzler, J. E. and Wilson, J. K.: Soluble organic phosphate ferti- 2007. She has got 11 years experience in Shriram Institute for Industrial Research,

lizer materials, USP-2213513 A (1940). Delhi, India as Scientist in the field of development and modification of surfactants,

51. Konzak, C. F. and Polle, E. A.: Processes for producing ethylene glycol phos- optical polymers, perm-selective membranes and analytical chemistry. She has also

phate esters and foliar fertilizers containing same, US Patent-5372627 A research experience on method development and validations of various national

(1994). and international R & D projects. She has authored two chapters in book, two re-

52. Konzak, C. F. and Polle, E. A.: Foliar phosphate fertilizers, US Patent-6436165 search papers and four conference papers in her credit.

B1 (2002).

53. Donald, H. Lorenz and Williams, E. P.: Method of emulsion polymerization

Dr. Geetha Seshadri, Assistant Director & Chief, has done her Ph. D. from Dr. B. R.

using phosphate esters of normal alkanols as surfactant, US Patent-

Ambedkar University, Agra, India in 2001. She has 22 years research experience in

For personal use only.

3963688 A (1976). the areas of fluoropolymers, surfactants, optical polymers, polymer nanocompo-

54. Philip, M. and Edwards, D.: Phosphate ester lubricants, EP-0349093 B1 sites, block co-polymers & tetrazole, perm-selective membranes and lubricants etc.

(1992). She has authored one book, more than 30 research and conference papers and 13

55. Peter, D.: Regeneration of phosphate ester lubricating fluids, US Patent patents. She has headed various research projects from national and international

5661117 A (1997). agencies.

56. Brown, K.: Condition-monitoring of phosphate ester hydraulic fluids, machinery

lubrication, http://www.machinerylubrication.com/Read/424/phosphate-

ester-hydraulic-fluids Dr. Ajay Kumar Tyagi, Senior Assistant Director & Chief and Head of the Depart-

57. Martin R. L.: Reaction product of nitrogen bases and phosphate esters as cor- ment, Material Science Division has 33 years of research experience. He has com-

rosion inhibitors, US Patent 5380466 A (1995). pleted his Ph.D in 1998 from Kanpur University, Kanpur, India. His research experi-

58. Person, H. K. L., Besse, M. E., Schmidt, B. E. and Sykes, C. S.: Alkyl ether amine ence is exclusively in the fields of polymer synthesis and their modifications such as

conveyor lubricants containing corrosion inhibitors, WO/1997/045509 A1 polylactide, polyglycolide, glycolide-caprolactone copolymers, styrene – butadiene

(1997). – styrene triblock copolymer, perfluorinated lubricating oil from hexafluoro propy-

59. Martin, T. W.: Pigmented inkjet inks containing phosphated ester derivatives, lene as radiation resistant materials, polyurethane based perm selective mem-

US patent 5972089 A (1999). branes, dry lubricants, adhesives and derivatization of natural polymers etc. He has

60. Martin, T. W., Pigmented inkjet inks containing phosphated ester derivatives, executed various national and international research projects. He has published

EP-848045 B1 (2001). more than 35 research papers in national and international journals and five pa-

61. Omatsu, T. and Kawauchi, K.: Water based pigment ink composition, US pa- tents. He is a member of Association of Carbohydrate Chemists and Technologists

tant-2005234150 A1 (2005). (India).

62. Barr, D. B., Bravo, R., Weerasekera, G., Caltabiano, L. M., Whitehead, R. D., Jr.,

Olsson, A. O., Caudill, S. P., Schober, S. E., Pirkle, J. L., Sampson, R. J. and

Needham, L. L.: Concentrations of dialkyl phosphate metabolites of organo-

phosphorus pesticides in the U.S. population, Environ. Health Perspect. 112

(2004) 186 – 200. PMid:14754573; DOI:10.1289/ehp.6503

63. Report on Phosphate Ester Market by Type (Triaryl Phosphate Esters, Trialkyl

Phosphate Esters, Alkyl Aryl Phosphate Ester), Application (Lubricants, Surfac-

tants, Pesticides, Fire Retardants), Region (North America, Europe, Asia-Pacific)

– Global Forecast to 2022, Report Code: CH 4050, 2017.

64. http://www.mrrse.com/phosphate-esters-market

Received: 18. 01. 2018

Revised: 16. 03. 2018

272 Tenside Surf. Det. 55 (2018) 4

You might also like

- CH 1Document44 pagesCH 1Dave CNo ratings yet

- Coatings 06 00024 PDFDocument22 pagesCoatings 06 00024 PDFcvazquez999No ratings yet

- Lieferprogramm Phosphate EstersDocument12 pagesLieferprogramm Phosphate Estersjangri1098100% (1)

- Fertilizer Technology MCQ PDFDocument13 pagesFertilizer Technology MCQ PDFKapilSahu75% (4)

- Measuring phosphorus in waterDocument17 pagesMeasuring phosphorus in waterMarcelino Putra PerdanaNo ratings yet

- 10.1.1.562.1017 PhosphateDocument8 pages10.1.1.562.1017 PhosphateKankan BhaumikNo ratings yet

- Alcohol Ethyoxylates As An Alternative To NonylPhenolsDocument3 pagesAlcohol Ethyoxylates As An Alternative To NonylPhenolsChristian Patrick FernandezNo ratings yet

- General Chemistry Document on Hydrocarbons and Functional GroupsDocument3 pagesGeneral Chemistry Document on Hydrocarbons and Functional GroupsKIM Tae HYUNGNo ratings yet

- New Chemistry in Functional Aliphatic Polyesters: Rong TongDocument13 pagesNew Chemistry in Functional Aliphatic Polyesters: Rong TonghungNo ratings yet

- Photocatalytic 1,2-Iminosulfonylation and Remote 1,6Document6 pagesPhotocatalytic 1,2-Iminosulfonylation and Remote 1,6ABHAY VISHWAKARMANo ratings yet

- nardmeDocument12 pagesnardmechristianaranzo098No ratings yet

- AGECHM LAB1 QFR For Expt #6Document2 pagesAGECHM LAB1 QFR For Expt #6Jasper AlicnasNo ratings yet

- 1 s2.0 S006641030454005X MainDocument4 pages1 s2.0 S006641030454005X MainShyam SathyamoorthiNo ratings yet

- Reactions 03 00040Document13 pagesReactions 03 00040Ibtissame AbbadNo ratings yet

- EstersDocument22 pagesEstersmeghanakanade4114No ratings yet

- Mechanism of Alcohol To Ester Rearrangement in Phosphorus Compounds1Document6 pagesMechanism of Alcohol To Ester Rearrangement in Phosphorus Compounds1edy harahapNo ratings yet

- Amin Et Al 2020 Etherified Amino Resins With Tailor Made Properties A Holistic Approach Via PolymerizatDocument16 pagesAmin Et Al 2020 Etherified Amino Resins With Tailor Made Properties A Holistic Approach Via Polymerizatsae1973No ratings yet

- Natali NotesDocument19 pagesNatali NotesNathaly Kate BohulanoNo ratings yet

- 1235341970528041Document26 pages1235341970528041Widayat DayatNo ratings yet

- Contribution From Department of Chemistry, LUMS Syed Babar Ali School of Science and Engineering, Opposite U Block, 54792, DHA LahoreDocument7 pagesContribution From Department of Chemistry, LUMS Syed Babar Ali School of Science and Engineering, Opposite U Block, 54792, DHA Lahorehazyhazy9977No ratings yet

- J. Org. Chem. 2009, 74, 7013–7022Document10 pagesJ. Org. Chem. 2009, 74, 7013–7022NoimurNo ratings yet

- Kinetics of Soybean Oil Epoxidation in A Semibatch Reactor: AccessDocument12 pagesKinetics of Soybean Oil Epoxidation in A Semibatch Reactor: AccessCinthia Sierra LgarsNo ratings yet

- Acs Joc 7b01947Document8 pagesAcs Joc 7b01947Abhishek PareekNo ratings yet

- ChemistryDocument29 pagesChemistryAbdulhaq Hadi AlhaddadNo ratings yet

- Surfactants and Their Use in Latex Technology: January 2013Document5 pagesSurfactants and Their Use in Latex Technology: January 2013herryNo ratings yet

- 2010 TLDocument6 pages2010 TLSudha PriyaNo ratings yet

- Indian Chemical Engineer: Click For UpdatesDocument22 pagesIndian Chemical Engineer: Click For UpdatessanketNo ratings yet

- Perspective: Chemistry and Applications of Organotin Complexes of Schiff BasesDocument45 pagesPerspective: Chemistry and Applications of Organotin Complexes of Schiff BasesSultana EstéreoNo ratings yet

- Epoxidation of Some Vegetable Oils and Their Hydrolysed Products With Peroxyformic Acid - Optimised To Industrial ScaleDocument13 pagesEpoxidation of Some Vegetable Oils and Their Hydrolysed Products With Peroxyformic Acid - Optimised To Industrial ScaleNovrilia Dwi PermatasariNo ratings yet

- OJC Vol33 No3 P 1347-1353Document7 pagesOJC Vol33 No3 P 1347-1353Nurul Apsari AjiNo ratings yet

- Epoxidation of Some Vegetable Oils and Their Hydrolysed Products With Peroxyformic Acid - Optimised To Industrial ScaleDocument12 pagesEpoxidation of Some Vegetable Oils and Their Hydrolysed Products With Peroxyformic Acid - Optimised To Industrial ScaleCinthia Sierra LgarsNo ratings yet

- G6 Alcohols Phenols and EthersDocument64 pagesG6 Alcohols Phenols and EthersHarijaNo ratings yet

- A New Phenolic Compound From Acetone Extract OF LICHEN Usnea Flexuosa TaylDocument5 pagesA New Phenolic Compound From Acetone Extract OF LICHEN Usnea Flexuosa TaylDeni oktaviaNo ratings yet

- Lett 8b04147Document5 pagesLett 8b04147Alane Priscilla AméricoNo ratings yet

- Study of The Alkali Treatment Effect On The Mechanical Behavior of The Composite Unsaturated Polyester-Alfa FibersDocument6 pagesStudy of The Alkali Treatment Effect On The Mechanical Behavior of The Composite Unsaturated Polyester-Alfa FibersSusy Hilza FatwaNo ratings yet

- Sinh T NG H P CyclotideDocument7 pagesSinh T NG H P CyclotideMinh TríNo ratings yet

- The Role of Aldehyde Oxidase in Drug Metabolism (Expert Opinion On Drug Metabolism & Toxicology, Vol. 8, Issue 4) (2012)Document17 pagesThe Role of Aldehyde Oxidase in Drug Metabolism (Expert Opinion On Drug Metabolism & Toxicology, Vol. 8, Issue 4) (2012)RamaNo ratings yet

- Antioxidant Assays: Total Phenolics AssayDocument6 pagesAntioxidant Assays: Total Phenolics AssayapekjrNo ratings yet

- A Status Review of Terpenes and Their Separation MethodsDocument15 pagesA Status Review of Terpenes and Their Separation MethodsDanielNo ratings yet

- Design and Characterization of Naphthalene Ionic LiquidsDocument8 pagesDesign and Characterization of Naphthalene Ionic LiquidssherlybonitaNo ratings yet

- Ninety Years of Using Azo Compounds of The Pyridine SeriesDocument5 pagesNinety Years of Using Azo Compounds of The Pyridine SeriesrajdewaanNo ratings yet

- Almeida, Andrade & Teixeira, 2016Document33 pagesAlmeida, Andrade & Teixeira, 2016Cáceres EmiNo ratings yet

- Partial Purification and Characterization of Polyphenol Oxidase From Sugarcane (Saccharum Officinarum L.)Document7 pagesPartial Purification and Characterization of Polyphenol Oxidase From Sugarcane (Saccharum Officinarum L.)Madelaine MaciasNo ratings yet

- chen-et-al-2020-phenolic-and-volatile-compounds-in-the-production-of-sugarcane-vinegarDocument9 pageschen-et-al-2020-phenolic-and-volatile-compounds-in-the-production-of-sugarcane-vinegarJezzel O. NatividadNo ratings yet

- BP301TP PDFDocument2 pagesBP301TP PDFVidit OberoiNo ratings yet

- BNThoratDocument2 pagesBNThoratumegeeNo ratings yet

- International Biodeterioration & BiodegradationDocument9 pagesInternational Biodeterioration & BiodegradationJuan Diego CárdenasNo ratings yet

- The Behaviour of Organic Compounds in Sulphuric Acid PDFDocument27 pagesThe Behaviour of Organic Compounds in Sulphuric Acid PDFTazkiyatan IsriaNo ratings yet

- Ekstraksi Dan Fraksinasi Fosfolipid Dari Limbah Pengolahan Minyak SawitDocument9 pagesEkstraksi Dan Fraksinasi Fosfolipid Dari Limbah Pengolahan Minyak SawitVivi MeynaNo ratings yet

- Catalysts: The Lord of The Chemical Rings: Catalytic Synthesis of Important Industrial Epoxide CompoundsDocument23 pagesCatalysts: The Lord of The Chemical Rings: Catalytic Synthesis of Important Industrial Epoxide CompoundsRosa OcanaNo ratings yet

- Salicylic Acid InformationDocument3 pagesSalicylic Acid Informationapi-343582965No ratings yet

- Flavour and Fragrance Development ReportDocument24 pagesFlavour and Fragrance Development ReportApurv RajNo ratings yet

- YU, J. VASANTHAN, T. TEMELLI, F. Analysis of Phenolic Acids in Barley by High-Performance Liquid Chromatography. 2001Document7 pagesYU, J. VASANTHAN, T. TEMELLI, F. Analysis of Phenolic Acids in Barley by High-Performance Liquid Chromatography. 2001Cauré Barbosa PortugalNo ratings yet

- Industrial Crops & ProductsDocument11 pagesIndustrial Crops & ProductsAleksandrs ArnautovsNo ratings yet

- 10 1021@acs Inorgchem 8b01097Document9 pages10 1021@acs Inorgchem 8b01097AmirNo ratings yet

- 1998-Mechanistic Action of Phenolic Antioxidants in Polymers A ReviewDocument22 pages1998-Mechanistic Action of Phenolic Antioxidants in Polymers A ReviewSopan TambekarNo ratings yet

- T1 - AR - Stage 4 - FQEDocument7 pagesT1 - AR - Stage 4 - FQEAmi ChanNo ratings yet

- Tabla Resume N Desinfect AntesDocument1 pageTabla Resume N Desinfect Antesjose ramírez yañezNo ratings yet

- RHB Synth Article 1Document6 pagesRHB Synth Article 1dogshtiNo ratings yet

- Bautista, John Mhar M. (Experiment 7)Document4 pagesBautista, John Mhar M. (Experiment 7)2g8vdspqm5No ratings yet

- Separation of Salicylic Acid Impurities With DiffeDocument4 pagesSeparation of Salicylic Acid Impurities With Diffemic92833292No ratings yet

- Polymers: Antioxidant Activity of Synthetic Polymers of Phenolic CompoundsDocument27 pagesPolymers: Antioxidant Activity of Synthetic Polymers of Phenolic CompoundsRico RamadhanNo ratings yet

- Paper Alpha AmylaseDocument2 pagesPaper Alpha AmylaseDr Pinklesh AroraNo ratings yet

- Green SurfactantsDocument9 pagesGreen SurfactantsDr Pinklesh AroraNo ratings yet

- Interaction of Gelatin and Cetylpyridinium ChlorideDocument12 pagesInteraction of Gelatin and Cetylpyridinium ChlorideDr Pinklesh AroraNo ratings yet

- Epoxy AdhesivesDocument9 pagesEpoxy AdhesivesDr Pinklesh AroraNo ratings yet

- P - Block PDFDocument60 pagesP - Block PDFSubham roushanNo ratings yet

- Biological Interactions: Forms of Soil PhosphorusDocument7 pagesBiological Interactions: Forms of Soil PhosphorusrutuparnnaNo ratings yet

- EP2414464B1Document48 pagesEP2414464B1vipin1222No ratings yet

- LiteraturDocument94 pagesLiteraturMuhammad Iqbal MaulanaNo ratings yet

- Manufacturing Commercial Phosphate FertilizerDocument2 pagesManufacturing Commercial Phosphate FertilizerGhulam Mohy UddinNo ratings yet

- NIST MSDS for pH Standards Potassium Dihydrogen Phosphate and Disodium Hydrogen PhosphateDocument4 pagesNIST MSDS for pH Standards Potassium Dihydrogen Phosphate and Disodium Hydrogen PhosphateApriliaPuspitaSNo ratings yet

- A Blend of Skimmed Milk and Vegetable Fat in Powdered FormDocument8 pagesA Blend of Skimmed Milk and Vegetable Fat in Powdered FormAnuradha MarapanaNo ratings yet

- CHM 201 2019-2020 Note1Document38 pagesCHM 201 2019-2020 Note1Adams TemitopeNo ratings yet

- Aluminium-Containing Scales in Water DistributionDocument21 pagesAluminium-Containing Scales in Water DistributionSimon Tin Hann PyngNo ratings yet

- Tenside Phosphate EsterDocument7 pagesTenside Phosphate EsterDr Pinklesh AroraNo ratings yet

- Amendment - List 03 - To - IP - 2022Document6 pagesAmendment - List 03 - To - IP - 2022QC qcNo ratings yet

- Gravimetric Lee AlanDocument2 pagesGravimetric Lee Alankaren capoteNo ratings yet

- PhosphorousDocument8 pagesPhosphorousUJJWAL JHANo ratings yet

- Technial Informations CA80TPDocument36 pagesTechnial Informations CA80TPchudungk57No ratings yet

- Lead Copper Control With Phosphates 20170413Document78 pagesLead Copper Control With Phosphates 20170413GhazanfarNo ratings yet

- Phosphate COOLING TOWERS PDFDocument23 pagesPhosphate COOLING TOWERS PDFDaneyal BabarNo ratings yet

- CH 8. P-Block (Chem - 2)Document77 pagesCH 8. P-Block (Chem - 2)Pradeep KumarNo ratings yet

- Iwamoto 1999Document87 pagesIwamoto 1999Иван БаканевNo ratings yet

- Synthesis and Characterization of Sodium TripolyphosphateDocument4 pagesSynthesis and Characterization of Sodium TripolyphosphateJournal 4 ResearchNo ratings yet

- P Block (English)Document207 pagesP Block (English)Aditya YadavNo ratings yet

- Utilization of Peanut Shells As Adsorbents For Selected Metals PDFDocument5 pagesUtilization of Peanut Shells As Adsorbents For Selected Metals PDFShea AllenNo ratings yet

- Food Additives INS-Codex PDFDocument34 pagesFood Additives INS-Codex PDFMrThao Imbx0% (1)

- Calcium PhosphateDocument3 pagesCalcium PhosphateMarsha Fendria PrastikaNo ratings yet

- Ammonium Polyphosphate SpecificationDocument3 pagesAmmonium Polyphosphate SpecificationMaggie VillacortaNo ratings yet

- Wastewater Characterization Lab 020409 FinalDocument9 pagesWastewater Characterization Lab 020409 FinalgiabrunNo ratings yet

- MAP ReferenciaDocument4 pagesMAP ReferenciaJanainaNo ratings yet

- 3D TRASAR 3DT230 Cooling Water Corrosion and Deposit Inhibitor - PB - SP (English)Document4 pages3D TRASAR 3DT230 Cooling Water Corrosion and Deposit Inhibitor - PB - SP (English)ROBERTO BELTRANNo ratings yet