Professional Documents

Culture Documents

Pipe Thickness Calculations

Uploaded by

BensmatOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pipe Thickness Calculations

Uploaded by

BensmatCopyright:

Available Formats

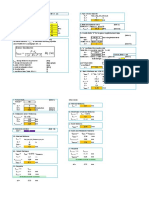

PIPE THICKNESS CALCULATIONS

As per A SME B 31.3 - 1996 Edit io n, 1998 Ad den da.

Design Data :

o

Design Pressure P : 46 barg Design Temp. T : 93 C

Nominal Pipe Size : 200 NPS Outside Diameter D : 219.075 mm

mm

Nominal wall thickness tn : 8.179 mm Minimum wall thickness tmin : 7.156 mm *)

o

Material Spec. : A 106 Gr.B Stress Value @ 93 C Sd : 1,379 bar

o

Corrosion Allowance c : 3.00 mm Stress Value @ 38 C St : 1,379 bar

Coefficient (Table 304.1.1) y : 0.4 ( t < D/6 ) Quality Factor E : 1

Note

Note : *) Mini

Minimu

mum

m thi

thick

ckne

ness

ss of pipe

pipe is equa

equall to Nomi

Nomina

nall thi

thick

ckne

ness

ss x 0.87

0.875

5

Required thickness :

Para. 304.1.2

P*D

t = +c = 6.60 mm < thk. selected,

selected, thus OK

2*(Sd*E + y*P)

Pipe selected

selected sch edule 40

Maximum Allo wable Pressure (New

(New & Cold)

St*E*tmin

P(N+C) = = 92.51 barg

(D/2) - y*tmin

Maximum Allow able Working Pressure (H

(Hot

ot & Corro ded)

Sd*E*(tmin-c)

P(H+C) = = 53 barg

(D/2) - y*(tmin-c)

Max im

im um

um A llll ow

ow ab

ab le

le No n Sh oc

oc k W.P. o f Fl an

an ge

ge Mat er

er ia

ial Gr ad

ad e A 105 (Gr ou

ou p 1.1)

o

At 93 C Design Temperature for 300 lb

lb, ANSI Rating = 47 barg

ax m u m owa e or n g r es s ur

ur e max = arg, m e y: ange

Hydrotest Pressure = 1.5 x Pmax x St / Sd = 69.81 barg

Para. 345.4.2

You might also like

- Pipe ThicknessDocument1 pagePipe ThicknessalvinchuanNo ratings yet

- SHELL THICKNESS CHECK-ASME Section VIIIDocument2 pagesSHELL THICKNESS CHECK-ASME Section VIIIskocogluNo ratings yet

- AISC Connection-2nd Edition - (2+2) Anchor Rod-FixedDocument16 pagesAISC Connection-2nd Edition - (2+2) Anchor Rod-FixedTuấnThanhNo ratings yet

- AISC Connection-2nd Edition - (4+4) Anchor Rod-FixedDocument14 pagesAISC Connection-2nd Edition - (4+4) Anchor Rod-FixedTuấnThanhNo ratings yet

- Vdocuments - MX - Calculation of The Minimum Thickness Required For A Heat ExchangerDocument1 pageVdocuments - MX - Calculation of The Minimum Thickness Required For A Heat ExchangerriccardoNo ratings yet

- S-Stamp Calculation Nozzle ShellDocument4 pagesS-Stamp Calculation Nozzle ShellmukeshNo ratings yet

- Rolled Shells (7.4.2) According To Standards EN 13445-3: Values For CalculationDocument3 pagesRolled Shells (7.4.2) According To Standards EN 13445-3: Values For Calculationmet-calcNo ratings yet

- Pipes. Wall Thickness Calculation - 8 Inch SCH 80Document2 pagesPipes. Wall Thickness Calculation - 8 Inch SCH 80Ali Hammouda100% (1)

- Base Plate With Moment Axial CompressionDocument4 pagesBase Plate With Moment Axial CompressionjigsNo ratings yet

- AG Base Plate With Moment Axial CompressionDocument4 pagesAG Base Plate With Moment Axial Compressionsivaguruswamy thangarajNo ratings yet

- AG Base Plate With Moment Axial CompressionDocument4 pagesAG Base Plate With Moment Axial CompressionMohit VatsNo ratings yet

- Base Plate Design With Moment and AxialDocument2 pagesBase Plate Design With Moment and AxialMai CNo ratings yet

- Section A: 2.1. Sling Design Load and SelectionDocument30 pagesSection A: 2.1. Sling Design Load and SelectionThomas StephenNo ratings yet

- Spherical Shells (7.4.3) EN 13445-3Document3 pagesSpherical Shells (7.4.3) EN 13445-3met-calcNo ratings yet

- AISC Connection-2nd Edition - (3+3) Anchor Rod-FixedDocument14 pagesAISC Connection-2nd Edition - (3+3) Anchor Rod-FixedTuấnThanhNo ratings yet

- 50 Inch Manhole Neck CalculationDocument2 pages50 Inch Manhole Neck CalculationLawrence LawrenceNo ratings yet

- Conical Shells (7.6.4) EN 13445-3Document3 pagesConical Shells (7.6.4) EN 13445-3met-calcNo ratings yet

- Piping Sizing Final Rev01 12Document1 pagePiping Sizing Final Rev01 12aNo ratings yet

- E.1.1) Nozzle Neck Thickness For Cyl. Shell Nozzles As Per UG-45Document2 pagesE.1.1) Nozzle Neck Thickness For Cyl. Shell Nozzles As Per UG-45Rajesh KumarNo ratings yet

- Longitudinal Stress (Circumferential Joints)Document2 pagesLongitudinal Stress (Circumferential Joints)SwatiMitraNo ratings yet

- Blind Calculation - RoarkDocument10 pagesBlind Calculation - Roarkrustamriyadi100% (2)

- Bolt TorqueDocument3 pagesBolt TorqueHeri KurniawanNo ratings yet

- Design of Flat Head For HydrotestDocument12 pagesDesign of Flat Head For HydrotestSAGAR100% (1)

- Thickness CalcuationDocument6 pagesThickness CalcuationRanjan KumarNo ratings yet

- Final ExaminationDocument7 pagesFinal ExaminationAwanNo ratings yet

- Wall THK Calculation Asme B31.4Document7 pagesWall THK Calculation Asme B31.4ISRAEL PORTILLONo ratings yet

- Pipe Thickness Calculation PDFDocument1 pagePipe Thickness Calculation PDFHeny Martha67% (3)

- Piping Calculation Program For ASME B31 1 CodeDocument3 pagesPiping Calculation Program For ASME B31 1 CodeAMIT100% (2)

- Rectangular Tank Satu LagiDocument1 pageRectangular Tank Satu LagiSteve MoonNo ratings yet

- Flat End With A Full-Face Gasket For A Pair of OpeningsDocument3 pagesFlat End With A Full-Face Gasket For A Pair of OpeningsEng-CalculationsNo ratings yet

- Head Nozzle and Flange Calculation, DN100 (CF) Size NozzleDocument7 pagesHead Nozzle and Flange Calculation, DN100 (CF) Size Nozzleakın ersözNo ratings yet

- Square Blind Flange With Stiffener ULDocument5 pagesSquare Blind Flange With Stiffener ULjoeriji100% (1)

- Lug DesignDocument1 pageLug DesignFandy SipataNo ratings yet

- Flat Ends With A Hub For Uniform Thickness ShellDocument5 pagesFlat Ends With A Hub For Uniform Thickness ShellEng-CalculationsNo ratings yet

- Calculation of RC PAD2Document1 pageCalculation of RC PAD2m 418No ratings yet

- Reference:: Anchor ChairDocument4 pagesReference:: Anchor ChairShaheed HossainNo ratings yet

- PTB E4.3.2 Conical ShellDocument2 pagesPTB E4.3.2 Conical ShellginoNo ratings yet

- Doubly Reinforced Concrete Beam Design - InvestigationDocument4 pagesDoubly Reinforced Concrete Beam Design - InvestigationMark Brien Vincent YbañezNo ratings yet

- Anchor Bolt - AISC ASDDocument7 pagesAnchor Bolt - AISC ASDameyyammaiNo ratings yet

- Cantilever Beam Design - PipeDocument1 pageCantilever Beam Design - Pipeberylqz5878No ratings yet

- Manual Roark FormulaDocument5 pagesManual Roark FormulaPeja JusohNo ratings yet

- Flat End With A Full-Face Gasket For Single Isolated OpeningDocument3 pagesFlat End With A Full-Face Gasket For Single Isolated OpeningEng-CalculationsNo ratings yet

- Weir Plate or Baffle Plate CalculationDocument2 pagesWeir Plate or Baffle Plate CalculationamaNo ratings yet

- Design Calculation For Anchor Chair API 650Document1 pageDesign Calculation For Anchor Chair API 650Mohammed Faizal Nv100% (2)

- Line Pipe THK CalculationDocument2 pagesLine Pipe THK CalculationRanjan KumarNo ratings yet

- TD RDMDocument3 pagesTD RDMIbtissam LachguerNo ratings yet

- Assignment CSTT 1Document21 pagesAssignment CSTT 1KHÁNH VÕ ĐĂNGNo ratings yet

- 25M 13L Qty.72Document3 pages25M 13L Qty.72AbdElrahman AbouElsaudNo ratings yet

- v756373001xb - Mds Sludge Decant TankDocument50 pagesv756373001xb - Mds Sludge Decant TankInamullah KhanNo ratings yet

- Pipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)Document1 pagePipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)farhadNo ratings yet

- ASME B31.3 Straight PipesDocument2 pagesASME B31.3 Straight Pipesjame11inNo ratings yet

- Gas Line - 20 BargDocument22 pagesGas Line - 20 Bargsaravanakkumar boominahtan100% (1)

- Head Thick CalculationsDocument2 pagesHead Thick CalculationsSwatiMitraNo ratings yet

- NeckThick CalculationsDocument2 pagesNeckThick CalculationsSwatiMitraNo ratings yet

- ASME BPVC VIII MinT CalculationsDocument2 pagesASME BPVC VIII MinT CalculationsSbuZikalalaNo ratings yet

- Nozzle Check 211039CDocument3 pagesNozzle Check 211039CGaurav BedseNo ratings yet

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Tinywow - 1-45 PDF ANG - 20037352 - 7Document1 pageTinywow - 1-45 PDF ANG - 20037352 - 7BensmatNo ratings yet

- Procedure S Cutting The Pipe With Wachs or Fein Saw: CompanyDocument3 pagesProcedure S Cutting The Pipe With Wachs or Fein Saw: CompanyBensmatNo ratings yet

- Cutting The Pipe With Wachs or Fein Saw Book 3Document2 pagesCutting The Pipe With Wachs or Fein Saw Book 3BensmatNo ratings yet

- Tinywow - 1-45 PDF ANG - 20037352 - 10Document1 pageTinywow - 1-45 PDF ANG - 20037352 - 10BensmatNo ratings yet

- Cups-13 A Method To Determine The Minimum Stack HeightDocument46 pagesCups-13 A Method To Determine The Minimum Stack HeightBensmatNo ratings yet

- Stopple ProceduresDocument3 pagesStopple ProceduresBensmatNo ratings yet

- Procedure: Book 3: Pipeline FacilitiesDocument9 pagesProcedure: Book 3: Pipeline FacilitiesBensmatNo ratings yet

- 2 Ecdaworkshoprlopeznov4ver3Document53 pages2 Ecdaworkshoprlopeznov4ver3BensmatNo ratings yet

- Safe Separation Distances From Natural Gas PipelinesDocument19 pagesSafe Separation Distances From Natural Gas PipelinesBensmatNo ratings yet

- Reducing Energy Consumption in Natural Gas Pressure Drop Stations by Employing Solar HeatDocument8 pagesReducing Energy Consumption in Natural Gas Pressure Drop Stations by Employing Solar HeatBensmatNo ratings yet

- UntitledDocument30 pagesUntitledBensmatNo ratings yet

- ClampSleeve InstallDocument15 pagesClampSleeve InstallBensmatNo ratings yet

- Hot-Tapping ProceduresDocument2 pagesHot-Tapping ProceduresBensmatNo ratings yet

- Pipeline Pigging Incident: Dave Shepherd Aug, 2005Document7 pagesPipeline Pigging Incident: Dave Shepherd Aug, 2005BensmatNo ratings yet

- UTI Evolution of Integrity Management March 15 2018Document39 pagesUTI Evolution of Integrity Management March 15 2018BensmatNo ratings yet

- Stop Ple Fittings With Lock o Ring Flange and PlugDocument26 pagesStop Ple Fittings With Lock o Ring Flange and PlugBensmatNo ratings yet

- The Art of PiggingDocument11 pagesThe Art of PiggingBensmatNo ratings yet

- Fired Equipment and DesignDocument35 pagesFired Equipment and DesignBensmatNo ratings yet

- PlotconDocument35 pagesPlotconBensmatNo ratings yet

- Document 31Document31 pagesDocument 31BensmatNo ratings yet

- What Is A Pipeline Pig and How Are They UsedDocument3 pagesWhat Is A Pipeline Pig and How Are They UsedBensmatNo ratings yet

- Water Bath HeaterDocument4 pagesWater Bath HeaterBensmatNo ratings yet

- Job Description-Piping EngineerDocument1 pageJob Description-Piping EngineerThirukkumaranBalasubramanianNo ratings yet

- ME130-2: Fluid Mechanics: Fluid Properties & Fluid StaticsDocument22 pagesME130-2: Fluid Mechanics: Fluid Properties & Fluid StaticsDeact AccountNo ratings yet

- Supersonic Wind TunnelDocument15 pagesSupersonic Wind TunnelAseem TanejaNo ratings yet

- Enerpac Pump SchematicDocument108 pagesEnerpac Pump Schematicjace100% (2)

- B31.1 Vs B31.3Document18 pagesB31.1 Vs B31.3Muhammed Ali Noureddeen100% (2)

- Dukler Et Al. (1969) CorrelationDocument8 pagesDukler Et Al. (1969) Correlationkhalid alrawiNo ratings yet

- 14M R9J HydDocument11 pages14M R9J HydMikeas YazNo ratings yet

- A Parametric Study of The Cavitation Inception Behavior of A Mixed Flow ImpellerDocument7 pagesA Parametric Study of The Cavitation Inception Behavior of A Mixed Flow ImpellerUmesh KulkarniNo ratings yet

- Comparison of Aerodynamics Characteristics of Naca 0015 & Naca 4415 Aerofoil BladeDocument12 pagesComparison of Aerodynamics Characteristics of Naca 0015 & Naca 4415 Aerofoil Bladevarun karthikeyanNo ratings yet

- Reducing Tee PDFDocument4 pagesReducing Tee PDFKKNo ratings yet

- PSV Sizing For VAPOUR OR GAS RELIEFDocument4 pagesPSV Sizing For VAPOUR OR GAS RELIEFD K SNo ratings yet

- Project OobleckDocument10 pagesProject OobleckAhmad Sabree Abdul BasitNo ratings yet

- Design of Bullah PileDocument1 pageDesign of Bullah PilePayal MondalNo ratings yet

- The Froude and Reynolds Numbers: GG352: Geomorphology Assignment 4 - 1Document8 pagesThe Froude and Reynolds Numbers: GG352: Geomorphology Assignment 4 - 1rema irmaNo ratings yet

- Bobcat Compact Mini Excavator 773 G Series Parts ManualDocument742 pagesBobcat Compact Mini Excavator 773 G Series Parts ManualLuis GarciaNo ratings yet

- What Create Wind?: CE 248 - Behavior of Plastic Design of Steel Structures Topic: Wind LoadsDocument5 pagesWhat Create Wind?: CE 248 - Behavior of Plastic Design of Steel Structures Topic: Wind LoadsMGNo ratings yet

- Circuit DiagramsDocument143 pagesCircuit DiagramsRebeca Santos100% (1)

- Oblique Shock WavesDocument25 pagesOblique Shock WavesDhinasuga DhinakaranNo ratings yet

- Lab Gas Flow (Afif)Document17 pagesLab Gas Flow (Afif)Nurshazwani syuhada bt al- badri100% (1)

- J500.05 Flat Glass Gages April 2014 PDFDocument20 pagesJ500.05 Flat Glass Gages April 2014 PDFahmedhassankhanNo ratings yet

- Float ValveDocument1 pageFloat Valveabdulkidwai2009No ratings yet

- Caleffi: Hydraulic Safety Groups For Hot Water Storage HeatersDocument2 pagesCaleffi: Hydraulic Safety Groups For Hot Water Storage HeatersMax.infoNo ratings yet

- Valve SheetDocument23 pagesValve SheetAris KancilNo ratings yet

- Models Heat Buoyancy Air (Comsol)Document28 pagesModels Heat Buoyancy Air (Comsol)Sandyely150890No ratings yet

- Controlling Piping System VibrationDocument11 pagesControlling Piping System Vibrationmohammad mortazavi100% (2)

- Fluid Mechanics - 1661429347Document10 pagesFluid Mechanics - 1661429347hussain lunawadiNo ratings yet

- Explanations To Hydraulic DiagramDocument7 pagesExplanations To Hydraulic Diagramsunil singhNo ratings yet

- Water Hammer ReportDocument2 pagesWater Hammer ReportEduardo Paulini VillanuevaNo ratings yet

- INS-004, Hydro-Testing Procedure For Bondstrand GRE and GRV Pipe-R1Document7 pagesINS-004, Hydro-Testing Procedure For Bondstrand GRE and GRV Pipe-R1jayhuacat7743100% (4)

- Pumps and CompressorsDocument16 pagesPumps and CompressorsAbc AbcNo ratings yet