Professional Documents

Culture Documents

Gauge Tolerance

Uploaded by

Nikhil SirOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gauge Tolerance

Uploaded by

Nikhil SirCopyright:

Available Formats

1.

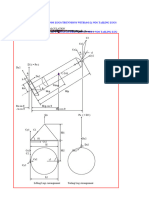

How to Calculate Gauge Tolerance (Plug and Snap)

Calculation of Gauge Tolerance

(Plug and Snap)

Simply the best way to calculate gauge tolerance by using IS : 3455 – 1971 Chart.

1. Plug Gauge Tolerance Calculation:-

GO = (K+Z) ± H/2

NOGO = G ± H/2

Where ‘K’ is minimum size,

‘G’ is maximum size,

‘Z’ , ‘H/2’ Value is taken from Chart through difference between

Maximum and Minimum size. It is called ‘T’ in µm. (nothing but Hole Tolerance)

For Example,

P/G Ø 20.0 ± 0.02 (19.98 / 20.02)

K = 19.98,

G = 20.02,

T = 20.02 - 19.98 = 0.04 (40 µm), you know (0.001mm = 1 µm)

Go to chart

Z = 0.005,

H/2 = 0.002,

GO = (K+Z) ± H/2

GO = (19.98+0.005) ± 0.002,

GO = 19.985 ± 0.002.

NOGO = G ± H/2

NOGO = 20.02 ± 0.002.

2. Snap Gauge Tolerance Calculation :-

GO = (G - Z1) ± H1/2

NOGO = (K+ ∞ 1) ± H1/2

For Example,

S/G 20.0 ± 0.02 (19.98 / 20.02)

K = 19.98,

G = 20.02,

T = 20.02 - 19.98 = 0.04 (40 µm), you know (0.001mm = 1 µm)

Go to chart

Z1 = 0.005,

H1/2 = 0.003,

GO = ( G - Z1 ) ± H1/2

GO = (20.02 – 0.005) ± 0.003,

GO = 20.015 ± 0.003.

NOGO = (K+ ∞ 1 ) ± H1/2

NOGO = 19.98 ± 0.003.

You might also like

- Polar Plot and Its Analysis - GATE Study Material in PDFDocument6 pagesPolar Plot and Its Analysis - GATE Study Material in PDFnidhi tripathiNo ratings yet

- ACP-sc-emp-cover Meter 6 InchDocument1 pageACP-sc-emp-cover Meter 6 InchagungNo ratings yet

- Chapter5 Part2Document19 pagesChapter5 Part2Grant HeilemanNo ratings yet

- 05 A 1pg Determination of Acceleration Due To GravityDocument4 pages05 A 1pg Determination of Acceleration Due To GravityDolly NaikNo ratings yet

- Predicting The Average Lead Angle in Turning Using Non-Dimensional Parameters and Considering The Size EffectDocument23 pagesPredicting The Average Lead Angle in Turning Using Non-Dimensional Parameters and Considering The Size EffectgdelfinoNo ratings yet

- Compound Pendulum Lab ReportDocument13 pagesCompound Pendulum Lab ReportHamzah Sohail100% (2)

- GARGANTA DANICA CENGR1221 Laboratory-Exercise-3Document7 pagesGARGANTA DANICA CENGR1221 Laboratory-Exercise-3Ibale, Arjay D.No ratings yet

- Compound Pendulum Lab ReportDocument13 pagesCompound Pendulum Lab ReportMuhammad Faizan Tariq54% (13)

- Free-Falling Object ExperimentDocument9 pagesFree-Falling Object ExperimentUgur ASİT100% (4)

- Freq ResponseDocument23 pagesFreq Responselili aboudNo ratings yet

- Polar Plot and Its Analysis GATE Study Material in PDFDocument6 pagesPolar Plot and Its Analysis GATE Study Material in PDFimvuuser1No ratings yet

- Roll No: - Total MarksDocument14 pagesRoll No: - Total MarksAnirudh Arora0% (1)

- Determination of Acceleration Due To Gravity CompressDocument8 pagesDetermination of Acceleration Due To Gravity Compressشەیدایانی قورئانNo ratings yet

- Noise FigureDocument17 pagesNoise FigureManel CharlesNo ratings yet

- FEM Solved ExampleDocument3 pagesFEM Solved ExampleMian AsimNo ratings yet

- Nyquist PlotDocument28 pagesNyquist PlotLloyds RajaNo ratings yet

- Bruno Dupire - Breakeven VolatilityDocument69 pagesBruno Dupire - Breakeven VolatilitygneymanNo ratings yet

- Gyro - Error, Correction of The SextantDocument10 pagesGyro - Error, Correction of The Sextanthectorrony52100% (1)

- ActivemicrowavereportDocument13 pagesActivemicrowavereportUğur Berkay ÇalışkanNo ratings yet

- Online Exp02 - Simple Pendulum - Lab Report 2456878 Uzair IsmailDocument6 pagesOnline Exp02 - Simple Pendulum - Lab Report 2456878 Uzair IsmailuziNo ratings yet

- Modulus of Rigidity of RubberDocument5 pagesModulus of Rigidity of RubberMuneeb IrfanNo ratings yet

- CH5-Frequency Response PDFDocument27 pagesCH5-Frequency Response PDFRidir ZolkefleNo ratings yet

- Geardesign Team 1 3EM2Document11 pagesGeardesign Team 1 3EM2Dries CaersNo ratings yet

- WR3Document8 pagesWR3Chris AdaminovicNo ratings yet

- Internal Convertion 3Document37 pagesInternal Convertion 3MANISH DASNo ratings yet

- Modulus of Rigidity DoneDocument5 pagesModulus of Rigidity DoneSujay Das SonuNo ratings yet

- Gyro - Error - Object-MoonDocument1 pageGyro - Error - Object-MoonJoshua KinneyNo ratings yet

- Gyro Error Calculation Using The MoonDocument1 pageGyro Error Calculation Using The MoonGB Pasana100% (1)

- Lesson Plan: S.N Date Planne D Topics Date Engage D Remark SDocument28 pagesLesson Plan: S.N Date Planne D Topics Date Engage D Remark SVARUN B MNo ratings yet

- LiftingDocument13 pagesLiftingrichardchiamNo ratings yet

- Multiplicity Results For Some Elliptic Problems With Concave NonlinearitiesDocument9 pagesMultiplicity Results For Some Elliptic Problems With Concave NonlinearitiesRay GobbiNo ratings yet

- Local Vol Delta-HedgingDocument53 pagesLocal Vol Delta-HedgingVitaly Shatkovsky100% (1)

- Frequency ResponseDocument62 pagesFrequency ResponseSujin PrajapatiNo ratings yet

- 3.1 G and M Codes On The Emco Compact 5 CNC Lathes: 3.4.1 Summary of CommandsDocument17 pages3.1 G and M Codes On The Emco Compact 5 CNC Lathes: 3.4.1 Summary of CommandsFilipe RosaNo ratings yet

- Gear CalculationsDocument14 pagesGear CalculationsBabette FreyNo ratings yet

- Chapter 3.Document12 pagesChapter 3.Sabari Gokul KNo ratings yet

- Chap3 2eDocument8 pagesChap3 2ehortalemosNo ratings yet

- Gasoline Demand and The 1973 Embargo: Econ 201 PS6 Suggested SolutionsDocument13 pagesGasoline Demand and The 1973 Embargo: Econ 201 PS6 Suggested SolutionsqiucumberNo ratings yet

- 00 Mathematical BackgroundsDocument113 pages00 Mathematical BackgroundsRevaNo ratings yet

- Bar PendulumDocument4 pagesBar Pendulumvidhiichauhan7No ratings yet

- Lecture Note About Non Harmonic MotionDocument6 pagesLecture Note About Non Harmonic MotionYasir LoneNo ratings yet

- Open Ended LAB: Name: Ayyan AhmadDocument7 pagesOpen Ended LAB: Name: Ayyan AhmadMaheenNo ratings yet

- Gear CalcDocument8 pagesGear CalcChetan PrajapatiNo ratings yet

- Goldstein Formula ProofDocument5 pagesGoldstein Formula ProofTubaguts1234No ratings yet

- Radio Graph TheoryDocument12 pagesRadio Graph TheoryMarty NobisNo ratings yet

- 1.0 Mechanical Analysis #Document8 pages1.0 Mechanical Analysis #Gayan Indunil JayasundaraNo ratings yet

- BDocument10 pagesBHoNo ratings yet

- Assign 1 Ada Vikas 2k19ec209Document8 pagesAssign 1 Ada Vikas 2k19ec209deepuNo ratings yet

- Report AlphaalphaalphaDocument3 pagesReport AlphaalphaalphaNik HumphriesNo ratings yet

- Experiment 4 Pendulum Oscillation With PC Interface: Principle and TaskDocument5 pagesExperiment 4 Pendulum Oscillation With PC Interface: Principle and TaskNguyễn Đức MạnhNo ratings yet

- Prelabf10308 Simple Pendulum EngDocument3 pagesPrelabf10308 Simple Pendulum EngNgwe Zin Lin LettNo ratings yet

- The Value of G Thus Obtained From The Two Inclined SlopesDocument2 pagesThe Value of G Thus Obtained From The Two Inclined SlopesNúmeros LegendariosNo ratings yet

- Tugs TekproDocument4 pagesTugs TekproElda Permata SariNo ratings yet

- Exp3 4Document3 pagesExp3 4AymanNo ratings yet

- Ruturaj Arvind Umaranikar 200979009 Assignment 3Document13 pagesRuturaj Arvind Umaranikar 200979009 Assignment 3Ruturaj UmaranikarNo ratings yet

- 5) Asymemtric - GRACHDocument34 pages5) Asymemtric - GRACHDunsScotoNo ratings yet

- Jim X. Chen: Jchen @cs - Gmu.eduDocument21 pagesJim X. Chen: Jchen @cs - Gmu.edukranthi142434No ratings yet

- Lin1997 - Minimum Bandwidth Problem For Embedding Graphs in CyclesDocument6 pagesLin1997 - Minimum Bandwidth Problem For Embedding Graphs in CyclesVale NarvaezNo ratings yet

- QAV Checksheet 23.05.2022 LDocument10 pagesQAV Checksheet 23.05.2022 LNikhil SirNo ratings yet

- ProcessProduct Quality Audit PlanDocument1 pageProcessProduct Quality Audit PlanNikhil SirNo ratings yet

- Process Audit Plan 22-23Document1 pageProcess Audit Plan 22-23Nikhil SirNo ratings yet

- Pareto AnalysisDocument7 pagesPareto AnalysisNikhil SirNo ratings yet

- Skill MatrixxDocument11 pagesSkill MatrixxNikhil SirNo ratings yet