Professional Documents

Culture Documents

Mechanical Short Circuit Strength Calculation for Equipment Connection with Flexible Conductor

Uploaded by

anoop13Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mechanical Short Circuit Strength Calculation for Equipment Connection with Flexible Conductor

Uploaded by

anoop13Copyright:

Available Formats

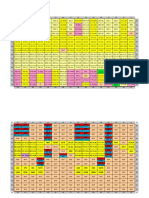

From Transformer

Bushing to LA-GT

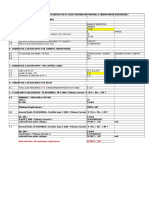

Calculation for Mechanical Short Circuit Strength of equipment connection with flexible conductor as per IEC 60865

1 Input Data

Following are the input data for the calculation. Other terms, factors and data used in the calculation are as defined i

Symbol Description Unit

V System Voltage kV 115

f System frequency Hz 50

3 phase initial symmetrical short circuit

I"k3 A 31500

current (rms)

g acceleration due to gravity m/s2 9.81

Initial static tensile force in main

Fst N 5000

conductor

Center Line distance between

l m 4.5

supports

lh Extend of one head armature and clamp m 0.2

lf Form Factor m 0.2

Center line distance between

a1 m 1.1

conductors (Phase to Phase spacing)

Center line distance between

a2 m 2.2

conductors (Phase to Phase spacing)

Equivalent distance between conductors

a m 1.65

(Phase to Phase spacing)

Mass of one set of connecting pieces

mz kg 1.3

(spacers)

Type of Conductor ACSR PANTHER

No. of sub-conductor in a main

n Nos. 1

conductor bundle

Effective distance between sub-

as m 0

conductors

mm2 261.5

As Cross-section of one sub-conductor

m 2

2.62E-04

mm 21

ds Diameter of the sub-conductor in bundle

m 2.10E-02

Mass per unit length of one sub- kg / km 974

m'

conductor of bundle kg / m 0.974

Final value of Young's modulus of N / mm 2

8.00E+04

E

elasticity of the sub-conductor N/m 2

8.00E+10

Cord length of the main conductor in the

leff m 3.7

span (l - 2lh - 2Lf)

lc =Ieff m 3.7

ns Nos. of spacers in the span Nos. 0

Resultant Mass per unit length of one

sub-conductor after considering the

ms' kg / m 1.621

mass of spacers within the span = m' +

{(ns x mz)/(n x Ic)}

Resultant spring constant of both

S N/m 1.00E+05

supports of one span

µ0 Electromagnetic constant N / m2 1.26E-06

2 Detailed Calculation for Short circuit forces

The characteristic Electromagnetic Load

per unit length on flexible main

2.01 F'

conductor in 3 Φ system is given by:

(IEC 60865 - I, Eq 19a)

= (µ0/2π) x (0.75) x (I"k32/a) x (lc/leff) N/m 90.45

The ratio of electromagnetic force under

short circuit to gravitational force on a

2.02 r

conductor is given by: (IEC 60865 - I, Eq

20)

= F' / (n x ms' x g) 5.69

The direction of the resulting force

2.03 δ1 exerted on the conductor is given by:

(IEC 60865 - I, Eq 21)

= tan-1 (r) deg 80.03

The equivalent static conductor sag at

2.04 fes midspan is given by: (IEC 60865 - I, Eq

22)

= (n x m's x g x leff2) / (8 x Fst) m 0.005

The period T, of conductor oscillations is

2.05 T

given by: (IEC 60865 - I, Eq 23)

= 2π x {0.8 x (fes / g)}1/2 sec 0.132

The resulting period, Tres, of the

conductor oscillation during the short

2.06 Tres

circuit current flow is given by: (IEC

60865 - I, Eq 24)

= T/[{1+r2}1/4 x {1-(π2/64) x (δ1/900)2}] sec

Actual Young's modulus of conductor,

2.07 Eeff

Es, is given by: (IEC 60865 - I, Eq 26)

= E x [0.3+0.7 x sin{Fst x 900 / (n x As x

For Fst/nAs ≤ σfin, N/m2

σfin)}]

#NAME? For Fst/nAs ≥ σfin, N/m2 3.83E+10

Lowest value of σ when Young's

σfin modulus becomes constant (IEC 60865 5.00E+07, N/m2

- I, Eq 27)

The stiffness norm is given by:

2.08 N

(IEC 60865 - I, Eq 25)

{1/(S x l)} + {1/(n x Eeff x As)} 2.34E-06

The stress factor, ζ, of the main

2.09 ζ conductor is given by: (IEC 60865 - I, Eq

28)

(n x g x ms' x leff)2 / (24 x Fst3 x N) 0.00046

During or at the end of the short circuit

current flow, the span will have

2.1 oscillated out of the steady state to the

angle given by: (Tk1=1 sec) (IEC 60865 -

I, Eq 29)

δend δ1[1-cos(3600 xTk1/Tres)] For 0 ≤ (Tk1/Tres) ≤ 0.5, deg

δend 2δ1 For (Tk1/Tres) > 0.5, deg

Tk1/Tres 4.742

Duration of first short circuit current flow

Where,

is given by:

Tk1 = sec 0.32

0.4T = sec 0.051

Therefore, as per clause No. 2.3.2.1 of

IEC 865-1, the true value of Tk1 (=

0.320 sec) shall be used to calculate δend

=> δend deg 154.77

Maximum swing out angle during or

2.11 after short circuit current flow, δm, is

given by: (IEC 60865 - I, Eq 31)

δmax 1.25 cos-1χ deg for: 0.766 ≤ χ ≤ 1

δmax 10 + cos-1χ

0

deg for: -0.985 ≤ χ ≤ 0.766

δmax 180 0

deg for: χ <-0.985

Where, Quantity for the maximum

2.12 χ swing-out angle, χ, is given as: (IEC -3.4676

60865 - I, Eq 30)

χ = 1-r sin δend for: 0 ≤ δend ≤ 900

χ = 1-r for: δend > 900

Therefore δmax deg 180

The load parameter φ is obtained as

2.13 follows:

(IEC 60865 - I, Eq 32)

φ 3[ √(1+r2) - 1] for: Tk1≥ Tres/4 10.735

3[r x sin(δend) + cos(δend) -1] for: Tk1< Tres/4

Span reaction factor, ψ (φ,ζ), is

2.14 ψ calculated as a real solution of the

equation: (IEC 60865 - I, A.6)

φ2ψ3+φ(2 + ζ)ψ2+(1 + 2ζ)ψ−ζ(2+φ)=0 for: 0 ≤ ψ ≤ 1 0.0054

The short circuit tensile force Ft is given

2.15 Ft

by: (IEC 60865 - I, Eq 33)

Ft = Fst (1 +φψ) N for: n = 1, single condr

Ft = 1.1 x Fst(1 + φψ) N for: n > 1, bundled condr

Ft N 5291.97

Ft kN 5.292

Drop forces need to be calculated only

when δ m ≥ 70 0 & r > 0.6

(IEC 60865 - I, Eq 35)

2.15 Ff The 'drop force' is given by:

Ff 1.2 x Fst √(1 + 8ζ x δm/1800) N for: r >0.6; δm≥700

Ff non-significant N for: r < 0.6; δm<700

Ff N 6011.05

Ff kN 6.011

Calculation for Horizontal Span

Displacement and Minimum Air

Clearance

The elastic expansion is given by: εela

2.16

2.16

(IEC 60865 - I, Eq 34)

εela = N x (Ft - Fst) 6.83E-04

The thermal expansion is given by (IEC

2.17 εth 1.21E-05

60865 - I, Eq 35)

εth = cth {I"k3/(n x As)}2 x Tres/4 for : Tk1≥

εth

Tres/4

εth = cth {I"k3/(n x As)}2 x Tk1/4 for : Tk1<

εth

Tres/4

where, cth m4/A2sec 1.70E-19

for: Aluminum, aluminum alloy &

aluminum/ steel conductors with cross-

section ratio of Al/ St ≤ 6

Dilation factor, CD, allows for sag

increase caused by elastic and thermal

2.18 CD

elongation of the conductor and is given

by: (IEC 60865 - I, Eq 36)

CD = {1 + 3/8 x (leff/fes)2 x (εela +εth)}1/2 11.4

Form factor, CF, allows for a possible

increase in the dynamic sag of the

2.19 CF conductor caused by a change in shape 1.15

of the conductor curve and is given by:

(IEC 60865 - I, Eq 37)

CF = 1.05 for: r ≤ 0.8

CF = 0.97 +0.1r for: 0.8 < r < 1.8

CF = 1.15 for: r ≥ 1.8

Dynamic Sag result (IEC 60865 - I, Eq

2.2 fed

38)

fed = CF*CD*fes m 0.067

Calculation for Horizontal Span

Displacement and Minimum Air

Clearance (IEC 60865 - I, Eq 45)

The maximum horizontal displacement

2.21 bh in midspan bh, due to a short circuit is m 0.065

given by:

bh = fed Sin δ1 m for: δmax ≥ δ1

bh = fed Sin δmax m for: δmax < δ1

The distance between the midpoints of

the two main conductors during a line-

2.22 amin to-line two-phase short circuit is in the

worst case given by:

(IEC 60865 - I, Eq 48)

amin = a - 2bh m 1.965

Structure Load due to Flexible

2.23 conductors

(IEC 60865 - I, 6.5.1)

Design Load for Post Insulators and

their supports i.e. steel structure is given kN 6.011

by Maximum Value of Ftd & Ffd

Connectors for flexible conductors shall

be rated on the basis of the maximum kN 7.938

value of 1.5Ftd & 1.0Ffd

From From From From From From

CB to ISOLATOR to CVT-2 to LA-

LA-GT to CVT-1 CVT-1 to CT CT to CB

ISOLATOR CVT-2 Line

lexible conductor as per IEC 60865 - 1 for SINGLE ACSR PANTHER Conductor

ed in the calculation are as defined in IEC-865, Part-I.

115 115 115 115 115 115

50 50 50 50 50 50

31500 31500 31500 31500 31500 31500

9.81 9.81 9.81 9.81 9.81 9.81

5000 5000 5000 5000 5000 5000

2 2 2.16 2 2.37 2

0.2 0.2 0.2 0.2 0.2 0.2

0.2 0.2 0.2 0.2 0.2 0.2

2.5 2.5 2.5 2.5 2.2 2.5

2.5 2.5 1.7 2.5 2.5 2.5

2.5 2.5 2.1 2.5 2.35 2.5

1.3 1.3 1.3 1.3 1.3 1.3

ACSR ZEBRA ACSR ZEBRA ACSR ZEBRA ACSR ZEBRA ACSR ZEBRA ACSR ZEBRA

1 1 1 1 1 1

0 0 0 0 0 0

484.48 484.48 484.48 484.48 484.48 484.48

4.84E-04 4.84E-04 4.84E-04 4.84E-04 4.84E-04 4.84E-04

28.62 28.62 28.62 28.62 28.62 28.62

2.86E-02 2.86E-02 2.86E-02 2.86E-02 2.86E-02 2.86E-02

1621 1621 1621 1621 1621 1621

1.621 1.621 1.621 1.621 1.621 1.621

7.32E+04 7.32E+04 7.32E+04 7.32E+04 7.32E+04 7.32E+04

7.32E+10 7.32E+10 7.32E+10 7.32E+10 7.32E+10 7.32E+10

1.2 1.2 1.36 1.2 1.57 1.2

1.2 1.2 1.36 1.2 1.57 1.2

0 0 0 0 0 0

1.621 1.621 1.621 1.621 1.621 1.621

1.00E+05 1.00E+05 1.00E+05 1.00E+05 1.00E+05 1.00E+05

1.26E-06 1.26E-06 1.26E-06 1.26E-06 1.26E-06 1.26E-06

59.69 59.54 70.88 59.54 63.34 59.54

3.75 3.74 4.46 3.74 3.98 3.74

75.05 77.35 75.05 75.91 75.05

0.001 0.001 0.001 0.001 0.001 0.001

0.043 0.043 0.049 0.043 0.056 0.043

0.024 0.024 0.026 0.024 0.031 0.024

3.83E+10 3.83E+10 3.83E+10 3.83E+10 3.83E+10 3.83E+10

5.05E-06 5.05E-06 4.68E-06 5.05E-06 4.27E-06 5.05E-06

0.000024 0.000024 0.000033 0.000024 0.000049 0.000024

13.1 13.1 12.455 13.1 10.279 13.1

0.32 0.32 0.32 0.32 0.32 0.32

0.017 0.017 0.019 0.017 0.022 0.017

150.09 150.09 154.71 150.09 151.81 150.09

-2.7439 -2.7439 -3.457 -2.7439 -2.9828 -2.7439

180 180 180 180 180 180

8.625 8.625 10.703 8.625 9.319 8.625

0.0006 0.0006 0.0006 0.0006 0.0006 0.0006

5023.8 5023.8 5029.54 5023.8 5025.72 5023.8

5.024 5.024 5.03 5.024 5.026 5.024

6000.58 6000.58 6000.8 6000.58 6001.17 6000.58

6.001 6.001 6.001 6.001 6.001 6.001

1.20E-04 1.20E-04 1.38E-04 1.20E-04 1.10E-04 1.20E-04

4.39E-06 4.39E-06 4.62E-06 4.39E-06 5.59E-06 4.39E-06

1.70E-19 1.70E-19 1.70E-19 1.70E-19 1.70E-19 1.70E-19

14.369 14.369 13.579 14.369 10.592 14.369

1.15 1.15 1.15 1.15 1.15 1.15

0.009 0.009 0.011 0.009 0.012 0.009

0.009 0.009 0.011 0.009 0.012 0.009

2.482 2.482 2.078 2.482 2.327 2.482

6.001 6.001 6.001 6.001 6.001 6.001

7.536 7.536 7.544 7.548 7.539 7.536

You might also like

- Transmission Line Design CalcDocument38 pagesTransmission Line Design CalcparmenderNo ratings yet

- DSLP Calculation by VikasDocument7 pagesDSLP Calculation by Vikasvikasrajput1989100% (2)

- Short Circuit CalculationDocument31 pagesShort Circuit Calculationmohammed hassan abdulaleemNo ratings yet

- IEC1597 and IEC865 equations to calculate current capacity and short circuit withstand capability of 33kV Panther conductorDocument2 pagesIEC1597 and IEC865 equations to calculate current capacity and short circuit withstand capability of 33kV Panther conductornb nbNo ratings yet

- DSLP Calculation 66kV Grid SubstationDocument8 pagesDSLP Calculation 66kV Grid SubstationanilmarturiNo ratings yet

- Full Opcodes Tables of CPUs: Z80A, Z80180 (HD64180)Document9 pagesFull Opcodes Tables of CPUs: Z80A, Z80180 (HD64180)Eugene LisovyNo ratings yet

- CALCULATIONS FOR BUSBAR & CONDUCTOR SIZINGDocument6 pagesCALCULATIONS FOR BUSBAR & CONDUCTOR SIZINGRavindra GoyalNo ratings yet

- EARTHING DESIGN CALCULATIONDocument10 pagesEARTHING DESIGN CALCULATIONarafinNo ratings yet

- DSLP (Control Room) DhamraiDocument3 pagesDSLP (Control Room) DhamraiarafinNo ratings yet

- Technical Specificationof IDT Solar ProjectDocument12 pagesTechnical Specificationof IDT Solar ProjectJitendra Pathak100% (1)

- Earthing calculation for NGR panelDocument4 pagesEarthing calculation for NGR panelnaran19794735No ratings yet

- 4-D03108-0 - Conductor Sizing & BPI Cantilever Strength CalculationDocument13 pages4-D03108-0 - Conductor Sizing & BPI Cantilever Strength CalculationunnvishnuNo ratings yet

- Geotechnical Report BH4-SPT PDFDocument14 pagesGeotechnical Report BH4-SPT PDFanoop13No ratings yet

- CC-SC Current Calculation Moose-ZebraDocument4 pagesCC-SC Current Calculation Moose-ZebraSomen SarkarNo ratings yet

- Sag-Tension Calculation IEEE STD 605 2008Document10 pagesSag-Tension Calculation IEEE STD 605 2008vishnuvyasNo ratings yet

- Power Grid Corporation of India LTDDocument13 pagesPower Grid Corporation of India LTD1382aceNo ratings yet

- DSLP Dirct Srole Lightning ProtectionDocument7 pagesDSLP Dirct Srole Lightning Protectiongsaiswaroopg100% (2)

- Planned Schedule For Koutiala Substation - Technical Consultancy (30.07.2012)Document3 pagesPlanned Schedule For Koutiala Substation - Technical Consultancy (30.07.2012)anoop13No ratings yet

- Jamalpur Earthing Calculation Final PDFDocument10 pagesJamalpur Earthing Calculation Final PDFarafinNo ratings yet

- Forces On Gantry-34Document5 pagesForces On Gantry-34vkjainabc100% (1)

- Short Circuit Force Calculation For 132 KV Substation at Noida-Sector 62Document7 pagesShort Circuit Force Calculation For 132 KV Substation at Noida-Sector 62raghvendraNo ratings yet

- Zebra Current Capacity Calculation SheetDocument1 pageZebra Current Capacity Calculation Sheetbinode100% (1)

- CIvil SpecificationDocument45 pagesCIvil Specificationanoop13No ratings yet

- Swing and Deflection CalculationsDocument28 pagesSwing and Deflection CalculationsanandpurushothamanNo ratings yet

- Aluminium Conductor Sizing - 275kVDocument10 pagesAluminium Conductor Sizing - 275kVsitifarhaniNo ratings yet

- Lightning Protection Calculations for 400/220/33kV Indrapuram SubstationDocument10 pagesLightning Protection Calculations for 400/220/33kV Indrapuram SubstationJay Rameshbhai ParikhNo ratings yet

- Basics of The RET-670:: Ret-670 Relay Calculation ProcedureDocument9 pagesBasics of The RET-670:: Ret-670 Relay Calculation ProcedurevenkateshbitraNo ratings yet

- Fault level calculation for 66kV substation HMSIDocument1 pageFault level calculation for 66kV substation HMSIrahulNo ratings yet

- 33 SCF Tower Span 18mDocument25 pages33 SCF Tower Span 18mamrit90320No ratings yet

- 1.0.0 Symbols & Units: PN SN R SC B BDocument34 pages1.0.0 Symbols & Units: PN SN R SC B BVelu SamyNo ratings yet

- Siemens - CCDocument11 pagesSiemens - CCtrymskvedaNo ratings yet

- EARTHING CALCULATION TITLEDocument28 pagesEARTHING CALCULATION TITLEANANDNo ratings yet

- Sag 340Document37 pagesSag 340ahmadove1No ratings yet

- Minimum clearances and voltage levels for substation equipmentDocument32 pagesMinimum clearances and voltage levels for substation equipmentVíctor RojasNo ratings yet

- D.S.L.P Calculation For 100Kv Switchyard For Centur Rayon by Rolling Sphere Method, As Per IEEE-std 998-1996Document36 pagesD.S.L.P Calculation For 100Kv Switchyard For Centur Rayon by Rolling Sphere Method, As Per IEEE-std 998-1996prabhaamj muraliNo ratings yet

- DSLP CalculationDocument7 pagesDSLP Calculationravi shankar100% (1)

- SAG Tension For TWIN-QUAD Conductor Considering No Wind - InputsDocument2 pagesSAG Tension For TWIN-QUAD Conductor Considering No Wind - InputsAnupam0103No ratings yet

- Larsen & Toubro Limited: ECC Division - EDRC (Electrical)Document10 pagesLarsen & Toubro Limited: ECC Division - EDRC (Electrical)jm.mankavil6230No ratings yet

- SGT-400 Product PresentationDocument42 pagesSGT-400 Product PresentationAnita Moya100% (3)

- Sag 340Document15 pagesSag 340tanujaayerNo ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- 1 RFP 2 X 75 MW Gipcl Gsecl at CharankaDocument297 pages1 RFP 2 X 75 MW Gipcl Gsecl at Charankaanoop13100% (1)

- Feynman Lectures Simplified 2C: Electromagnetism: in Relativity & in Dense MatterFrom EverandFeynman Lectures Simplified 2C: Electromagnetism: in Relativity & in Dense MatterNo ratings yet

- CT Sizing For MalawiDocument2 pagesCT Sizing For MalawiDharmenderSinghChoudharyNo ratings yet

- As D SW SP 4600 3Document9 pagesAs D SW SP 4600 3Odipiyo Paul100% (2)

- Busbar Sizing For SubstationDocument22 pagesBusbar Sizing For Substationdundi_kumarNo ratings yet

- JD-132-QH-E41-03 - Strand Conductor SizingDocument15 pagesJD-132-QH-E41-03 - Strand Conductor SizingRami The OneNo ratings yet

- Sag Tension 765kVDocument11 pagesSag Tension 765kVzain abideenNo ratings yet

- Short-Circuit Currents - Calculation of Effects The Second Edition of Iec Publication 865Document10 pagesShort-Circuit Currents - Calculation of Effects The Second Edition of Iec Publication 865Hassan Bagheri100% (1)

- Short Circuit Calculation 22-8-12Document31 pagesShort Circuit Calculation 22-8-12erikaNo ratings yet

- SC Calculations - EditDocument118 pagesSC Calculations - Editeps.hvdc.ocNo ratings yet

- Sag Tension 765kVDocument11 pagesSag Tension 765kVvikasrajput1989100% (1)

- Aluminium Pipe Bus PDFDocument6 pagesAluminium Pipe Bus PDFaviral mishraNo ratings yet

- DSLP 11 3mDocument7 pagesDSLP 11 3msureshn829No ratings yet

- DSLP-Mast AndraDocument10 pagesDSLP-Mast AndraBNo ratings yet

- Technical Data 33kV AIS VH3Document5 pagesTechnical Data 33kV AIS VH3mahi229No ratings yet

- 22 Standard Earthing Philosophy of GETCO R 2 25-0-711Document4 pages22 Standard Earthing Philosophy of GETCO R 2 25-0-711Ramesh AnanthanarayananNo ratings yet

- Current Distribution in Parallel HTS TapesDocument5 pagesCurrent Distribution in Parallel HTS TapesDante FilhoNo ratings yet

- Design Calculation of Tower T3Document52 pagesDesign Calculation of Tower T3Allan MwesigwaNo ratings yet

- Design Calculation of Tower t1&t2Document57 pagesDesign Calculation of Tower t1&t2Allan MwesigwaNo ratings yet

- CircuitsDocument22 pagesCircuitsapi-3732151100% (1)

- Transmission Line Parameters, Equations & Examples ExplainedDocument107 pagesTransmission Line Parameters, Equations & Examples ExplainedNaasir SheekeyeNo ratings yet

- Fault Current CalculationDocument31 pagesFault Current CalculationKamesh1977No ratings yet

- WINSEM2019-20 ECE2004 TH VL2019205005255 Reference Material I 24-Feb-2020 Planar Transmission LineDocument12 pagesWINSEM2019-20 ECE2004 TH VL2019205005255 Reference Material I 24-Feb-2020 Planar Transmission Linenidhi patelNo ratings yet

- Book1(AutoRecovered)Document37 pagesBook1(AutoRecovered)nikkoelbao96No ratings yet

- Simulation Study of Rectangular Waveguide and Microstrip Line ComponentsDocument12 pagesSimulation Study of Rectangular Waveguide and Microstrip Line ComponentsRishikant KashyapNo ratings yet

- GTRDocument12 pagesGTRanoop13No ratings yet

- Geotechnical Investigation - Uganda Side PDFDocument1 pageGeotechnical Investigation - Uganda Side PDFanoop13No ratings yet

- Earthing BOQ For ICR - GI Strips, Earth Pits & ChemicalsDocument2 pagesEarthing BOQ For ICR - GI Strips, Earth Pits & Chemicalsanoop13No ratings yet

- 33KV CTPT Unit 2015 PDFDocument27 pages33KV CTPT Unit 2015 PDFanoop13No ratings yet

- ONergy Investment Deck ACEF 16Document22 pagesONergy Investment Deck ACEF 16anoop13No ratings yet

- 11KV CT and 33KV CT PT Performence PDFDocument8 pages11KV CT and 33KV CT PT Performence PDFanoop13No ratings yet

- Automatic Static Transfer SwitchDocument2 pagesAutomatic Static Transfer Switchanoop13No ratings yet

- Instrument Transformer GTPDocument6 pagesInstrument Transformer GTPanoop13No ratings yet

- TECH DATADocument4 pagesTECH DATAanoop13No ratings yet

- FDP Brochure 2018Document2 pagesFDP Brochure 2018anoop13No ratings yet

- Zzkumar, Zzanoop: Zzkumar, Zzanoop Wednesday, May 02, 2018 6:26 PM Govil, Nitin Resignation From The Services of CompanyDocument1 pageZzkumar, Zzanoop: Zzkumar, Zzanoop Wednesday, May 02, 2018 6:26 PM Govil, Nitin Resignation From The Services of Companyanoop13No ratings yet

- Brochure TG enDocument8 pagesBrochure TG enpascal_chinNo ratings yet

- Synchrotact CSS: Synchronizing System For Synchronous GeneratorsDocument8 pagesSynchrotact CSS: Synchronizing System For Synchronous Generatorsanoop13No ratings yet

- Synchrotact CSS: Synchronizing System For Synchronous GeneratorsDocument8 pagesSynchrotact CSS: Synchronizing System For Synchronous Generatorsanoop13No ratings yet

- Gothic Architecture FranceDocument5 pagesGothic Architecture Franceanoop13No ratings yet

- Automatic Transfer Switch (Ats) 1600-3000 AMP ZTSCTL Series With Mx200 Microprocessor-Based Control PanelDocument7 pagesAutomatic Transfer Switch (Ats) 1600-3000 AMP ZTSCTL Series With Mx200 Microprocessor-Based Control Panelanoop13No ratings yet

- Fault Level1 ModelDocument1 pageFault Level1 Modelanoop13No ratings yet

- Fault Level2 ModelDocument1 pageFault Level2 Modelanoop13No ratings yet

- FAULT LEVEL Model PDFDocument1 pageFAULT LEVEL Model PDFanoop13No ratings yet

- Fault Level ModelDocument1 pageFault Level Modelanoop13No ratings yet

- 2EHV Susbattions PSJG Apr11Document22 pages2EHV Susbattions PSJG Apr11G.RameshNo ratings yet

- Semiconductor Nanoclusters CourseDocument3 pagesSemiconductor Nanoclusters Courseanoop13No ratings yet

- Magnetic ForceDocument1 pageMagnetic Forceanoop13No ratings yet

- 1HSM 9543 23-03en DCB Application Guide Ed3 - 2013-09 - EnglishDocument60 pages1HSM 9543 23-03en DCB Application Guide Ed3 - 2013-09 - EnglishBelmin ŠabićNo ratings yet

- Sharing of Ists Transmission Charges & Losses: ErldcDocument119 pagesSharing of Ists Transmission Charges & Losses: Erldcanoop13No ratings yet

- Quality Planning ProcessDocument47 pagesQuality Planning ProcessRAZOR GAMINGNo ratings yet

- No. Hotel Address City Star Number of Room Room Allocation PIC Phone EmailDocument27 pagesNo. Hotel Address City Star Number of Room Room Allocation PIC Phone Emailali71usmanNo ratings yet

- BV261 - U Type Butterfly ValveDocument2 pagesBV261 - U Type Butterfly ValveFAIYAZ AHMEDNo ratings yet

- Guia de Configuracion de Firewall Basico en GWN7000 Grandstream PDFDocument16 pagesGuia de Configuracion de Firewall Basico en GWN7000 Grandstream PDFmiguel pcNo ratings yet

- Zerust Flange Savers - WebDocument2 pagesZerust Flange Savers - WebFederico MoranNo ratings yet

- 150ACEBDocument1 page150ACEBBryan LeinwetterNo ratings yet

- Business PlanDocument49 pagesBusiness Plandanie krisyaNo ratings yet

- Endterm Algebra 2019 TT01Document1 pageEndterm Algebra 2019 TT01khang nguyễnNo ratings yet

- Test 1Document6 pagesTest 1AKASH PALNo ratings yet

- Strand & Funtowicz Springer2017Document14 pagesStrand & Funtowicz Springer2017Roger StrandNo ratings yet

- Module Chapter 4 - GE 106Document7 pagesModule Chapter 4 - GE 106Justin Roi ConstantinoNo ratings yet

- Hospitality Industry Mini Project Sem IIndDocument18 pagesHospitality Industry Mini Project Sem IIndSatyam JadonNo ratings yet

- Firestop Product ApplicationsDocument18 pagesFirestop Product Applicationsc1565No ratings yet

- Candle Power Stirling Engine PDFDocument4 pagesCandle Power Stirling Engine PDFFodor EmericNo ratings yet

- Convergys X3: 3-Part WBC Differential Hematology AnalyzerDocument2 pagesConvergys X3: 3-Part WBC Differential Hematology AnalyzerPhong Nguyễn Windy100% (1)

- Gazette On Minimum Wages RMG (Bangladesh) - 2018 - (English)Document11 pagesGazette On Minimum Wages RMG (Bangladesh) - 2018 - (English)Mazharul IslamNo ratings yet

- Spekers ProjectDocument2 pagesSpekers ProjectIsa JoyceNo ratings yet

- Additive Manufacturing Processes and ApplicationsDocument3 pagesAdditive Manufacturing Processes and ApplicationsNishant MayekarNo ratings yet

- HVAC-Indoor AC-LG-Cassette 4 Way 2x2Document4 pagesHVAC-Indoor AC-LG-Cassette 4 Way 2x2Ashar HassanNo ratings yet

- Tez PortalDocument1 pageTez Portalkiran BawadkarNo ratings yet

- Maths (Ist yr)Document4 pagesMaths (Ist yr)MEMES WORLDNo ratings yet

- Nut, Double Hexagon, Self Locking: Page 1/3Document3 pagesNut, Double Hexagon, Self Locking: Page 1/3Renato WatanabeNo ratings yet

- Queuing TheoryDocument25 pagesQueuing TheoryVishal Kapoor100% (1)

- Qualis VHDL-QuickReferenceCard V2.1 PDFDocument2 pagesQualis VHDL-QuickReferenceCard V2.1 PDFlakithaNo ratings yet

- The Ultimate Guide To WaterjetDocument9 pagesThe Ultimate Guide To WaterjetNsidibe Michael EtimNo ratings yet

- Buddy Memory AllocationDocument3 pagesBuddy Memory AllocationBibek GuptaNo ratings yet

- Configurando CMC FACDocument14 pagesConfigurando CMC FACDante ChutorianscyNo ratings yet

- Raspberry Pi Documentation - Remote AccessDocument51 pagesRaspberry Pi Documentation - Remote AccesshelioxNo ratings yet