Professional Documents

Culture Documents

Design of Filter House Structure

Uploaded by

Powerhouse ShaftOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of Filter House Structure

Uploaded by

Powerhouse ShaftCopyright:

Available Formats

LARSEN & TOUBRO LIMITED EDRC - BMH BU, MMH IC

COKE HANDLING SYSTEM PACKAGE (CHSP) FOR DOCUMENT NO DATE

PROJECT:

DCU AISHWARYA PROJECT AT IOCL HALDIA, W.B. O16086-C-BM-CS-DC-0163 04.10.2016

TRANS. TOWER TT-4 : DESIGN CALCULATION OF DSGN CHKD APP REV

TITLE:

SUPERSTRUCTURE SBK ABL ANS B

Design of Monorail

10.11.2014

O14044-C-BM-CS-DC-0033

Beam.

Sensitivity: LNT Construction Internal Use

#

L&T Construction

Water & Effluent treatment IC

Design, build, operate and maintain, and transfer DOCUMENT NO. DATE

water supply system in Belagavi city of Karnataka

PROJECT: State, India for cost effective and sustainable

upscaling to continuous (24x7) pressurized water

LE200357-C-WS-WT-DC-3011

supply

DESIGNED CHECKED REV

TITLE: Filter House

MAH CKP

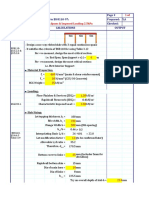

Design of 0T Straight Monorail

Capacity of Monorail = 0 kN

Impact Factor = 1.1 (For manually operated)

Hoist load/ CPB weight = 2 kN

Design Capacity of Monorail = 0*1.1+2 = 2 kN

Assuming the section as ISMB250 @ 37.3

2 kN 0.373 kN/m

A B

4.5 m

Ra Rb

Ra + Rb = 3.68 kN

Taking Moments @ A, Rb = 1.84 kN KLez = 4.5 m

Ra = 1.84 kN KLey = 4.5 m

Section Properties:

Izz = 51300000 mm4 Iyy = 3350000 mm4

Zez = 410000 mm 3

Zey = 53500 mm3

Rzz = 104 mm Ryy = 26.5 mm

Zpz = 465710 mm3 Zpy = 89800 mm3

fy = 250 N/ mm2 fu = 410 Mpa d= 250 mm

Additional loads : (Design of Monorail systems - By Tomas H Orihuela Jr, PE) γmo = 1.1

Axial load on the beam = 10% of 0 KN = 0 KN γm1= 1.25

Lateral load on the beam = 20% of 0 KN = 0 KN γf= 1.5

Max Bending Moment Mz = 3.19 KN. M Mz = 4.785 My = 0

(Unit: KN &

Factored

m)

Max Bending Moment My = 0 KN. M N= 0 Vy= 2.76

Section classification Type Rolled- I Vz = 0

Flange criteria: B= 125 mm Tf = 12.5 e= 1

Limit for

Class

b= 63mm b/tf = 5.0 flange

Plastic 9.4 Plastic

Web criteria: tw = 7mm d/tw = 36.2 10.5 Compact

Plastic 15.7 Semi compact

Limit for web Class

Hence the section is classified as Plastic

Compression Capacity: 84 Plastic

Sensitivity: LNT Construction Internal Use

#

L&T Construction

Water & Effluent treatment IC

Design, build, operate and maintain, and transfer DOCUMENT NO. DATE

water supply system in Belagavi city of Karnataka

PROJECT: State, India for cost effective and sustainable

upscaling to continuous (24x7) pressurized water

LE200357-C-WS-WT-DC-3011

supply

DESIGNED CHECKED REV

TITLE: Filter House

MAH CKP

Euler buckling stress fcc = (π2E)/ (KL/r) 2 105 Compact

Effective Slenderness ratios KLz/rz = 43.3 KLy/ry = 169.81 126 Semi compact

Sensitivity: LNT Construction Internal Use

#

L&T Construction

Water & Effluent treatment IC

Design, build, operate and maintain, and transfer DOCUMENT NO. DATE

water supply system in Belagavi city of Karnataka

PROJECT: State, India for cost effective and sustainable

upscaling to continuous (24x7) pressurized water

LE200357-C-WS-WT-DC-3011

supply

DESIGNED CHECKED REV

TITLE: Filter House

MAH CKP

Max. slenderness ratio = 169.81 < 180 Hence O.K E= 200000 Mpa

fcc z = 1054.28 N/ mm2 fcc y = 68.45 N/ mm2

Non- dimensional effective slenderness ratio lz = 0.49 ly = 1.91

Buckling class: Z-Z axis a Y-Y axis b h / bf = 2

a= 0.21 a= 0.34

Ф = 0.5 [1 + a(λ – 0.2) + λ2] χ = 1/ (Ф+ (Ф2 - λ2)0.5)

fz= 0.65 fy= 2.61 cz= 0.93 cy= 0.23

fcd = χ fy / γmo A= 4750 mm2

fcd z = 211.36 Mpa fcd y = 52.27 Mpa fy / γ mo = 227.27 Mpa

Compression Capacity Pdz = 1003.96 KN Pdy = 248.28 KN

Shear Capacity:

Vdy = fy x h x tw / γ mo x 1.732 = 226.35 KN Vdy > Vy O.K

Vdz = fy x 2 x b x tf / γ mo x 1.732 = 410.06 KN Vdz > Vz O.K

Flexural Capacity:

Compression flange is Laterally unsupported

Elastic lateral torsional buckling moment: 2 EI y 2 EI w μ= 0.3

M cr GI t

( LLT ) 2 ( LLT ) 2

bi t i3

G = E/2(1+m) = 76923.08 N/mm2 It = 160022.841666667 (bfxtf3)/3+((D-2xtf)xtw3)/3

3

Iw = Warping constant = 1 f f I y hy2 f 0.5 for symetric I section hy = (D - tf) = 237.5 mm

Iw = 47240234375 mm6 Mcr = 67.809 KN- m

Non dimensional slenderness ratio(λLT): bZ p f y ≤ Sqrt (1.2 Ze fy / Mcr)

LT

M cr bb = 1

1.3103445 ≤ 1.347 1.31

>0.4 Therefore Lateral buckling governs

1

1.0 2 aLT = 0.21

LT

LT

LT

2

2

LT

0.5

LT 0.5 1 ( LT 0.2) LT

ΦLT = 1.48 c LT = 0.46 < 1

Sensitivity: LNT Construction Internal Use

#

L&T Construction

Water & Effluent treatment IC

Design, build, operate and maintain, and transfer DOCUMENT NO. DATE

water supply system in Belagavi city of Karnataka

PROJECT: State, India for cost effective and sustainable

upscaling to continuous (24x7) pressurized water

LE200357-C-WS-WT-DC-3011

supply

DESIGNED CHECKED REV

TITLE: Filter House

MAH CKP

f bd LT f y / mo = 104.55 N/mm2

M d b Z p f bd = 48.69 KN- m

Flexural capacity (Mdz) = 48.69 KN- m

Flexural capacity (Mdy) = b Zp fy 1.2 Z e f y

Md

mo mo

= 20.41 > 14.59

= 14.59 KN- m

Check for Section strength:

n= N/Nd = 0 5n = 0

Nd = Ag x fy/gmo = 1079.55 a1= 1

Mndz = 54.05 > 48.69 Mndy = 14.59 KN- m a2= 2

= 48.69 KN- m

(My/Mndy)a1 + (Mz/Mndz)a2 ≤ 1.0 = 0.01 < 1 Hence O.K

(N/Nd)+(My/Mdy)+(Mz/Mdz) ≤ 1.0 0.1 < 1

Check for Overall member strength:

Ky = 1+ (ly-0.2) ny ≤ 1 +0.8 ny ny = 0.0000

= 1 < 1 = 1

Kz = 1+ (lz-0.2) nz ≤ 1 +0.8 nz nz = 0.0000

= 1 < 1 = 1

KLT = 0.1LT n y 0.1ny Assuming sway members

1 1

CmLT 0.25 CmLT 0.25

CmLT = 0.6+0.4y = 1 Cmy= 0.9

= 1 < 1 Therefore, KLT = 1 Cmz= 0.9

P Cmy M y Mz

ky k LT 1.0 = 0.1

Pdy M dy M dz

P Cmy M y Cmz M z

0.6 k y kz 1.0 = 0.09 Hence O.K

Pdz M dy M dz

Check for strength of bottom flange against combined Global & Local bending :

sz, local = γf k1 Pk / t2

Where,

k1 - coefficient to be taken from the following table - 1 based on c/a value

Pk - load per wheel (no. of wheels = 4)

t - flange thickness at (b-d)/4 from the flange edge, for parallel flange beams = tf

Pk

Sensitivity: LNT Construction Internal Use

#

L&T Construction

Water & Effluent treatment IC

Design, build, operate and maintain, and transfer DOCUMENT NO. DATE

water supply system in Belagavi city of Karnataka

PROJECT: State, India for cost effective and sustainable

upscaling to continuous (24x7) pressurized water

LE200357-C-WS-WT-DC-3011

supply

DESIGNED CHECKED REV

TITLE: Filter House

MAH CKP

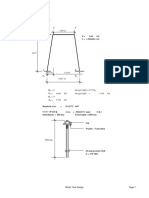

Tf = 12.5 mm

Additional

a c e Plate @

e = 16 mm Bottom 0 mm

c = 62.5 - 16 = 46.5 mm

c/a = 46.5 / 62.5 = 0.74

Table - 1

c/a 0.67 0.7 0.75 0.8 0.85 0.9

k1 0.8 1.1 1.5 1.9 2.2 2.6

k1 = 1.42

sz, local = 1.5x1.42*(2*1000/4)/12.5^2 = 6.82 N/mm 2

Mz/Zp,zz + σz,local < fy/γm0

17.09 < 227.27 HENCE OK

Check for Deflection:

Actual deflection=PL3/48EI As per IS 800:2007 Table-

6

= 2*1000*4500^3/48/51300000/200000 = 0.37 mm Limit 500

Permissible Deflection = 9.00 mm HENCE O.K

Sensitivity: LNT Construction Internal Use

#

L&T Construction

Water & Effluent treatment IC

Design, build, operate and maintain, and transfer DOCUMENT NO. DATE

water supply system in Belagavi city of Karnataka

PROJECT: State, India for cost effective and sustainable

upscaling to continuous (24x7) pressurized water

LE200357-C-WS-WT-DC-3011

supply

DESIGNED CHECKED REV

TITLE: Filter House

MAH CKP

Sensitivity: LNT Construction Internal Use

#

You might also like

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- 3a. MonorailDocument15 pages3a. MonorailLagnajit DasNo ratings yet

- ASD-Design of Steel BeamDocument5 pagesASD-Design of Steel BeamsivakumarNo ratings yet

- Typical Beam Column Design ElectricalDocument4 pagesTypical Beam Column Design ElectricalPrabhumk07No ratings yet

- L&T Water Treatment DesignDocument2 pagesL&T Water Treatment DesignPowerhouse ShaftNo ratings yet

- STG Side Runner DesignDocument10 pagesSTG Side Runner DesignJohnclaude ChamandiNo ratings yet

- Appendix A1Document5 pagesAppendix A1Thomas Stephen100% (1)

- AiscDocument13 pagesAiscsteven bianesNo ratings yet

- 1 Rib DimensionsDocument6 pages1 Rib DimensionsimranmehfoozNo ratings yet

- Columns DesignDocument60 pagesColumns DesignifsrebraNo ratings yet

- 2023-01-13 - BP - Process Water Sleeper CalculationsDocument27 pages2023-01-13 - BP - Process Water Sleeper CalculationsPruthviraj JuniNo ratings yet

- Aisc360 Box Steel DesignDocument3 pagesAisc360 Box Steel DesignHattori HanzoNo ratings yet

- DESIGN OF TWO-WAY SLAB Page16Document1 pageDESIGN OF TWO-WAY SLAB Page16Keana Lauren Lamaton AbuanNo ratings yet

- AISC360 composite member designDocument2 pagesAISC360 composite member designHattori HanzoNo ratings yet

- Footing Calculation SheetDocument1 pageFooting Calculation SheetSiva JaseNo ratings yet

- JETTY 3000dwt: Title Document No.: Breasting Dolphin-Engineering Calculation Revision: Issued Date: CompanyDocument2 pagesJETTY 3000dwt: Title Document No.: Breasting Dolphin-Engineering Calculation Revision: Issued Date: CompanyAnonymous nXGOGxyeNo ratings yet

- Your Logo: 1 Rib DimensionsDocument8 pagesYour Logo: 1 Rib DimensionsAamirShabbirNo ratings yet

- Larsen & Toubro Limited Ecc Division: Transformer Transportation On Solding Khad Bridge Design Review of PierDocument3 pagesLarsen & Toubro Limited Ecc Division: Transformer Transportation On Solding Khad Bridge Design Review of PiervibishnanNo ratings yet

- Deck Girder - Top GirderDocument3 pagesDeck Girder - Top GirdervibishnanNo ratings yet

- R.C. Slab Design Calculation Sheet for Two Way Slab S1Document1 pageR.C. Slab Design Calculation Sheet for Two Way Slab S1sallysel90No ratings yet

- PILE ANALYSISDocument4 pagesPILE ANALYSISRuemu Godwin InikoriNo ratings yet

- Base PlateDocument13 pagesBase PlateNaga Manikanta TatikondaNo ratings yet

- BP - Process Water Sleeper CalculationsDocument13 pagesBP - Process Water Sleeper CalculationsPruthviraj JuniNo ratings yet

- Bu Tfl.u 1 2: Checking and Packing Hall Checked byDocument3 pagesBu Tfl.u 1 2: Checking and Packing Hall Checked byHarjasa AdhiNo ratings yet

- 3.column DesignDocument48 pages3.column DesignReuben James BangaoilNo ratings yet

- Slab Design6 Edj ROOFDocument2 pagesSlab Design6 Edj ROOFhedayatullahNo ratings yet

- Mathcad - SENGKANG SLOOF S-01 GUDANG CMTFDocument4 pagesMathcad - SENGKANG SLOOF S-01 GUDANG CMTFAndre NovanNo ratings yet

- Design Parameter PositionDocument38 pagesDesign Parameter PositionLenielle AmatosaNo ratings yet

- Design of Composite Beam-and-Slab Using I 500x190x13x25 Steel SectionDocument4 pagesDesign of Composite Beam-and-Slab Using I 500x190x13x25 Steel SectionThắngg TrịnhhNo ratings yet

- Check For Compression Welds Between Beam Flanges and End PlateDocument3 pagesCheck For Compression Welds Between Beam Flanges and End PlateKrish ChandNo ratings yet

- Slab design calculations for two-storey residential projectDocument6 pagesSlab design calculations for two-storey residential projectZulkiflee TaugNo ratings yet

- Design review of arch compression structureDocument3 pagesDesign review of arch compression structurevibishnanNo ratings yet

- Design of Cantilever Slab:: Material and PropertiesDocument3 pagesDesign of Cantilever Slab:: Material and PropertiesPoshan DhunganaNo ratings yet

- Appendix A3Document6 pagesAppendix A3Thomas Stephen100% (1)

- Gantry CraneDocument31 pagesGantry Cranekushaljp8989No ratings yet

- Sumitomo Corporation: Checked by of Area: Turbine Build. Rev Dept StructuralDocument18 pagesSumitomo Corporation: Checked by of Area: Turbine Build. Rev Dept Structuralabhi aroteNo ratings yet

- Pile DesignDocument9 pagesPile Designhabibur Rahman Khan100% (1)

- Example 5.1Document6 pagesExample 5.1Aisyah JamalNo ratings yet

- Slab Design Calculation: f (5* f A /8 A βDocument1 pageSlab Design Calculation: f (5* f A /8 A βchannajayamangala100% (1)

- Design calculations for 11m span crane gantry girderDocument20 pagesDesign calculations for 11m span crane gantry girderkushaljp8989No ratings yet

- Calcs - TK609 Fujairah.Document5 pagesCalcs - TK609 Fujairah.PmohamedFazilNo ratings yet

- Beam Design TemplateDocument9 pagesBeam Design TemplateWinston AdvinculaNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document5 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Murthy GunaNo ratings yet

- Sheet Pile Design: Fspiii S275 Hot RolledDocument1 pageSheet Pile Design: Fspiii S275 Hot Rolledhessian123No ratings yet

- Flexural beam design calculationDocument17 pagesFlexural beam design calculationReceb AgaNo ratings yet

- Open Foundation With Eccentric Loading and Moments-FinalDocument6 pagesOpen Foundation With Eccentric Loading and Moments-FinalMahadev Sastry100% (1)

- Base Plate Design Is 800 2007Document147 pagesBase Plate Design Is 800 2007pandian100% (1)

- 10m Slab BridgeDocument20 pages10m Slab BridgeYosef Kiros100% (1)

- Arch - BracingDocument3 pagesArch - BracingvibishnanNo ratings yet

- 4.beam Design Singly and DoublyDocument10 pages4.beam Design Singly and DoublyReuben James BangaoilNo ratings yet

- 8.A Arch Main Member With BendingDocument4 pages8.A Arch Main Member With BendingvibishnanNo ratings yet

- Check Shear and Bending Capacity of Reinforced Concrete BeamDocument1 pageCheck Shear and Bending Capacity of Reinforced Concrete BeamAthar YogaNo ratings yet

- One-Way Ribbed Slab Design As Per BS8110Document5 pagesOne-Way Ribbed Slab Design As Per BS8110yusuf abdinasir100% (5)

- Elevated Water Tank Design Spreadsheet - 7Document1 pageElevated Water Tank Design Spreadsheet - 7ArielNo ratings yet

- Purlin and RunnerDocument8 pagesPurlin and RunnerBabu Sundararaman0% (1)

- Beam Columns Example - Is 800Document7 pagesBeam Columns Example - Is 800anil97232No ratings yet

- Crane & CorbelDocument3 pagesCrane & CorbelWangTFNo ratings yet

- Attachment 1 - Bi-Axial Bending CheckDocument2 pagesAttachment 1 - Bi-Axial Bending CheckYang W OngNo ratings yet

- Charge-Based MOS Transistor Modeling: The EKV Model for Low-Power and RF IC DesignFrom EverandCharge-Based MOS Transistor Modeling: The EKV Model for Low-Power and RF IC DesignNo ratings yet

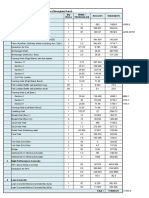

- Barrage BOQDocument19 pagesBarrage BOQPowerhouse ShaftNo ratings yet

- Reply R-AFC.4667.09.301 R1 CRSDocument10 pagesReply R-AFC.4667.09.301 R1 CRSPowerhouse ShaftNo ratings yet

- Barrage Concrete QuantitiesDocument1 pageBarrage Concrete QuantitiesPowerhouse ShaftNo ratings yet

- Barrage BOQDocument19 pagesBarrage BOQPowerhouse ShaftNo ratings yet

- Barrage Concrete Quantities13 Dec 16Document1 pageBarrage Concrete Quantities13 Dec 16Powerhouse ShaftNo ratings yet

- L&T Construction: B D F K N Q S CDocument1 pageL&T Construction: B D F K N Q S CPowerhouse ShaftNo ratings yet

- Property drawing confidentialityDocument1 pageProperty drawing confidentialityPowerhouse ShaftNo ratings yet

- Barrage Concrete Quantities13 Dec 16Document1 pageBarrage Concrete Quantities13 Dec 16Powerhouse ShaftNo ratings yet

- L&T Construction: Typical Grade Slab DetailDocument1 pageL&T Construction: Typical Grade Slab DetailPowerhouse ShaftNo ratings yet

- 0.2 ContentsDocument9 pages0.2 ContentsPowerhouse ShaftNo ratings yet

- L&T Construction: PLAN AT EL (+) 529.750M (TOC)Document1 pageL&T Construction: PLAN AT EL (+) 529.750M (TOC)Powerhouse ShaftNo ratings yet

- LTCD Kuidfc Wet Uwwm SK 20-21 204Document2 pagesLTCD Kuidfc Wet Uwwm SK 20-21 204Powerhouse ShaftNo ratings yet

- L&T Construction Water Treatment Filter Complex DesignDocument3 pagesL&T Construction Water Treatment Filter Complex DesignPowerhouse ShaftNo ratings yet

- 0.1 Title ContentsDocument6 pages0.1 Title ContentsPowerhouse ShaftNo ratings yet

- 25 - Roof SlabDocument6 pages25 - Roof SlabPowerhouse ShaftNo ratings yet

- 23 Column RCDocument203 pages23 Column RCPowerhouse ShaftNo ratings yet

- 22 Beam RADocument1,579 pages22 Beam RAPowerhouse ShaftNo ratings yet

- L&T Construction Document PropertyDocument108 pagesL&T Construction Document PropertyPowerhouse ShaftNo ratings yet

- 9 Raft 818.850MDocument9 pages9 Raft 818.850MPowerhouse ShaftNo ratings yet

- Java Programming: Lab Assignment 2Document17 pagesJava Programming: Lab Assignment 2Sanjana chowdary50% (4)

- Gartner Reprint 2022Document33 pagesGartner Reprint 2022Sajan Rajagopal100% (1)

- (GUIDE) Advanced Interactive Governor Tweaks Buttery Smooth and Insane Battery Life! - Page 519 - Xda-DevelopersDocument3 pages(GUIDE) Advanced Interactive Governor Tweaks Buttery Smooth and Insane Battery Life! - Page 519 - Xda-Developersdadme010% (2)

- Business Strategy, PerformanceDocument20 pagesBusiness Strategy, Performance6oktoberday2023No ratings yet

- An SAP Consultant - ABAP - ALV Blocked List1Document3 pagesAn SAP Consultant - ABAP - ALV Blocked List1Shikhar AgarwalNo ratings yet

- Uti MF v. Ito 345 Itr 71 - (2012) 019taxmann - Com00250 (Bom)Document8 pagesUti MF v. Ito 345 Itr 71 - (2012) 019taxmann - Com00250 (Bom)bharath289No ratings yet

- TM 9-1651 Data Transmission System m3, January 1942Document78 pagesTM 9-1651 Data Transmission System m3, January 1942Advocate100% (1)

- Cis Bin Haider GRP LTD - HSBC BankDocument5 pagesCis Bin Haider GRP LTD - HSBC BankEllerNo ratings yet

- Del Monte Golf Club in BukidnonDocument1 pageDel Monte Golf Club in BukidnonJackieNo ratings yet

- Incidentrequest Closed Monthly JunDocument250 pagesIncidentrequest Closed Monthly Junأحمد أبوعرفهNo ratings yet

- HW1Document1 pageHW1mohsenanNo ratings yet

- Nevada Reports 1882-1883 (17 Nev.) PDFDocument334 pagesNevada Reports 1882-1883 (17 Nev.) PDFthadzigsNo ratings yet

- Key Benefits of Cloud-Based Internet of Vehicle (IoV) - Enabled Fleet Weight Management SystemDocument5 pagesKey Benefits of Cloud-Based Internet of Vehicle (IoV) - Enabled Fleet Weight Management SystemVelumani sNo ratings yet

- Order From U.S. Disctrict Judge Jesus G. Bernal To Chino Valley UnifiedDocument9 pagesOrder From U.S. Disctrict Judge Jesus G. Bernal To Chino Valley UnifiedBeau YarbroughNo ratings yet

- Personal Financial StatementDocument3 pagesPersonal Financial StatementChristopher MacLeodNo ratings yet

- Federal Ombudsmen Institutional Reforms Act, 2013Document8 pagesFederal Ombudsmen Institutional Reforms Act, 2013Adv HmasNo ratings yet

- Global Service Learning: M325D MH / M325D L MH Material HandlersDocument52 pagesGlobal Service Learning: M325D MH / M325D L MH Material Handlersanon_828943220100% (2)

- Epc50-50e Om 2-20Document46 pagesEpc50-50e Om 2-20Sidhi SadanNo ratings yet

- OE-254/GRC antenna parts listDocument2 pagesOE-254/GRC antenna parts listVictor GarciaNo ratings yet

- Sample Administrative Disicplinary CasesDocument13 pagesSample Administrative Disicplinary CasesWen DyNo ratings yet

- Telecommunications: Office of The Communications Authority (OFCA)Document2 pagesTelecommunications: Office of The Communications Authority (OFCA)ChiWoTangNo ratings yet

- FINAL Exam - Answer SheetDocument1 pageFINAL Exam - Answer SheetViggo VillanuevaNo ratings yet

- Haukongo Nursing 2020Document86 pagesHaukongo Nursing 2020Vicky Torina ShilohNo ratings yet

- ISO 9001 Quality Management ProceduresDocument7 pagesISO 9001 Quality Management ProceduresFendi100% (1)

- File Signature LabDocument3 pagesFile Signature LabGheorghe RotariNo ratings yet

- The Bank and The Mundhra AffairDocument14 pagesThe Bank and The Mundhra AffairAmbika MehrotraNo ratings yet

- BLRBAC Emergency Shutdown Procedure (February 2012)Document18 pagesBLRBAC Emergency Shutdown Procedure (February 2012)SubburajMechNo ratings yet

- OCP - SQL&PL - SQL (Vol1)Document322 pagesOCP - SQL&PL - SQL (Vol1)api-3814149100% (1)

- Coal Petroleum: Crude OilDocument25 pagesCoal Petroleum: Crude Oiljojo basenNo ratings yet