Professional Documents

Culture Documents

Cat Dcs Sis Controller CSSISImageServletmatik

Uploaded by

imam nahrowiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cat Dcs Sis Controller CSSISImageServletmatik

Uploaded by

imam nahrowiCopyright:

Available Formats

COMPONENT LOCATIONS Filter Bypass Switch KENR5173-02

Item

Description

Part Schematic Additional service covers located on the left side of the June 2010 FLUID POWER SYMBOLS

Number Number Location machine are: A C

BASIC COMPONENT SYMBOLS

IMPLEMENT R8

(A) The cab filter access.

1 PUMP GROUP 252-2679 D7

IMPLEMENT VALVE GP (B) The test panel access. R3 PUMP or MOTOR FLUID CONDITIONER SPRING CONTROL VALVES RESTRICTION LINE RESTRICTION

MAIN AUX.

2-SECTION PUMP

PUMP: VARIABLE and

PRESSURE COMPENSATED

2 VALVE GROUP- LIFT, TILT 247-1753 E2 (FIXED)

3 VALVE GROUP- LIFT, TILT, RIP 252-5067 E2 (C) The hystat hydraulic filters access (953D) and

57 engine. 35

4 VALVE GROUP- LIFT, TILT, MP 247-1749 E2

5 VALVE GROUP-LIFT, TILT, MP, RIP 247-1750 E2

(D) The alternator access and tool box (963D).

B VARIABILITY SPRING

(ADJUSTABLE)

LINE RESTRICTION

(VARIABLE)

PRESSURE

COMPENSATION

HYDRAULIC PNEUMATIC

ENERGY TRIANGLES

LINE RESTRICTION

VARIABLE and PRESSURE

ATTACHMENT

COMPENSATED

6 CYLINDER GROUP-LIFT 248-8788 C1

(Figure: 1)

D VALVE ENVELOPES

VALVES

VALVE PORTS

7 CYLINDER GROUP-LIFT 252-6337 C1

8 CYLINDER GROUP-TILT 269-6483 B1

9 CYLINDER GROUP-RIPPER 286-0814 E1

Starter TWO POSITION THREE POSITION TWO-WAY FOUR-WAY

10 CYLINDER GROUP-MP BUCKET 292-9044 D1 ONE POSITION THREE-WAY

IMPLEMENT VALVE GP (Internal Components) Both the implement hydraulic system, demand fan system, and the hystat system can be easily checked using the remote CONTROL VALVES CHECK VALVES

11 ACCUMULATOR 160-2669 B1 taps on the test panel. The taps are used to check the: AB AB

12 VALVE GROUP-DEAD ELECTRONICS LOWER 112-1817 B1 (Figure: 4)

13 VALVE GROUP-PILOT SHUTOFF SOLENOID 221-4486 B2 Located in the service area at the left rear of the machine on the 953D are the: P T P T

14 VALVE GROUP-PILOT SOLENOID 189-8898 B2-D2, B3-D3 R8 R6 R4 R2 NORMAL POSITION SHIFTED POSITION INFINITE POSITION

BASIC

SYMBOL

SPRING

LOADED

SHUTTLE PILOT

CONTROLLED

(35) Left and Right Hystat Charge Filter

R0 FR PUMP LOOP PRESS. MB PORT (LEFT LOOP)

58

15 VALVE GROUP-RELIEF 227-1184 E3

Cylinder

R0 R1 RR PUMP LOOP PRESS. MA PORT (RIGHT LOOP)

(R9) RR Pump Charge Pressure Port (Right Loop). FLUID STORAGE RESERVOIRS

16 VALVE GROUP-CHECK (LIFT) 257-7732 C2 (R4) FR Pump Charge Pressure Port (Left Loop).

calibration R2 FR PUMP CHARGE PRESS. G PORT (LEFT LOOP)

17 VALVE GROUP-RELIEF (LIFT) 266-3594 C3 port R3 RR PUMP CHARGE PRESS. G PORT (RIGHT LOOP)

18 VALVE GROUP-RELIEF (TILT, MP, RIPPER) 266-3592 B3, D2 R4 FR PUMP CASE PRESS. R PORT (LEFT LOOP)

R5 PARK BRAKE PRESS. PB PORT VENTED PRESSURIZED RETURN ABOVE FLUID LEVEL RETURN BELOW FLUID LEVEL

19 ANTI DRIFT VALVE 257-7730 D3, E3

R6 IMPL PUMP OUTLET PRESS. B PORT

20 VALVE GP- LOAD SENSE FLOW REGULATOR 227-1185 E3 (Figure: 2) R7 IMPL PUMPCASE FILLING PORT HYSTAT CHARGE FILTERS MEASUREMENT ROTATING SHAFTS

21 VALVE GROUP-MARGIN RELIEF 299-7210 E2

R1

R8

R9

IMPL PUMP SIGNAL PRESS. LS PORT

FAN PUMP OUTLET PRESS. B PORT 953D Track-Type Loader

Diagnostic Mounted next to the panel are the cylinder

HYSTAT

Hydraulic and Power Train System

PRESSURE TEMPERATURE FLOW UNIDIRECTIONAL BIDIRECTIONAL

connector calibration port and diagnostic connector Left F-N-R

30 PUMP GROUP- DRIVE/REVERSE CHARGE 243-6637 C6 port for connecting ET to the machine. Charge Pressure

31 MOTOR GROUP-RH 243-6640 A9

port R3 Relief Valves.

Control Valves COMBINATION CONTROLS

32 MOTOR GROUP-LH 243-6639 E9 R7

33 VALVE GROUP- RETURN MANIFOLD 281-1680 E5

R9 R5 Right F-N-R LBP1-980

Control Valves

34 VALVE GP- LOCKOUT AND BRAKE SOLENOID 252-2237 E5 SOLENOID SOLENOID SOLENOID SOLENOID and SERVO THERMAL DETENT

Cross Over or MANUAL and PILOT PILOT or MANUAL

35 CHARGE FILTER 264-2995 D7

Relief Valves.

36 PRESSURE SENSOR- 'G' PORT 261-0420 E9 MANUAL CONTROL SYMBOLS

37 VALVE GROUP - CHECK 185-4026 D6

FAN G H P15

40

41

PUMP GROUP

MOTOR GROUP

251-9555

280-7283

FAN MANIFOLD and ASSOCIATED COMPONENTS

C8

C9

Just below the cab filter compartment the

following components can be accessed:

P19

A B P16

PUSH-PULL LEVER

RELEASED PRESSURE

MANUAL SHUTOFF GENERAL MANUAL

PILOT CONTROL SYMBOLS

PUSH BUTTON PEDAL

REMOTE SUPPLY PRESSURE

SPRING

42 MANIFOLD GROUP - (STANDARD FAN MANIFOLD) 252-7008 C9 (E) the cab support brace.

42a MANIFOLD GROUP- (REVERSING FAN OPTION) 291-9652 C9

30

43 VALVE GROUP-FAN CONTROL SOLENOID 211-2092 C8

(F) the hydraulic test panel.

EXTERNAL RETURN INTERNAL RETURN SIMPLIFIED COMPLETE INTERNAL

59 44 VALVE-CHECK (ANTI CAVITATION) 177-3868 C8

(G) one of the hystat charge filters for the

SUPPLY PRESSURE

45 VALVE GROUP-AUTO REVERSING SOLENOID 241-5895 C9 963D. The second hydraulic filter is

P20 ACCUMULATORS CROSSING AND JOINING LINES HYDRAULIC AND PNEUMATIC CYLINDERS

46 VALVE GROUP-DIVERTER VALVE 252-7010 C9 mounted behind the first one. See E (Figure: 5)

47 VALVE GROUP-CROSSOVER RELIEF 208-0886 C9 (figure:1) and (figure:4) for the location of

the 953D hystat filters (item number 35). This illustration shows the two power train hystat pumps. The left drive pump is on the SPRING LOADED GAS CHARGED LINES CROSSING LINES JOINING SINGLE ACTING DOUBLE ACTING

right nearest the flywheel housing, and the right drive pump is in the center ahead of the

48 SPIDER AS. 241-8534 C9

(H) the hand pump to raise the cab. implement pump. Components and service points shown include:

MISCELLANEOUS F (Figure: 3)

HYDRAULIC PUMPS HYDRAULIC MOTORS INTERNAL PASSAGEWAYS

(30) Left (A) and Right (B) hystat drive pump group.

TANK GROUP and ASSOCIATED COMPONENTS (P15) FR pressure test port. (Plugged, Tap must be installed for testing) FIXED VARIABLE DISPLACEMENT FIXED VARIABLE DISPLACEMENT INFINITE THREE TWO

50 TANK GROUP 280-2053 A7, A8 DISPLACEMENT NON-COMPENSATED DISPLACEMENT NON-COMPENSATED POSITIONING POSITION POSITION

The cab may be tilted nearly 90° forward to access some of the system components. The cab support brace (1) will (P16) FR pressure test port. (Plugged, Tap must be installed for testing)

51 SCREEN-SUCTION (IMPLEMENT) 202-6625 A8

support the cab at a maximum angle of approximately 30°. Angling the cab further than 30° requires the use of a hoist or (P19) RR pressure test port. (Plugged, Tap must be installed for testing)

52 SCREEN-SUCTION (FAN AND CHARGE) 142-8929 A7, A8 service truck boom.

60 (P20) RR pressure test port. (Plugged, Tap must be installed for testing) UNIDIRECTIONAL UNIDIRECTIONAL

53 BREATHER 183-3873 A7

54 VALVE GP-CHECK (BACK PRESSURE) 270-4350 A7 NOTE: The hystat charge filters are mounted at the left rear in the engine compartment on the 953D. FLOW IN ONE PARALLEL CROSS FLOW ALLOWED IN

DIRECTION FLOW FLOW EITHER DIRECTION

BIDIRECTIONAL BIDIRECTIONAL

55 TEMPERATURE SENSOR- TANK OIL 256-6453 A7

56 OIL COOLER 266-2070 E5

REMOTE TEST PANEL ACCESS HYSTAT PUMP GROUPS © 2010 Caterpillar Printed in U.S.A.

All Rights Reserved

TAP LOCATIONS

PRESSURE, SAMPLING AND SENSOR

Schematic

Tap Number Description

Location Radiator Cooling

implement pump suction line Guard Fan

REMOTE PRESSURE PORT LOCATION

35 36 32 37 34 33 30 1 40 R0-R9 7 60 57 58 56 10 Assembly Module

R0 FR PUMP LOOP PRESS. MB PORT (LEFT LOOP) D8 This illustration to the left shows the variable displacement

R1 RR PUMP LOOP PRESS. MA PORT (RIGHT LOOP) D8

*9 40 implement pump and the fixed displacement fan pump. Electrical Symbols Table

The implement pump control valve receives an implement

R2 FR PUMP CHARGE PRESS. G PORT (LEFT LOOP) C5 load signal from the implement valve signal network to Hydraulic Symbols (Electrical)

R3 RR PUMP CHARGE PRESS. G PORT (RIGHT LOOP) D6 control pump displacement.

R4 FR PUMP CASE PRESS. R PORT (LEFT LOOP) D5 56

R5 PARK BRAKE PRESS. PB PORT C7

Fan speed is controlled by a PWM solenoid in the fan

control manifold or reversing fan

41

R6

R7

IMPL PUMP OUTLET PRESS. B PORT

IMPL PUMPCASE FILLING PORT

D8

E5

41 manifold.

Components shown include the:

56

G M

R8 IMPL PUMP SIGNAL PRESS. LS PORT D7 Transducer Transducer

(1) variable displacement implement pump. Generator Electric Motor

R9 FAN PUMP OUTLET PRESS. B PORT C7

1 (40) fan pump.

(Fluid) (Gas / Air)

(Dimensions: 39 inches x 24 inches)

LOCAL PRESSURE PORT LOCATIONS

P14 FR PUMP 'MA' PORT C6

P15 FR PUMP 'X1' PORT (Plugged) C6

48

P16 FR PUMP 'X2' PORT (Plugged) C6

(Figure: 7) Shutoff

KENR5173-02

P18 RR PUMP 'MB' PORT D6 (Figure: 10) Switch

P19 RR PUMP 'X1' PORT (Plugged) C7

P20 RR PUMP 'X2' PORT (Plugged) C7 Radiator and cooler core cleaning and service can be accomplished Pressure Switch Pressure Switch Temperature Switch Electrical Wire

P21 RR PUMP 'Y' PORT D7 by unlocking the fan and guard assembly to allow the fan to be (Adjustable)

Fill Tube

On the 953D the hydraulic oil tank is mounted in the left front of swung to the side for radiator cooling module service. The demand

the machine (50). An oil level sight gauge is mounted to the left fan control manifold is mounted to the machine frame below the radia-

59 *9 31 7 8 10 hand side of the tank and is visible while standing at the left 50 tor. A hydraulic motor (41) drives the fan. A reversing demand fan is Electrical Symbols (Electrical)

front side of the machine.

available as an attachment. The ground level engine shutoff

The tank can be filled from above the machine through the fill 57 switch is located on the lower right.

tube.

T

Tank A The hydraulic oil temperature sensor (not shown) is mounted 11

60 8 56 to the rear of the tank near pump suction line hoses. FAN MOTOR and COOLING Pressure Temperature Level Flow

Symbol Symbol Symbol Symbol

To the left of the tank are the main hydraulic control valve

35 group (57) and the accumulator forthe pilot system (11).

B

A Wire Number Identification Codes

Oil Level

Sight Gauge (Figure: 8)

B 48 44 Electrical Schematic Example Hydraulic Schematic Example

43 Current Standard

Current Standard

41

32 31 A Components of the 953D implement control valve group include the: Harness identification code

This example indicates

20 Page,

wire 135 in harness "AG". Wire

56 (A) inlet manifold 47 Circuit Number Wire Color

36 B 12 (B) bucket tilt control valve

Identification

(Figure: 6) 325-AG135 PK-14

(C) loader arm lift control valve 45

B (D) MP bucket control valve 46 325-PK

C (E) ripper control valve

(Figure: 11) Circuit Identification Wire Color Wire Gauge

59 Number

The two variable speed drive motors are the same. Each motor group consists of the C (13) pilot shut off solenoid and outlet manifold

This illustration shows the reversing demand fan manifold. The manifold is

following components: (15) line relief and makeup valve mounted to the machine frame below the cooling modules. The Machine Previous Standard

(F) PWM solenoid valve ECM and the Engine ECM work together to control the fan solenoids.

(32) left drive motor D Wire

Wire Color

(12) manual lower valve Components of the manifold include the:

(31) right drive motor

(A) motor control valve pressure sense line *9 E

(Figure: 9) (A) Line to fan motor, (46) Diverter Valve 325-PK-14

(B) speed sensor (one on each motor)

(B) Drain line from fan motor, (47) Crossover Relief Valve

(36) motor control valve pressure sensor (POR) 36 32 31 37 34 33 30 1 40 R0-R9 7 57 58 10 (43) Fan Control Solenoid, (45) Auto Reversing Solenoid

B A

(C) motor displacement control PWM solenoid F 15 13 Circuit Number

Identification

Wire Gauge

(EXAMPLE VALVE)

*#9 Ripper Lift Cylinders Not Shown

HYSTAT MOTOR GROUPS COMPONENT LOCATIONS IMPLEMENT CIRCUIT DEMAND FAN MANIFOLD

9 8 7 6 5 4 3 2 1

REVERSE 2 3 4 5 57 58 LOAD SENSE

DRAIN

LS T2 PILOT

PUMP

36 T FROM

T CLR 56 21

+ 35 HYSTAT BRAKE

33

CUTOFF RELEASE

U (IS) (PBS)

E

G

20 15 TANK E

Outlet Manifold

TO R5 JOYSTICK

A B CLR

PS PB 9

FORWARD

MC1

Machine 14

MC2

ECM 19

MU 18

P

14

A4 RIPPER

LEFT PC1

MU

PC2 B4

MOTOR R8

R3 R2 34

P21 18

RAISE

LOWER

35

LOWER

RAISE

32

HOLD

R9 R6 37 Y

Y R0 Ripper Control Valve

P18 10

D Standard Fan Manifold 14 D

42 19

B B FE FA G MB FA G MB FORWARD 18

L A T D

B 14

B HST E

A3 MP-BKT

B COR

B3

COR

CW

ACTR ACTR

ENGINE 18

CLOSE

OPEN

B P

CLOSE

C F

OPEN

HOLD

MP Bucket Control Valve

COR CHRG COR

41 44 43 CHRG T

48 7 6

R

REVERSE

S S L L1 S X2 X1 MA A B T X2 X1 MA A

A D T D R3 14 14

M2 HST

DRAIN

PILOT

TANK

B E

40 1 A2 LIFT

FORWARD

30 C

REVERSE

C B2

R7 R1 P14

M1 P

P20 and P19

Taps must be

P16 and P15

Taps must be 17 16

C F installed for

testing

installed for

testing

RAISE

LOWER

47 46 45 44 43

LOWER

FLOAT

RAISE

HOLD

Lift Control Valve

42a

Reversing Fan Option:

If reversing fan option is selected,

standard fan manifold is replaced

20 Page, Color 2, (Dimensions: 39 inches x 24 inches)

with reversing fan manifold.

14 14

B1

A1 TILT

18

17

KENR5173-02

RACKBACK

DUMP

DUMP

HOLD

RACK

Tilt Control Valve

B 8 B

FORWARD

12

A B REVERSE

Inlet Manifold 13

T PR ACC TPR P

11

G 53 54

LINE PATTERNS

U 50 Pressure Line

+ Pilot / Load Sensing Pressure

A Drain / Return Lines A

T 55 HYDRAULIC CIRCUIT COLOR DESCRIPTIONS

IMPLEMENT PUMP OUTPUT CIRCUIT Component Group

PILOT PUMP CIRCUIT

RIGHT DRIVE PUMP OUTPUT CIRCUIT Attachment

MOTOR

SUPPLY LINE

DRAIN / RETURN LINE Air Line

STEERING CIRCUIT THIS SCHEMATIC IS FOR THE 953D TRACK-TYPE LOADER

60 52 51 52 LOAD SENSE CIRCUIT

TILT CYLINDER CIRCUIT

CALLOUTS PART #: 265-6615 CHG05

Components are shown installed on a fully operable machine with the key and engine

31 Taps (Pressure, Sampling,Sensor) by letter

MP-BUCKET CYLINDER CIRCUIT

YY

LIFT CYLINDER CIRCUIT

off and transmission shifter in neutral.

RIPPER CYLINDER CIRCUIT

BRAKE CIRCUIT

52 Components by number Refer to the appropriate Service Manual for Troubleshooting, Specifications and Systems Operations

9 8 7 6 5 4 3 2 1

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Cat Cis Sis PController CSSISC8Document3 pagesCat Cis Sis PController CSSISC8imam nahrowiNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Cat Cis Sis PController CSSISC6Document3 pagesCat Cis Sis PController CSSISC6imam nahrowiNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Cat Cis Sis PController CSSISC9Document2 pagesCat Cis Sis PController CSSISC9imam nahrowi100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Cat Cis Sis PController CSSISC5Document2 pagesCat Cis Sis PController CSSISC5imam nahrowiNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Techdoc Print Page - jspt1Document5 pagesTechdoc Print Page - jspt1imam nahrowiNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Cat Dcs Sis ControllerpolmatikDocument2 pagesCat Dcs Sis Controllerpolmatikimam nahrowiNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Oporeation Cammon RailDocument14 pagesOporeation Cammon Railimam nahrowiNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- E398 Low Pressure Fuel RailDocument2 pagesE398 Low Pressure Fuel Railimam nahrowiNo ratings yet

- Adjust 1Document6 pagesAdjust 1imam nahrowiNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Astm-53-A-53m-07Document22 pagesAstm-53-A-53m-07Allen EspeletaNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Statically Indeterminate Structures by The Displacement Method-1Document19 pagesStatically Indeterminate Structures by The Displacement Method-1mathewsujith31No ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- KTTC2 Thành Đ TDocument68 pagesKTTC2 Thành Đ TKhoa PhanNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Cálculo HidraulicoDocument9 pagesCálculo HidraulicoTuco MlmNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Concrete TechnologyDocument16 pagesConcrete Technologysefatwrdk21No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Experimental Behaviour of Concrete-Filled Stiffened Thin-Walled Steel Tubular ColumnsDocument11 pagesExperimental Behaviour of Concrete-Filled Stiffened Thin-Walled Steel Tubular ColumnshanlamphamNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Foundation Plan Second Floor Framing Plan Roof Framing Plan: C1F1 C1F1 C1F1 RB RBDocument1 pageFoundation Plan Second Floor Framing Plan Roof Framing Plan: C1F1 C1F1 C1F1 RB RBDanica Mae Amicay100% (1)

- Design of Stair-Case: (Limit State Method As Per IS 456-2000)Document2 pagesDesign of Stair-Case: (Limit State Method As Per IS 456-2000)Sujan SinghNo ratings yet

- Steady State FlowDocument111 pagesSteady State FlowKaoru AmaneNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- memoriaDeCalculoDeInst TermomecánicaDocument135 pagesmemoriaDeCalculoDeInst TermomecánicaESTUDIO GF INSTALACIONES S.R.LNo ratings yet

- Daily Marketing Maret 15Document27 pagesDaily Marketing Maret 15Bella MuharamNo ratings yet

- NEW - Structural Design & Analysis (Pt. 1)Document23 pagesNEW - Structural Design & Analysis (Pt. 1)Rein Aira OrdanezNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Structural Specs Vol (1) .2 Part1Document225 pagesStructural Specs Vol (1) .2 Part1faaderinto5964No ratings yet

- Hilti CatalogueDocument40 pagesHilti CatalogueMatt Tremoglie100% (1)

- Approved Grain Stability Book PDFDocument254 pagesApproved Grain Stability Book PDFDaryl JumuadNo ratings yet

- CRSI Tech - Note - ETN B 1 15 PDFDocument6 pagesCRSI Tech - Note - ETN B 1 15 PDFrickhuezoNo ratings yet

- Rebound Hammer TestDocument15 pagesRebound Hammer TestAmir AkmalNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- University of Zimbabwe B.Sc. (Engineering) Honours - Level IIDocument5 pagesUniversity of Zimbabwe B.Sc. (Engineering) Honours - Level IIkundayi shavaNo ratings yet

- General Fit Out Guidelines ADocument2 pagesGeneral Fit Out Guidelines Armilin.mrNo ratings yet

- Rail JointsDocument15 pagesRail JointsGulzar HussainNo ratings yet

- B.Tech CE IInd YEAR 2020-21Document25 pagesB.Tech CE IInd YEAR 2020-21designer STRNo ratings yet

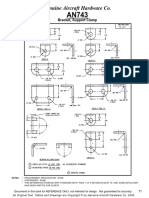

- Bracket An743Document2 pagesBracket An743RhianNo ratings yet

- Moment Resisting Wood Post-To-Concrete Peir ConnectionDocument86 pagesMoment Resisting Wood Post-To-Concrete Peir ConnectionFidan DaskalovNo ratings yet

- Geotechnical InvestigationsDocument13 pagesGeotechnical InvestigationsJames ZhangNo ratings yet

- Flat SlabDocument38 pagesFlat SlabRicky Gunawan100% (1)

- Guidelines For Maintenance Dredging in Trinidad and TobagoDocument48 pagesGuidelines For Maintenance Dredging in Trinidad and TobagoJudson FarrayNo ratings yet

- Beach House ArchitecturalDocument3 pagesBeach House ArchitecturalMARKCHRISTMASNo ratings yet

- Engine Test Facilities: Related Commercial ResourcesDocument4 pagesEngine Test Facilities: Related Commercial ResourcespencoxxxNo ratings yet

- Construction ScheduleDocument11 pagesConstruction ScheduleScienceYilma YilmaNo ratings yet

- Asphalt Paving Materials-Jukka Laitinen PDFDocument7 pagesAsphalt Paving Materials-Jukka Laitinen PDFjoe briffaNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)