Professional Documents

Culture Documents

Bluefire Developer For High Contrast Film

Uploaded by

jbenscr0 ratings0% found this document useful (0 votes)

35 views2 pagesOriginal Title

Bluefire developer for high contrast film

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

35 views2 pagesBluefire Developer For High Contrast Film

Uploaded by

jbenscrCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Exposing and processing Bluefire™ Police film

Image Characteristics Exposure

Bluefire Police is an ultra-high resolution panchromatic Bluefire Police is of a type of film for which there are no

black and white film. It is insensitive to infra-red. ANSI or ISO speed rating standards. For that reason, EI

(Exposure Index) ratings are specified. For practical

Its grain is so fine that it does not degrade image detail purposes, an IE speed is the same as an ASA or ANSI

even at extremes of enlargement. speed. For example, an exposure meter set to ASA 80 will

This makes it an ideal film for surveillance at a distance give the correct exposure for an EI 80 film.

with a telephoto lens, where positive identification of Bluefire Police should be exposed at EI 80 for pictorial

structures or individuals requires extreme enlargement of purposes, and developed in Bluefire HR developer. This is

small portions of the negative. This was the film's original the minimum exposure that gives excellent prints on

commercial purpose. standard No. 2 grade enlarging paper.

But it also records a full 21-step gray scale and makes Expose it carefully, ± 1/3 stop, for good shadow and

lovely, full-scale pictorial images when processed in highlight detail.

Bluefire HR developer.

It should be exposed at EI 100 when used as a high-contrast

With its clear base it can be reversal processed, to make microfilm or technical film and processed in Bluefire Micro

black and white slides. or Kodak D-19.

Its images have a “biting clarity” that comes from the It can be processed for pictorial images in specialized

combination of clear base, sub-microscopic grain, and high developers such as POTA, Formulary TD-3, Clayton Ultra,

acutance (sharp microscopic image edges). Spur Nanospeed and Docuspeed, and Labor Partner

Docufine LC and HC. However, film speed may be

reduced.

Resolution of image detail

Note: Bluefire Police film has a magenta anti-halation

Films lose sharpness because of internal reflections during undercoat that washes out during processing. It will color your

exposure, which expose unwanted grains (“halation”). stop bath and fixer, and you will probably see it in your wash

water. It has no effect and can be ignored.

Bluefire Police has a magenta light-absorbing layer

between its base and light-sensitive emulsion. This layer Bluefire Police has a very thin emulsion, and it fixes,

(which washes out during processing) absorbs light which washes, and dries in less time than ordinary films.

has traveled through the emulsion and would otherwise

reflect back. Development: Develop in Bluefire HR developer for 12

to 16 minutes at 20° to 21° (68° to 70° F). Time varies

It is also coated extremely thinly, and its emulsion contains with agitation.

only grains of cubic shape, uniformly sized, which

minimizes the amount of light that reflects from exposed Continuous agitation, for 12 minutes — Agitate

grains to nearby, non-image grains. gently and continuously. You can ensure uniformity

from roll to roll by using a mechanical processor, such

As a result, Bluefire Police can resolve more than 800 line as those made by Jobo. Yields good contrast and

pairs per millimeter under laboratory conditions, when gradation, shadow and highlight detail is excellent.

processed as a high contrast microfilm.

Intermittent agitation, for 14 minutes — Agitate 5

The use of 35mm camera equipment, and processing for seconds every 30 seconds after an initial 30 seconds of

pictorial contrast, lowers resolution. gentle agitation. Do not rotate or invert the tank.

Instead, shake the tank straight up and down without

Nonetheless, the Bluefire Police film and Bluefire HR

rotation. Agitate carefully to minimize risk of streaking

developer combination is capable of extreme enlargement.

or mottling. Yields less contrast and better highlight

A properly exposed and processed 35mm Bluefire Police

detail than continuous agitation.

negative can be enlarged to as much as 100x without losing

image detail to grain. Compensating agitation, for 16 minutes — Use

intermittent agitation (as above) for three minutes, then

Even the best camera and enlarger lenses have much less

a five-second up-down shake every three minutes for

resolving power than this film. The practical maximum

the remaining time. Inexact technique can produce

enlargement is generally no more than about 40x because

streaks or mottling in areas of solid light tone, such as

of lens resolution losses. Enlarging a 35mm negative to 40x

skies or skin. Yields the lowest contrast and best

gives a print of about 3 by 4.5 feet (1m x 1.5m).

gradation, with excellent shadow and highlight detail.

When enlarged to extremes, shadows and highlights that

Stop bath: Use any ordinary acid stop bath, or plain

are pure black or white on normal sized prints will reveal

water.

considerable detail. This is because the detail is there, in the

negative, but is too small to be visible on a normal sized Fixer: Bluefire Police is generally fully fixed in as little

print. As a result, a negative created for normal printing as 90 seconds with ordinary ammonium thiosulfate

may not have solid blacks and whites when greatly rapid fixers. It is good practice to test a scrap of film in

enlarged. Images intended for extreme enlargement should your fixer in daylight, so you can time how long it takes

be exposed with that in mind. to clear. Fixing will be complete in 1.5 times as long as

the clearing time.

Processing:

Wash: Water conservation is of concern, so the

All films, including Bluefire Police, should be processed following method is recommended:

promptly after exposure. Exposure initiates chemical

reactions which degrade the latent image over as little as a Fill the tank with fresh water. Agitate gently. After 30

few weeks. Films that cannot be processed within a month seconds, drain the water. Fill again and agitate

can be preserved by refrigeration or freezing in moisture- continuously for 30 seconds. Then drain.

proof containers such as Zip-Loc type bags.

Repeat six more times, with or without agitation, so

Maintain uniform temperatures in all solutions throughout your film has been in eight changes of water over the

the processing cycle, including washing. course of about six to eight minutes total cycle time.

Use any ordinary developing equipment, stainless steel or Dry: Rinse the film in a wetting agent according to the

plastic. manufacturer's directions. Hang it vertically to dry

undisturbed at room temperature in a dust-free place.

You will have the most consistent results using a tank large Do not wipe or touch the wet emulsion layer. Do not

enough to hold your film plus at least one empty spiral reel use forced air or heat.

on top. The empty space above your film allows good

solution flow during agitation.

Bluefire Photo Science

Bluefire Photo Science is a business unit of Adox Fotowerke, Inc, Calgary

Bluefire is a trademark and Adox is a registered trademark of Adox Fotowerke, Inc

You might also like

- Little Women Debuts on Broadway in 1912Document11 pagesLittle Women Debuts on Broadway in 1912jbenscrNo ratings yet

- How To Make Good Pictures Kodak 1922Document176 pagesHow To Make Good Pictures Kodak 1922jbenscrNo ratings yet

- Professional Film Data GuideDocument65 pagesProfessional Film Data GuidefontapNo ratings yet

- Watercolor SecretsDocument60 pagesWatercolor Secretsmissdoisneau98% (47)

- Camera Filters: by Ira TiffenDocument20 pagesCamera Filters: by Ira TiffentaswiNo ratings yet

- Capture a wide range of tones with proper exposure and developmentDocument8 pagesCapture a wide range of tones with proper exposure and developmentTunisha SharmaNo ratings yet

- 6-7. Elements of Visual Design PDFDocument59 pages6-7. Elements of Visual Design PDFbalaganesh100% (1)

- Tiffen Len FiltersDocument22 pagesTiffen Len FiltersGarland HolderNo ratings yet

- Ves Handbook of Visual Effects CH 3Document7 pagesVes Handbook of Visual Effects CH 3Venkat G VarmaNo ratings yet

- How To Read Your Eyeglasses PrescriptionDocument9 pagesHow To Read Your Eyeglasses PrescriptionPravin S ShindeNo ratings yet

- Understanding Hyperfocal Distance for Sharp Landscape PhotosDocument9 pagesUnderstanding Hyperfocal Distance for Sharp Landscape PhotosPalanisamy BalasubramaniNo ratings yet

- LIT For Wedding Photographers - Mark CondonDocument139 pagesLIT For Wedding Photographers - Mark CondonLucia Lopez100% (1)

- Fujicolour Superia 200 Data SheetDocument4 pagesFujicolour Superia 200 Data SheetDF100% (1)

- GdfgOfgdPRO CdfgdHEAT SdfgHEETDocument3 pagesGdfgOfgdPRO CdfgdHEAT SdfgHEETRăzvan RoșcaNo ratings yet

- Radiographic FILMDocument54 pagesRadiographic FILMg1381821No ratings yet

- Fujicolor Superia 100Document4 pagesFujicolor Superia 100tester1972No ratings yet

- Ilford Push ProcessingDocument4 pagesIlford Push ProcessingMax BoNo ratings yet

- Kodak B&W cn400 PDFDocument6 pagesKodak B&W cn400 PDFjp_kellerNo ratings yet

- Rodenstock Camera Lens FiltersDocument11 pagesRodenstock Camera Lens FiltersAlex CalderonNo ratings yet

- 1 - Sensitized MaterialDocument30 pages1 - Sensitized Materialmarvin fajardo100% (1)

- Detailed Lesson Plan Primary Colors SemisDocument6 pagesDetailed Lesson Plan Primary Colors SemisMylei Ramos Colisao92% (13)

- ILFORD Push ProcessingDocument4 pagesILFORD Push ProcessingEmile OuroumovNo ratings yet

- Pro 400h Datasheet PDFDocument8 pagesPro 400h Datasheet PDFAlian HernandezNo ratings yet

- Imagepac User Guide OkDocument2 pagesImagepac User Guide OkepidebleNo ratings yet

- KODAK VISION Color Print Film 2383 3383 Data SheetDocument7 pagesKODAK VISION Color Print Film 2383 3383 Data Sheet零点先生ZeroNo ratings yet

- Rollei IR 40845 5 PDF-DatasheetDocument15 pagesRollei IR 40845 5 PDF-DatasheetmrthumbNo ratings yet

- Tiffen Fiter DescriptionsDocument8 pagesTiffen Fiter DescriptionsAkif DemirelNo ratings yet

- FUJIFILM Superia X-TRA 400 color negative film guideDocument6 pagesFUJIFILM Superia X-TRA 400 color negative film guideFelipe EduardoNo ratings yet

- The Practical Accessories: Back To Main Camera Manual PageDocument25 pagesThe Practical Accessories: Back To Main Camera Manual PageuruburetamaNo ratings yet

- FUJICHROME ASTIA 100F Professional (RAP100F) : 1. Features and Uses 2. SpeedDocument8 pagesFUJICHROME ASTIA 100F Professional (RAP100F) : 1. Features and Uses 2. Speedtester1972No ratings yet

- Forensic Photography ReportDocument25 pagesForensic Photography ReportKristine joy Del rosarioNo ratings yet

- FUJIFILM Superia X-TRA 800 Film GuideDocument4 pagesFUJIFILM Superia X-TRA 800 Film Guideheraasku7194No ratings yet

- Transitions Are Used To Indicate A Scene ChangeDocument6 pagesTransitions Are Used To Indicate A Scene Changeartimpresro9108No ratings yet

- Day-for-Night Filming TechniquesDocument7 pagesDay-for-Night Filming TechniquesArian Sánchez CovisaNo ratings yet

- Image Receptors: Dr. Chona D. CabatayDocument37 pagesImage Receptors: Dr. Chona D. CabatayEzekiel MartinezNo ratings yet

- Catch Those Juicy Bugs When & Where You Can!Document22 pagesCatch Those Juicy Bugs When & Where You Can!Ana Laura NavasNo ratings yet

- FUJICHROME Velvia 100 Professional (RVP100) : Base Thickness Sizes - Rolls Emulsion Number Base MaterialDocument8 pagesFUJICHROME Velvia 100 Professional (RVP100) : Base Thickness Sizes - Rolls Emulsion Number Base MaterialDong Yang HsuNo ratings yet

- Lo2 PhotographyDocument7 pagesLo2 Photographyapi-263705263No ratings yet

- FUJICOLOR SUPERIA 200 color negative film features and usageDocument4 pagesFUJICOLOR SUPERIA 200 color negative film features and usageheraasku7194No ratings yet

- Forensic 1 Lesson 3Document28 pagesForensic 1 Lesson 3Cristine AvancenaNo ratings yet

- Important Diff Between Digital Camera & FilmrollDocument9 pagesImportant Diff Between Digital Camera & FilmrollSandeep KanyanNo ratings yet

- Salt Printing Exposing The Print PDFDocument1 pageSalt Printing Exposing The Print PDFLuis A GuevaraNo ratings yet

- Filtros Foto PDFDocument24 pagesFiltros Foto PDFGala TutoríasNo ratings yet

- 35mm Films and ISO's: Color Negative Film For Color PrintsDocument8 pages35mm Films and ISO's: Color Negative Film For Color PrintsZa Banga Mobutu SeseNo ratings yet

- Fuji Reala Data SheetDocument4 pagesFuji Reala Data SheetNate CochraneNo ratings yet

- Depth Camera Presets and Settings GuideDocument20 pagesDepth Camera Presets and Settings GuideRich ManNo ratings yet

- c4d Render TipzDocument4 pagesc4d Render TipzCory ShawNo ratings yet

- Konica Color Centuria 100 Film: Technical Data SheetDocument3 pagesKonica Color Centuria 100 Film: Technical Data SheetRichard KingstonNo ratings yet

- Fiche Technique - Film Agfa CP-BU M (Anglais)Document4 pagesFiche Technique - Film Agfa CP-BU M (Anglais)أنور مازوز أبو يوسفNo ratings yet

- Module 3 in Forensic Photography Chapter 3Document4 pagesModule 3 in Forensic Photography Chapter 3escasinasjeralyn42No ratings yet

- Agfa Range of Films: Technical DataDocument8 pagesAgfa Range of Films: Technical DataCHERPINNo ratings yet

- Sketch Book WorkDocument16 pagesSketch Book Workapi-263705680No ratings yet

- Essential Green Screen Setup TipsDocument5 pagesEssential Green Screen Setup TipsVaibhav ParasharNo ratings yet

- Film JargonDocument32 pagesFilm JargonAlice ZhuNo ratings yet

- Unit One-Introduction To Digital CamerasDocument3 pagesUnit One-Introduction To Digital Camerasapi-442506422No ratings yet

- Vrayforc4D Physical Camera - : A Rough Guide For Architectural RenderingDocument4 pagesVrayforc4D Physical Camera - : A Rough Guide For Architectural RenderingjohnautodidacteNo ratings yet

- Elgin Photographing ObjectsDocument4 pagesElgin Photographing Objectsamcv2220No ratings yet

- 3.films and Radiographic ProcessingDocument18 pages3.films and Radiographic ProcessingJonorie Bag-oyenNo ratings yet

- digitizing_35mm_film_at_homeDocument7 pagesdigitizing_35mm_film_at_homeMamu Shaddi backupNo ratings yet

- X - Ray Film: by Sahil Gupta Assistant Professor RIMT UniversityDocument37 pagesX - Ray Film: by Sahil Gupta Assistant Professor RIMT UniversityZainNo ratings yet

- Photo InsightsDocument41 pagesPhoto InsightsModumo BWNo ratings yet

- Darkroom Safelight GuidelinesDocument6 pagesDarkroom Safelight Guidelinescimke666No ratings yet

- 3M EU PB PantherCSDocument2 pages3M EU PB PantherCSFaith_No_MoreNo ratings yet

- Canon T80 Selling PointsDocument20 pagesCanon T80 Selling PointsjbenscrNo ratings yet

- Kodak Colorburst - 50Document27 pagesKodak Colorburst - 50jbenscrNo ratings yet

- KiiPix Hints&Tips - USDocument2 pagesKiiPix Hints&Tips - USjbenscrNo ratings yet

- Polaroid 665fdsDocument5 pagesPolaroid 665fdsjbenscr100% (1)

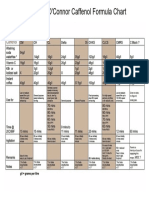

- Félim OConnor Caffenol ChartDocument1 pageFélim OConnor Caffenol ChartjbenscrNo ratings yet

- Arista Liquid C41Document2 pagesArista Liquid C41jbenscrNo ratings yet

- Fomaspeed Variant Iii: Black-And-White Variable-Contrast Enlarging RC Photographic PaperDocument2 pagesFomaspeed Variant Iii: Black-And-White Variable-Contrast Enlarging RC Photographic PaperjbenscrNo ratings yet

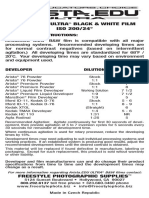

- AristaEDU - Ultra - 200 Developing InstructionsDocument1 pageAristaEDU - Ultra - 200 Developing InstructionsjbenscrNo ratings yet

- Bicycle Kodaks 1897Document45 pagesBicycle Kodaks 1897jbenscrNo ratings yet

- At Home With The Kodak 1922Document35 pagesAt Home With The Kodak 1922jbenscrNo ratings yet

- Digital Photography Basics: Kent Messamore 9/5/2011Document42 pagesDigital Photography Basics: Kent Messamore 9/5/2011Prabhat KiskuNo ratings yet

- Full Download Business Law Text and Cases Legal Ethical Global and Corporate Environment 12th Edition Clarkson Test BankDocument36 pagesFull Download Business Law Text and Cases Legal Ethical Global and Corporate Environment 12th Edition Clarkson Test Bankeliasfosterhs6r100% (32)

- ProEXR ManualDocument39 pagesProEXR Manualjohntt7No ratings yet

- Byonic Eye Powered by NanogeneratorDocument17 pagesByonic Eye Powered by NanogeneratorSurabhi MohapatraNo ratings yet

- Color WheelDocument19 pagesColor WheelZenia Fe Llausas McVeyNo ratings yet

- New Management Strategies For Ectopia LentisDocument14 pagesNew Management Strategies For Ectopia LentisximoNo ratings yet

- Sikkens Autowave Refinishes Price List July 2022Document3 pagesSikkens Autowave Refinishes Price List July 2022Sekretaris Warna Tanjung JayaNo ratings yet

- CO Arts6 q2 Mod2 Elements and Principles Applied in Digital ArtDocument25 pagesCO Arts6 q2 Mod2 Elements and Principles Applied in Digital ArtRv Ramos PerezNo ratings yet

- PEDRO Men ESS-1Document29 pagesPEDRO Men ESS-1Egi Part IINo ratings yet

- Pant Ones Watch BookDocument10 pagesPant Ones Watch BookAndressa BinterNo ratings yet

- Digital Image Processing LAB MANUAL 6th Sem-FinalDocument20 pagesDigital Image Processing LAB MANUAL 6th Sem-FinalKapil KumarNo ratings yet

- DIP Zero To Hero Practice ManualDocument230 pagesDIP Zero To Hero Practice ManualAmmar ButtNo ratings yet

- Painting Techniques with a Limited PaletteDocument36 pagesPainting Techniques with a Limited PaletteDesiré Angelica GANo ratings yet

- CoreGraphics FrameworkDocument475 pagesCoreGraphics FrameworkSunheang TyNo ratings yet

- ABUAD Optometry Proposed Roster for General Optometry Preclinic IIDocument2 pagesABUAD Optometry Proposed Roster for General Optometry Preclinic IIEshiramhe AugustineNo ratings yet

- Tabela de Cores HTMLDocument11 pagesTabela de Cores HTMLBiel Divulgações - O terror das ProduçõesNo ratings yet

- Mapeh 10 Module (Week 8) QTR 2Document12 pagesMapeh 10 Module (Week 8) QTR 2Marjorie PalmaNo ratings yet

- Photoshop မွတ္စုမ်ားDocument439 pagesPhotoshop မွတ္စုမ်ားbyuuharNo ratings yet

- Achieving Excellence in Cataract Surgery - Chapter 12Document14 pagesAchieving Excellence in Cataract Surgery - Chapter 12Arif MohammadNo ratings yet

- Examples of Fields That Use Digital Image Processing PDFDocument2 pagesExamples of Fields That Use Digital Image Processing PDFMaria100% (2)

- Derma OLUWOLE OLUMODEJIDocument13 pagesDerma OLUWOLE OLUMODEJIbrightagbotuiNo ratings yet

- Design and ColourDocument35 pagesDesign and ColoursamanthaNo ratings yet

- Reasoning Checklist 232 PDF 2022 by Parul GeraDocument26 pagesReasoning Checklist 232 PDF 2022 by Parul Gerayuvraj.bizcraftNo ratings yet

- Uveal Coloboma: The Related SyndromesDocument3 pagesUveal Coloboma: The Related Syndromeslavinia diaNo ratings yet