Professional Documents

Culture Documents

Upvc Solvent Cements

Uploaded by

Mathi Vinoth PillaiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Upvc Solvent Cements

Uploaded by

Mathi Vinoth PillaiCopyright:

Available Formats

ISO 9001:2008 COMPANY

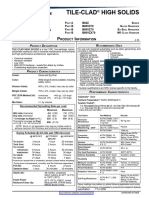

TECHNICAL DATASHEET

200 PVC (PVC-U)

LOW VOC PVC SOLVENT CEMENT

GENERAL DESCRIPTION:

NeoSeal® 200 is a clear, low VOC emission, regular bodied, fast setting, high strength PVC solvent cement for all

classes and schedules 40 of pipe and fittings with interference fit through 4 inch (110mm) diameter. It can be used

without primer on non-pressure systems if local codes permit.

APPLICATION:

NeoSeal® 200 is for use on all types of PVC plastic pipe applications, Type I and Type II. It is suitable for use with

potable water pressure systems, irrigation, turf, conduit, industrial pipe applications, sewer, drain, waste and vent

systems. NOTE: NeoSeal®solvent cements should never be used in a PVC system using or being tested by

compressed air or gases; including air-over-water booster.

SPECIFICATIONS:

COLOR: Clear

RESIN: PVC

SPECIFIC GRAVITY: 0.920 ± 0.040

BROOKFIELD VISCOSITY: Min. 90 cP @ 73°F ± 2°F (23°C ± 1°C)

VOC: Max. 510 g/l.

STANDARDS AND CERTIFICATION LISTINGS:

• Meets ASTM D 2564 Standard.

• Certified by NSF International for compliance with NSF/ANSI 14 and ASTM

• Meets SCAQMD Rule 1168/316A.

• Compliant with LEED® (Leadership in Energy and Environmental Design) Green

Building requirement. Credit can be claimed for – Indoor Environmental Quality.

• Meets the requirements of National Electrical Manufacturers Association (NEMA)

TC-2, TC-6 and TC-8

AVAILABILITY:

This product is available in 118ml (4 oz.), 237ml (8 oz.), 473ml (16 oz.) and 946ml (32 oz.) metal can.

SHELF LIFE:

3 years in tightly sealed containers. The date code of manufacture is stamped on the bottom of the container. Stability

of the product is limited by the evaporation of the solvent when the container is opened. Evaporation of solvent will

cause the cement to thicken and reduce its effectiveness. Adding of thinners to change viscosity is not recommended

and may significantly change the properties of the cement.

QUALITY ASSURANCE:

NeoSeal®200 is carefully evaluated to assure that consistent high quality is maintained. Gas chromatography, and

additional in depth testing ensures each batch is manufactured according to standards. A batch identification code

is stamped on each can and assures traceability of all materials used in the manufacturing.

NeoSeal Adhesive Pvt. Ltd.

628/7 GIDC Savli, At. Manjusar,Vadodara – 391775, Gujarat, INDIA

info@neoseal.net; Ph:+91-90999 35744; www.neoseal.net

You might also like

- Carboguard 890 PDSDocument2 pagesCarboguard 890 PDSLinnie McleodNo ratings yet

- Revised Pacifica Bandini Engineering's ReportDocument10 pagesRevised Pacifica Bandini Engineering's ReportGarry PonferradaNo ratings yet

- CE141142Document44 pagesCE141142Omen JettNo ratings yet

- Distributors Manual On Geosynthetics and GeotextilesDocument44 pagesDistributors Manual On Geosynthetics and Geotextileshillamng100% (1)

- Carboguard 891 Product Data SheetDocument4 pagesCarboguard 891 Product Data SheetPrakashNo ratings yet

- PG770Document2 pagesPG770akankshas06No ratings yet

- Polyguard 600 CoatingsDocument2 pagesPolyguard 600 CoatingstechdocuNo ratings yet

- PVC TdsDocument2 pagesPVC TdsGİZEM D.No ratings yet

- Datasheet SP 2000wDocument2 pagesDatasheet SP 2000wWilliam Boyle Jr.No ratings yet

- Never-Seez® India Call +91-891-6666482Document2 pagesNever-Seez® India Call +91-891-6666482Project Sales CorpNo ratings yet

- Hydrophilic Butyl Rubber Waterstop Prevents Passage of WaterDocument2 pagesHydrophilic Butyl Rubber Waterstop Prevents Passage of WaterKenji TanNo ratings yet

- NSPure Ni SpecDocument2 pagesNSPure Ni SpecPieter van der WaltNo ratings yet

- Epoxy Anchoring Adhesive: Simpson Strong-Tie Anchoring and Fastening Systems For Concrete and MasonryDocument1 pageEpoxy Anchoring Adhesive: Simpson Strong-Tie Anchoring and Fastening Systems For Concrete and MasonryJonathan DouglasNo ratings yet

- Sikafloor - 264 EngDocument5 pagesSikafloor - 264 Engbassem kooliNo ratings yet

- Never-Seez® India +91-891-2564393Document2 pagesNever-Seez® India +91-891-2564393Project Sales CorpNo ratings yet

- PVC Resin Technical Data SheetDocument2 pagesPVC Resin Technical Data Sheetkashyappathak01No ratings yet

- Sanitile 755 PDSDocument4 pagesSanitile 755 PDSnarmathaNo ratings yet

- Pds CPD SikaGrout212 UsDocument2 pagesPds CPD SikaGrout212 Usanjas_tsNo ratings yet

- Pds CPD SikaGrout212 Us PDFDocument2 pagesPds CPD SikaGrout212 Us PDFshashank sharmaNo ratings yet

- Anvol WG 46 Fire Resistant Hydraulic Fluid Data SheetDocument2 pagesAnvol WG 46 Fire Resistant Hydraulic Fluid Data SheetMassimiliano VolaNo ratings yet

- 00-Master Catalog PDFDocument96 pages00-Master Catalog PDFAatikh RasheedNo ratings yet

- Aircol PD RangeDocument2 pagesAircol PD RangecarmaNo ratings yet

- Carbomastic 15 PDS 2013Document2 pagesCarbomastic 15 PDS 20134508366279No ratings yet

- Tds CPD SikaGrout312 UsDocument2 pagesTds CPD SikaGrout312 Usikusokos6594100% (3)

- Quintolubric 888 BrochureDocument5 pagesQuintolubric 888 BrochurePraveen Kumar MishraNo ratings yet

- Product Datasheet BiohesiveDocument3 pagesProduct Datasheet Biohesivebolang cepuNo ratings yet

- Glo Sikagrout 800 en Corp 01 2023Document5 pagesGlo Sikagrout 800 en Corp 01 2023jpantazis1975No ratings yet

- TDS 0038 DisboPOX-230-SF 201908Document7 pagesTDS 0038 DisboPOX-230-SF 201908Insafians PowerNo ratings yet

- Flipper Foam Seal for WindowsDocument4 pagesFlipper Foam Seal for WindowsAndrew LeeNo ratings yet

- 5 Star GroutDocument2 pages5 Star Groutchong pak limNo ratings yet

- 0091 Amercoat 91 PDS May 08Document2 pages0091 Amercoat 91 PDS May 08donaldoguerreroNo ratings yet

- Devran 224HS PdsDocument2 pagesDevran 224HS Pdsjopedro96No ratings yet

- Catalogue CPVCDocument4 pagesCatalogue CPVCmedo.k016No ratings yet

- Earthkeeper Hydraulic Oil TDS 9005Document1 pageEarthkeeper Hydraulic Oil TDS 9005Jose Luis Ramirez RamirezNo ratings yet

- 4010 TDS EnglishDocument1 page4010 TDS EnglishJose Luis Ramirez RamirezNo ratings yet

- General Description:: Product Data SheetDocument2 pagesGeneral Description:: Product Data Sheettana g.importNo ratings yet

- Carboquick 200 PDSDocument4 pagesCarboquick 200 PDSMarcelo Alejandro MarinoNo ratings yet

- Sikafloor 92EG en EG (11 2019) 2 1Document4 pagesSikafloor 92EG en EG (11 2019) 2 1Ahmed IbrahimNo ratings yet

- C Eagle (Va10 51) TDSDocument1 pageC Eagle (Va10 51) TDSzoranbr1No ratings yet

- PolyguardDocument2 pagesPolyguardJack MayNo ratings yet

- Bumen Catalog 2Document68 pagesBumen Catalog 2yourxmen2910No ratings yet

- AK-TDS-213 ARAKRIL VVA 150 (En)Document2 pagesAK-TDS-213 ARAKRIL VVA 150 (En)Vitaliy RomaniukNo ratings yet

- Carboguard 635 Thinned 50% - Sealer PDSDocument5 pagesCarboguard 635 Thinned 50% - Sealer PDSjakeNo ratings yet

- 666 C0 D 01Document2 pages666 C0 D 01Clef GonadanNo ratings yet

- Pintura Epoxica Sherwin Willians Hoja SeguridadDocument4 pagesPintura Epoxica Sherwin Willians Hoja Seguridad1No ratings yet

- Masterseal NP 472 (Brisk)Document2 pagesMasterseal NP 472 (Brisk)MumtazNo ratings yet

- Polyken 1019Document1 pagePolyken 1019Vijay KumarNo ratings yet

- 18 - Sikafloor - 264 - SGDocument6 pages18 - Sikafloor - 264 - SGPaul ManiquisNo ratings yet

- JOINLEADER 880 Weatherproof Silicone Sealant TDSDocument5 pagesJOINLEADER 880 Weatherproof Silicone Sealant TDSdasaNo ratings yet

- ZL 440 Product Data SheetDocument3 pagesZL 440 Product Data SheetVishal ChudasamaNo ratings yet

- Quality TestDocument3 pagesQuality TestsijogeorgeofficialNo ratings yet

- 134 TDS Updated Feb 2016 78-8141-8528-2 Rev ADocument6 pages134 TDS Updated Feb 2016 78-8141-8528-2 Rev AUriel GarciaNo ratings yet

- E Program Files An ConnectManager SSIS TDS PDF Interswift 6600 Eng A4 20170426Document4 pagesE Program Files An ConnectManager SSIS TDS PDF Interswift 6600 Eng A4 20170426Erwin MalmsteinNo ratings yet

- FF1021 Acoutstical Smoke Sealant SheetDocument2 pagesFF1021 Acoutstical Smoke Sealant SheetChinith012No ratings yet

- Sigunit Sika l72 Af Pds enDocument3 pagesSigunit Sika l72 Af Pds enAenul NulNo ratings yet

- Cassida WGDocument3 pagesCassida WGRaghavendra MurthyNo ratings yet

- Datasheet DC 150 PDFDocument2 pagesDatasheet DC 150 PDFquyen2012No ratings yet

- WL Hydrex Mineral PDSDocument1 pageWL Hydrex Mineral PDSAung Myat ThuNo ratings yet

- Sikaswell s-2 ENDocument4 pagesSikaswell s-2 ENNguyenNo ratings yet

- LR-C-VentureClad Catalogue 01Document16 pagesLR-C-VentureClad Catalogue 01himanshu desaiNo ratings yet

- Adeco Graphite Grease: Technical Data SheetDocument1 pageAdeco Graphite Grease: Technical Data SheetVelibor KaranovicNo ratings yet

- BGBRotary Swivel JointDocument4 pagesBGBRotary Swivel Jointoscar_escorza9226No ratings yet

- 76th Conference on Glass Problems, Version A: A Collection of Papers Presented at the 76th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, Ohio, November 2-5, 2015From Everand76th Conference on Glass Problems, Version A: A Collection of Papers Presented at the 76th Conference on Glass Problems, Greater Columbus Convention Center, Columbus, Ohio, November 2-5, 2015S. K. SundaramNo ratings yet

- Mepl CPCLCBR Eil Qap&ds 001 2022 2023Document7 pagesMepl CPCLCBR Eil Qap&ds 001 2022 2023Mathi Vinoth PillaiNo ratings yet

- Mepl CPCLCBR Eil Qap&Ds 002 2022 2023 Rev 0Document51 pagesMepl CPCLCBR Eil Qap&Ds 002 2022 2023 Rev 0Mathi Vinoth PillaiNo ratings yet

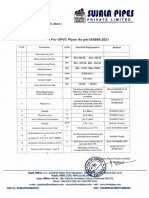

- Approval of Ms. Sujala Pipes Pvt. Ltd. - UPVC VendorDocument3 pagesApproval of Ms. Sujala Pipes Pvt. Ltd. - UPVC VendorMathi Vinoth PillaiNo ratings yet

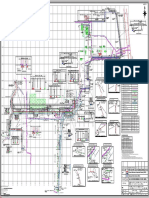

- Mepl CPCLCBR Eil DWG 002 2022 2023Document5 pagesMepl CPCLCBR Eil DWG 002 2022 2023Mathi Vinoth PillaiNo ratings yet

- Mepl CPCLCBR Eil DWG 001 2022 2023Document5 pagesMepl CPCLCBR Eil DWG 001 2022 2023Mathi Vinoth PillaiNo ratings yet

- Geomachine Drill Rigs Purpose of UseDocument1 pageGeomachine Drill Rigs Purpose of UseMathi Vinoth PillaiNo ratings yet

- 5-1940-8040 Rev. 05Document15 pages5-1940-8040 Rev. 05Mathi Vinoth PillaiNo ratings yet

- 5+MTC+Ultrafine Week+No.+27Document1 page5+MTC+Ultrafine Week+No.+27Mathi Vinoth PillaiNo ratings yet

- 3UltraFine MSDSDocument6 pages3UltraFine MSDSMathi Vinoth PillaiNo ratings yet

- 5-6842-1060 Rev - 4 - Civil & STRLDocument22 pages5-6842-1060 Rev - 4 - Civil & STRLMathi Vinoth PillaiNo ratings yet

- Data SheetDocument1 pageData SheetMathi Vinoth PillaiNo ratings yet

- 8-1940-6010 Rev. 05Document35 pages8-1940-6010 Rev. 05Mathi Vinoth PillaiNo ratings yet

- Data Sheet For Line StopDocument7 pagesData Sheet For Line StopMathi Vinoth PillaiNo ratings yet

- Soal Text ReportDocument1 pageSoal Text ReportRosa Anggoro0% (1)

- Wavin: Inspection ChambersDocument62 pagesWavin: Inspection ChambersXAVIER RUBIONo ratings yet

- Annex I Discharge Types Eligible For Coverage Under The VGPDocument4 pagesAnnex I Discharge Types Eligible For Coverage Under The VGPLogesh RajNo ratings yet

- One WASH Program - Final PDFDocument206 pagesOne WASH Program - Final PDFDavid TabangNo ratings yet

- Module 2Document27 pagesModule 2Sajed AbdulrahmanZaiNo ratings yet

- E Book16CrocodileDocument18 pagesE Book16CrocodileNUR ALIAH IZZATI BINTI MOHD RAFI BS20160556No ratings yet

- Design and Analysis of Remote Operated Water Bodies Cleaning MachineDocument4 pagesDesign and Analysis of Remote Operated Water Bodies Cleaning MachineInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- KARNATAKA'S BIODIVERSITY AT A GLANCEDocument96 pagesKARNATAKA'S BIODIVERSITY AT A GLANCESameer MajliNo ratings yet

- Oil Well Drilling Fluid Safety Data SheetDocument3 pagesOil Well Drilling Fluid Safety Data SheetJose AlejandroBlancoNo ratings yet

- Class 10th English Notes Final 2020Document52 pagesClass 10th English Notes Final 2020Husain Ali67% (3)

- Eco-friendly conservation methods for your villageDocument2 pagesEco-friendly conservation methods for your villageAnaya Bedi67% (12)

- Seaorbiter en PDFDocument8 pagesSeaorbiter en PDFowiswellNo ratings yet

- GRIHA LD Master Plan (5 Star) - Nalanda University - GreenTree GlobalDocument22 pagesGRIHA LD Master Plan (5 Star) - Nalanda University - GreenTree GlobalAbdul WajidNo ratings yet

- Ellis County, Texas: Custom Soil Resource Report ForDocument21 pagesEllis County, Texas: Custom Soil Resource Report Forapi-105867910No ratings yet

- Distribution of Turbidity Values, Total Suspended Solids and Heavy Metals PB, Cu in Tanah Merah Beach Waters and Semujur Island Waters, Bangka Tengah RegencyDocument10 pagesDistribution of Turbidity Values, Total Suspended Solids and Heavy Metals PB, Cu in Tanah Merah Beach Waters and Semujur Island Waters, Bangka Tengah Regencyhighfive pologeeNo ratings yet

- OTTERSDocument6 pagesOTTERSMiguel LleraNo ratings yet

- Optimum Design of Stilling Basin PDFDocument8 pagesOptimum Design of Stilling Basin PDFZiza LukovacNo ratings yet

- Description - Components of Wet FGD SystemDocument55 pagesDescription - Components of Wet FGD SystemDo Ngoc TriuNo ratings yet

- 4module in Environmental ScienceDocument5 pages4module in Environmental ScienceVirgie OrtizNo ratings yet

- Human Hair and Coconut Coir As Hybrid Membrane For LeadDocument62 pagesHuman Hair and Coconut Coir As Hybrid Membrane For LeadAlyssum MarieNo ratings yet

- Environmental Movements in IndiaDocument11 pagesEnvironmental Movements in Indiamohini saranNo ratings yet

- Optimizing Perforations in Buried High Density Polyethylene Pipes For Drainage ApplicationsDocument12 pagesOptimizing Perforations in Buried High Density Polyethylene Pipes For Drainage ApplicationsNaresh GajNo ratings yet

- Energy ManagementDocument41 pagesEnergy ManagementZillyNo ratings yet

- SMU Civil Engineering Plumbing Systems SyllabusDocument5 pagesSMU Civil Engineering Plumbing Systems SyllabusMark Anthony TajonNo ratings yet

- Chukchi Sea (Russian: Чуко́тское мо́ре,Document3 pagesChukchi Sea (Russian: Чуко́тское мо́ре,Kaushik ChatterjeeNo ratings yet

- Test A: Choose The Part That Need Correcting in Each SentenceDocument4 pagesTest A: Choose The Part That Need Correcting in Each Sentencekieu anh nguyenNo ratings yet

- Msds 2021-Pac PowderDocument7 pagesMsds 2021-Pac PowderMa. Coleen TorresNo ratings yet