Professional Documents

Culture Documents

Id159986496482 0101

Id159986496482 0101

Uploaded by

Navin DrycoolOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Id159986496482 0101

Id159986496482 0101

Uploaded by

Navin DrycoolCopyright:

Available Formats

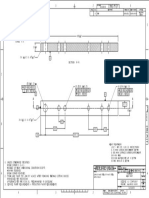

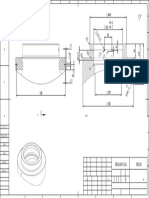

1 2 3 4 5 6

238.8

190.75

A 190.25 A

( 95.25 )

129.5

( 95.25 )

109.7

B B

190.75

238.8

190.25

111.3

14 ¥2 ¥

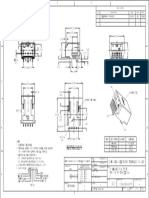

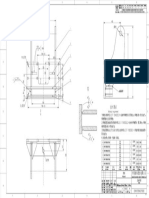

SENSOR BRACKET

C 71.6 ( 34 )¥ ( 31 )¥ C

(9.404) 69.6

45 ¥2 ¥

DETAIL D, SECTION B-B

SCALE 1.500

SEE TABLE, SHT. 1

SEE DETAIL D

D 165.50 D

TOP OF SENSOR BRACKET

163.50

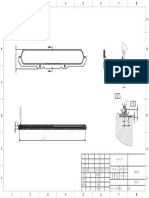

DISCHARGE LINE

12.75-12.85 I.D.

X 17.0 MIN. x

SUCTION LINE

19.13-19.23 I.D.

E X 17.0 MIN x E

404.4

360.4

OIL SIGHT GLASS

230.5

F SCHRADER VALVE

F

AND COVER

78.0

55.0

11.0

BASELINE

G G

Note:

The dome sensor bracket after painting should be confirmed by the flollowing gauge:

B 1. Go-gauge: 8.97+/-0.01

2. Nogo-gauge: 9.73+/-0.01

General

Tolerances

Drawing Status: Production Print 2

Surface Area (m ) Key characteristic

Table

Estimated Mass (Kg) Critical characteristic

Projection Scale Size According to Danfoss standard 502Z0024

.X=±3.0

H .XX=±N/A B ECR-2015-6882 16/04/15 0.300 B Material :

H

.XXX=±N/A A ECR-2014-5985 25/06/14 Designation

ANG°=±N/A

Roughness (μm)

Revision

Designer

ECR Number

Wu Fang

Date

VZH028/035/044 outline

N/A Approval Zhang Qiang

Confidential: Property of Danfoss Commercial Compressors. Not to SHEET 1 of 1

ANSI Y14.5M-1994 be handed over to copied or used by third party. Two or three

dimensional reproduction of contents to be authorized by Danfoss CC.

B.5 0VG8213B B

1 2 3 4 5 6

You might also like

- Just Kidding - ScoreDocument4 pagesJust Kidding - Scorecuntissazza20% (5)

- HVP-90 Partes de PiezasDocument66 pagesHVP-90 Partes de PiezasGerardo Elias100% (3)

- WHRF00601 3B01Document1 pageWHRF00601 3B01hulaneNo ratings yet

- 660D液压Document1 page660D液压Iman SantosaNo ratings yet

- 294.3 (Maximum Length 504.3 (Minimum Length 122.9 236 25Document1 page294.3 (Maximum Length 504.3 (Minimum Length 122.9 236 25Gerardo RodríguezNo ratings yet

- GB893 1-1986Document5 pagesGB893 1-1986ottoNo ratings yet

- GB877 1986Document3 pagesGB877 1986ottoNo ratings yet

- PG 405 22T Long (PJ-31073)Document1 pagePG 405 22T Long (PJ-31073)puravidaamirNo ratings yet

- La Abeja Maya-FlautaDocument1 pageLa Abeja Maya-FlautaCarmen Grancha SimónNo ratings yet

- Examdays TSAP - AP Sachivalayam Model Papers PDF 24Document9 pagesExamdays TSAP - AP Sachivalayam Model Papers PDF 24Krishna BasapuramNo ratings yet

- ZY8 - 01r304130000Document2 pagesZY8 - 01r304130000Trà NguyễnNo ratings yet

- 对重 HAA25QM1&CWT HAA25QM1Document2 pages对重 HAA25QM1&CWT HAA25QM1Ali DiabNo ratings yet

- 2.單位換算 題目+答案 中印Document1 page2.單位換算 題目+答案 中印yoganicma27No ratings yet

- FFB Scraper Conveyor No. 1ADocument1 pageFFB Scraper Conveyor No. 1ABuditama ChandranegaraNo ratings yet

- Su 53650Document1 pageSu 53650FernandoNo ratings yet

- 一年级数学练习 1Document3 pages一年级数学练习 1Apple ChowNo ratings yet

- 500x300plancha Pre-EmbebidaDocument1 page500x300plancha Pre-EmbebidaOscar TorresNo ratings yet

- 500x300plancha Pre-EmbebidaDocument1 page500x300plancha Pre-EmbebidaOscar TorresNo ratings yet

- FL42SC 03 2504a R5Document1 pageFL42SC 03 2504a R5yanyunovemberNo ratings yet

- srsc45h 3 9g-3aDocument1 pagesrsc45h 3 9g-3aRachid SmailiNo ratings yet

- Dokumen - Tips - Buku Asas Fardhu AinDocument45 pagesDokumen - Tips - Buku Asas Fardhu Ainphoenix fireNo ratings yet

- 10101C (G+G 20222012)Document1 page10101C (G+G 20222012)iarina gigiNo ratings yet

- Bonding PDFDocument1 pageBonding PDF魏龙No ratings yet

- 1.焊缝分类参照Q/ZLTF 1040050.1《结构件焊缝要求 第1部分:焊缝分类》要求执行, 焊缝等级均为C类焊缝; 2.焊缝质量及检验要求等级参照Q/ZLTF 缺陷质量分级》要求执行; 3.图纸及图框未注尺寸公差与形位公差参照Q/ZLTF 《焊接件通用检验规程》 要求执行;Document1 page1.焊缝分类参照Q/ZLTF 1040050.1《结构件焊缝要求 第1部分:焊缝分类》要求执行, 焊缝等级均为C类焊缝; 2.焊缝质量及检验要求等级参照Q/ZLTF 缺陷质量分级》要求执行; 3.图纸及图框未注尺寸公差与形位公差参照Q/ZLTF 《焊接件通用检验规程》 要求执行;Regi HermawanNo ratings yet

- Sudut 33Document1 pageSudut 33Dwijendra Ida BagusNo ratings yet

- RC 45 066Document2 pagesRC 45 066li geneNo ratings yet

- GB829 1988Document3 pagesGB829 1988ottoNo ratings yet

- GB894 1-1986Document10 pagesGB894 1-1986ottoNo ratings yet

- GB858 1988Document3 pagesGB858 1988ottoNo ratings yet

- 1 021 口袋书W450 25U(8P)Document4 pages1 021 口袋书W450 25U(8P)Joel Jeffery SarkarNo ratings yet

- 發射平台 5mmDocument1 page發射平台 5mm林秉緯No ratings yet

- GB93 1987Document3 pagesGB93 1987ottoNo ratings yet

- 主机装配 HAA25QQ2&Machine Assembly HAA25QQ2Document4 pages主机装配 HAA25QQ2&Machine Assembly HAA25QQ2Ali DiabNo ratings yet

- المسقط الافقي لمحاور الاعمدة الميدةDocument1 pageالمسقط الافقي لمحاور الاعمدة الميدةAhmed AlbahriNo ratings yet

- RC 45 056Document4 pagesRC 45 056li geneNo ratings yet

- 03Document1 page03y.n.shinNo ratings yet

- RC 45 062Document2 pagesRC 45 062li geneNo ratings yet

- www.bahar.asia: 墙钉 ABS PPDocument1 pagewww.bahar.asia: 墙钉 ABS PPhassanNo ratings yet

- 108-5-四技二專-00共同科目 數學 (C) 卷解析Document3 pages108-5-四技二專-00共同科目 數學 (C) 卷解析Allen ZhenNo ratings yet

- 1000-315 Manifold-Rev-4Document1 page1000-315 Manifold-Rev-4saudNo ratings yet

- RC 45 058Document4 pagesRC 45 058li geneNo ratings yet

- RC 45 054Document4 pagesRC 45 054li geneNo ratings yet

- GB855 1988Document2 pagesGB855 1988ottoNo ratings yet

- 20230206反弹的六大特征Document54 pages20230206反弹的六大特征deying ruanNo ratings yet

- JXLBJF2Document7 pagesJXLBJF2yuanbo wangNo ratings yet

- 80t11 Tablas de Cubicacion de TTPDocument1 page80t11 Tablas de Cubicacion de TTPArmado GarciaNo ratings yet

- Y7-S A结构 (220V-100W、220V-200W、220V-400W) - 2D图纸Document4 pagesY7-S A结构 (220V-100W、220V-200W、220V-400W) - 2D图纸projetos.v2No ratings yet

- Hkbu Campus-Map PDFDocument1 pageHkbu Campus-Map PDFFar Away0% (1)

- GB73 1985Document3 pagesGB73 1985ottoNo ratings yet

- GAYA BATANG B WiDocument1 pageGAYA BATANG B Wi20I Nyoman Pande Agus PujawanXI BKP1No ratings yet

- UntitledDocument76 pagesUntitledkishore kumarNo ratings yet

- Hino Do Galo Da Madrugada - Alto - 2015-01-11 1858Document2 pagesHino Do Galo Da Madrugada - Alto - 2015-01-11 1858GeanNo ratings yet

- RC 45 064Document4 pagesRC 45 064li geneNo ratings yet

- UntitledDocument1 pageUntitledmergyNo ratings yet

- Grapher绘制二维图形Document208 pagesGrapher绘制二维图形zhyhhNo ratings yet

- 2016七月数学试卷一Document6 pages2016七月数学试卷一FayeNo ratings yet

- 投資新手入門 (四) 第一次股票證券開戶,要注意些什麼?【最新證券、期貨手續費行情】 - Mr.Market市場先生Document1 page投資新手入門 (四) 第一次股票證券開戶,要注意些什麼?【最新證券、期貨手續費行情】 - Mr.Market市場先生Yun LaiNo ratings yet

- srsc45h 3 9g-5Document1 pagesrsc45h 3 9g-5Rachid SmailiNo ratings yet

- S155-B 轧臼壁Document1 pageS155-B 轧臼壁kev YNo ratings yet

- Scarlatti Sonata K 322 L 485 Guitar Chitarra PDFDocument2 pagesScarlatti Sonata K 322 L 485 Guitar Chitarra PDFAntonio FresiNo ratings yet

- Embano.8 WebDocument52 pagesEmbano.8 WebSallyNo ratings yet

- Соловьев Владимир. - Собрание Сочинений. Том 2. (1878-1880)Document404 pagesСоловьев Владимир. - Собрание Сочинений. Том 2. (1878-1880)Davor KatunarićNo ratings yet

- Mission Impossible DoubleBass FingeredDocument2 pagesMission Impossible DoubleBass FingeredAndoniNo ratings yet

- Dream High 2Document11 pagesDream High 2Jack Lim Chen KuokNo ratings yet

- 台語的 8 聲和變調Document10 pages台語的 8 聲和變調Dreng Huang黃政No ratings yet

- TUSA - Violin 1Document1 pageTUSA - Violin 1Eugenio MarcuelloNo ratings yet

- Offiwiz FileDocument93 pagesOffiwiz FileUd SjjdNo ratings yet

- 四年级音乐全年计划 Rancangan Pengajaran Tahunan Pendidikan Muzik Kssr Semakan Tahun 4Document7 pages四年级音乐全年计划 Rancangan Pengajaran Tahunan Pendidikan Muzik Kssr Semakan Tahun 4RACHEL R.A PIONG MoeNo ratings yet

- ¡Tú Reinarás!Document10 pages¡Tú Reinarás!JoseNo ratings yet