Professional Documents

Culture Documents

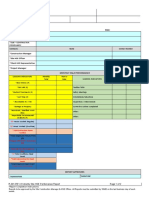

Ballast Tank Corrosion Protection

Uploaded by

nima100%(1)100% found this document useful (1 vote)

11 views13 pagesOriginal Title

Ballast tank

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

11 views13 pagesBallast Tank Corrosion Protection

Uploaded by

nimaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 13

Ballast tank

• A ballast tank is a compartment within a boat, ship or other

floating structure that holds water, which is used as ballast to

provide hydrostatic stability for a vessel, to reduce or

control buoyancy, as in a submarine, to correct trim or list, to

provide a more even load distribution along the hull to reduce

structural hogging or sagging stresses, or to increase draft, as in

a semi-submersible vessel or platform

• Using water in a tank provides easier weight adjustment than the stone or

iron ballast used in older vessels, and makes it easy for the crew to reduce a

vessel's draft when it enters shallower water, by temporarily pumping out

ballast. Airships use ballast tanks mainly to control buoyancy and correct

trim

• Ballast tanks and crude cargo tanks are continuously exposed

to corrosive environment. Typically, ballast condition is worst

in terms of corrosion damage, particularly in empty or

partially filled conditions. Cathodic protection or coatings are

commonly adopted for protecting structures from corrosive

environment.

• Problems are due to improperly designed, applied, and

maintained corrosion systems, and incompatibilities

between structural and corrosion protection systems, such

as flexible bulkhead covered with stiff coatings and corrosion

cells set up between the parent materials and the weld heat

affected zone (HAZ) region resulting in grooving corrosion.

• Coating and coating inspection

• The application of coatings to water ballast tanks and cargo

tanks is the primary means of corrosion protection for ships

and is recognized as one of the most important factors

affecting integrity, maintenance cost and service life.

Coatings serve mainly to minimize the corrosion rate,

thereby potentially delaying the utilization of the built-in

corrosion margins included in a vessel's structural scantlings.

Anode Location

• In ballast-only or cargo ballast tanks of clean oil tankers,

anodes should be distributed evenly over all the uncoated

structure but with some emphasis on horizontal surfaces.

The majority of anodes will therefore be located on the

bottom structure.

• Coating Breakdown and Corrosion

• Ballast tanks are required to be surveyed periodically for coating

breakdown and corrosion. Lloyd’s Register Rules and Regulations for

the Classification of Ships, include this requirement.

DAMAGES

• During loading and unloading damages may be caused to holds,

comings, ladders and cargo gear, mainly due to the use of mechanical

appliances. Such damages must be recorded in the Deck Log Book

and a “Letter of Protest” is delivered to the stevedores. Care is taken

that any such letter be delivered within the time limits set forth in the

charter party and a copy thereof be faxed/mailed to the Company

(refer to S & Q Procedures Manual , section 3). Another inspection

takes place jointly by the crew and the stevedores for the verification

of damages. The stevedores are asked to accept responsibility for any

such damage in writing.

• Stevedores may damage the ship, or its equipment (e.g. cranes,

derricks and winches), or cargo. Charter parties usually contain a

Stevedore Damage clause, the terms of which the master should be

aware of, familiar with and adhere to. * In case of damage to the ship

or its equipment, a stevedore damage report in the following terms

should be sent to the stevedore company management as soon as

possible after the damage occurred or has been discovered.

• Take the photographs of any damage or circumstances relating to the

incident and all affected cargoes, damaged parts of vessels’ structure etc.,

if possible, but do not give them out of your hands unless you are

instructed to do so! This might strengthen your owners or the ship’s

position.

• Collect objects / parts and statements, if possible, in order to have

evidences safeguarded.

• All relevant documentation (e.g. Bill of Lading, Charter Party, Cargo

Manifests, Mate’s Receipts, Instructions of Charterers or other parties

interested in the cargo), written claims from third parties, statement of

facts, medical bills etc., concerning damages to cargo, ship or other third

party property or persons.

Damage Report / Statement of Facts

The responsible person in charge must prepare a report,

which as a standard should contain details regarding:

• Name of vessel

• Name of assured ship owner

• Voyage details (insofar as relevant)

• Position / Port of incident

• Date and time of the incident / damages caused

• Bill of Lading no. (if relevant)

• Kind / Specie and approximate numbers/volume/value of

cargo or damaged property or person(s) injured in question

• Name of claimant

• Kind and estimation of extent of damages caused

• Possible causes of damage / loss

• Limit any report to facts, not personal opinions:

• Do not give an opinion, especially in the accident report, as to who was

responsible

• Do not allow crew members to express opinions towards third parties outside the

vessel

• Do not already admit any liability, either verbally or writing

• Do not sign a document, which you know contains incorrect information

• Do not think the problem will go away if you do nothing

CAPT.A.AMINIAN

You might also like

- Guide to Laying Up Ships Safely & Minimising ClaimsDocument8 pagesGuide to Laying Up Ships Safely & Minimising ClaimsRajesh Kumar PandeyNo ratings yet

- Lashing and Securing Deck CargoesDocument15 pagesLashing and Securing Deck CargoesmajdirossrossNo ratings yet

- Securing Deck Cargoes: Essential Guidelines for Proper LashingDocument15 pagesSecuring Deck Cargoes: Essential Guidelines for Proper LashingBay Bunker0% (1)

- Structural Damage - HTMLDocument3 pagesStructural Damage - HTMLstamatisNo ratings yet

- Notes on Subdivision and StabilityDocument15 pagesNotes on Subdivision and Stabilitynishant100% (2)

- SURVEY Dry DockingDocument2 pagesSURVEY Dry DockingRennie Joshi100% (2)

- C - 3.1 Timber CargoDocument9 pagesC - 3.1 Timber CargoНикита НовикNo ratings yet

- 1.design Codes JettyDocument7 pages1.design Codes Jettym_aswanto100% (1)

- Marine Contracts Introduction and HistoryDocument16 pagesMarine Contracts Introduction and HistoryVinod Thomas EfiNo ratings yet

- Deck Cargo Handling GuideDocument35 pagesDeck Cargo Handling GuideInnocentvishwaNo ratings yet

- Unit 6 Cargo Space Defect and InspectionDocument4 pagesUnit 6 Cargo Space Defect and Inspection8598 Tushar ModiNo ratings yet

- SM TutorialDocument23 pagesSM TutorialSapna DasNo ratings yet

- Emergencies To Do ListDocument68 pagesEmergencies To Do ListAung Htet KyawNo ratings yet

- P&I Club cargo evidence guideDocument5 pagesP&I Club cargo evidence guidecatalinNo ratings yet

- Navigate Safely with Proper Under Keel ClearanceDocument8 pagesNavigate Safely with Proper Under Keel ClearanceErsin SaltNo ratings yet

- Presentation - Dry Bulk and Tanker Shipping, Time Charters, BLsDocument32 pagesPresentation - Dry Bulk and Tanker Shipping, Time Charters, BLsNuman Kooliyat IsmethNo ratings yet

- General Procedures and Precautions in Dry Dock:: Before EntryDocument9 pagesGeneral Procedures and Precautions in Dry Dock:: Before EntryPankaj Kumar100% (2)

- SHIPS LAY UP AND REACTIVATION GUIDEDocument23 pagesSHIPS LAY UP AND REACTIVATION GUIDERiteshNo ratings yet

- SME4451 AKM Mohiuddin (Final)Document13 pagesSME4451 AKM Mohiuddin (Final)A.K.M. MohiuddinNo ratings yet

- Seamanship 2 - Cargo Handling and StowageDocument6 pagesSeamanship 2 - Cargo Handling and StowageFrenzie Mae Vasquez Rivera67% (3)

- Seamanship Inspect and Report Defects and Damage To Cargo Spaces and Hatch Covers and Ballast Tanks PDFDocument8 pagesSeamanship Inspect and Report Defects and Damage To Cargo Spaces and Hatch Covers and Ballast Tanks PDFAjay Singh0% (1)

- Standard Bulk Cargoes-Hold Preparation and CleaningDocument32 pagesStandard Bulk Cargoes-Hold Preparation and CleaningSoyHan BeLen100% (3)

- Bulletin #2 SGC Marine Services Steel Cargo Claims in ChileDocument4 pagesBulletin #2 SGC Marine Services Steel Cargo Claims in ChileJAIME GONZALEZNo ratings yet

- Interview HintsDocument4 pagesInterview HintsAgnes Llanes CruzNo ratings yet

- Cargo Handling 5, Task 3: Open QuestionsDocument3 pagesCargo Handling 5, Task 3: Open QuestionsViking JohanssonNo ratings yet

- SEAM - 3 - ASSIGNMENT GapoyDocument5 pagesSEAM - 3 - ASSIGNMENT GapoyFrednixen Bustamante GapoyNo ratings yet

- Complete Cargo Loss ControlDocument82 pagesComplete Cargo Loss Controlmoe_htwe_1No ratings yet

- Cargo Securing ManualDocument38 pagesCargo Securing ManualKannanNo ratings yet

- Basic Naval Architecture Chapter - 3 Classification Societies and Governmental OrganizationsDocument38 pagesBasic Naval Architecture Chapter - 3 Classification Societies and Governmental OrganizationsAtreyapurapu Krishna0% (1)

- Hatch Cover-6-10Document5 pagesHatch Cover-6-10alin grecuNo ratings yet

- Presentation Construction ShipsDocument43 pagesPresentation Construction Shipsmarinela979100% (3)

- Seam 3bDocument8 pagesSeam 3bjun franklin fundalNo ratings yet

- NNPC PUBLISHES GUIDE ON CARRIAGE OF STEEL CARGODocument12 pagesNNPC PUBLISHES GUIDE ON CARRIAGE OF STEEL CARGOJuan Alfaro100% (1)

- Deck Cargoes: Causes of LossesDocument5 pagesDeck Cargoes: Causes of LossesSaid Al AbdNo ratings yet

- Measurement of Bulk Cargoes - Draught SurveysDocument18 pagesMeasurement of Bulk Cargoes - Draught SurveysPaulo Ricardo100% (1)

- Bulk Cargo Measurement GuideDocument18 pagesBulk Cargo Measurement GuideHRodas EcNo ratings yet

- Crew AgreementsDocument13 pagesCrew AgreementsKumaresh Shanmuga Sundaram100% (1)

- Unit 7: Maritime LawDocument59 pagesUnit 7: Maritime Lawbehzad parsiNo ratings yet

- Charter PartyDocument150 pagesCharter PartyAnemonia100% (8)

- Part 8 DrydockDocument9 pagesPart 8 Drydockaungthein_san100% (1)

- AMastersGuidetoContainerSecuring2ndEdition 3Document50 pagesAMastersGuidetoContainerSecuring2ndEdition 3tenedero100% (1)

- Damage To Bulk Cargo (Edited)Document4 pagesDamage To Bulk Cargo (Edited)Asif Siddiqui100% (2)

- Hatch Cover-11-15Document5 pagesHatch Cover-11-15alin grecuNo ratings yet

- Rec. - No. - 133 - pdf2226 Guidelines For Pilot Schemes of Extended Interval Between Surveys in Dry-Dock - Extended Dry-Docking EDD SchemeDocument4 pagesRec. - No. - 133 - pdf2226 Guidelines For Pilot Schemes of Extended Interval Between Surveys in Dry-Dock - Extended Dry-Docking EDD SchemeMarlon Alejandro Arboleda TapiaNo ratings yet

- (25452843 - New Trends in Production Engineering) Impact of Dock Tanks Pumping Plan On Structural Loads of A Dock and A ShipDocument7 pages(25452843 - New Trends in Production Engineering) Impact of Dock Tanks Pumping Plan On Structural Loads of A Dock and A ShipСергей ДедовNo ratings yet

- Naval Arch - Entire Portion As Per MMD QuestionsDocument55 pagesNaval Arch - Entire Portion As Per MMD QuestionsJagdeep Singh RainaNo ratings yet

- 15-AVA-2014-0015-P&I Condition Surveys & PSC Inspections - A Cause For ConcernDocument21 pages15-AVA-2014-0015-P&I Condition Surveys & PSC Inspections - A Cause For ConcernBtwins123No ratings yet

- Time Charter Survey Most DemandingDocument166 pagesTime Charter Survey Most DemandingVignesh Gunasekar100% (3)

- Charter PartyDocument150 pagesCharter Partychandreshptl86% (7)

- Proclamation 1258 — Rules for the Measurement of Vessels for the Panama CanalFrom EverandProclamation 1258 — Rules for the Measurement of Vessels for the Panama CanalNo ratings yet

- A Guide to Ship Repair Estimates in Man-hoursFrom EverandA Guide to Ship Repair Estimates in Man-hoursRating: 4.5 out of 5 stars4.5/5 (5)

- Commercial Ship Surveying: On/Off Hire Condition Surveys and Bunker SurveysFrom EverandCommercial Ship Surveying: On/Off Hire Condition Surveys and Bunker SurveysRating: 4.5 out of 5 stars4.5/5 (6)

- Shipping Practice - With a Consideration of the Law Relating TheretoFrom EverandShipping Practice - With a Consideration of the Law Relating TheretoNo ratings yet

- Piloting, Seamanship and Small Boat Handling - Vol. VFrom EverandPiloting, Seamanship and Small Boat Handling - Vol. VRating: 5 out of 5 stars5/5 (2)

- Factors Contributing to Road Accidents in ZimbabweDocument6 pagesFactors Contributing to Road Accidents in ZimbabwePhillip JengwaNo ratings yet

- ForewordDocument261 pagesForewordFifo FifoNo ratings yet

- SMSR18 Summary of ChangesDocument13 pagesSMSR18 Summary of ChangesHynea HNo ratings yet

- Torts Additional Quasi-Delict CasesDocument6 pagesTorts Additional Quasi-Delict CasesJudee AnneNo ratings yet

- Lukla AirportDocument25 pagesLukla AirportlmnduniaNo ratings yet

- Tiu V ArresgadoDocument3 pagesTiu V ArresgadoTrisha Ortega100% (1)

- December 2022Document3 pagesDecember 2022imranul haqNo ratings yet

- Benelli302R User's Manual BookDocument15 pagesBenelli302R User's Manual BookLeonardoNo ratings yet

- 2020 Non Technical Skills Integration Good Practice GuideDocument83 pages2020 Non Technical Skills Integration Good Practice GuideIsmail Ibn Hashim100% (1)

- Indoctrination Training EWISDocument29 pagesIndoctrination Training EWISRavde Sj Tim MartinezNo ratings yet

- ISO SocketDocument3 pagesISO SocketChris TeohNo ratings yet

- SEARCH FLIGHT - Airline TicketsDocument5 pagesSEARCH FLIGHT - Airline TicketsOvidiu PopescuNo ratings yet

- Railway Signalling HistoryDocument18 pagesRailway Signalling HistoryWindow SeatNo ratings yet

- GD 302 Smart Motorways - Upgrading Hard Shoulder Running To All Lane Running Operation-WebDocument55 pagesGD 302 Smart Motorways - Upgrading Hard Shoulder Running To All Lane Running Operation-WebAbinashNo ratings yet

- Coastwise Lighterage Vs CADocument12 pagesCoastwise Lighterage Vs CAwarren pontimayorNo ratings yet

- Missing Pilot: A Dangerous JourneyDocument1 pageMissing Pilot: A Dangerous JourneyialexflorinNo ratings yet

- SAFETY IS OUR STRONGEST COMMITMENTDocument16 pagesSAFETY IS OUR STRONGEST COMMITMENTthanushreeNo ratings yet

- PadmanabanDocument11 pagesPadmanabanarstjunkNo ratings yet

- Goibibo flight booking confirmation for New Delhi to Mumbai trip on August 20Document1 pageGoibibo flight booking confirmation for New Delhi to Mumbai trip on August 20Jebin SultanaNo ratings yet

- DPWH Conducts Maintenance Enhancement Training (MET) Program For Maintenance Personnel in PalawanDocument5 pagesDPWH Conducts Maintenance Enhancement Training (MET) Program For Maintenance Personnel in PalawanJamie Jade MoralesNo ratings yet

- 8431-Tema 4 1 SOLAS Class MaterialsDocument69 pages8431-Tema 4 1 SOLAS Class MaterialsZuri MpowerNo ratings yet

- Mandatory Reporting Fields Date:: R-001-REV.01-Montly Site HSE Performance Report Page 1 of 2Document2 pagesMandatory Reporting Fields Date:: R-001-REV.01-Montly Site HSE Performance Report Page 1 of 2Ravelle JacquireNo ratings yet

- Principles of WatchkeepingDocument29 pagesPrinciples of Watchkeepingirby AcabadoNo ratings yet

- National Safety Council Defensive Driving Course 4Document57 pagesNational Safety Council Defensive Driving Course 4Sylvia Donaldson100% (1)

- Toolbox Talk 11: Critical Risks - Traffic ManagementDocument2 pagesToolbox Talk 11: Critical Risks - Traffic ManagementPravin Gowardun100% (1)

- NTSB Aviation Investigation ReportDocument3 pagesNTSB Aviation Investigation ReportChelsea CollinsworthNo ratings yet

- AAH Book of The Titanic 3rd Ed - 2016 UK PDFDocument180 pagesAAH Book of The Titanic 3rd Ed - 2016 UK PDFManoelNo ratings yet

- ATR 72 - Wikipedia PDFDocument17 pagesATR 72 - Wikipedia PDFRanjan Kumar SahooNo ratings yet

- Operating Manual RVM by JAWA-ADVENTURE-ENGDocument40 pagesOperating Manual RVM by JAWA-ADVENTURE-ENGFatih NakNo ratings yet

- A350 Cokpit PosterDocument3 pagesA350 Cokpit Posterhrpolo46409No ratings yet