Professional Documents

Culture Documents

Aer Jusq

Uploaded by

Pacumio ClaretteOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aer Jusq

Uploaded by

Pacumio ClaretteCopyright:

Available Formats

By the combustion of fuel, an engine may transform chemical energy into heat energy, generating power

to drive vehicles, machinery, and other equipment. As a portion of the total heat produced by the

combustion of fuel as it is utilized to drive the piston downward and then generate energy. The extra heat

is then dispersed by the exhaust gases as they pass through the exhaust valves, and the remaining heat is

then absorbed by the engine itself. This raises the temperature of the engine, which is then lowered by

the coolant to keep the engine at a suitable operating temperature within the range of its normal

operating temperature.

The most basic components of an automotive engine cooling system are the radiator, fan, water pump,

coolant reservoir, thermostat, heater core, and any plumbing required for the radiator and heater core.

When the engine is started, the water pump attached to it circulates the required amount of coolant

around the engine cylinder through the lower radiator tank and then through the coolant passages. The

engine block, the cylinder head, and finally the radiator outlet are all places where the coolant travels

after leaving the lower tank. The coolant then works to absorb the heat produced by combustion and

moves in the direction of the radiator inlet.

But until the coolant temperature is raised to at least above engine operating temperature, which ranges

from 200 to 250 degrees Celsius, the thermostat prevents the coolant from flowing towards the radiator.

At this point, the coolant is compelled to flow through the heater core through the bypass line in the event

that the heater within the cabin is turned on. Heat is transferred from the coolant to the air flowing within

the passenger compartment via the heater core, a miniature radiator that serves as a heat exchanger.

The thermostat, on the other hand, serves as a regulating valve to manage the coolant flow into the

radiator and keep the engine temperature within a desirable range. There are several components inside

the thermostat, including the rod, wax pallet, spring, rubber diaphragm, valve and case assembly, and a

chamber filled with wax and a rod pressed against it.

The wax starts to melt as the coolant going through the thermostat reaches higher temperatures, typically

180 Fahrenheit. The wax expands thermally as a result of melting, pushing the rod and enabling the

coolant to flow outside.

When the coolant runs through the thermostat, a thermostatic switch turns on the fan. Through the upper

radiator hose, coolant that has passed the thermostat valve reaches the radiator upper tank. Due to the

possibility of a buildup of high pressure that might prevent coolant from entering the upper tank due to

the high temperature of the coolant, the upper tank is equipped with a pressure regulating valve that

opens when the system pressure exceeds the normal value. High pressure coolant may flow into the

coolant overflow tank when the valve is opened.

The coolant releases its stored heat to the air moving through the gaps between the flat tubes as it flows

downhill. The heat transfer rate is then further improved for a better cooling effect by adding fins to the

flat tubes, which increase the airflow and, in turn, the rate at which heat is transferred. The coolant's

temperature significantly drops as it reaches the radiator's bottom tank. The engine cylinder is circled by

the cold coolant once again, and the cycle is then repeated.

You might also like

- AUTOTECH Cooling SystemDocument47 pagesAUTOTECH Cooling SystemSesatthiri SesatNo ratings yet

- To Murugappa StudentsDocument12 pagesTo Murugappa StudentsNaveen RajaNo ratings yet

- Cool automotive radiatorsDocument8 pagesCool automotive radiatorsShambhuNath VermaNo ratings yet

- Engine Cooling SystemsDocument49 pagesEngine Cooling SystemsTyler GoodwinNo ratings yet

- FMP-617 Farm Mechanization Practical 3Document2 pagesFMP-617 Farm Mechanization Practical 3رانا ریحان انور خاںNo ratings yet

- Description: Cooling SystemDocument2 pagesDescription: Cooling SystemvixentdNo ratings yet

- UNIT IV - Engine Cooling SystemsDocument55 pagesUNIT IV - Engine Cooling SystemsANSH ROHATGI (RA2111011010002)No ratings yet

- Test Cooling - Arman ShaikhDocument4 pagesTest Cooling - Arman ShaikhArmanNo ratings yet

- How Car Cooling Systems WorkDocument4 pagesHow Car Cooling Systems WorkyagneshNo ratings yet

- Cooling Sys Fall 17 PDFDocument41 pagesCooling Sys Fall 17 PDFEmirBerkCanpolatNo ratings yet

- Automotive Cooling SystemDocument58 pagesAutomotive Cooling SystemMoniruzzaman ShuvoNo ratings yet

- Engine Cooling Systems: Air vs LiquidDocument5 pagesEngine Cooling Systems: Air vs LiquidAnoj pahathkumburaNo ratings yet

- Cooling Systems AssignmentDocument14 pagesCooling Systems AssignmentBecky DavisNo ratings yet

- Cooling System Report (Automotive Tech.)Document5 pagesCooling System Report (Automotive Tech.)Mohamed AhmedNo ratings yet

- Internal Combustion Engine Cooling SystemDocument6 pagesInternal Combustion Engine Cooling Systemzohaib sattarNo ratings yet

- Automobile Engg (Unit-03)Document15 pagesAutomobile Engg (Unit-03)SUDHARSHAN REDDYNo ratings yet

- Heat Pump TrainerDocument6 pagesHeat Pump TrainerAfzaal FiazNo ratings yet

- Land Robert EnfriamientoDocument8 pagesLand Robert EnfriamientoJose Luis LopezNo ratings yet

- The Pump and The ThermostatDocument6 pagesThe Pump and The ThermostatChudhary waseem asgharNo ratings yet

- Cooling SystemDocument7 pagesCooling SystemAshish KumarNo ratings yet

- Chapter 5) Engine Cooling and Lubrication System Necessity of Engine CoolingDocument14 pagesChapter 5) Engine Cooling and Lubrication System Necessity of Engine CoolingRajNo ratings yet

- Keep It CoolingDocument10 pagesKeep It CoolingChudhary waseem asgharNo ratings yet

- Al-Hussein Bin Talal University College of Engineering mechanical engineering CAR COOLING SYSTEMDocument5 pagesAl-Hussein Bin Talal University College of Engineering mechanical engineering CAR COOLING SYSTEMJaber AbdallahNo ratings yet

- Lubrication System: ComponentsDocument4 pagesLubrication System: ComponentsAira VieneNo ratings yet

- Cooling System Basic PrinciplesDocument2 pagesCooling System Basic PrinciplesBryan MartinezNo ratings yet

- Cooling System of Internal Combustion EngineDocument8 pagesCooling System of Internal Combustion EnginePathfinderNo ratings yet

- CFD Radiator by Nano AjayDocument35 pagesCFD Radiator by Nano AjayPooja BanNo ratings yet

- Presentation On Cooling SystemDocument26 pagesPresentation On Cooling SystemPawan Kumar100% (1)

- Cooling SystemsDocument2 pagesCooling SystemsLazarus GutaNo ratings yet

- How Engine Cooling System WorksDocument50 pagesHow Engine Cooling System WorksJAHID HOSSAIN100% (1)

- Effects of OverheatingDocument46 pagesEffects of OverheatingSajjad Hossain ShuvoNo ratings yet

- Performance Analysis of Car RadiatorDocument16 pagesPerformance Analysis of Car RadiatorBT20MEC047 Jeet BhaktaNo ratings yet

- Automotive Technology: Cooling SystemDocument43 pagesAutomotive Technology: Cooling Systempreethu02No ratings yet

- Engine Cooling SystemDocument28 pagesEngine Cooling SystemSagar Dadhich100% (1)

- What Is A Cooling System?: Drs - Hari Purwoko Dra - Asroni Situmorang Drs - Olo Siburian Drs.M.Arifin DalimunteDocument17 pagesWhat Is A Cooling System?: Drs - Hari Purwoko Dra - Asroni Situmorang Drs - Olo Siburian Drs.M.Arifin DalimunteArjono GultomNo ratings yet

- Water Cooling System ExplainedDocument9 pagesWater Cooling System ExplainedRANDY JR. LANGUIDONo ratings yet

- Engine Systems OverviewDocument7 pagesEngine Systems OverviewMwasi KivingeNo ratings yet

- AEH307 2 Cooling SystemDocument28 pagesAEH307 2 Cooling SystemsiphulwazijamesNo ratings yet

- Cooling System: Prepared By: Glen AbeganDocument52 pagesCooling System: Prepared By: Glen AbeganJade AbeganNo ratings yet

- Lect02 - Engine Cooling SystemDocument19 pagesLect02 - Engine Cooling SystemMaunish Shah100% (1)

- Liquid Cooled SystemsDocument9 pagesLiquid Cooled Systemsananth k rNo ratings yet

- Cooling SystemDocument3 pagesCooling SystemDavid Marzel jiing19No ratings yet

- Engine Systems 1Document5 pagesEngine Systems 1anuradhaNo ratings yet

- AutoTech Lecture 2 - Cooling SystemDocument26 pagesAutoTech Lecture 2 - Cooling SystemTaimoor AsifNo ratings yet

- Refrigeration Cycle DiagramDocument7 pagesRefrigeration Cycle DiagramsrybsantosNo ratings yet

- Engine Cooling System: Uet-Gspct-Mech-21 Syed Ihtasham Javaid ShahDocument19 pagesEngine Cooling System: Uet-Gspct-Mech-21 Syed Ihtasham Javaid Shah21-Syed Ihtasham Javaid ShahNo ratings yet

- A Short Course On Cooling SystemsDocument21 pagesA Short Course On Cooling Systemsnemo_nadalNo ratings yet

- Cooling SystemDocument15 pagesCooling SystemRonnel BarocNo ratings yet

- Task 3: Liquid CoolingDocument4 pagesTask 3: Liquid CoolinghabibullaNo ratings yet

- Cooling System Keeps Engines from OverheatingDocument8 pagesCooling System Keeps Engines from OverheatingRâdển Mẳs SựryọỡNo ratings yet

- Major Elements of Refrigeration System and Their FunctionsDocument8 pagesMajor Elements of Refrigeration System and Their FunctionsXahid HasanNo ratings yet

- Stirling Engine Cycle and TypesDocument19 pagesStirling Engine Cycle and TypesTitti SuhaibNo ratings yet

- How Generator Cooling WorksDocument3 pagesHow Generator Cooling WorksSaad jamilNo ratings yet

- Engine Cooling SystemDocument3 pagesEngine Cooling SystemSurjit Kumar GandhiNo ratings yet

- Performance and Efficiency Test of Refrigeration PlantDocument26 pagesPerformance and Efficiency Test of Refrigeration PlantGigi Sales100% (2)

- 11.chapter 4Document13 pages11.chapter 4KhantLayNo ratings yet

- Chapter 9Document47 pagesChapter 9Siraj MohammedNo ratings yet

- How Automobile Cooling Systems Work to Maintain Optimal Engine TemperatureDocument19 pagesHow Automobile Cooling Systems Work to Maintain Optimal Engine TemperatureHari Purwadi100% (1)

- Engine Cooling System: Group 1Document17 pagesEngine Cooling System: Group 1Jose Luis RattiaNo ratings yet

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- CFP NotesDocument9 pagesCFP NotesPacumio ClaretteNo ratings yet

- Workshop Lecture-2Document7 pagesWorkshop Lecture-2Pacumio ClaretteNo ratings yet

- Class Attendance JANUARY 2023Document51 pagesClass Attendance JANUARY 2023Pacumio ClaretteNo ratings yet

- Four Stroke EnginesDocument5 pagesFour Stroke EnginesPacumio ClaretteNo ratings yet

- 2020 Certificate of Attendance ASISDocument1 page2020 Certificate of Attendance ASISPacumio ClaretteNo ratings yet

- 2020 Certificate of Attendance ASISDocument1 page2020 Certificate of Attendance ASISPacumio ClaretteNo ratings yet

- Health 9 TG Draft 3.24.2014 PDFDocument114 pagesHealth 9 TG Draft 3.24.2014 PDFKeanneMarieJandusay100% (2)

- Norms and Values FinalDocument36 pagesNorms and Values FinalPacumio ClaretteNo ratings yet

- What To Do Before An Earthquake What To Do During An EarthquakeDocument8 pagesWhat To Do Before An Earthquake What To Do During An EarthquakePacumio ClaretteNo ratings yet

- Palaro Data Entry ATHLETEDocument27 pagesPalaro Data Entry ATHLETEPacumio ClaretteNo ratings yet

- Second Periodical Test Mapeh G9Document3 pagesSecond Periodical Test Mapeh G9Pacumio ClaretteNo ratings yet

- Social Dances Etiquette and MixersDocument21 pagesSocial Dances Etiquette and MixersLudge-An Lipon Olivar-DemecilloNo ratings yet

- Arts L1Document6 pagesArts L1Pacumio ClaretteNo ratings yet

- Social Dances Etiquette and MixersDocument21 pagesSocial Dances Etiquette and MixersLudge-An Lipon Olivar-DemecilloNo ratings yet

- NARRATIVE-NCSU2018 TaekwondoDocument6 pagesNARRATIVE-NCSU2018 TaekwondoPacumio ClaretteNo ratings yet

- Par QDocument2 pagesPar QTalisman CentreNo ratings yet

- Arts L1Document6 pagesArts L1Pacumio ClaretteNo ratings yet

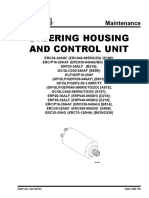

- Steering Housing and Control Unit: MaintenanceDocument20 pagesSteering Housing and Control Unit: MaintenanceNgo Ngoc TuNo ratings yet

- Cate 825 6M33 WPG825 7 12M26Document3 pagesCate 825 6M33 WPG825 7 12M26Nicolas DodoricoNo ratings yet

- History of Steam Engine InnovationsDocument3 pagesHistory of Steam Engine Innovationsakmo alimbayNo ratings yet

- BW219D 4Document2 pagesBW219D 4Charles GrantNo ratings yet

- Bendix Duraflo 596 Air Compressor: DescriptionDocument40 pagesBendix Duraflo 596 Air Compressor: DescriptionSebastian OlayaNo ratings yet

- VAG K+CAN key device programs keys and bypasses immobilizersDocument4 pagesVAG K+CAN key device programs keys and bypasses immobilizersalmia tronics100% (1)

- The Effect of Valve Timing Diagram On Engine PerformanceDocument3 pagesThe Effect of Valve Timing Diagram On Engine PerformanceMuhammadKhizarSiddique100% (1)

- Design and Analysis of Turbochargers: March 2016Document12 pagesDesign and Analysis of Turbochargers: March 2016Irah ZinirahNo ratings yet

- Catalogue Perkins 1104C 44TAG2Document8 pagesCatalogue Perkins 1104C 44TAG2RobNo ratings yet

- Operator'S ManualDocument52 pagesOperator'S ManualAlbertoNo ratings yet

- 14M3 - Motor GraderDocument2 pages14M3 - Motor GraderhendrynNo ratings yet

- 1302Document158 pages1302Joseph de los santos100% (2)

- Valves and Valve Stem Seals - Installation PDFDocument2 pagesValves and Valve Stem Seals - Installation PDFAnonymous nIcSGEwNo ratings yet

- QSK78 Engine OverviewDocument58 pagesQSK78 Engine Overviewshinichie100% (2)

- KADETT - Fault Codes GMDocument2 pagesKADETT - Fault Codes GMbelacrkva0% (1)

- DetroitDocument56 pagesDetroitAbabsa KomatsuNo ratings yet

- Amvi Rto Mains 2020 - Study Material: - Second EditionDocument27 pagesAmvi Rto Mains 2020 - Study Material: - Second EditionUjwala SonawaneNo ratings yet

- Cat d9r BrochureDocument20 pagesCat d9r Brochureayush bansalNo ratings yet

- Aap Ki Unnati Ka Sachcha Saathi: Ficiency Fitability GressDocument6 pagesAap Ki Unnati Ka Sachcha Saathi: Ficiency Fitability GressSubham BhartiNo ratings yet

- BMK 1045 1 enDocument84 pagesBMK 1045 1 enGilvan Franqueta100% (3)

- Ficha Tecnica NBT 55Document60 pagesFicha Tecnica NBT 55Jesus CastilloNo ratings yet

- FillyDocument27 pagesFillyMinh ChuNo ratings yet

- Earthmoving Landscaping - Excavators - Excavator 3.5 AC U35 3 AC - Operation ManualDocument98 pagesEarthmoving Landscaping - Excavators - Excavator 3.5 AC U35 3 AC - Operation ManualAlbertoNo ratings yet

- Differences in crosshead lubrication arrangements between Sulzer and MAN B&W enginesDocument1 pageDifferences in crosshead lubrication arrangements between Sulzer and MAN B&W enginesVijay A100% (3)

- 1300 MAXTRAK CRUSHER SPECIFICATIONDocument6 pages1300 MAXTRAK CRUSHER SPECIFICATIONEndro Suhadi0% (2)

- Performance of The Four Strokes Diesel EngineDocument9 pagesPerformance of The Four Strokes Diesel EngineDiyar Nezar100% (1)

- IO-540-A-B-C-D-E-G Parts Catalog PC-215-1Document93 pagesIO-540-A-B-C-D-E-G Parts Catalog PC-215-1alex castroNo ratings yet

- Hyundai 50D-9, 60D-9, 70D-9, 80D-9 ManualDocument229 pagesHyundai 50D-9, 60D-9, 70D-9, 80D-9 ManualDa Nang Jeep ToursNo ratings yet

- Saur CompressorDocument20 pagesSaur CompressorsridharNo ratings yet

- Nauticat 38Document4 pagesNauticat 38f.sastreguaschNo ratings yet