Professional Documents

Culture Documents

Axial Piston Pump PARKER

Uploaded by

Moataz NazeemOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Axial Piston Pump PARKER

Uploaded by

Moataz NazeemCopyright:

Available Formats

Bulletin HY11-PVI 016 /UK

Installation Manual

Series PV

Design series ≥ 40, PVplus

Axial Piston Pump

Variable Displacement

Parker Hannifin GmbH & Co. KG

Pump and Motor Division

Neefestraße 96

09116 Chemnitz, Germany

Phone: +49 371 3937 0

Fax: +49 371 3737 488

E-mail: infopmd@parker.com

Copyright ©2006, Parker Hannifin GmbH & Co. KG

Axial Piston Pump

Installation Manual Series PV

Contents Page

1. Installation and start-up 3

2. Displacement adjustment 6

3. Standard pressure compensator, code F*S 6

4. Remote pressure compensator, code FRC 7

5. Remote pressure compensator, codes FR1, FRZ 8

6. Load sensing compensator, code FFC 9

7. Load sensing compensator, codes FF1, FFZ 10

8. Two-spool load sensing compensator, codes FT1, FTZ 11

9. Horse power compensator, codes *L*, *C* 12

10. Proportional displacement control, code FPV 14

11. Electrohydraulic p/Q control, codes FPR, FPZ 15

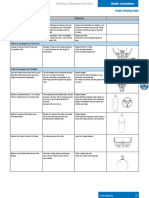

12. Compensator accessories 16

12.1 Pressure pilot valve, code PVAC1P* 16

12.2 Multiple pressure pilots, codes PVAC1E*, PVAC2P*,

PVAC2E* and PVAC2M* 17

13. Trouble shooting guide 18

Note: The compensator ordering code is represented by the last three digits of the pump

ordering code (digit 13 to 15).

Note

This document and other information from Parker Hannifin GmbH, its

subsidiaries, sales offices and authorized distributors provide product

or system options for further investigation by users having technical

expertise. Before you select or use any product or system it is important

that you analyse all aspects of your application and review the

information concerning the product or system in the current product

catalogue. Due to the variety of operating conditions and applications

for these products or systems, the user, through his own analysis and

testing, is solely responsible for making the final selection of the

products and systems and assuring that all performance and safety

requirements of the application are met. The products are subject to

change by Parker Hannifin GmbH at any time without notice.

IA PVI016 UK.PMD RH

2 Parker Hannifin GmbH & Co. KG

Pump and Motor Division

Axial Piston Pump

Installation Manual Series PV

1. Installation and start-up and filtered fluid, free of air bubbles. No turbulences

For a safe and disruption free operation of any ma- or high flow velocities should occur at the tube inlet.

chine or system a careful installation and start up Therefore position inlet as far as possible away from

following the manufacturers instruction is mandato- return line and drain line. Make sure that the fluid

ry. circulation in the reservoir does keep return flow from

Hydraulic systems can be designed for many totally suction pipe inlet. In case of positive head use shut

different functions and they require consequently off valve in the inlet, monitored with proximity switch

different start up procedures. The hydraulic pump is or equivalent to avoid start up of motor when valve

in this respect only one, but nevertheless very im- is closed. When installed into the reservoir use short

portant component of the whole system. suction pipe with pipe end cut under 45°.

A general start up instruction therefore can give many Pressure port

helpful hints but it needs to be completed by specific Select correct pressure rating for pipe, hose and

additions depending of the individual nature of the connectors. Take pressure peaks into account. Di-

system or power unit. mension the piping according to the port size. Pre-

During installation and start up the following steps vent excitation of the system by using flexible port

need to be carried out carefully: connections.

Visual inspection Drain port

Make sure that all components of the shipment are Always use highest possible drain port of the pump.

complete, free of any damage, free of outside con- Drain port must be higher than pump centerline or

tamination and properly protected against ingres- install additional air bleed line. Never combine pump

sion of contamination. drain line with other return lines and/or drain lines.

Pump shall not be able to run empty. Max. allowable

Cleanliness

case pressure ≤0.5bar (2bar peak), also during com-

Contamination of any kind is the enemy of any hy-

pensation.

draulic component. It is still the number 1 cause for

Use low pressure pipe/hose, as short as possible

component failure. Therefor maximum care and

and full cross section according to port dimension.

cleanliness are required during all handling and

Do not use elbows or sharp corners. When drain

managing of parts that come in contact with the hy-

port is on the side of the pump drain line should have

draulic fluid. All ports of the pumps and other com-

bridge higher than pump top (also when installed in

ponents must be covered until pipes or hoses are

reservoir). Drain pipe must end at least 200 mm be-

mounted to them. Perform assembly preferably in a

low fluid level even at lowest filling level. Never let

dry and dust free room. Use only suitable tools.

drain flow go direct into suction area of reservoir (tem-

Installation perature, air bubbles). Max. length 2m, otherwise use

Installation horizontal or vertical, avoid rigid connec- larger pipe diameter than port size.

tion from pump to reservoir cover or frame and to Note: During operation of PV pumps of all sizes un-

inlet and outlet piping to prevent excitation of the der the following conditions:

whole system due to pump vibrations.

Q ~ Qmax

Suction port pinlet < 2 bar absolute

Position to the side or to the bottom, max. fluid ve- Poutlet < 25 bar

locity approx. v = 0.5m/sec, cut suction pipe inlet un- (e. g. low pressure circulation) the drain flow can

der 45°. Minimum distance from bottom 2 - 3 times change direction. Fluid is taken from the case into

diameter and, even at lowest fluid level, approx. the piston mainly through the decompression ori-

200mm below fluid level. Inlet pressure, even during fice and across the slipper. There is a danger that

compensation, never should drop below 0.8bar (ab- the pump case runs dry, the pump overheats and

solute). the bearings lack of lubrication when the fluid is re-

Absolute gas tight connection (risk of cavitation, moved from the pump case.

noise). Air bubbles due to vacuum in the inlet can Therefore the drain pipe must be able to take fluid

destroy pumps within a short time due to cavitation from the reservoir. That means: The drain line must

erosion. Suction pipe should be as short as possi- end below fluid level, and a check valve in the drain

ble. Use only clean, low pressure pipe, avoid sharp line is not permissible. If it has to be installed for

elbows and any restriction of cross section. whatever reason the case needs to be flushed with

The suction pipe must have access to clean, cooled a flow of 10 - 15% of the nominal pump flow.

IA PVI016 UK.PMD RH

3 Parker Hannifin GmbH & Co. KG

Pump and Motor Division

Axial Piston Pump

Installation Manual Series PV

Port positions for PV (shown for clockwise rotation, for ccw rotation ports are mirrored)

Alternative drain port

Drain port

Interface for

compensator

Suction port Gage port

(inlet)

Flushing port, covered Pressure port

below pump (outlet)

Flushing port

The PV pumps of design series 40 (PVplus) are The flushing flow should be taken from the return

equipped with a flushing port. This port is smaller flow of the separate cooling and filter circuit. Pre-

in diameter than the drain port(s) and is located load at 1 to 2 bar, consider orifice corresponding

opposite to these ports in the bottom of the pump to preload pressure and recommended flushing

case. The flushing flow can - depending on the flow.

actual working conditions - be used to keep the

pump case filled, to warm up the pump (during Drive input

cold temperature operation) or for a better heat For direct drive use elastic coupling free of axial

dissipation. Permanent dead head operation and radial reaction forces. Please follow strictly

(>15min) either for pumps of frame size 3 and the instructions of the coupling supplier regard-

larger (PV063 and higher) or at high input speeds ing axial clearance, axial displacement and an-

above 1,800rpm as well as high environmetntal gular tolerances. Couplings never shall be mount-

temperatures flushing are recommended. Also ed using a hammer. Threads in the shaft end al-

dead head operation with HFC fluids (water gly- low smooth mounting of the coupling.

cole) requires flushing of the pump case, to avoid The drive shaft should only carry true torque.

high fluid temperatures. Contact Parker for allowable side loads or axial

The flushing flow depends on the frame size forces.

of the pump: PV pumps are normally for one direction of rota-

Frame size 1 4 to 6 l/min tion only. Therefore check rotation of drive motor

prior to installation.

Frame size 2 5 to 8 l/min

Frame size 3 7 to 10 l/min

Frame size 4 9 to 12 l/min

Frame size 5 13 to 17 l/min

IA PVI016 UK.PMD RH

4 Parker Hannifin GmbH & Co. KG

Pump and Motor Division

Axial Piston Pump

Installation Manual Series PV

Electrical interface

Check voltage, current, phase and connection prop- Cleanliness level for systems with higher re-quire-

erties. Verify direction of motor rotation. ments for operational life and functional safety

Fluid reservoir should be 18/16/13 according to ISO 4406; corre-

The reservoir needs to meet all system requirements sponding filter rating x = 10µm ( b10≥75 ) accord-

concerning design, size, location and porting. Be- ing to ISO 4572.

side beeing reservoir for the hydraulic fluid, the tank Use filter with indicator or electrical signal when

also supports heat dissipation, air removal, water capacity limit is approached.

removal and contamination sedimentation. Often the Suction filter should be avoided. Suction conditions

reservoir also is the fundament for the motor pump will be affected. Filter can be blocked and cause

unit. In this case the separation of pump and re- cavitation and severe pump damage. When used,

maining structure by elastic means is mandatory to a vacuum sensor with shut off function is manda-

avoid noise and vibration being induced into the tory.

frame work. The reservoir needs to be carefully Properly dimensioned breather rating ≤10µm

sealed against ingression of contamination and should be used. Observe min. and max. fluid level;

water. A level indicator and thermometer should be consider exchange volume with cylinders in the

placed in an easily accessible location. system.

Fluid content (general rule): stationary systems 3 Filling of pump case

to 4 times pump nominal flow, 1 times or even small-

Pump case must be filled via the drain port, to

er in mobile systems.

ensure lubrication, sealing and smooth start up.

Filling of the system

Start up

Use only high quality mineral oil based fluids, like

HLP oils according to DIN 51524 part 2. For other Check if all ports are properly connected accord-

fluids (HFC, HFD, bio degradable or synthetic flu- ing to the specification, all connectors are tight-

ids) please contact Parker and review the Hydrau- ened and all adjustments are made.

lic Fluids Information in Catalogue 2500/UK. Open suction valve!

Operation viscosity should be 16 to 100mm²/s, op- Switch system to free circulation or to lowest pres-

timum viscosity range is in the 20 to 40mm²/s, max. sure. Allow air bleeding for quick priming. Start

viscosity for short time up to 320mm²/s. pump in tip mode operation until pump and all pipes

Because of the possibly uncompatible ingredients are filled and free from air bubbles.

fluids should not be mixed (separation of fluid, re- If pump does not build up pressure double check

duction or loss of fluid properties). the installation.

Pay highest attention on cleanliness! Raise pressure setting only when all air is removed.

Fill system only via a filtration device. Use filtration Let the pump work at reduced pressure for 5 - 10

unit, when basic contamination of the refill fluid ex- min, check if all pipes and connections are leak

ceeds class 10 according NAS 1638 (contamina- free and tight.

tion level 18/16/13 according to ISO 4406). Hy- Observe reservoir: fluid level, built up of foam, flu-

draulic fluid supplied in barrels typically exceeds id temperature. When system is warmed up first

these contamination levels. functional tests can be performed.

Filtration

Filtration is the most important factor to the opera-

tional life of the hydraulic system. Statistical analy- Note

ses indicate, that contamination is by far the most All pumps are tested and adjusted after assem-

important reason for system or component failure. bly in our factory.

Use return line, pressure and/or bypass filtration. If no specific pre-setting is required on the order

Bypass filtration usually is most efficient. For gen- only the compensating pressure needs to be ad-

eral purpose hydraulic systems with limited require- justed. Depending on the compensator option this

ments for operational life contamination level 20/ might be done on a pilot valve only. In this case

18/15 according to ISO 4406 should be desired; no adjustments on the compensator or the pump

corresponding filter rating: x = 25µm ( b25≥75 ) ac- is required. Only after service or repair a basic

cording to ISO 4572. adjustment needs to be performed.

IA PVI016 UK.PMD RH

5 Parker Hannifin GmbH & Co. KG

Pump and Motor Division

Axial Piston Pump

Installation Manual Series PV

2. Displacement adjustment

All axial piston pumps of the PV series are

Minimum adjustable

equipped with an adjustable displacement limiter.

change per mm

Displacement c

(approx. cm³/U)

(approx. cm³/U)

(approx. cm³/U)

hange per turn

The servo piston stroke is limited at full displace-

Displacement

displacement

ment by a screw, guided in the end cover plug of

the servo piston bore. The screw is protected

against unintentional adjustment by a self-sealing

lock nut. Size

The factory setting of the displacement is accord- PV016 1.5 1.5 9

ing to the nominal displacement of the pump. An PV020 1.5 1.5 13

adjustment may only be made to a lower displace- PV023 1.5 1.5 16

ment (turning screw in). An adjustment to a higher

PV032 2.2 2.2 17

than the nominal displacement can destroy the

pump. PV040 2.2 2.2 25

Adjustment should only be made with the pump PV046 2.2 2.2 30

working at full displacement (not compensated) PV063 3.4 3.4 35

and at a low output. At full displacement the piston PV080 3.4 3.4 50

area of the servo piston is under case pressure. PV092 3.4 3.4 65

Opening the self-sealing nut will only cause a neg- PV140 5.6 8.4 20

ligible leakage under these conditions.

PV180 5.6 8.4 60

PV270 6.8 10.2 120

Adjustment screw

Lock nut 3. Standard pressure compensator, code ...F*S

The adjustment of the compensating pressure is

performed for the standard pressure compensa-

tor directly at the compensator.

To adjust the pressure, the lock nut (SW 19) is to

be loosened and the adjustment spindle is to be

turned. Turning clockwise will increase the com-

pensating pressure, turning counter-clockwise will

decrease the compensating pressure. The adjust-

ment spindle has a thread pitch of 1mm (thread

M 12 x 1).

The following limits exist for the three spring op-

tions:

Minimum pressure

Pressure variation

Nominal pressure

per turn / per mm

Note! Maximum

Pressure range

adjustment

possible

setting

D 140bar 8 - 10 bar 20 bar 170 bar

Turning the adjustment screw clockwise will reduce

the pumps displacement. For the sizes PV016 – H 210 bar 8 - 10 bar 40 bar 350 bar

PV092 the thread pitch is 1mm, for sizes PV140 –

W 350 bar 8 - 10 bar 60 bar 450 bar

PV270 the thread pitch is 1.5mm. The following

table shows the displacement change per mm resp. Note! Danger of spring overload at maximum

per turn and the minimum adjustable displacement: possible adjustment pressure!

IA PVI016 UK.PMD RH

6 Parker Hannifin GmbH & Co. KG

Pump and Motor Division

Axial Piston Pump

Installation Manual Series PV

Snap ring

Adjustment

spindle

Lock nut

Although for all three springs the min. adjustable The max. possible pressure adjustment is

pressure is approx. 8 - 10bar (min. compensating reached, when the spindle is completely turned

pressure of a PV pump), for the spring code H a in (snap ring touches the lock nut). In this situa-

min. pressure adjustment of 40 bar and for the tion there is a danger of spring overload depend-

spring code W a min. pressure adjustment of ing of manufacturing tolerances. If such a high

70bar is recommended. Adjusting lower pressures adjustment should be prohibited, washers can be

with these springs can lead to an extremely slow placed between lock nut and snap ring.

compensator response.

4. Remote pressure compensator, code FRC

Snap ring

Adjustment

spindle

Lock nut

Remote port

For the remote pressure compensator the pres- The pilot valve can be mounted as far as 15m

sure adjustment is done at a pressure pilot valve away from the pump. Please note for a distance

(not included in the shipment of the pump). The above 5m, that low temperatures and a high fluid

pilot valve is connected to the remote port. viscosity can significantly increase the compen-

The pressure pilot valve must be capable of hand- sating pressure.

ling securely a pilot flow of approx. 1.2l/ The pilot connection should be dimensioned to

min.Therefore a nominal flow of 3 - 6l/min is re- avoid any considerable pressure drop in this line.

commended for the pilot valve. Selection of a pi- The pressure adjustment and the max. pressure

lot valve too small or too large can result in com- setting are given by type and setting of the pilot

pensator instability. valve.

The pilot port thread can be determined from the The min. compensating pressure can be calcu-

ordering code of the pump (threads and port lated from the min. adjustable pressure of the pi-

code): lot valve plus the differential pressure setting at

the compensator.

Threads and Port Factory setting for the compensator differential

port code dimensions pressure is 15 ±1bar. This adjustment should only

be modified, if specifically required. To change

1 G 1/4 BSPP

the adjustment the lock nut is to be loosened and

3 7/16-20 UNF the adjustment spindle to be turned. Clockwise

7 M12 x 1.5 ISO 6149-1 turning will increase the differential pressure set-

8 M12 x 1.5 ISO 6149-1 ting.

IA PVI016 UK.PMD RH

7 Parker Hannifin GmbH & Co. KG

Pump and Motor Division

Axial Piston Pump

Installation Manual Series PV

The adjustment range reaches from approx. 8bar

For differential pressure adjustment the true differ-

to approx. 80bar. The actual compensating pres-

ential pressure should be measured (pump outlet

sure is given by the pressure setting of the pilot

pressure minus pilot pressure). An adjustment only

valve at nominal pilot flow (approx. 1.2l/min) plus

measuring pump outlet pressure requires an abso-

the compensator differential pressure. lutely pressure free remote port.

At factory setting and fully unloaded remote port

Functional descriptions and circuit diagrams of

the min. compensating pressure is 15bar. all compensators see Catalogue HY11-2500/UK,

chapter 1.

5. Remote pressure compensator, codes FR1, FRZ

Mounting interface NG6, DIN 24 340 for pressure pilot valve

Snap ring

Adjustment

spindle

Lock nut

For the remote pressure compensator the pres- The min. compensating pressure can be calcu-

sure adjustment is done at a pressure pilot valve lated from the min. adjustable pressure of the pi-

(not included in the shipment of the pump). This lot valve plus the compensating differential pres-

pilot valve is mounted to the NG6 interface on sure adjusted at the compensator.

top of the compensator valve. Parker offers a wide Factory setting for the compensator differential

variety of compensator accessories (pilot valves) pressure is 15 ±1bar. This adjustment should only

under ordering code PVAC* . be modified if necessary. To change the adjust-

The pressure pilot valve must be capable of hand- ment the lock nut is to be loosened and the ad-

ling securely a pilot flow of approx. 1.2l/ justment spindle to be turned. The adjustment

min.Therefore a nominal flow of 3 - 6l/min is re- range reaches from approx. 8bar to approx. 80

commended for the pilot valve. Selection of a pi- bar. The actual compensating pressure is given

lot valve too small or too large can result in com- by the pressure setting of the pilot valve at nom-

pensator instability. inal pilot flow (approx. 1.2l/min) plus the compen-

The pilot valve is mounted directly on top of the sator differential pressure.

compensator valve (mounting interface NG6, DIN At factory setting and fully unloaded remote cham-

24340 on compensator topside). The mounting ber (compensator spring chamber) the min. com-

threads for the pilot valve are M5 for threads and pensating pressure is 15bar.

port code 1 and 8 or #10 - 24 UNC for threads For differential pressure adjustment the true dif-

and port code 3 and 7. ferential pressure should be measured (pump

Beside a manual operated pilot valve (e. g. code outlet pressure minus pilot pressure). An adjust-

PVAC1P*) also a proportional pressure valve (e. ment when only measuring the pump outlet pres-

g. DSAE* or RE*) or a multiple pressure pilot cir- sure requires an absolutely pressure free com-

cuit (e.g. PVAC2P*) can be installed. pensator spring chamber.

Compensator accessories see Catalogue HY11- Functional descriptions and circuit diagrams of

2500/UK, chapter 1. all compensators see Catalogue HY11-2500/UK,

Proportional pressure pilot valves and driver elec- chapter 1.

tronics to operate these valves see Catalogue

HY11-2500/UK, chapters 4 and 10.

The pressure adjustment, and the max. pres-

sure are defined by type and nature of the pres-

sure pilot valve.

IA PVI016 UK.PMD RH

8 Parker Hannifin GmbH & Co. KG

Pump and Motor Division

Axial Piston Pump

Installation Manual Series PV

6. Load sensing compensator, code FFC

Snap ring

Adjustment

spindle

Lock nut

Load sensing port

The load sensing or flow compensator primarily The pressure pilot valve must be capable of hand-

controls the pump output flow. To achieve this the ling securely a pilot flow of approx. 1.2l/

load pressure after a main stream throttle valve min.Therefore a nominal flow of 3 - 6l/min is re-

(load sensing valve, not included in the shipment commended for the pilot valve. Selection of a pi-

of the pump) is connected to the load sensing lot valve too small or too large can result in com-

port of the compensator. The compensator con- pensator instability.

trol strategy is, to keep the pressure drop con- The pressure adjustment and the max. pressure

stant across this main stream throttle valve. are defined by type and nature of the pressure

To add pressure compensation to the load sens- pilot valve.

ing function, an orifice (Ø 0.8mm) is to be added The minimum compensating pressure can be

into the load sensing line and a pressure-pilot calculated from the min. adjustable pressure of

valve must be connected between orifice and the pilot valve plus the compensating differential

compensator valve (see circuit diagram). pressure adjusted at the compensator.

Circuit diagram of a load sensing compensator with external pressure pilot valve

IA PVI016 UK.PMD RH

9 Parker Hannifin GmbH & Co. KG

Pump and Motor Division

Axial Piston Pump

Installation Manual Series PV

The connecting thread at the load sensing port is The actual compensating pressure is given by the

defined by the threads and port option of the pump pressure setting of the pilot valve at nominal pilot

ordering code: flow (approx. 1.2l/min) plus the compensator dif-

ferential pressure.

Threads and Port

At factory setting and fully unloaded remote cham-

port code dimensions

ber (compensator spring chamber) the minimum

1 G 1/4 BSPP compensating pressure is 10bar.

3 7/16-20 UNF For differential pressure adjustment the true dif-

7 M12 x 1.5 ISO 6149-1 ferential pressure should be measured (pump

outlet pressure minus pilot pressure). An adjust-

8 M12 x 1.5 ISO 6149-1

ment only measuring pump outlet pressure re-

Factory setting for the compensator differential quires an absolutely pressure free compensator

pressure is 10 ±1bar. This adjustment should only spring chamber.

be modified if necessary. To change the adjust- The pressure adjustment also influences the ef-

ment the lock nut is to be loosened and the ad- fective output flow of the pump. The higher the

justment spindle to be turned. differential pressure setting, the higher the flow

The adjustment range reaches from approx. 8bar at a given setting of the load sensing valve.

to approx. 80bar. Note, that a higher adjustment Functional descriptions and circuit diagrams of

means higher power losses at the load sensing all compensators see Catalogue HY11-2500/UK,

valve. chapter 1.

7. Load sensing compensator, codes FF1, FRZ

Mounting interface NG6, DIN 24 340 for pressure pilot valve

Snap ring

Adjustment spindle

Lock nut

Load sensing port

The load sensing or flow compensator primarily The pressure pilot valve must be capable of hand-

controls the pump output flow. To achieve this the ling securely a pilot flow of approx. 1.2l/

load pressure after a main stream throttle valve min.Therefore a nominal flow of 3 - 6l/min is re-

(load sensing valve, not included in the shipment commended for the pilot valve. Selection of a pi-

of the pump) is connected to the load sensing lot valve too small or too large can result in com-

port of the compensator. The compensator con- pensator instability.

trol strategy is, to keep the pressure drop across The thread at the load sensing port is given by the

this main stream throttle valve constant. threads and port option of the pump ordering code:

In addition the compensator with the code FF1

Threads and Port

comes with a top side mounting interface NG6

port code dimensions

DIN 24340 and a pilot orifice Ø 0.8mm in the load

sensing port. Directly on the mounting interface 1 G 1/4 BSPP

a pressure pilot valve can be mounted. The mount- 3 7/16-20 UNF

ing threads for the pilot valve are M5 for threads

7 M12 x 1.5 ISO 6149-1

and port code 1 and 8 or #10 - 24 UNC for threads

and port code 3 and 7. 8 M12 x 1.5 ISO 6149-1

IA PVI016 UK.PMD RH

10 Parker Hannifin GmbH & Co. KG

Pump and Motor Division

Axial Piston Pump

Installation Manual Series PV

The pressure adjustment and the max. pressure At factory setting and fully unloaded remote cham-

are defined by type and nature of the pressure pi- ber (compensator spring chamber) the min. com-

lot valve. pensating pressure is 10bar.

The min. compensating pressure can be calculat- For differential pressure adjustment the true differ-

ed from the min. adjustable pressure of the pilot ential pressure should be measured (pump outlet

valve plus the compensating differential pressure pressure minus pilot pressure). An adjustment only

adjusted at the compensator. measuring pump outlet pressure requires an absolu-

Factory setting for the compensator differential tely pressure free compensator spring chamber.

pressure is 10 ±1bar. This adjustment should only The pressure adjustment also influences the effec-

be modified if necessary. To change the adjustment tive output flow of the pump. The higher the differ-

the lock nut is to be loosened and the adjustment ential pressure setting is, the higher the flow is go-

spindle to be turned. The adjustment range is from ing to be at a given setting of the load sensing

approx. 8bar to approx. 80bar. The actual compen- valve.

sating pressure is given by the pressure setting of Functional descriptions and circuit diagrams of

the pilot valve at nominal pilot flow (approx. 1.2l/ all compensators see Catalogue HY11-2500/UK,

min) plus the compensator differential pressure. chapter 1.

8. Two-spool load sensing compensator, codes FT1, FTZ

Mounting interface NG6, DIN 24 340 for pressure pilot valve

Snap ring

Adjustment spindle

Lock nut

ssure

remote pre Snap ring

pe nsa tor

com

Adjustment spindle

nsator Lock nut

ng compe

load sensi

Load sensing port

The two spool compensator, code FT1 has two sep- is 15 ±1bar. These adjustments should only be

arate compensator valves for flow and pressure. modified, when necessary.

The flow compensation is done with the lower valve. To change the adjustment the lock nut is to be

It is connected to the load sensing port of the hy- loosened and the adjustment spindle to be turned.

draulic circuit. The adjustment range reaches from approx. 8 bar

The remote pressure compensator is mounted on to approx. 80bar. The actual compensating pres-

top of the flow compensator and it overrides the sure is given by the pressure setting of the pilot

flow compensation, when pressure setting is valve at nominal pilot flow (approx. 1.2l/min) plus

reached. On the mounting interface NG6, DIN 24340 the compensator differential pressure.

on top of the pressure compensator stage – as At factory setting and fully unloaded remote cham-

described for the remote pressure compensator FR1 ber (compensator spring chamber) the min. com-

– any pressure pilot valve can be mounted, as long pensating pressure is 10bar.

as is fulfills the requirements described there. For differential pressure adjustment the true dif-

Mounting interface, threads and port dimensions ferential pressure should be measured (pump out-

see Catalogue HY11-2500/UK, chapter 5. let pressure minus pilot pressure). An adjustment

The factory setting of the flow compensator is 10 ± only measuring pump outlet pressure requires an

1bar, the adjustment for the pressure compensator absolutely pressure free compensator spring

chamber.

IA PVI016 UK.PMD RH

11 Parker Hannifin GmbH & Co. KG

Pump and Motor Division

Axial Piston Pump

Installation Manual Series PV

9. Horse power compensator, codes *L*, *C* Section of a horse power compensated pump

Depending on its type, the horse power compen-

sator consists of a modified remote pressure com-

pensator or a modified load sensing compensa-

tor in combination with the horse power pilot car-

tridge. The opening pressure of this pilot cartridge

depends on the actual displacement of the pump.

At large displacements the opening pressure is

low. As the displacement is reduced the opening

pressure is increased according to the form of

the contour sleeve in the pump. That leads to the

desired control characteristic (constant input

horse power).

That is achieved by having the pilot cartridge seat

being guided by the contour sleeve. This contour

sleeve is firmly connected to the servo piston.

The contour represents the desired input horse

power. Horse power pilot cartridge

The horse power pilot cartridge is internally con- Set screw

nected to the compensator valve. Compensator

valves for horse power compensated pumps dif- Lock nut

fer from standard compensator valves only in this

additional port in the mounting interface.

For a standard horse power compensator with

ordering code *L* a modified remote pressure

compensator is used. For a horse power com-

pen-sator with load sensing, code *C* a modified

load sensing compensator is used.

Constant horse power curve with adjustment

At the adjustment screw of the horse power pilot

valve a basic adjustment of the horse power com-

pensator can be made.

Attention: 0.1 mm equals approx. 20 bar!

After loosening the lock nut (self-sealing nut) the

compensator control curve can be moved by

turning the adjustment screw (adjustment A in

the diagram left). This adjustment, done to meet

the required constant input horse power curve,

is already made during the factory test and should

be modified only in exceptional cases.

To adjust the correct constant horse power curve

Adjustment A a measuring device is required. An output power

Tolerance compensation for optimized perfor- measurement requires pressure and flow meter-

mance; done at pilot cartridge. ing. An input power measurement requires torque

Adjustment B and speed measurement or a measurement of

the electric motor current.

Max.pressure setting; done at pressure pilot

valve.

IA PVI016 UK.PMD RH

12 Parker Hannifin GmbH & Co. KG

Pump and Motor Division

Axial Piston Pump

Installation Manual Series PV

9.1 Horse power compensator, ordering codes *LA resp. *CA

Mounting interface NG6, DIN 24 340 for pressure pilot valve

Snap ring

Adjustment spindle

Lock nut

Load sensing port, for

code *LA plugged

A horse power compensator with ordering codes requirements. Valve selection, requirements and

*LA resp. *CA has a compensator valve with a mounting dimensions see Catalogue HY11-2500/

topside mounting interface NG6, DIN 24340. Any UK, chapter 4.

pilot valve can be mounted when it fulfills the

9.2 Horse power compensator, ordering codes *LB resp. *CB

Snap ring

Adjustment spindle

Lock nut

Remote resp.

load sensing port

For horse power compensators with ordering If another compensating pressure or a closer tol-

codes *LB resp. *CB the compensator valve has erance is required, an external pilot valve can be

a pilot port on its side. If no pilot valve pilot valve connected. External pilot valve, requirements and

for adjustable pressure compensation is con- adjustment procedures see Catalogue HY11-

nected, the compensating pressure is defined by 2500/UK, chapter 3.

the design of the contour sleeve and can be in Functional descriptions and circuit diagrams of

the range of 370 ± 20bar, depending on the ad- all compensators see Catalogue HY11-2500/UK,

justment of the horse power pilot valve. chapter 1.

9.3 Horse power compensator, ordering codes *LC resp. *CC

Lock nut With horse power compen-

sator ordering code *LC

Set screw resp. *CC an adjustable

pressure pilot valve is includ-

ed in the shipment. The valve

pilot valve

pressure is mounted on top of the

C 1 P C MNS

PVA compensator valve. After

loosening the lock nut, turn-

. ing of the adjustment screw

ssure resp

remote pre allows a setting of the com-

n g

load sensi pensating pressure between

tor Load sensing

compensa approx. 20bar and 350bar

port, for code

(adjustment B in figure on

*LC plugged

previous page).

IA PVI016 UK.PMD RH

13 Parker Hannifin GmbH & Co. KG

Pump and Motor Division

Axial Piston Pump

Installation Manual Series PV

10. Proportional displacement control, code FPV

Cap nut

Lock nut Electrical connection

The electrohydraulic proportional displacement After that the zero setting of the LVDT must be

control consists of the proportional displacement controlled. The LVDT must be connected to ter-

control valve shown above and the inductive po- minals 23, 24 and 25 of the electronic control mod-

sition transducer (LVDT) used for the displace- ule and the solenoid to terminals 14 and 15.

ment feedback.

Setting dimension for LVDT armature Inductive position transducer (LVDT)

A [mm] A [mm] A [mm]

Size 40 41 42 Plug with

PV016-PV023 80.25 63.5 73.5 O-ring

sealing

PV032-PV046 80.25 63.5 73.5

PV063-PV092 81.75 65 75

PV140-PV180 81.75 65 75 Zero

PV270 81.75 65 75 adjustment

(secured)

Series 40

Do not

adjust!

Series 41

Electrical

connection

Series 42

LVDT and proportional displacement control valve When the pump is running the input command for

are factory set and the adjustment is secured. Any the displacement is to be set to 0 and the pressure

new or re-adjustment is only necessary after re- relief valve of the system / test rig should be set to

pair or service. a pressure > 25bar. All other valves of the system

Prior to an adjustment first the setting dimension of must be closed.

the LVDT probe is to be checked (see figure and The pump then will compensate at the min. com-

table above). The adjustment is secured with an ad- pensating pressure (10 ± 2bar) to its min. displace-

hesive. ment. By adjusting the zero adjustment potentiom-

Any new adjustment must be secured with an ad- eter at the LVDT the voltage at the diagnosis output

hesive, to avoid unintentional variation of the ad- must be adjusted to 0V, because this situation rep-

justment. resents the absolute minimum working displace-

ment of the pump.

IA PVI016 UK.PMD RH

14 Parker Hannifin GmbH & Co. KG

Pump and Motor Division

Axial Piston Pump

Installation Manual Series PV

Then the set command for the displacement must If the max. displacement is reached at an input

be raised, until the max. swash plate angle is command considerably below 10V, a correction

reached. This can either be checked by monitoring can also be achieved by setting the MAX potenti-

the diagnosis output or by using a flow meter. The ometer accordingly.

swash plate angle has reached its maximum, when To perform a basic adjustment of the proportional

the displacement does not grow further, even when displacement compensator valve, first the cap nut,

the input command is increased. If the input com- the lock nut and the O rings and washers must

mand reaches 10V (or 20mA for electronic mod- be removed.

ules with current input = max. input command) be- Then a medium input command is to be adjusted

fore the max. displacement is reached, the displace- (e. g.: 50% displacement).

ment can be increased further by using the MAX

potentiometer on the module.

Set screw (basic

compensator valve

adjustment)

In this control situation the proportional solenoid Note

should draw approx. 60% of its nominal current The proportional displacement control code

(nominal current 1.3A; current in control situation FPV does not include pressure compensation.

750mA). Under this condition the solenoid works Therefore the hydraulic circuit must be

at half its nominal force in control position and a equipped with a pressure relief valve capable

similar control response speed is achieved for of the full pump output flow.

upstroking and downstroking. Turning the set screw

varies the solenoid current. Clockwise turning in-

creases the solenoid current. After that the set

screw is to be secured with the lock nut and the

adjustment screw to be covered by the cap nut.

See Catalogue HY11-2500/UK, chapter 10.

11. Electrohydraulic p/Q control, codes FPR, FPZ

The electrohydraulic p/Q control, code FPR is For an electronic pressure adjustment the use of a

equipped with an additional remote pressure com- proportional pressure pilot valve with NG6 mount-

pensator valve on top of the proportional displace- ing interface is recommended, e. g.: the series

ment control valve. This valve overrides the dis- DSAE* or RE* on top of the remote pressure com-

placement control, when the max. pressure set- pensator stage. These valves are optimally adjus-

ting of the pilot valve is reached (see figure on ted for use with pump compensator and can be

following page). powered by the electronic control modules PQ0*-

This remote pressure compensator is equivalent P00 or PQ0*-Q00. The solenoid of the pressure

to the valve used for pressure compensation in valve is to be connected to terminals 16 and 17 of

the two spool-compensator code FT1, described the control module.

in Catalogue 2500/UK, chapter 8. There also the Please note: The proportional control only can work,

adjustment is described. As noted there the com- when the pump output pressure is above 10 - 15bar.

pensating differential pressure is factory set to 12 Below that the servo spring of the pump cannot be

±1bar, leading to a minimum compensating pres- compressed and the pump will not compensate.

sure of also 12bar.

IA PVI016 UK.PMD RH

15 Parker Hannifin GmbH & Co. KG

Pump and Motor Division

Axial Piston Pump

Installation Manual Series PV

Mounting interface NG6, DIN 24 340

for pressure pilot valve

Basic compensator

setting

Electrical connection

Basic adjustment of the proportional displacement See also installation manuals for electronic mod-

control valve (lower valve) see Catalogue HY11- ules PQ0*-P00, Bulletin 3241-M1/UK and PQ0*-

2500/UK, chapter 10. Q00, Bulletin 3242-M1UK.

For adjustment of the remote pressure compen- Functional descriptions and circuit diagrams of

sator stage, see remote pressure compensator all compensators see Catalogue HY11-2500/UK,

FR1 in Catalogue HY11-2500/UK, chapter 4. chapter 1.

12. Compensator accessories

12.1 Pressure relief pilot valve, code PVAC1P*

The pressure relief pilot valve code PVAC1P* is After loosening the lock nut SW13 an adjustment

optimally tuned for the requirements of the com- of the compensating pressure for the pump is pos-

pensator valves of the series PV. It has a mount- sible in a range of approx. 20bar up to 350bar.

ing interface NG6 according to DIN 24340 and The pressure pilot valve is also available with a

can be mounted directly on top of all compensa- DIN lock.

tor valves with the topside mounting interface.

Lock nut

Set screw

IA PVI016 UK.PMD RH

16 Parker Hannifin GmbH & Co. KG

Pump and Motor Division

Axial Piston Pump

Installation Manual Series PV

12.2 Multiple pressure pilots PVAC1E*, PVAC2P*, PVAC2E* aund PVAC2M*

For multiple pressure pilots, codes PVAC2P*, two direct-action pressure cartridge valves is used

PVAC2E* and PVAC2M* a sandwich valve with to pilot the pump.

Mounting interface for

DCV series D1VW

(directional control valve

included in shipment)

Set screw

Lock nut

For code PVAC2P* a single-solenoid directional When energizing solenoid A (B-side) the spring

control valve is included for pressure selection. The chamber is connected to the A-side pilot cartridge;

valve switches between low pressure setting and the pressure adjusted here controls the pump.

high pressure setting. During low pressure both pi- When solenoid B is energized the spring cham-

lot cartridges are connected to the compensator, in ber of the compensator is connected to pilot car-

the high pressure situation (solenoid energized) only tridge B; then the pressure adjusted on this car-

the A-side cartridge is connected. Therefore the B- tridge defines the pump compensating pressure.

side pilot needs to be set for low pressure. The di- With this version the pressure settings can be

rectional control valve series D1VW has spool code adjusted independently; no high / low preference

6. is to be observed. The DCV of the series D1VW

For code PVAC2E* for pressure selection a two- has spool code 2.

solenoid directional control valve is included, which This version should be used, when between high

switches between low pressure setting, high pres- and low pressure selection the standby opera-

sure setting and standby pressure. In neutral posi- tion is used in the machine cycle.

tion both cartridges are connected to the compen- Code PVAC1E* is similar to code PVAC2P*, with

sator valve. The lower pressure defines the com- the exception, that only one pilot cartridge is in-

pensating pressure of the pump. When the A sole- stalled. In neutral position of the D1VW the

noid (B-side) of the DCV is energized only the A- standby pressure is selected.

side cartridge is connected; the (higher) pressure

Please consult our main Catalogue HY11-2500/

adjusted there defines the compensating pressure.

UK for all further information and functional de-

When solenoid B is energized the valve spool con- scriptions.

nects all four ports. Then the spring chamber of the

compensator valve is directly connected to the case

drain of the pump, the pump compensates works

at minimum compensating pressure (standby).

The directional control valve series D1VW has spool

code 55. This spool code is used to avoid a blocked

spool position during transient. For more information, spare parts or service

This version is recommended, when during a ma- please contact:

chine cycle the pressure is to be switched between

high and low. Parker Hannifin GmbH & Co. KG

For code PVAC2M* also a dual solenoid valve is Pump and Motor Division

used. In neutral position all four ports are connected. Neefestraße 96

The compensator spring chamber is connected to 09116 Chemnitz, Germany

the case drain, the pump is compensating at min. Phone: +49 371 3937 0

compensating pressure (standby). Fax: +49 371 3737 488

E-mail: infopmd@parker.com

IA PVI016 UK.PMD RH

17 Parker Hannifin GmbH & Co. KG

Pump and Motor Division

Axial Piston Pump

Installation Manual Series PV

13. Trouble shooting guide

Pump delivers no output flow.

Drive motor does not turn.

Reason Motor is not connected correctly or one of the three phases has failed. Motor does

not turn smoothly when pump is disconnected from pump.

Solution Check motor connections, check electrical power supply.

Reason Pump mechanically blocked. Motor turns smoothly when disconnected from pump.

Solution Send pump to factory for service.

Drive motor only turns at slow speed.

Reason Motor is not selected properly. In star circuit not enough torque.

Solution Start pump at unloaded system. Use motor with more horse power.

Reason Pump is hydraulically blocked. No function of compensator, no pressure relief valve.

Pump stops after e few turns.

Solution Check function of pump compensator (see below). Start pump at unloaded sys-

tem.

Drive motor turns, pump does not turn.

Reason Coupling is not or not correctly mounted.

Solution Check coupling assembly and correct it.

Drive motor turns and pump turns.

Reason Wrong direction of rotation.

Solution Change direction of motor rotation.

Reason Fluid reservoir empty or not filled to level, suction line ends above fluid level.

Solution Fill reservoir to required level, if necessary increase suction pipe length.

Reason Suction line is blocked. E. g. by plugs, cleaning tissues, plastic-plugs. Ball valve in

the suction line closed. Suction filter blocked.

Solution Check suction line for free flow. Open valves in suction line. Valves should be

equipped with electrical indicator. Check suction filter.

Reason Suction line not gas tight, pump gets air into suction port.

Solution Seal suction line against air ingression.

Reason Pressure line / system is not able to bleed air out.

Solution Unload pressure port, unload system before start, bleed air from pressure line.

Pump does not build up pressure, but delivers full flow at low pressure.

Reason Standard pressure compensator is set to minimum pressure.

Solution Adjust compensator setting to desired pressure.

Reason Orifice in remote pressure compensator blocked.

Solution Make sure orifice Ø 0.8 mm in control spool is free and open.

Reason No pressure pilot valve connected to port PR.

Solution Install suitable pressure pilot valve and adjust it to the desired setting.

Reason Multiple pressure pilot selector valve is not energized. Pump works in stand-by.

Solution Energize selector valve solenoid.

Reason No load sensing line connected.

Solution Connect system load sensing port to compensator.

Reason Load sensing valve is closed or too small.

Solution Open load sensing valve, use larger valve size.

Reason Too much pressure drop between pump and load sensing valve.

Solution Make sure connection is wide enough and has not too much pressure drop.

Reason Differential pressure at compensator is adjusted improperly (too low).

IA PVI016 UK.PMD RH

18 Parker Hannifin GmbH & Co. KG

Pump and Motor Division

Axial Piston Pump

Installation Manual Series PV

Reason Horse power compensator setting changed.

Solution Check setting of horse power compensator and correct it, if required.

Reason Proportional displacement control is not connected as required.

Solution Check wiring; connect according to installation manual for electronic module.

Reason Displacement transducer (LVDT) adjustement changed.

Solution Correct zero setting at displacement transducer.

Reason Electronic module has no supply power.

Solution Make sure module is powered with 22 - 36 V DC.

Reason Plug instead of orifice Ø 0.8 mm in the load sensing line to pump.

Solution Install orifice as required.

Reason Cylinder block lifts from valve plate due to excessive wear.

Solution Send pump to factory for service.

Pump does not compensate.

Reason No orifice is in load sensing line to compensator code FFC.

Solution Install orifice Ø 0.8 mm as shown in circuit diagram (page 9).

Reason No pressure pilot valve connected to compensator or valve is blocked.

Solution Connect pressure pilot valve to compensator, make sure valve opens as required.

Reason Load sensing line connected incorrectly (e. g. upstream of load sensing valve)

Solution Connect load sensing line downstream (actuator side) of load sensing valve..

Reason No or too low pressure at pump outlet port.

Solution Pump outlet pressure must be at least 15 bar, because otherwise the bias spring in

the pump cannot be compressed.

Pump does not upstroke, sticks at zero displacement.

Reason Compensator is blocked due to contamination.

Solution Clean hydraulic fluid, clean compensator valve.

Reason Cable to LVDT or proportional solenoid is interrupted.

Solution Check wiring and make sure cable is ok. Replace if necessary.

Compensator is unstable.

Reason Compenstor spool sticks, due to contamination of hydraulic fluid.

Solution Clean hydraulic system, clean compensator valve.

Reason Compensator differential pressure changed (too low or too high).

Solution Adjust compensator differential pressure to required setting.

Reason Wrong pilot orifice or pressure pilot valve improperly selected.

Solution Select pilot orifice and pressure pilot valve as recommended.

Reason Dynamic critical system, e. g.: pressure compensator combined with pressure re-

ducing valve, load sensing (flow) compensator combined with flow control valve.

Solution Use remote pressure compensator instead of standard pressure compensator, in-

stall orifice in load sensing line remote from compensator (as close as possible to

load sensing valve).

IA PVI016 UK.PMD RH

19 Parker Hannifin GmbH & Co. KG

Pump and Motor Division

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Mission Magnum I ManualDocument41 pagesMission Magnum I Manualwatt_hr100% (2)

- 12T1600 Mud Pump Clearance Check FormDocument1 page12T1600 Mud Pump Clearance Check FormMoataz Nazeem100% (1)

- 12T1600 Mud Pump Clearance Check FormDocument1 page12T1600 Mud Pump Clearance Check FormMoataz Nazeem100% (1)

- 12T1600 Mud Pump Clearance Check FormDocument1 page12T1600 Mud Pump Clearance Check FormMoataz Nazeem100% (1)

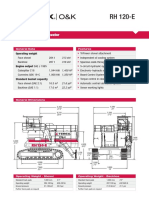

- Terex RH120-E - Specifications - M 121.3 (05-2007)Document8 pagesTerex RH120-E - Specifications - M 121.3 (05-2007)Craig Gordon100% (1)

- FEM 9.881 EnglischDocument8 pagesFEM 9.881 EnglischMa PonyNo ratings yet

- C15 Flash Codes Table (BEM)Document5 pagesC15 Flash Codes Table (BEM)Moataz NazeemNo ratings yet

- Cavins Blowout Preventer Test ProcedureDocument6 pagesCavins Blowout Preventer Test ProcedureMoataz NazeemNo ratings yet

- 11in 5K Double Ram BOP Specs SheetDocument5 pages11in 5K Double Ram BOP Specs SheetMoataz NazeemNo ratings yet

- Accum BldrMaint TroubleShootDocument2 pagesAccum BldrMaint TroubleShootObdulioNo ratings yet

- Yearly inspection checklist for brake lever assemblyDocument11 pagesYearly inspection checklist for brake lever assemblyMoataz NazeemNo ratings yet

- 2-1 - Allison Transmissions 5000 - 6000Document54 pages2-1 - Allison Transmissions 5000 - 6000Moataz NazeemNo ratings yet

- User Manual For Choke Control PanelDocument23 pagesUser Manual For Choke Control PanelMoataz NazeemNo ratings yet

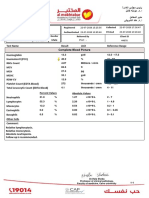

- 26 Year Male 61620503543: Patient NameDocument2 pages26 Year Male 61620503543: Patient NameMoataz NazeemNo ratings yet

- Eng Amin 2Document1 pageEng Amin 2Moataz NazeemNo ratings yet

- Item Type Item Name ValueDocument1 pageItem Type Item Name ValueMoataz NazeemNo ratings yet

- ANNEX 1 Mitigation-Policy - Longines Jumping Rankings - Decision For FEI Board - 31mar2020Document1 pageANNEX 1 Mitigation-Policy - Longines Jumping Rankings - Decision For FEI Board - 31mar2020Moataz NazeemNo ratings yet

- Ecdc Rig 9 9Document1 pageEcdc Rig 9 9Moataz NazeemNo ratings yet

- CV 2Document2 pagesCV 2Moataz NazeemNo ratings yet

- Diesel Engine Training Manual: Introduction to Mechanical Design and SystemsDocument124 pagesDiesel Engine Training Manual: Introduction to Mechanical Design and SystemsMoataz NazeemNo ratings yet

- Bghfy2018 0142Document39 pagesBghfy2018 0142Moataz Nazeem100% (1)

- Complete Blood Picture: 50 Year Male 24620514727Document2 pagesComplete Blood Picture: 50 Year Male 24620514727Moataz NazeemNo ratings yet

- Top DrveDocument2 pagesTop DrveJohn Jairo SimancaNo ratings yet

- Manual - Remote Control Console PDFDocument34 pagesManual - Remote Control Console PDFMehdi Hajd Kacem0% (1)

- 2 - Bearing Clearance MeasurementDocument5 pages2 - Bearing Clearance MeasurementMoataz Nazeem100% (1)

- TDS-10S Top Drive Drilling System: Service ManualDocument254 pagesTDS-10S Top Drive Drilling System: Service Manuallsantiagogarcia6344No ratings yet

- 18 - Fork Lift Defect - OptDocument4 pages18 - Fork Lift Defect - OptMoataz NazeemNo ratings yet

- Electrical Power SteeringDocument32 pagesElectrical Power SteeringBacot BangetNo ratings yet

- PS1800 C-SJ3-18: Solar Submersible Pump System For 4" WellsDocument2 pagesPS1800 C-SJ3-18: Solar Submersible Pump System For 4" WellsSYAHRULNo ratings yet

- Parameter Identification and Modelling of Separately Excited DC MotorDocument8 pagesParameter Identification and Modelling of Separately Excited DC MotorIJIERT-International Journal of Innovations in Engineering Research and TechnologyNo ratings yet

- Power Electronics and Its Challenges - RashidDocument3 pagesPower Electronics and Its Challenges - Rashidgeraleao208No ratings yet

- I175e Q2a Datasheet enDocument30 pagesI175e Q2a Datasheet enmax_ingNo ratings yet

- Baldor. Pump MotorsDocument550 pagesBaldor. Pump MotorsJavier SumozaNo ratings yet

- Protection of Rotating Machinery: ProblemsDocument3 pagesProtection of Rotating Machinery: Problemsmoses kakwenaNo ratings yet

- New 400/600A Series-A Type Vacu-Break Fusible Panelmounted Disconnect SwitchDocument8 pagesNew 400/600A Series-A Type Vacu-Break Fusible Panelmounted Disconnect SwitchJorge Arturo Restrepo AguirreNo ratings yet

- Auma ManualDocument92 pagesAuma ManualAnu R Remanan0% (2)

- A Complete Equivalent Circuit of A Linear InductionMotor With Sheet SecondaryDocument16 pagesA Complete Equivalent Circuit of A Linear InductionMotor With Sheet SecondarymuratNo ratings yet

- Hologic Selenia Installation and Hardware Maintenance Manual Rev 003 PDFDocument236 pagesHologic Selenia Installation and Hardware Maintenance Manual Rev 003 PDFYuriy KizyurNo ratings yet

- 13 Determination of Equivalent Circuit Parameters of A 1-Ph Induction Motor.Document3 pages13 Determination of Equivalent Circuit Parameters of A 1-Ph Induction Motor.Ashwani BhadaniNo ratings yet

- TRACTION CONTROLLER UNIT FOR ELECTRIC VEHICLESDocument18 pagesTRACTION CONTROLLER UNIT FOR ELECTRIC VEHICLESGiridharNo ratings yet

- Storage Feeder: Constant Yarn Tension, Fewer Knitting FaultsDocument2 pagesStorage Feeder: Constant Yarn Tension, Fewer Knitting FaultscobaNo ratings yet

- Dbss - HSDD - Startup Routine: Field Component ManualDocument25 pagesDbss - HSDD - Startup Routine: Field Component ManualМихаил100% (1)

- Emx20Clc: General DataDocument3 pagesEmx20Clc: General Dataأبو زينب المهندسNo ratings yet

- Katalog Techn Unterlagen Antriebe Ex enDocument468 pagesKatalog Techn Unterlagen Antriebe Ex enHani AlyyanNo ratings yet

- Night Patrolling RobotsDocument7 pagesNight Patrolling RobotsIJARSCT JournalNo ratings yet

- Mpms Combi Controller Fault CodesDocument4 pagesMpms Combi Controller Fault CodesFatih YÜKSELNo ratings yet

- WackerNeuson HMS enDocument3 pagesWackerNeuson HMS enPATRICK PEPINNo ratings yet

- Electric Bike ReportDocument33 pagesElectric Bike ReportGautham M A100% (1)

- Service ManualDocument65 pagesService Manualcengiz kutukcuNo ratings yet

- Equipment Definition: Operation and Maintenance ManualDocument9 pagesEquipment Definition: Operation and Maintenance ManualgodwinNo ratings yet

- O&m - Unilever VentilationDocument39 pagesO&m - Unilever VentilationMahmur Alihuddin100% (1)

- Wirth TPK 2200Document2 pagesWirth TPK 2200PABLOHEREDIANo ratings yet

- QuickdrawDocument32 pagesQuickdrawNoe JimenezNo ratings yet

- Catalog AEG-Lafert Motors - enDocument112 pagesCatalog AEG-Lafert Motors - enRudianto0% (1)

- Alarms, Faults and System Messages 8.5 List of Alarms and FaultsDocument7 pagesAlarms, Faults and System Messages 8.5 List of Alarms and FaultsRaman ButtarNo ratings yet