Professional Documents

Culture Documents

66 241 1 PB

66 241 1 PB

Uploaded by

AT 98Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

66 241 1 PB

66 241 1 PB

Uploaded by

AT 98Copyright:

Available Formats

END REFLECTION LOSS IN REAL DUCT SYSTEMS

Emanuel Mouratidis1

1

VAW Systems Ltd., 1300 Inkster Blvd, Winnipeg, Manitoba

1 Introduction HVAC systems normally include elbow turns and off-sets

between the fan and the termination. Uniform plane wave

Lighter building construction has contributed to a focus on action may be rare in real systems, thus ERL may be subject

low frequency (LF) noise. The LF is difficult to predict to End Reflection System Effects (ERSE).

within a noise path analysis and potentially more arduous to

mitigate once a mechanical system is installed. For fans and

3 Experimental Study

air distribution systems, there is a palpable need for a better

understanding of LF as a means to improve equipment This study was not configured to measure ERL directly. The

performance, sound quality and occupant comfort. One of effects could be observed indirectly through a controlled

the key considerations in LF noise control is the amount of system configuration. The testing was conducted in the

attenuation realized by the duct termination. The current VAW Systems Noise Control Applications Laboratory

prediction tools indicate that a significant amount of LF (NCAL), located in Newmarket, ON. The apparatus is based

sound will reflect back through the duct when a sudden area on the applicable sections of the ISO 7235 [4] and the

change is encountered. Limited research is available on ASTM E477 [5] standards. The set-up (Figure 1) includes a

system interactions for this vital acoustic phenomena found large, absorptive source chamber housing loudspeakers that

in most ventilation systems. This study may help improve produce broadband pink noise. The source is connected to a

the assessment of LF duct reflection in real systems. modular wind tunnel consisting of heavy steel walls. The

NCAL offers the ability to readily modify the wind tunnel

2 Background into straight, elbow and multi-elbow configurations. Two

duct configurations (Table 1) were assessed: (1) straight;

The LF physical phenomena called End Reflection Loss and, (2) double-elbow. The uniform duct between the miter

(ERL; dB) may be described as the apparent change in elbow and the termination was 8xDe. The measurements

sound power observed at a duct termination, as derived by were made with a sound intensity system, including both in-

the difference between the incident and reflected sound duct and end-of-duct sound intensity levels (Li; dB). The

power at the duct termination or boundary. ERL occurs in sound power levels (Lw; dB ref10-12 watts) in this study are

the plane wave region, defined at frequencies below the cut- derived from the Li data as per the ISO 9614-3 [6] standard.

off (fc; Hz) for ducts or openings:

c (1)

f =c

2 De

where: c = speed of sound in air (m/s); and,

De = equivalent duct diameter (m).

One of the earliest descriptions of ERL was found in the

book Noise Reduction [1]. This was followed by handbooks

published by the American Society of Heating,

Refrigeration, and Air-Conditioning Engineers (ASHRAE),

called the Guide and Data Book [2]. This appears to be the

basis of the ERL used today, including the current

ASHRAE Handbook for both a flush termination and one

that extends into a space. Recent research [3] has enhanced

the understanding of ERL. This work included various

termination conditions (diffusers, grilles and flexible ducts).

This work did not focus on the impacts, if any, from the

conditions further upstream from the termination. ERL is

based on analytical assumptions for long, straight duct

sections. ASHRAE provides a cautionary note: “Many air

distribution systems and fan equipment do not have long

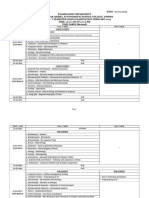

Figure 1: Experimental Set-up – Double-Elbow

straight sections (greater than 3xDe)…effects of these

configurations on ERL are not known”. The literature does Configuration Size (mm) Cut-off Freq. (Hz)

not provide any further guidance on the system related

Straight 900x600 207

impacts. Real systems rarely provide more than 3 x De of

Double Elbow 600x600 253

uniform duct immediately ahead of the termination. For

example, a fan intake may be open to atmosphere, and Table 1: Wind Tunnel Set-up

The straight duct layout is rarely encountered in real There is an apparent spread in the corrected sound

systems, thus may be considered a baseline condition. The power at the duct termination when the conditions upstream

length of the wind tunnel was set to a Duct Length Ratio are varied. We may define the ERSE (Table 3) as the range

(DLR) of 0, 6, 10 and 16, where DLR may be defined as: in Lwout*, as observed for various DLR, as follows:

WindTunnel Length (2) ERSE = Lwout* Max – Lwout* Min (4)

DLR =

De

The Li measurements were taken at various locations,

The double elbow layout allows for an evaluation of a consisting of a microphone traverse that divided the section

common interaction between a radius and miter fitting. The into 9 equal areas. This process created Li contours and

space between the elbows was set to a DLR of 0, 1, 2 and 4. were evaluated as: “Very Uniform” (all 9 measurements

within +/- 1 dB); “Uniform” (all 9 measurements within +/-

4 Results 2 dB); and, “Not Uniform” (>3 dB spread). Changing the

space between the two elbows form DLR = 0 to 2 did not

The measured Lw at the termination (Lwout) is corrected impact the Li contours near the source and at the

(Lwout*) at each 1/3-octave band frequency with the termination. The corresponding Li contour at the miter

attenuation of the additional duct (ILDLR), as follows: elbow changed from Very Uniform to Not Uniform at 50

Lwout* = Lwout + ILDLR (3) and 63 Hz. Virtually all of the contours at > 63 Hz were

found to be Very Uniform for all measurement locations.

The straight wind tunnel resulted in a near constant

sound power into the system (Lwin) for changing DLR. As Duct System Third-Octave Band Frequency (Hz)

highlighted in Table 2, the standard deviation (SD, dB) of Configuration 50 63 80 100 125 160

the Lwin was significantly smaller than the corresponding Straight 2.4 5.9 3.0 2.3 1.8 0.9

SD of the Lwout* for the measurements taken at four DLR. Double Elbow 4.3 6.0 3.8 2.6 0.9 2.0

Similar results were found for the double elbow

configuration. Over the range of DLR in this study, the Lwin Table 3: Range in Lwout* (ERSE; dB) for Apparent Constant Lwin

was relatively constant, while the corresponding Lwout*

varied significantly for relatively small system changes. 5 Conclusion

Measurement Third-Octave Band Frequency (Hz) The impacts on ERL may be observed through system duct

Location 50 63 80 100 125 160 changes. The configurations noted in this study are

Lwin 0.69 0.33 0.10 0.33 0.17 0.18 relatively straightforward, but resemble some real-life

Lwout* 0

1.07 2.57 1.39 0.97 0.93 0.42 systems. In a controlled laboratory set-up, conditions ahead

of the termination appear to significantly impact the

Table 2: SD (dB) of Lwin and Lwout* for Straight Duct apparent ERL, resulting in ERSE. In-duct measurements

The Lwout* may be investigated closely while under may provide some value in terms of identifying conditions

apparent constant Lwin. As shown in Figure 2, the LF where the ERSE may emerge. Users of the analytical ERL

Lwout* varied at a level close to the corresponding ERL. tools should apply the values with caution, as the ERSE

appears to be close to the magnitude of the ERL itself.

Further research may look at a potential relationship

between the sound field in the duct and the resulting ERSE.

References

[1] L.L. Beranek, Noise Reduction, McGraw-Hill Book

Co., Inc., New York, 1960.

[2] ASHRAE Handbooks: American Soc. of Heating,

Refrigeration & Air-Cond Engineers, Atlanta, 1987-2011.

Figure 2: Straight Duct Lwout* for increasing DLR (50,63&80Hz) [3] Cunefare, K. and A. Michaud. 2008. Reflection of

airborne noise at duct terminations. ASHRAE Research

As shown in Figure 3, the double-elbow configuration Project RP-1314, Final Report.

resulted in a similar Lwout* trend for a small change in DLR. [4] ISO 7235:2003 Acoustics -- Laboratory measurement

procedures for ducted silencers and air-terminal units --

Insertion loss, flow noise and total pressure loss.

[5] ASTM E477-13, Standard Test Method for Measuring

Acoustical & Airflow Performance of Duct Liner Materials

& Prefabricated Silencers, ASTM Int.,Conshohocken, 2013.

[6] ISO 9614-3:2002 Acoustics - Determination of sound

power levels of noise sources using sound intensity - Part 3:

Precision method for measurement by scanning.

Figure 3: Double Elbow Lwout* for increasing DLR (50,63&80Hz)

You might also like

- JBL Audio Engineering for Sound ReinforcementFrom EverandJBL Audio Engineering for Sound ReinforcementRating: 5 out of 5 stars5/5 (2)

- Floral Design Principles and Elements ReadingDocument12 pagesFloral Design Principles and Elements ReadingIo Gy100% (2)

- Attenuator Design Reference ManualsDocument29 pagesAttenuator Design Reference ManualsChetan GaliNo ratings yet

- Sound Attenuator-AMCA-21-11-2020Document17 pagesSound Attenuator-AMCA-21-11-2020AT 98No ratings yet

- Room AcousticsDocument88 pagesRoom AcousticsArunNo ratings yet

- Physics and Musical InstrumentsDocument13 pagesPhysics and Musical InstrumentsMax Zimmerman100% (1)

- Unit I Notes July2016Document153 pagesUnit I Notes July2016Ranjith KumarNo ratings yet

- Electronic Devices and Circuits: In Three VolumesFrom EverandElectronic Devices and Circuits: In Three VolumesRating: 3.5 out of 5 stars3.5/5 (2)

- Meyer Line ArrayDocument8 pagesMeyer Line Arraydub6kONo ratings yet

- JBL SSDMDocument105 pagesJBL SSDMEmmanuel Zamora Manuelini ZamoriniNo ratings yet

- Testing Loudspeakers With WaveletsDocument23 pagesTesting Loudspeakers With WaveletsyogimgurtNo ratings yet

- List of Contents: S/No. Subject Page NumberDocument24 pagesList of Contents: S/No. Subject Page NumberAbdelrahman DaakirNo ratings yet

- Iso 105 B06Document8 pagesIso 105 B06Hugo Jimenez FalconNo ratings yet

- Out Door Noise PropagationDocument19 pagesOut Door Noise PropagationhwjayanthiNo ratings yet

- Vibration Analysis - Knock Out Drum Gullfaks CDocument8 pagesVibration Analysis - Knock Out Drum Gullfaks Clis_sugiantoroNo ratings yet

- Vibrations Eoliennes IntroDocument26 pagesVibrations Eoliennes Intromacjosmanuel5453No ratings yet

- AES5488 Heil Bauman Urban WavefrontSculptureTechnologyDocument14 pagesAES5488 Heil Bauman Urban WavefrontSculptureTechnologyshuttNo ratings yet

- L-ACOUSTICS - AES - Preprint - 2001 - Wavefront - Sculpture TechnologyDocument14 pagesL-ACOUSTICS - AES - Preprint - 2001 - Wavefront - Sculpture Technologyromina_cmbNo ratings yet

- Reiche 2000 0458Document4 pagesReiche 2000 0458Particle Beam Physics LabNo ratings yet

- 2 Noise in AmplifierDocument16 pages2 Noise in AmplifierMuraleetharan BoopathiNo ratings yet

- Apparent Transducer Non-Reciprocity in An Ultrasonic Ow MeterDocument4 pagesApparent Transducer Non-Reciprocity in An Ultrasonic Ow MeterHamid M SedighiNo ratings yet

- (1978) - Sharp - Predicting Methods For The Sound Transmission of Building ElementsDocument11 pages(1978) - Sharp - Predicting Methods For The Sound Transmission of Building ElementsNahuel ArmandoNo ratings yet

- Criterio BonelloDocument11 pagesCriterio BonelloDonaldo Garcia MendietaNo ratings yet

- 160Vs80 meterIsolatedOff Center Fedantennas PDFDocument11 pages160Vs80 meterIsolatedOff Center Fedantennas PDFΑΝΔΡΕΑΣ ΤΣΑΓΚΟΣNo ratings yet

- 4P1 1731Document3 pages4P1 1731Ahmed Abd EllatifNo ratings yet

- A Matched Bow-Tie Antenna at 433MHz For Use in UndDocument7 pagesA Matched Bow-Tie Antenna at 433MHz For Use in UndShivam GaunsNo ratings yet

- Audio Bandwidth ExtensionDocument14 pagesAudio Bandwidth ExtensionRio de NestaNo ratings yet

- PREPRINTNO: 951 (D-3) : Roy F. Allison Allison Acoustics Inc. Wayland, MassachusettsDocument16 pagesPREPRINTNO: 951 (D-3) : Roy F. Allison Allison Acoustics Inc. Wayland, Massachusettsdonald141No ratings yet

- Aeolian VibrationDocument16 pagesAeolian Vibrationaxf9dtjhdNo ratings yet

- Noise Dalam Sistem Elektronika (Pertemuan 1)Document12 pagesNoise Dalam Sistem Elektronika (Pertemuan 1)ats harmatsistaNo ratings yet

- Vibrations Eoliennes Intro PDFDocument26 pagesVibrations Eoliennes Intro PDFkolombo1776No ratings yet

- An Ultrawideband Coplanar Waveguide-Fed Tapered Ring Slot AntennaDocument6 pagesAn Ultrawideband Coplanar Waveguide-Fed Tapered Ring Slot AntennaDr-Gurpreet KumarNo ratings yet

- Erbium Doped Fibre Amplifiers: 1532 Nm. The Different Gain Equalizing Techniques Employed To RemoveDocument0 pagesErbium Doped Fibre Amplifiers: 1532 Nm. The Different Gain Equalizing Techniques Employed To RemoveGed GladNo ratings yet

- Lawrence Berkeley Laboratory University of California, Berkeley, CA 94720, USADocument7 pagesLawrence Berkeley Laboratory University of California, Berkeley, CA 94720, USAParticle Beam Physics LabNo ratings yet

- Water Pipe Leak Detection Using Electromagnetic Wave Sensor For The Water IndustryDocument6 pagesWater Pipe Leak Detection Using Electromagnetic Wave Sensor For The Water Industryjenkora88No ratings yet

- Acoustic Properties of Heated Twin Jets?: KantolaDocument28 pagesAcoustic Properties of Heated Twin Jets?: Kantolaila_368684492No ratings yet

- Ryder2003 DIAGNOSTICO DE FALLAS USANDO SFRADocument7 pagesRyder2003 DIAGNOSTICO DE FALLAS USANDO SFRARoyer Guerra huamanNo ratings yet

- 80-Meter Dipoles and Inverted-Vs A Graphical ScrapbookDocument36 pages80-Meter Dipoles and Inverted-Vs A Graphical ScrapbookΑΝΔΡΕΑΣ ΤΣΑΓΚΟΣNo ratings yet

- Silencer Design by Using Array Resonators For Low-Frequency Band Noise ReductionDocument8 pagesSilencer Design by Using Array Resonators For Low-Frequency Band Noise ReductionmarcosNo ratings yet

- P. Design and Fabrication of An Ultrasonic Speaker With Thickness Mode Piezoceramic TransducersDocument6 pagesP. Design and Fabrication of An Ultrasonic Speaker With Thickness Mode Piezoceramic TransducersMaría Campo ValeraNo ratings yet

- IET Electric Power Appl - 2013 - Pramanik - Interleaved Winding and Suppression of Natural FrequenciesDocument8 pagesIET Electric Power Appl - 2013 - Pramanik - Interleaved Winding and Suppression of Natural FrequenciesSamer Abdulaziz SadaqaNo ratings yet

- GENESIS 1.3: A Fully 3D Time-Dependent FEL Simulation Code: S. ReicheDocument6 pagesGENESIS 1.3: A Fully 3D Time-Dependent FEL Simulation Code: S. ReicheParticle Beam Physics LabNo ratings yet

- AES Ureda Analysis of Line ArraysDocument41 pagesAES Ureda Analysis of Line ArraysVenkatesan Thanigai ArasuNo ratings yet

- Satellite Performance EDFA at RecievrDocument11 pagesSatellite Performance EDFA at RecievrEhab Salah EldeenNo ratings yet

- UNP NoiseDocument12 pagesUNP Noisejofinjv3194No ratings yet

- Active Noise Control, IEEE Signal Process. Mag., OctoberDocument25 pagesActive Noise Control, IEEE Signal Process. Mag., OctoberNeamu ValentinNo ratings yet

- مختصر تقييم التكوين 2Document3 pagesمختصر تقييم التكوين 2Rafia SharafadNo ratings yet

- Free Electron Lasers: Giuseppe Dattoli and Alberto RenieriDocument6 pagesFree Electron Lasers: Giuseppe Dattoli and Alberto RenieriMarco ManciniNo ratings yet

- Flow-Induced Pulsations in Pipe Systems With Closed Side Branches: Study of The Effectiveness of Detuning As Remedial MeasureDocument6 pagesFlow-Induced Pulsations in Pipe Systems With Closed Side Branches: Study of The Effectiveness of Detuning As Remedial MeasureJose BijoyNo ratings yet

- Chirped-Beam Two-Stage Free-Electron Laser For High-Power Femtosecond X-Ray Pulse GenerationDocument8 pagesChirped-Beam Two-Stage Free-Electron Laser For High-Power Femtosecond X-Ray Pulse GenerationParticle Beam Physics LabNo ratings yet

- Feedback Paper AcrobatDocument43 pagesFeedback Paper AcrobatVivek Kumar RuhilNo ratings yet

- The Offset System Electrical Resistivity Sounding Its Use With A Multicore CableDocument16 pagesThe Offset System Electrical Resistivity Sounding Its Use With A Multicore Cablebahrul.hidayah@yahoo.comNo ratings yet

- Atmospheric Extinction Corrections For Wet ObservationsDocument22 pagesAtmospheric Extinction Corrections For Wet ObservationsbelenNo ratings yet

- Ground Borne NoiseDocument10 pagesGround Borne NoisecataninoNo ratings yet

- Roman N. Tolchenov Et Al - Weak Line Water Vapor Spectrum in The 11 787-13 554 CM - 1 RegionDocument6 pagesRoman N. Tolchenov Et Al - Weak Line Water Vapor Spectrum in The 11 787-13 554 CM - 1 RegionKmaxx2No ratings yet

- Matching Dipole Antenna Using The L-C Series Network: November 2013Document6 pagesMatching Dipole Antenna Using The L-C Series Network: November 2013Panji KuncoroNo ratings yet

- Theoretical Acoustic Reson Palerme 2008 DDocument9 pagesTheoretical Acoustic Reson Palerme 2008 DJeff SalesNo ratings yet

- Single-Sideband Transmission by Envelope: Elimination RestorationDocument4 pagesSingle-Sideband Transmission by Envelope: Elimination Restorationgaurav bhargavNo ratings yet

- Comparison Calculating: High VoltageDocument2 pagesComparison Calculating: High VoltageCésar DiazNo ratings yet

- Absolute EPR Spin Echo #69A PDFDocument15 pagesAbsolute EPR Spin Echo #69A PDFchaparalNo ratings yet

- Meteorological Applications - 2006 - Ito - Design and Performance of An Acoustic Antenna For A Phased Array Doppler SodarDocument8 pagesMeteorological Applications - 2006 - Ito - Design and Performance of An Acoustic Antenna For A Phased Array Doppler SodarMetrach AbdrazakNo ratings yet

- Fixed Louvers Drainable Blades Catalogue September2021 Rev.1Document6 pagesFixed Louvers Drainable Blades Catalogue September2021 Rev.1AT 98No ratings yet

- 1752-23-01.02 (Emc)Document7 pages1752-23-01.02 (Emc)AT 98No ratings yet

- Ventex Louver Products CatalogDocument32 pagesVentex Louver Products CatalogAT 98No ratings yet

- 1 UST Hospital Harmonics Testing ResultDocument11 pages1 UST Hospital Harmonics Testing ResultAT 98No ratings yet

- Rastogi 19535Document8 pagesRastogi 19535AT 98No ratings yet

- 2020 Supply MapDocument18 pages2020 Supply MapAT 98No ratings yet

- Sound LevelDocument1 pageSound LevelAT 98No ratings yet

- Enhancing Egg CartonsDocument27 pagesEnhancing Egg CartonsAT 98No ratings yet

- Stabilisasi Tanah Ekspansif Dengan Campuran Abu Batu Bara Dan AbuDocument16 pagesStabilisasi Tanah Ekspansif Dengan Campuran Abu Batu Bara Dan AbuLydia DarmiyantiNo ratings yet

- Scientific Machine Learning Through Physics-Informed Neural Networks: Where We Are and What's NextDocument67 pagesScientific Machine Learning Through Physics-Informed Neural Networks: Where We Are and What's NextprfdjkdkvcssdNo ratings yet

- 292902revised Time Table-B.sc.-Bca-V Semester (Main) Examination February 2024Document3 pages292902revised Time Table-B.sc.-Bca-V Semester (Main) Examination February 2024nawojeh586No ratings yet

- Introduction To Medical Imaging: BME/EECS 516 Douglas C. Noll (Edited by JF)Document24 pagesIntroduction To Medical Imaging: BME/EECS 516 Douglas C. Noll (Edited by JF)quickdannyNo ratings yet

- 4th Q Las w1 w4 MathDocument21 pages4th Q Las w1 w4 MathDahlia ThymeNo ratings yet

- Course Name: Level: Ad, Adb, Bs Course Code: 5405 Semester: Spring 2022 Assignment: 2 Due Date: 02-10-2022 Total Assignment: 2 Late Date: 02-10-2022Document23 pagesCourse Name: Level: Ad, Adb, Bs Course Code: 5405 Semester: Spring 2022 Assignment: 2 Due Date: 02-10-2022 Total Assignment: 2 Late Date: 02-10-2022Sikandar AkramNo ratings yet

- ASQDocument15 pagesASQKiko BaONo ratings yet

- Energy ProductionDocument23 pagesEnergy ProductionSkruzdelyte MielaNo ratings yet

- CBSE Class 12 Maths SyllabusDocument6 pagesCBSE Class 12 Maths Syllabusanshu dudiNo ratings yet

- Catalog 14Document1 pageCatalog 14msajanjNo ratings yet

- Formula FizikDocument1 pageFormula FizikAzizi AbdullahNo ratings yet

- MTO For Instrument Hook Up Materials, Bulk & SupportDocument50 pagesMTO For Instrument Hook Up Materials, Bulk & SupportdikaNo ratings yet

- National Level Mathematical Olympiad (NMO-I)Document14 pagesNational Level Mathematical Olympiad (NMO-I)Abhisek SubediNo ratings yet

- College Physics 9th Edition Serway Test BankDocument35 pagesCollege Physics 9th Edition Serway Test Bankshannonsellersdfrjxwiabt100% (34)

- 1 Mat071 Module1 PDFDocument100 pages1 Mat071 Module1 PDFjurilyn alvadorNo ratings yet

- Italian C-130J Performance ManualDocument478 pagesItalian C-130J Performance ManualHaddad AnisNo ratings yet

- Design Data:: 5.16.14 Example 5.33: Inverted T-Beam Combined FoundationDocument7 pagesDesign Data:: 5.16.14 Example 5.33: Inverted T-Beam Combined FoundationThimira ShehanNo ratings yet

- ASTM International Committee E20 On Temperature MeasurmentDocument2 pagesASTM International Committee E20 On Temperature MeasurmentkumarNo ratings yet

- On Optimal Offensive Strategies in Basketball PDFDocument9 pagesOn Optimal Offensive Strategies in Basketball PDFCoach-NeilKhayechNo ratings yet

- Density and Dimensions of Preformed Pipe-Covering-Type Thermal InsulationDocument3 pagesDensity and Dimensions of Preformed Pipe-Covering-Type Thermal InsulationMina RemonNo ratings yet

- One-Dimensional Swell or Collapse of Cohesive Soils: Standard Test Methods ForDocument9 pagesOne-Dimensional Swell or Collapse of Cohesive Soils: Standard Test Methods ForAhmedJardakNo ratings yet

- Experiment 4: Transformer: Circuit ModelDocument10 pagesExperiment 4: Transformer: Circuit ModelManuel AquinoNo ratings yet

- Chapter 4 Image Production and EvaluationDocument97 pagesChapter 4 Image Production and EvaluationDsk Ricafrente BonitNo ratings yet

- List of Technical Staf For Fyp Supervisor (2022)Document14 pagesList of Technical Staf For Fyp Supervisor (2022)Amir WafiNo ratings yet

- 2nd LAW THERMO2Document6 pages2nd LAW THERMO2Ervin MogarNo ratings yet

- Documents - Pub Holman Heat Transfer 10th Solution ManualDocument443 pagesDocuments - Pub Holman Heat Transfer 10th Solution Manualعمر الأطفيحيNo ratings yet

- CV For MEP Site EngineerDocument3 pagesCV For MEP Site EngineerMohamed IbrahimNo ratings yet