Professional Documents

Culture Documents

IMG - 0142 PSME Code 2012 141

Uploaded by

Bugoy2023Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IMG - 0142 PSME Code 2012 141

Uploaded by

Bugoy2023Copyright:

Available Formats

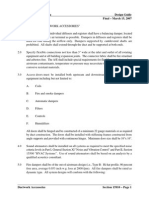

shall have an equivalent effective area categorized condensing appliances shall rd

equal to the effective area of the round pipe terminate over public walkways or over an area

for which it is substituted and the minimum where condensate or vapor could create a

internal dimension of the pipe shall be two nuisance or hazard or could be detrimental b

(2) inches (50 mm). the operation of regulators, relief valves, or other

equipment. Where local experience indicates

802.7.3.3 The vent cap or a roof assembly that condensate is a problem with Category I

shall have a venting capacity not less than and Category lll appliances, this provision shal

that of the pipe to which it is attached. also apply. [NFPA 54:10.8]

802.7.4 Support of Single Wall Metal Pipe. All 802.9 Condensation Drain.

portions of single wall metal pipe shall be

supported for the design and weight of the 802.9.1 Provision shall be made to collect and

material employed. dispose of condensate from venting systerns

serving Category ll and Category lV gas

802J.5 Marking. Single wall metal pipe shall utilization equipment and non-categorized

comply with the marking provisions of Section condensing appliances in accordance with

802.6.6. [NFPA 54:'lO.7i Section 802.8.4.

802.8 Through the Wall Vent Termination' 802.9.2 Where local experience indicates that

condensation is a problem, provision shall be

802.8.{ A mechanical draft venting system shall made to drain off and. dispose of condensate

terminate at least three (3) feet (0.9 m) above from venting systems serving Category I and

any forced air inlet located within ten (10) feet Category lll gas utilization equipment in

accoidahce with Section 802.8.4- [NFPA

'

(3.1 m).

Exception 1: This provision shall not apply 54:10.91

to the combustion air intake of a direct vent

apPliance. 802.{0 Vent Connectors for Category I Gas

Utilization EquiPment.

Exception 2: This provision shall not apply

to the separation of the integral outdoor air 802.10.{ Where Required. A vent connector

inlet and flue gas discharge of listed outdoor shall be used to connect gas utilization

appliances. equipment to a gas vent, chimney, or single wal

metal pipe, except where the gas vent, chimney'

802.8.2 A mechanical draft venting system of or single wall metal pipe is directly connected to

other than direct vent type shall terminate at the equiPment.

least four (4) feet (1.2 m) below, four (4) feet

(1.2m) horizontally from, or one (1) feet (300 802.10.2 Materials.

mm) above any door, operable window, or

gravity air inlet into any building. The bottom of 802.10.2.1A vent connector shall be made

the vent terminal shall be located at least twelve of noncombustible, corrosion resistant

(12) inches (300 mm) above grade. material capable of withstanding the vent

gas temperature produced by the gas

802.8.3 The vent terminal of a direct vent utilization equipment and of suffiqient

appliance with an input of 10,000 Btu/h (3 kW)or thickness to withstand physical damage.

less shall be located at least six (6) inches

(150mm) from any air opening into a building, 802.10.2.2 Where the vent connector used

and such an appliance with an input over for gas utilization equipment having a draft

10,000Btu/h (3 kW) but not over 50,000 Btu/h hood or a Category I appliance is located in

(14.7kW) shall be installed with a nine (9) inches or passes through an unconditioned area.

(230mm) vent termination clearance, anq 1t that portion of the vent connector shall be

appliance with an input over 50,000 Btu/h listed Type B, listed Type L, or listed vent

(14.7kW) shall have at least a twelve (12) inches material having equivalent insulation

(300mm) vent termination clearance. The qualities.

bottom of the vent terminal and the air intake

shall be located at least twelve (12) inches (300 802.10.2.3 Where the vent connector used

mm) above grade. for gas utilization equipment having a draft

hood or a Category I appliance is located in

802.8.4 Through the wall vents for Category ll or passes through attics and crawl spaces,

and Category lV aPPliances and non- that portion of the vent connector shall be

142 2012 PHILIPPINE MECHANICAL ENGINEERING CODE

You might also like

- IMG - 0144 PSME Code 2012 144Document1 pageIMG - 0144 PSME Code 2012 144Bugoy2023No ratings yet

- IMG - 0140 PSME Code 2012 139Document1 pageIMG - 0140 PSME Code 2012 139Bugoy2023No ratings yet

- NOH VNTG & CMBSTNDocument34 pagesNOH VNTG & CMBSTNbernie_uyNo ratings yet

- IMG - 0146 PSME Code 2012 146Document1 pageIMG - 0146 PSME Code 2012 146Bugoy2023No ratings yet

- Duct SystemsDocument32 pagesDuct SystemsJherson GravidesNo ratings yet

- Revised National Plumbing Code of The Philippines 101-225Document125 pagesRevised National Plumbing Code of The Philippines 101-225Kenneth D. PacadaNo ratings yet

- Rowan University Design Guide 2013Document3 pagesRowan University Design Guide 2013zeliteNo ratings yet

- Good Engineering PracticeDocument3 pagesGood Engineering PracticeGui Bruno BackhamNo ratings yet

- Significant Changes From The 2009 Icc To 2012Document87 pagesSignificant Changes From The 2009 Icc To 2012Vịt BầuNo ratings yet

- Steam 1Document4 pagesSteam 1NaNo ratings yet

- Natplum 7Document66 pagesNatplum 7towiwaNo ratings yet

- Section - 15910 Ductwork AccessoriesDocument3 pagesSection - 15910 Ductwork AccessoriesalbrgmailNo ratings yet

- Chapter 7 (ACMV)Document140 pagesChapter 7 (ACMV)engkankwNo ratings yet

- Specif-Dust Extraction SystemDocument12 pagesSpecif-Dust Extraction SystemChristopher LloydNo ratings yet

- Fjytt-Afa: Fire Safety in Petroleum Refineries and Fertilizer Plants - Code of PracticeDocument13 pagesFjytt-Afa: Fire Safety in Petroleum Refineries and Fertilizer Plants - Code of PracticeAravind B PatilNo ratings yet

- Sfpe Nfpa 13 Presentation PDFDocument40 pagesSfpe Nfpa 13 Presentation PDFاحمد الجزار2007No ratings yet

- HepvO PIC Aug2003Condensate DrainDocument2 pagesHepvO PIC Aug2003Condensate DrainAhmed TahaNo ratings yet

- Crown Home Consultants: Cleopatra Plaza Tower (Nasr City) Specifications 15861/1 Rev.0 March.2012Document3 pagesCrown Home Consultants: Cleopatra Plaza Tower (Nasr City) Specifications 15861/1 Rev.0 March.2012Waleed Abd El-HamiedNo ratings yet

- Substation SafetyDocument7 pagesSubstation Safetysandeep_chauhan3770100% (2)

- ES-20.14 Waste Heat PTT Public Co., LTD Recovery Units Engineering Standard REV: 02Document10 pagesES-20.14 Waste Heat PTT Public Co., LTD Recovery Units Engineering Standard REV: 02Nikki RobertsNo ratings yet

- Ac Units Technical Specifications Annex ADocument44 pagesAc Units Technical Specifications Annex Aengr.genaNo ratings yet

- ECO-Panel Design N Installation Manual - ContentsDocument12 pagesECO-Panel Design N Installation Manual - ContentstechnokakiNo ratings yet

- Rules - and - Regulations - For - The - Classification - of - Ships 26tra16Document2 pagesRules - and - Regulations - For - The - Classification - of - Ships 26tra16Nikola TušekNo ratings yet

- PEE 1560-ACMV SpecDocument97 pagesPEE 1560-ACMV SpecjimiNo ratings yet

- ME Laws WK 6Document45 pagesME Laws WK 6Charle CandelarioNo ratings yet

- Fabrication, Installation, Commissioning & Testing of Compressed Air System With Associated ComponentsDocument7 pagesFabrication, Installation, Commissioning & Testing of Compressed Air System With Associated Componentsabdeslem mouloudjNo ratings yet

- Gradi IPDocument109 pagesGradi IPDino PedutoNo ratings yet

- Promat Self Supporting DuctsDocument9 pagesPromat Self Supporting DuctsBen CarrollNo ratings yet

- App027 Flue ApertureDocument5 pagesApp027 Flue Aperturechong pak limNo ratings yet

- Icc Imc Mechanical.2012 PDFDocument169 pagesIcc Imc Mechanical.2012 PDFmodulor3dNo ratings yet

- Crime HQ BoqDocument42 pagesCrime HQ BoqNitish YadavNo ratings yet

- Changes For The New Edition Denise Beach Denise Beach Senior Engineer, NFPADocument33 pagesChanges For The New Edition Denise Beach Denise Beach Senior Engineer, NFPAVaibhav SawantNo ratings yet

- Fire Safety Setup - Rev 2 - 18032020Document101 pagesFire Safety Setup - Rev 2 - 18032020anthony tiensunNo ratings yet

- Ups Ventilation IMCDocument1 pageUps Ventilation IMCkhanace786No ratings yet

- Local Exhaust Minimum DistanceDocument1 pageLocal Exhaust Minimum DistanceKrishna PATELNo ratings yet

- General Specification: Building Services Branch Architectural Services DepartmentDocument220 pagesGeneral Specification: Building Services Branch Architectural Services DepartmentdvtherionNo ratings yet

- Research No 5Document11 pagesResearch No 5Hanie GraceNo ratings yet

- 2011 NEC Code 300.5Document8 pages2011 NEC Code 300.5Ano Ni MousNo ratings yet

- Wall Mount: Installation, OperationDocument7 pagesWall Mount: Installation, OperationTradutor TécnicoNo ratings yet

- Odour Control Unit PDFDocument4 pagesOdour Control Unit PDFjuncNo ratings yet

- 4.2.1.1 Outside Air Intakes Shall: (See Section 6.3 For Smoke Damper Operation To Restrict The Intake of Smoke.)Document7 pages4.2.1.1 Outside Air Intakes Shall: (See Section 6.3 For Smoke Damper Operation To Restrict The Intake of Smoke.)Sujit DungaNo ratings yet

- Fire Protection CDPDocument29 pagesFire Protection CDPPopa IulianNo ratings yet

- 52331HVACDucts 000Document4 pages52331HVACDucts 000carlos ruizNo ratings yet

- Sl. No. Description of Work Unit Qty. Rate Amount Rate Amount Total Amount Rs. Rs. Rs. Rs. Rs. I Option-1Document12 pagesSl. No. Description of Work Unit Qty. Rate Amount Rate Amount Total Amount Rs. Rs. Rs. Rs. Rs. I Option-1mdalt9180100% (2)

- The Design and Manufacture of Commercial Kitchen Extraction SystemsDocument17 pagesThe Design and Manufacture of Commercial Kitchen Extraction Systemsmaxmorek33% (3)

- Capitulo 4Document7 pagesCapitulo 4thanatitosNo ratings yet

- Max. Height ??: Installation RequirementsDocument1 pageMax. Height ??: Installation RequirementsAlign EngineeringNo ratings yet

- P4 Production and Application of Plastic Pipes Piping Systems On Ships P4Document13 pagesP4 Production and Application of Plastic Pipes Piping Systems On Ships P4argentum19619692No ratings yet

- Traps: Louisiana State Plumbing Code, 2000 Edition© 69Document4 pagesTraps: Louisiana State Plumbing Code, 2000 Edition© 69OviyaNo ratings yet

- Buildings Department Practice Note For Authorized Persons, Registered Structural Engineers and Registered Geotechnical Engineers APP-27Document5 pagesBuildings Department Practice Note For Authorized Persons, Registered Structural Engineers and Registered Geotechnical Engineers APP-27speedo3076No ratings yet

- Tech Specs For Nitrogen GeneratorDocument5 pagesTech Specs For Nitrogen Generatorn.hartonoNo ratings yet

- Plumb Ling VentingDocument30 pagesPlumb Ling VentingNatthasart MuangsuankwanNo ratings yet

- Chap - 7-Ventilation and Smoke Purging SystemDocument21 pagesChap - 7-Ventilation and Smoke Purging SystemAbubacker Siddique SulthanNo ratings yet

- Chimneys and Fireplaces: 2003 International Residential Codex 263Document10 pagesChimneys and Fireplaces: 2003 International Residential Codex 263bisrat meseretNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- IMG - 0044 ESAS 2001 Solved Problem Objectives 9-18Document1 pageIMG - 0044 ESAS 2001 Solved Problem Objectives 9-18Bugoy2023No ratings yet

- Img - 0048 MCQ For Power & Ipe 87Document1 pageImg - 0048 MCQ For Power & Ipe 87Bugoy2023No ratings yet

- Img - 0046 MCQ For Power & Ipe 83Document1 pageImg - 0046 MCQ For Power & Ipe 83Bugoy2023No ratings yet

- Img - 0043 MCQ For Power & Ipe 77Document1 pageImg - 0043 MCQ For Power & Ipe 77Bugoy2023No ratings yet

- Img - 0045 MCQ For Power & Ipe 81Document1 pageImg - 0045 MCQ For Power & Ipe 81Bugoy2023No ratings yet

- Img - 0047 MCQ For Power & Ipe 85Document1 pageImg - 0047 MCQ For Power & Ipe 85Bugoy2023No ratings yet

- Img - 0049 MCQ For Power & Ipe 89Document1 pageImg - 0049 MCQ For Power & Ipe 89Bugoy2023No ratings yet

- IMG - 0128 PSME Code 2008 119Document1 pageIMG - 0128 PSME Code 2008 119Bugoy2023No ratings yet

- Img - 0044 MCQ For Power & Ipe 79Document1 pageImg - 0044 MCQ For Power & Ipe 79Bugoy2023No ratings yet

- Img - 0050 MCQ For Power & Ipe 91Document1 pageImg - 0050 MCQ For Power & Ipe 91Bugoy2023No ratings yet

- Img - 0041 MCQ For Power & Ipe 73Document1 pageImg - 0041 MCQ For Power & Ipe 73Bugoy2023No ratings yet

- IMG - 0130 PSME Code 2008 121Document1 pageIMG - 0130 PSME Code 2008 121Bugoy2023No ratings yet

- Img - 0042 MCQ For Power & Ipe 75Document1 pageImg - 0042 MCQ For Power & Ipe 75Bugoy2023No ratings yet

- IMG - 0126 PSME Code 2008 117Document1 pageIMG - 0126 PSME Code 2008 117Bugoy2023No ratings yet

- IMG - 0124 PSME Code 2008 115Document1 pageIMG - 0124 PSME Code 2008 115Bugoy2023No ratings yet

- IMG - 0100 PSME Code 2012 98Document1 pageIMG - 0100 PSME Code 2012 98Bugoy2023No ratings yet

- IMG - 0130 ESAS 2001 Solved Problem Objectives 23-15Document1 pageIMG - 0130 ESAS 2001 Solved Problem Objectives 23-15Bugoy2023No ratings yet

- IMG - 0096 PSME Code 2012 94Document1 pageIMG - 0096 PSME Code 2012 94Bugoy2023No ratings yet

- IMG - 0121 PSME Code 2008 112Document1 pageIMG - 0121 PSME Code 2008 112Bugoy2023No ratings yet

- IMG - 0094 PSME Code 2012 92Document1 pageIMG - 0094 PSME Code 2012 92Bugoy2023No ratings yet

- IMG - 0098 PSME Code 2012 96Document1 pageIMG - 0098 PSME Code 2012 96Bugoy2023No ratings yet

- IMG - 0092 PSME Code 2012 90Document1 pageIMG - 0092 PSME Code 2012 90Bugoy2023No ratings yet

- Img - 0095 MCQ Ece Board Exam 177Document1 pageImg - 0095 MCQ Ece Board Exam 177Bugoy2023No ratings yet

- Img - 0091 MCQ Ece Board Exam 169Document1 pageImg - 0091 MCQ Ece Board Exam 169Bugoy2023No ratings yet

- Img - 0097 MCQ Ece Board Exam 181Document1 pageImg - 0097 MCQ Ece Board Exam 181Bugoy2023No ratings yet

- Img - 0098 MCQ Ece Board Exam 183Document1 pageImg - 0098 MCQ Ece Board Exam 183Bugoy2023No ratings yet

- Img - 0092 MCQ Ece Board Exam 171Document1 pageImg - 0092 MCQ Ece Board Exam 171Bugoy2023No ratings yet

- Img - 0096 MCQ Ece Board Exam 179Document1 pageImg - 0096 MCQ Ece Board Exam 179Bugoy2023No ratings yet

- Img - 0099 MCQ Ece Board Exam 185Document1 pageImg - 0099 MCQ Ece Board Exam 185Bugoy2023No ratings yet

- Img - 0093 MCQ Ece Board Exam 173Document1 pageImg - 0093 MCQ Ece Board Exam 173Bugoy2023No ratings yet

- F612/F627/F626B: Semi-Lugged Gearbox Operated Butterfly Valves PN16Document1 pageF612/F627/F626B: Semi-Lugged Gearbox Operated Butterfly Valves PN16RonaldNo ratings yet

- Rotary InformationDocument14 pagesRotary InformationMohammad UsmanNo ratings yet

- BiyDaalt2+OpenMP - Ipynb - ColaboratoryDocument3 pagesBiyDaalt2+OpenMP - Ipynb - ColaboratoryAngarag G.No ratings yet

- Hidden Beam DesignDocument8 pagesHidden Beam DesignAnil kumar R100% (1)

- Yellampalli S. Wireless Sensor Networks - Design, Deployment..2021Document314 pagesYellampalli S. Wireless Sensor Networks - Design, Deployment..2021Myster SceneNo ratings yet

- Module 2 Global Youth: A Estrutura Do Teste Sintetiza-Se No Quadro SeguinteDocument11 pagesModule 2 Global Youth: A Estrutura Do Teste Sintetiza-Se No Quadro SeguinteLaura HenriquesNo ratings yet

- OpenTxt VIM TablesDocument20 pagesOpenTxt VIM Tablesmanasb27No ratings yet

- Interview Management - ORCDocument4 pagesInterview Management - ORCAbdulrhmanHaddadyNo ratings yet

- 1 Correlation Between Na2SiO3 NaOH Ratio ADocument6 pages1 Correlation Between Na2SiO3 NaOH Ratio AedwardcolmeNo ratings yet

- Easy Scrub Cap Pattern PayhipDocument8 pagesEasy Scrub Cap Pattern PayhipFang Fang100% (1)

- ITC LAB 4 - FlowchartsDocument7 pagesITC LAB 4 - FlowchartspathwayNo ratings yet

- DRV 33Document38 pagesDRV 33Alpha ConsultantsNo ratings yet

- Comprehensive Comparison of 99 Efficient Totem-Pole PFC With Fixed PWM or Variable TCM Switching FrequencyDocument8 pagesComprehensive Comparison of 99 Efficient Totem-Pole PFC With Fixed PWM or Variable TCM Switching FrequencyMuhammad Arsalan FarooqNo ratings yet

- Homework #3: MDPS, Q-Learning, &: PomdpsDocument18 pagesHomework #3: MDPS, Q-Learning, &: Pomdpsshivam pradhanNo ratings yet

- Svit - Module 4Document30 pagesSvit - Module 4gjtuyNo ratings yet

- Oracle Database 12c: Administration Workshop Student Guide Volume 2 D78846GC10 - sg2Document374 pagesOracle Database 12c: Administration Workshop Student Guide Volume 2 D78846GC10 - sg2Nelson NelsonNo ratings yet

- Chap 4 R SCM CoyleDocument28 pagesChap 4 R SCM CoyleZeeshan QaraNo ratings yet

- Section - : Exit To Main MenuDocument186 pagesSection - : Exit To Main Menuadi67% (3)

- User's Manual: A200 SeriesDocument194 pagesUser's Manual: A200 SeriesedgarNo ratings yet

- Virtual Museums A Survey and Some IssuesDocument9 pagesVirtual Museums A Survey and Some IssuesCeaser SaidNo ratings yet

- Basaraba Resume 2023 2Document3 pagesBasaraba Resume 2023 2api-701709208No ratings yet

- The Holland Code Career Test: Your Career Interest ProfileDocument31 pagesThe Holland Code Career Test: Your Career Interest ProfileLewwandi VithanageNo ratings yet

- Computer Vision - Ipynb - ColaboratoryDocument17 pagesComputer Vision - Ipynb - Colaboratoryzb laiNo ratings yet

- Fuel Temperature SensorDocument12 pagesFuel Temperature SensorAakarsh Verma100% (2)

- Hvac and Refrigiration System: Group 1Document52 pagesHvac and Refrigiration System: Group 1Jessa Mae CatabayNo ratings yet

- Managerial Economics and Strategy: Third EditionDocument30 pagesManagerial Economics and Strategy: Third EditionRaeNo ratings yet

- Energy Storage Unit Service - Manual PDFDocument28 pagesEnergy Storage Unit Service - Manual PDFathinabeba100% (1)

- Ethical Hacking DissertationDocument5 pagesEthical Hacking DissertationWriteMyPapersUK100% (1)

- Oracle Ow811 Certification Matrix 161594Document8 pagesOracle Ow811 Certification Matrix 161594ps.calado5870No ratings yet

- M2 Pre-Task: Application Software - System Software Driver Software Programming SoftwareDocument2 pagesM2 Pre-Task: Application Software - System Software Driver Software Programming SoftwareBee Anne BiñasNo ratings yet