Professional Documents

Culture Documents

IMG - 0121 PSME Code 2008 112

Uploaded by

Bugoy20230 ratings0% found this document useful (0 votes)

30 views1 pageThis document discusses requirements for flexible hydraulic connections used in elevators, dumbwaiters, escalators, and moving walks. It specifies that flexible hose and fitting assemblies may be used for hydraulic connections if they meet certain criteria, such as having a bursting strength of at least 10 times the working pressure and being permanently marked with the replacement date, which must be no more than 6 years beyond installation. It also outlines relief valve requirements, stating that each pump must be equipped with a relief valve preset to open at no greater than 125% of working pressure and sized to discharge the pump's maximum rated capacity without excessive pressure increase.

Original Description:

PSME

Original Title

IMG_0121 PSME Code 2008 112

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses requirements for flexible hydraulic connections used in elevators, dumbwaiters, escalators, and moving walks. It specifies that flexible hose and fitting assemblies may be used for hydraulic connections if they meet certain criteria, such as having a bursting strength of at least 10 times the working pressure and being permanently marked with the replacement date, which must be no more than 6 years beyond installation. It also outlines relief valve requirements, stating that each pump must be equipped with a relief valve preset to open at no greater than 125% of working pressure and sized to discharge the pump's maximum rated capacity without excessive pressure increase.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

30 views1 pageIMG - 0121 PSME Code 2008 112

Uploaded by

Bugoy2023This document discusses requirements for flexible hydraulic connections used in elevators, dumbwaiters, escalators, and moving walks. It specifies that flexible hose and fitting assemblies may be used for hydraulic connections if they meet certain criteria, such as having a bursting strength of at least 10 times the working pressure and being permanently marked with the replacement date, which must be no more than 6 years beyond installation. It also outlines relief valve requirements, stating that each pump must be equipped with a relief valve preset to open at no greater than 125% of working pressure and sized to discharge the pump's maximum rated capacity without excessive pressure increase.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

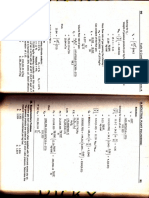

CHAPTER 6 - ELEVATORS, DUMBWAITERS, ESCALATORS AND MOVING WALKS

(c) Pipe Supports. Piping shall be so more than 6 Years beYond

supported as to eliminate undue the installation date'

stresses at ioints and flttingS,

particularly at any section of the (2) Flexible couplings shall be so

line subject to vibration. designed and constructed thd.

failure of the sealing elemeril

(d) Flexible Hydraulic Connections. will not Permit seParation d

Ftexible hose and fitting the Parts connected.

assemblies, and flexible

coup\ings, may be used tot $.5I f Rs\ei and Gheck\ a\rres

hydraulic connections. Where

installed between the check valve (a) PumP Relief Valves. Eadt

pump or groqp of PumPs shatl be

or control valve and the cYlinder,

they shall conform to the tollowing

,bquiilped- with a

relief valve

requirements: conforming to the

requirements:

(1) Flexible hose and fitting

assemblies shall: (1) Type and Location. TtE

relief valve shall be located

(a) not be installed within the between the PumP and the

hoist-waY, hot Project into check ,valve and shall be d

or through any wall. such a tyPe and so installed in

lnstallation shall be the by-pass connection thd

accomPlished without the valve cannot be shut d

intro-ducing twist in the from the hydraulic sYstem.

hose, and shall conform

with the minimuni bending (2) Setting, The relief valve shd

radius of SAE 100 R2 be Preset to open at a

tyPe, High Pressure, Steel pressure not greater than

Wire Reinforced, Rubber 125% of working Pressure.

Covered HYdraulic Hose

sPecified in SAE J517D. (3) Size. The size of the relief

valve and bY-Pass shall be

(b) have a bursting strength sufficient to Pass the

sufficient to withstand not maximurn rated caPacitY

'd less than 10 times the pump without raising tlc

working Pressure. TheY pressure more than

shall be tested in the above that at which the valle

factory or in the field Prior opens. Two or more

to installation at the valves may be used to obtah

pressure of not less than the required caPacitY.

5 times working Pressure

and shall be marked with (4) Sealing. Relief valves

daie and Pressure oftest. exposed

adjustments, ifused,

(c) be comPatible with the have their means

fluid used; adjustments sealed

being set to the

(d) be of non-reusable tYPe pressure.

fittings;

Exception [Sec. 6.5.7.2

(e) be PermanentlY marked No relief valves is required

with the SAE hose tYPe centrifugal pumps driven

identification and the induction motors, Provided

required rePlacement shut-off, or

date which shall not be pressure which the PumP can

develop, is not greater than

112

You might also like

- 2. Forsthoffer's Rotating Equipment Handbooks: PumpsFrom Everand2. Forsthoffer's Rotating Equipment Handbooks: PumpsRating: 1 out of 5 stars1/5 (1)

- Measuring Optical LossDocument1 pageMeasuring Optical Lossdesigner_0039904No ratings yet

- Installation and Maintenance Manual (Ebara Non-Submersible Pump)Document36 pagesInstallation and Maintenance Manual (Ebara Non-Submersible Pump)tm_2075% (8)

- Trane TWE-In-2A 18-GE02D1-3 TWE030P130B0 Air Handler Installer's Guide Installation Manual (November 2001) OcrDocument12 pagesTrane TWE-In-2A 18-GE02D1-3 TWE030P130B0 Air Handler Installer's Guide Installation Manual (November 2001) OcrPatrickHenryNo ratings yet

- Phy 01Document212 pagesPhy 01Varsha Dange100% (1)

- Maintain and Improve Your Powerboat: 100 Ways to Make Your Boat BetterFrom EverandMaintain and Improve Your Powerboat: 100 Ways to Make Your Boat BetterNo ratings yet

- Ultraviolet and X-Ray Spectroscopy of The Solar Atmosphere - K Phillips, Et Al, (Cambridge, 2008) WWDocument390 pagesUltraviolet and X-Ray Spectroscopy of The Solar Atmosphere - K Phillips, Et Al, (Cambridge, 2008) WWRaphael CusatiNo ratings yet

- EHV KV: Guide For Installation of Oil-Immersed Transformers and AboveDocument18 pagesEHV KV: Guide For Installation of Oil-Immersed Transformers and Aboveruel delacruz100% (1)

- CVS Series 50 Chemical Injection Pump ManualDocument12 pagesCVS Series 50 Chemical Injection Pump Manualiqmpslab0% (1)

- Delta Valves Tech Tips PDFDocument20 pagesDelta Valves Tech Tips PDFBrendon CorreaNo ratings yet

- CI/ASCE 38-02: Standard Guideline For The Collection and Depiction of Existing Subsurface Utility DataDocument20 pagesCI/ASCE 38-02: Standard Guideline For The Collection and Depiction of Existing Subsurface Utility DataBlakeNo ratings yet

- Valencia Knutsen - Cargo Operat - AdministratorDocument328 pagesValencia Knutsen - Cargo Operat - AdministratorDarioNo ratings yet

- Pipeline and Hazardous Materials Safety Admin., DOT 178.337-9Document2 pagesPipeline and Hazardous Materials Safety Admin., DOT 178.337-9AssemNo ratings yet

- ASME VIII DIV 1 - M-11 - Posição Vertical Instalação PsvsDocument1 pageASME VIII DIV 1 - M-11 - Posição Vertical Instalação PsvsPaulo Paulucci NetoNo ratings yet

- Evaporator Coil Installation Instructions 96654002 ADPDocument4 pagesEvaporator Coil Installation Instructions 96654002 ADPgeoffffNo ratings yet

- Cessna®: Service/Parts ManualDocument7 pagesCessna®: Service/Parts ManualFranco PugaNo ratings yet

- Omi PB 02 0 Eng Plug ValveDocument4 pagesOmi PB 02 0 Eng Plug Valveakhilsyam21No ratings yet

- Product Standard: Pumps FP60300Document17 pagesProduct Standard: Pumps FP60300vikalp123123No ratings yet

- 3890137e Tech Spec Data Sheets 1556604052Document14 pages3890137e Tech Spec Data Sheets 1556604052Prakash AnnamalaiNo ratings yet

- Chap 25 PDFDocument24 pagesChap 25 PDFnelson escuderoNo ratings yet

- CVC-XP Pilot Valve: Installation GuideDocument4 pagesCVC-XP Pilot Valve: Installation Guidefabricheste CEFIRENo ratings yet

- Operation & Maintenance: AnnuallyDocument1 pageOperation & Maintenance: AnnuallyADVIKA GOWTHAMNo ratings yet

- FBV Series Full-Flow Seacocks: Installation, Operation, and MaintenanceDocument1 pageFBV Series Full-Flow Seacocks: Installation, Operation, and MaintenanceStathis MoumousisNo ratings yet

- 2296 IomDocument16 pages2296 IomKirill HrushkovNo ratings yet

- Installer's Guide: Condensing UnitsDocument8 pagesInstaller's Guide: Condensing UnitsOmar PiñaNo ratings yet

- Transformer Pressure Relief Valve For Power TransformersDocument4 pagesTransformer Pressure Relief Valve For Power TransformersKizito Emmanuel KyeyuneNo ratings yet

- Isolation Valve - Watts B3001Document2 pagesIsolation Valve - Watts B3001AHMAD ISLAHINo ratings yet

- EvacDocument1 pageEvacMansur KhanNo ratings yet

- DV-5 Deluge Valve With Remote-Resetting Trim 2 To 8 Inch (DN50 To DN200) General DescriptionDocument24 pagesDV-5 Deluge Valve With Remote-Resetting Trim 2 To 8 Inch (DN50 To DN200) General DescriptionAwais AshrafNo ratings yet

- 49 CFR Ch. I (10-1-01 Edition) 173.34: 173.34 Qualification, Maintenance and Use of CylindersDocument13 pages49 CFR Ch. I (10-1-01 Edition) 173.34: 173.34 Qualification, Maintenance and Use of Cylindersleunamsayan100% (1)

- MN4051 0322Document8 pagesMN4051 0322Dênis DáyolNo ratings yet

- WaterWorker Vertical Well Tank Installation ManualDocument12 pagesWaterWorker Vertical Well Tank Installation ManualS100% (1)

- Ca GoyenDocument23 pagesCa GoyenGunalan RavichanthiranNo ratings yet

- 8 Hydraulic and Pnuematic Power SystemsDocument62 pages8 Hydraulic and Pnuematic Power SystemsAtom SmasherNo ratings yet

- Pressure Vessels Lectures 162Document1 pagePressure Vessels Lectures 162AlenNo ratings yet

- Chemetron - FM200.Sigma - Series.Data - Sheet 3Document6 pagesChemetron - FM200.Sigma - Series.Data - Sheet 3nayel95No ratings yet

- Concealed Water Cooled Package Unit: Installation & MaintenanceDocument15 pagesConcealed Water Cooled Package Unit: Installation & MaintenanceavindNo ratings yet

- ML B 90 b90mm951Document2 pagesML B 90 b90mm951Angel Vieira MendezNo ratings yet

- IMG - 0144 PSME Code 2008 136Document1 pageIMG - 0144 PSME Code 2008 136Arwyn BermasNo ratings yet

- Bombas TriplexDocument98 pagesBombas TriplexYiikii CueLlo GonzsaLeszNo ratings yet

- Regulation Pompe Sauer Danfos Series 90Document2 pagesRegulation Pompe Sauer Danfos Series 90ezeazeazeaeNo ratings yet

- CSA Athena Float ValvesDocument16 pagesCSA Athena Float ValveswinsasimahaaNo ratings yet

- Beckett - Fundamentals of Pressure Relief Valves in Natural GasDocument5 pagesBeckett - Fundamentals of Pressure Relief Valves in Natural GasFrancoNo ratings yet

- Technical Specification - Transformer (31-8-2020)Document15 pagesTechnical Specification - Transformer (31-8-2020)Abhishek Kumar SinhaNo ratings yet

- Pressure Vessels Lectures 161Document1 pagePressure Vessels Lectures 161AlenNo ratings yet

- Model Da8: (Formerly DA8/9) Direct-Acting, Positive Bias Differential Back Pressure RegulatorDocument18 pagesModel Da8: (Formerly DA8/9) Direct-Acting, Positive Bias Differential Back Pressure RegulatorBoubekeur HamegNo ratings yet

- A New Gas Lift SystemDocument8 pagesA New Gas Lift SystemVeronica ArronithaNo ratings yet

- Pentair Goyen Threaded Pulse Jet ValvesDocument11 pagesPentair Goyen Threaded Pulse Jet Valvesraul_giralNo ratings yet

- High Pressure Carbon Dioxide Systems: Design, Installation, Recharge, and Maintenance ManualDocument5 pagesHigh Pressure Carbon Dioxide Systems: Design, Installation, Recharge, and Maintenance ManualMOHAMMED HADINo ratings yet

- Tech Data S: Nical HeetDocument9 pagesTech Data S: Nical HeetPaul MartinNo ratings yet

- Catalogo Actuador MorinDocument14 pagesCatalogo Actuador MorinErika MendezNo ratings yet

- Pentair Goyen Manifold Mount Pulse Jet ValvesDocument11 pagesPentair Goyen Manifold Mount Pulse Jet ValvesAbhishek PatelNo ratings yet

- EM00136453 Kompact AMS ML Rev1.0Document34 pagesEM00136453 Kompact AMS ML Rev1.0Emilio Jose EstevezNo ratings yet

- E3551 SAF DSV Katalogversion LQDocument22 pagesE3551 SAF DSV Katalogversion LQGabriel AmorimNo ratings yet

- Atvus PRVDocument6 pagesAtvus PRVvipulpanchotiyaNo ratings yet

- Transmission Pressures - Test (SENR9159-10)Document3 pagesTransmission Pressures - Test (SENR9159-10)Anderson Oliveira SilvaNo ratings yet

- Valves SpecsDocument3 pagesValves SpecsTareq AlsadiNo ratings yet

- 12V Water PumpDocument11 pages12V Water PumpOrganic MechanicNo ratings yet

- Air Admittance Valves (Ventapipe) : SectionDocument5 pagesAir Admittance Valves (Ventapipe) : SectionDinesh GuptaNo ratings yet

- Section - Viii: Technical Specifications of TransformersDocument21 pagesSection - Viii: Technical Specifications of TransformersSrini DuddupudiNo ratings yet

- Accumulator Block - Hydac - SAFDocument26 pagesAccumulator Block - Hydac - SAFBenAbrahamSamuelNo ratings yet

- Check Valve: Product Bulletin 50-13 CDocument2 pagesCheck Valve: Product Bulletin 50-13 CHuong QuangNo ratings yet

- Installation Operation Maintenance Mission 2500 Supreme PDFDocument16 pagesInstallation Operation Maintenance Mission 2500 Supreme PDFRAHULNo ratings yet

- Cold Startup Boiler and TurbineDocument5 pagesCold Startup Boiler and TurbinejasvinderNo ratings yet

- FlowserverDocument12 pagesFlowserverCesar Cedano VivarNo ratings yet

- Img - 0046 MCQ For Power & Ipe 83Document1 pageImg - 0046 MCQ For Power & Ipe 83Bugoy2023No ratings yet

- Img - 0048 MCQ For Power & Ipe 87Document1 pageImg - 0048 MCQ For Power & Ipe 87Bugoy2023No ratings yet

- Img - 0043 MCQ For Power & Ipe 77Document1 pageImg - 0043 MCQ For Power & Ipe 77Bugoy2023No ratings yet

- IMG - 0044 ESAS 2001 Solved Problem Objectives 9-18Document1 pageIMG - 0044 ESAS 2001 Solved Problem Objectives 9-18Bugoy2023No ratings yet

- Img - 0045 MCQ For Power & Ipe 81Document1 pageImg - 0045 MCQ For Power & Ipe 81Bugoy2023No ratings yet

- Img - 0047 MCQ For Power & Ipe 85Document1 pageImg - 0047 MCQ For Power & Ipe 85Bugoy2023No ratings yet

- Img - 0050 MCQ For Power & Ipe 91Document1 pageImg - 0050 MCQ For Power & Ipe 91Bugoy2023No ratings yet

- IMG - 0130 PSME Code 2008 121Document1 pageIMG - 0130 PSME Code 2008 121Bugoy2023No ratings yet

- Img - 0044 MCQ For Power & Ipe 79Document1 pageImg - 0044 MCQ For Power & Ipe 79Bugoy2023No ratings yet

- Img - 0049 MCQ For Power & Ipe 89Document1 pageImg - 0049 MCQ For Power & Ipe 89Bugoy2023No ratings yet

- Img - 0042 MCQ For Power & Ipe 75Document1 pageImg - 0042 MCQ For Power & Ipe 75Bugoy2023No ratings yet

- IMG - 0128 PSME Code 2008 119Document1 pageIMG - 0128 PSME Code 2008 119Bugoy2023No ratings yet

- Img - 0041 MCQ For Power & Ipe 73Document1 pageImg - 0041 MCQ For Power & Ipe 73Bugoy2023No ratings yet

- IMG - 0092 PSME Code 2012 90Document1 pageIMG - 0092 PSME Code 2012 90Bugoy2023No ratings yet

- IMG - 0100 PSME Code 2012 98Document1 pageIMG - 0100 PSME Code 2012 98Bugoy2023No ratings yet

- IMG - 0126 PSME Code 2008 117Document1 pageIMG - 0126 PSME Code 2008 117Bugoy2023No ratings yet

- IMG - 0098 PSME Code 2012 96Document1 pageIMG - 0098 PSME Code 2012 96Bugoy2023No ratings yet

- Img - 0098 MCQ Ece Board Exam 183Document1 pageImg - 0098 MCQ Ece Board Exam 183Bugoy2023No ratings yet

- IMG - 0130 ESAS 2001 Solved Problem Objectives 23-15Document1 pageIMG - 0130 ESAS 2001 Solved Problem Objectives 23-15Bugoy2023No ratings yet

- IMG - 0124 PSME Code 2008 115Document1 pageIMG - 0124 PSME Code 2008 115Bugoy2023No ratings yet

- IMG - 0094 PSME Code 2012 92Document1 pageIMG - 0094 PSME Code 2012 92Bugoy2023No ratings yet

- Img - 0097 MCQ Ece Board Exam 181Document1 pageImg - 0097 MCQ Ece Board Exam 181Bugoy2023No ratings yet

- Img - 0095 MCQ Ece Board Exam 177Document1 pageImg - 0095 MCQ Ece Board Exam 177Bugoy2023No ratings yet

- Img - 0091 MCQ Ece Board Exam 169Document1 pageImg - 0091 MCQ Ece Board Exam 169Bugoy2023No ratings yet

- Img - 0099 MCQ Ece Board Exam 185Document1 pageImg - 0099 MCQ Ece Board Exam 185Bugoy2023No ratings yet

- IMG - 0096 PSME Code 2012 94Document1 pageIMG - 0096 PSME Code 2012 94Bugoy2023No ratings yet

- Img - 0090 MCQ Ece Board Exam 167Document1 pageImg - 0090 MCQ Ece Board Exam 167Bugoy2023No ratings yet

- Img - 0092 MCQ Ece Board Exam 171Document1 pageImg - 0092 MCQ Ece Board Exam 171Bugoy2023No ratings yet

- Img - 0093 MCQ Ece Board Exam 173Document1 pageImg - 0093 MCQ Ece Board Exam 173Bugoy2023No ratings yet

- Img - 0096 MCQ Ece Board Exam 179Document1 pageImg - 0096 MCQ Ece Board Exam 179Bugoy2023No ratings yet

- June 2011 (v2) QP - Paper 1 CIE Chemistry IGCSEDocument16 pagesJune 2011 (v2) QP - Paper 1 CIE Chemistry IGCSEMedo O. EzzatNo ratings yet

- AntennasDocument34 pagesAntennasMoneth PerezNo ratings yet

- Protection of Power Systems: 8. Impedance (Distance) RelaysDocument41 pagesProtection of Power Systems: 8. Impedance (Distance) RelaysMonika LeonitaNo ratings yet

- Hertz HSK 165 6Document7 pagesHertz HSK 165 6syamkimi75No ratings yet

- C32 Bernoulli S Apparatus 1628736606598Document6 pagesC32 Bernoulli S Apparatus 1628736606598Somya MaheshwariNo ratings yet

- Document 311653Document65 pagesDocument 311653jonathan romeroNo ratings yet

- Valves BasicsDocument94 pagesValves BasicsSamuel Onyewuenyi100% (1)

- Basement Ventilation CalculationDocument4 pagesBasement Ventilation CalculationShubhajit ChakrabortyNo ratings yet

- Invertec v275-sDocument33 pagesInvertec v275-sjuanNo ratings yet

- On JALDocument14 pagesOn JALArvind BajpaiNo ratings yet

- Industrial Scientific - 17152355-1Document20 pagesIndustrial Scientific - 17152355-1Prejit RadhakrishnaNo ratings yet

- How I Distill Ipa: WarningDocument6 pagesHow I Distill Ipa: WarningAidenNo ratings yet

- Plumbing - TR BaliDocument84 pagesPlumbing - TR BaliardibujangNo ratings yet

- WR - SS02 - E1 - 1 ZXSDR Base Station Structure and Principle 65pDocument64 pagesWR - SS02 - E1 - 1 ZXSDR Base Station Structure and Principle 65psivakumarNo ratings yet

- Norbro40 PDFDocument11 pagesNorbro40 PDFMargaret DaughertyNo ratings yet

- HVAC System Operation DescriptionDocument10 pagesHVAC System Operation DescriptionMohamed Khaled Fadl DahabNo ratings yet

- 140113105004Document16 pages140113105004Jaymit PatelNo ratings yet

- Mechanics Practice Papers 2Document13 pagesMechanics Practice Papers 2Sarvesh DubeyNo ratings yet

- w-NEXT Product Information SheetDocument2 pagesw-NEXT Product Information SheetRommel GeronimoNo ratings yet

- Drawings of ReservoirDocument1 pageDrawings of ReservoirNimco CadayNo ratings yet

- MSC Phy SyllabusDocument38 pagesMSC Phy SyllabusKartik chandra beheraNo ratings yet

- Task Risk Assessment Refresher Training: Sangachal TerminalDocument34 pagesTask Risk Assessment Refresher Training: Sangachal TerminalRauf HuseynovNo ratings yet

- Waste Heat To Power ApplicationsDocument10 pagesWaste Heat To Power ApplicationsArul PrakashNo ratings yet

- Real Ielts Exams Writing Task 1 by Vuaielts.1Document23 pagesReal Ielts Exams Writing Task 1 by Vuaielts.1Cẩm TúNo ratings yet

- AWH Brochure Cleaning TechnologyDocument2 pagesAWH Brochure Cleaning Technologyktsaknakis_1No ratings yet