Professional Documents

Culture Documents

5111 April-2019

Uploaded by

75Ujwal TDOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

5111 April-2019

Uploaded by

75Ujwal TDCopyright:

Available Formats

\

PART_C

\

[Maximum Marks: 60]

[Answer one full question from each unit. Each full question carries 15 marks]

UMT-I

Itr. (a) Explain about press working equipment with a neat sketch. 8

(b) Differentiate between compound die and combination die.

IV. (a) Explain the method to reduce the cutting force during the press working 8

E

(b) Sketch and explain single row and double row sfip layout. 7

EG

UMT-tr

LL

V. (a) Discuss about diflerent types ofpilots with a neat sketcb.

8

CO

(b) With a neat sketch explain knockout and shedder mechanisrn, 7

OR

VI. (a) Two holes, one 5 cm square and another

C

8 cm diameter are to be cut in a metallic sheet

I

of 3mm

HN

thick. If shear strength ofmaterial is 3000 kg/cm2, determine

(0 (il)

EC

Cutting force Stripping force 8

(b) Explain with a neat sketch about spring loaded stripper. 7

YT

UNIT = III

L

PO

VII. (a) Describe edge bending and V - bending operation with simple sketches. 8

(b) List out the advantages and limitations of compound tool. 7

N

OR

DI

VIII. (a) Explain working ofprogressive die with a neat sketch.

A'

(b) Write a short note on spring back phenomenon.

M

TINIT - IV

D(. (a) Discuss the factors affecting drawing operation.

ft) Write short note on frne blanking operation.

OR

X. (a) Define the terms, draw ratio; thickness ratio and drawing ratio in press tools 8

(b) Explain about materials suitable for fine blanking 7

?'tl\l Ar

j

:' :

TED (15) slr1

Q;ffiat!,.P

rr6rre!er v

(Revision -2015)

DIPLOMA EXAMINATION IN ENGINEERING/TBCIINOLOGY/

MAI{AGEMENTiCOMMERCIAL PRACTICE' APRIL - 2OI9

PRESS TOOL TECHNOLOGY

[Time: 3 Hours]

[Maximum Marks: 100]

E

PART-A

EG

[Maximum Marks: 101

(Answer all questions in one or two s€ntences' Each question canies 2 marks)

LL

CO

I 1. Definc Punching operation.

2. What is direct pilot.

C

3. What are the important points to be considered during bending?

I

HN

4. Name the differetrt types of commonly used forming dies.

5. State shut height of a die. [5x2:10]

EC

PART_B

YT

[Maximum Marks: 30]

L

PO

ll. Atswer anlt Jive of folLo'wing questions. Each question csries 6 marlc

l. Explain with a neat sketch cut off and parting off operation.

N

DI

2. Compare piercing and blanking operation.

3. Describe the different types ofpower presses used in press tool operation'

A'

4. Calculate the bending force for a 450 bend in aluminium blank. The following daia is given:

M

Blank thickness : / mrn; Bend length: 1000 mm; Die opening = 8 x metal thickness

Ultimite tensile streneth : 455 N/mm2.

5. DeFure the following.

(i) Bend allowance (ii) Angle ofbend (iii) Set back

6. Describe embossing type of forming operation in press tools.

7. Calculate blank diameter to make a steel shell having 100 mm outer diameter and 50 mm height

with 3 mm thick sheet metal.

[5x6:30]

You might also like

- College College: Signature@ff3...Document2 pagesCollege College: Signature@ff3...Gokul KrishnanNo ratings yet

- 4053 Oct-2017Document3 pages4053 Oct-2017Ayush SinghNo ratings yet

- Assets Questions-2018 Automobile Semester-3 3052-October2018Document2 pagesAssets Questions-2018 Automobile Semester-3 3052-October2018AswinNo ratings yet

- 4022 Oct-2017Document2 pages4022 Oct-201734 Midhun. TA MENo ratings yet

- College: Diploma Management/CommercialDocument3 pagesCollege: Diploma Management/CommercialMercyNo ratings yet

- College College: - Parts'Document3 pagesCollege College: - Parts'Saurabh Kumar 53No ratings yet

- Manufacturing: ProcessDocument22 pagesManufacturing: ProcessKKNo ratings yet

- 5032 Oct - 2018Document2 pages5032 Oct - 2018Muneef NNo ratings yet

- 5051 Apr 20Document3 pages5051 Apr 20Rithik Raj RanjuNo ratings yet

- r05322102 Aerospace Vehicle Structures IIDocument12 pagesr05322102 Aerospace Vehicle Structures IISRINIVASA RAO GANTA100% (2)

- 5032 Apr-19Document2 pages5032 Apr-19Muneef NNo ratings yet

- 3023 Manufacturing Process - QPDocument3 pages3023 Manufacturing Process - QPMuhd Shabeeb ANo ratings yet

- S.E (2008 - 2012 Pattern)Document581 pagesS.E (2008 - 2012 Pattern)sagar shindeNo ratings yet

- WWW - Manaresults.Co - In: B.Tech III Year II Semester (R13) Supplementary Examinations December 2016Document1 pageWWW - Manaresults.Co - In: B.Tech III Year II Semester (R13) Supplementary Examinations December 2016poongothai sNo ratings yet

- PU Paper Manufacturing Science KME-403 - NewDocument2 pagesPU Paper Manufacturing Science KME-403 - Newdaso khagoNo ratings yet

- College: Oma Examnati On Management/Commercial Practicii 20I9Document2 pagesCollege: Oma Examnati On Management/Commercial Practicii 20I9Sam JhonsonNo ratings yet

- Be - Electrical Engineering - Semester 5 - 2019 - May - Power Electronics Pe Pattern 2015Document2 pagesBe - Electrical Engineering - Semester 5 - 2019 - May - Power Electronics Pe Pattern 2015sahish pandavNo ratings yet

- Machine Tool Tech.Document7 pagesMachine Tool Tech.Shashi Bhushan PatelNo ratings yet

- 4042 April-2019Document2 pages4042 April-2019AkhilNo ratings yet

- 6183 Apr-19Document2 pages6183 Apr-19Shibli ThangalNo ratings yet

- 6013 Apr-19Document3 pages6013 Apr-19Suraj KumarNo ratings yet

- 5032 Oct-2019Document2 pages5032 Oct-2019Muneef NNo ratings yet

- College: - Diploma ExaminationDocument2 pagesCollege: - Diploma ExaminationSuraj KumarNo ratings yet

- Question PaperDocument30 pagesQuestion Papervaishnavi mathapatiNo ratings yet

- WWW - Ssmpoly.ac - In: Electrical and Electronics EngineeringDocument2 pagesWWW - Ssmpoly.ac - In: Electrical and Electronics EngineeringAjith K ANo ratings yet

- Met204 Manufacturing Process, July 2021Document2 pagesMet204 Manufacturing Process, July 2021Mohammed SalaNo ratings yet

- En 04 104 (A) Engineering Chemistry (A), June 2007Document2 pagesEn 04 104 (A) Engineering Chemistry (A), June 2007Jathi PathriNo ratings yet

- Nov Dec 2019Document2 pagesNov Dec 2019pecoxor808No ratings yet

- TED (15) - 3021 Reg. No: Electrical & Electronics EngineeringDocument3 pagesTED (15) - 3021 Reg. No: Electrical & Electronics EngineeringMuhd Shabeeb ANo ratings yet

- Jntuworld: R09 Set No. 2Document6 pagesJntuworld: R09 Set No. 2Dr-Asit Kumar ParidaNo ratings yet

- 4021 Oct-2017Document4 pages4021 Oct-2017HAMDUNo ratings yet

- College: Diploma Examination AprilDocument2 pagesCollege: Diploma Examination AprilSam JhonsonNo ratings yet

- College College: Diploma ExaminationDocument2 pagesCollege College: Diploma ExaminationGokul KrishnanNo ratings yet

- Ee2254-Linear Integrated Circuits and Applications-R8Document2 pagesEe2254-Linear Integrated Circuits and Applications-R8Jeeva KNo ratings yet

- 5032 April - 2018Document2 pages5032 April - 2018Muneef NNo ratings yet

- Analog Devices ND Circuts-3031-15 PDFDocument2 pagesAnalog Devices ND Circuts-3031-15 PDFsajith lal vNo ratings yet

- AugustSeptember 2022Document1 pageAugustSeptember 2022mdshabankhan05No ratings yet

- SE 2008 Electronics E&TCDocument63 pagesSE 2008 Electronics E&TCManish kumar 50No ratings yet

- VTU - B.E B.Tech - 2019 - 8th Semester - July - CBCS 2015 Scheme - MECH - 15ME82 Additive ManufacturingDocument2 pagesVTU - B.E B.Tech - 2019 - 8th Semester - July - CBCS 2015 Scheme - MECH - 15ME82 Additive ManufacturingBikash ChoudhuriNo ratings yet

- 3021 Oct 20Document2 pages3021 Oct 20akkgptcktmNo ratings yet

- rr210302 Basic ElectronicsDocument4 pagesrr210302 Basic ElectronicsSrinivasa Rao GNo ratings yet

- TSC Model 2019-2Document2 pagesTSC Model 2019-2samrajsmsNo ratings yet

- Diploma Examination in Engineering/Technology/ Management/Coümercial Practice - October, 2018Document2 pagesDiploma Examination in Engineering/Technology/ Management/Coümercial Practice - October, 2018Muhd Shabeeb ANo ratings yet

- Production Process of Automobile Components - QPDocument2 pagesProduction Process of Automobile Components - QPBOScoNo ratings yet

- Met307 - BDocument2 pagesMet307 - BSudeesh SudevanNo ratings yet

- Measurement and Metrology Rme 401Document2 pagesMeasurement and Metrology Rme 401UTTKARSH SACHANNo ratings yet

- Diploma Examination in Engineering/Technology/ Management/Commercial Practice - Aprial, 2019Document2 pagesDiploma Examination in Engineering/Technology/ Management/Commercial Practice - Aprial, 2019Muhd Shabeeb ANo ratings yet

- Ii 1Document13 pagesIi 1simbu oneoneNo ratings yet

- Be - Electrical Engineering - Semester 5 - 2018 - November - Power Electronics Pe Pattern 2015Document3 pagesBe - Electrical Engineering - Semester 5 - 2018 - November - Power Electronics Pe Pattern 2015sahish pandavNo ratings yet

- Be First Year Fe Engineering Semester 1 2019 October Basic Electronics Engineering Pattern 2019Document2 pagesBe First Year Fe Engineering Semester 1 2019 October Basic Electronics Engineering Pattern 2019Satish AsaneNo ratings yet

- 6042 April-2019Document2 pages6042 April-2019vinayak jithNo ratings yet

- 14 Ee 304 Dec15Document1 page14 Ee 304 Dec15Bhanath ShankerNo ratings yet

- Dec 2013 Jan 2014Document1 pageDec 2013 Jan 2014mabhatNo ratings yet

- DC EndsemDocument2 pagesDC EndsemAniket baroorkarNo ratings yet

- 1Q Oct-2018Document2 pages1Q Oct-2018Sam JhonsonNo ratings yet

- DSS 2 (7th&8th) May2018Document2 pagesDSS 2 (7th&8th) May2018Piara SinghNo ratings yet

- Assignment No 7Document3 pagesAssignment No 7Ranjit GadgeNo ratings yet

- Mould Theory 2 NoteDocument19 pagesMould Theory 2 Note75Ujwal TDNo ratings yet

- Cadd Lab S4Document33 pagesCadd Lab S475Ujwal TDNo ratings yet

- Course ObjectivesDocument5 pagesCourse Objectives75Ujwal TDNo ratings yet

- PTT Press ToolDocument34 pagesPTT Press Tool75Ujwal TDNo ratings yet

- Elements Machine Shop PDFDocument493 pagesElements Machine Shop PDFJaypes ManzanoNo ratings yet

- SC37 SC42 SC46 SC49 Scc3 Cast Steel Gear: G G G G GDocument3 pagesSC37 SC42 SC46 SC49 Scc3 Cast Steel Gear: G G G G GJayce GreenfelderNo ratings yet

- текстDocument13 pagesтекстРоман ЯковенкоNo ratings yet

- Tunisian Ebook Liesure Arts Beginning PatternsDocument54 pagesTunisian Ebook Liesure Arts Beginning PatternsJill Krahling92% (12)

- CNC Lathe List: Item CK0640 CK0660 CK0680Document10 pagesCNC Lathe List: Item CK0640 CK0660 CK0680MUHAMMAD NAUMANNo ratings yet

- Amigurumi White Rabbit Free Crochet Pattern - AmigurumiDocument18 pagesAmigurumi White Rabbit Free Crochet Pattern - AmigurumiBegoña Martinez0% (1)

- Daisyandstorm Com-Free Dumbledore Amigurumi Pattern CrochetDocument6 pagesDaisyandstorm Com-Free Dumbledore Amigurumi Pattern CrochetTiago Faria100% (3)

- Machining Process-Ii: (Assignment)Document5 pagesMachining Process-Ii: (Assignment)Sobia JamilNo ratings yet

- Knauf BS EN Partition Manual 4Document7 pagesKnauf BS EN Partition Manual 4abuyeheaNo ratings yet

- Review On Single Point Cutting ToolDocument5 pagesReview On Single Point Cutting ToolHarsh100% (1)

- Golden Ratio CalipersDocument4 pagesGolden Ratio CalipersFrancois VaaltynNo ratings yet

- 2 Catalogo de Norton Discos AbrasivosDocument1 page2 Catalogo de Norton Discos AbrasivosRonnie FuertesNo ratings yet

- SLD Magic 2Document12 pagesSLD Magic 2Deny Arisandi DarisandNo ratings yet

- Pramet 2016.2 - en PDFDocument26 pagesPramet 2016.2 - en PDFManish MoghaNo ratings yet

- Inside Crochet 107Document100 pagesInside Crochet 107Екатерина Матушинец100% (2)

- Miteebite 2017 CatalogDocument52 pagesMiteebite 2017 Catalogkebbab faroukNo ratings yet

- Dyeing - Printing-Finishing Member Mills (General Member)Document17 pagesDyeing - Printing-Finishing Member Mills (General Member)alaminNo ratings yet

- Mechanical FitterDocument9 pagesMechanical Fitterjayaarnav0% (1)

- Xl4000 Series AlkDocument19 pagesXl4000 Series AlkJesant17No ratings yet

- 103 - Table Saw Panel SledDocument2 pages103 - Table Saw Panel SledRob PierceNo ratings yet

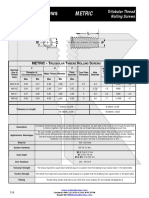

- Met Thread RollDocument3 pagesMet Thread Rollalfred2000No ratings yet

- DataSheets2010 - Datasheet CPM 154 CMv12010Document2 pagesDataSheets2010 - Datasheet CPM 154 CMv12010jobseekeramatxNo ratings yet

- Linen Pants Construction DiagramDocument1 pageLinen Pants Construction DiagramVishnu Priya SahasranamanNo ratings yet

- Vee-Kerchief - Just Too Much YarnDocument8 pagesVee-Kerchief - Just Too Much YarnMilagrosNo ratings yet

- List of Manufacturing Processes: CastingDocument10 pagesList of Manufacturing Processes: Castingjohndesign123No ratings yet

- AluminumDocument5 pagesAluminumBlueOneGaussNo ratings yet

- Pearl Sweater: Mrs - Deer.KnitsDocument6 pagesPearl Sweater: Mrs - Deer.KnitsSophie Cimon100% (1)

- Tutorial QuestionsDocument2 pagesTutorial QuestionsAmber MomentNo ratings yet

- Make A Real Viking StoolDocument13 pagesMake A Real Viking StoolRod HyattNo ratings yet

- Gunsmithing With Simple Hand ToolsDocument107 pagesGunsmithing With Simple Hand Toolsthegoodpatriot72% (32)