Professional Documents

Culture Documents

ZB Turbines Control - 969

ZB Turbines Control - 969

Uploaded by

zakaly0 ratings0% found this document useful (0 votes)

43 views20 pagesOriginal Title

ZB TURBINES CONTROL - 969

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

43 views20 pagesZB Turbines Control - 969

ZB Turbines Control - 969

Uploaded by

zakalyCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 20

Suez Oil Company

Intercompany Memo

Ret: 944/22

To :C.8T. Board

From : O-1

CC: 0-10/0-40/0-70/ C-1

Date : 26/12/2022

Subj. : ZB turbines control & excitation systems upgrade

SUCO operates 4EA T8500 gas turbines generators & other GEA units in service for gas plant production

facilities at Zeit Bay field. During lst few years, we experienced difficulties to obtain spare parts or to repair

defective parts of control system; as most of parts are obsolete or no longer supported, to maintain our

turbines operation.

So we plan to upgrade turbines control system, upgrading job has been already performed successfully for

four units “3 in power generation units & 1 in gas production”. Upgrading the control system package

based on the similar Allen Bradley control logix, vibration, fire & gas system of the already upgraded units

to achieve reduction & unify in spare parts stock.

Based on the attached scope of work and TRF (include the recommended bidders) your kind approval to

issue a tender to proceed with the subject as soon as possible for a lump sum offer (supply materials,

installation, commissioning and start-up) to upgrade the following:-

- Ruston TB5000 gas turbine driven generator (GT-10010) with estimated funds $900,000.

- Ruston TBS000 gas turbine driven compressor (GT-2502 HPI) with estimated funds $500,000.

- Generator control panels (4 panels) for power generators with estimated funds $200,000.

Suco standard’ terms and conditions for such services are to be applied.

Attachments:

-Tender request form to C. &T. Board

~ Suco’ Scope of work.

~ Copy of the approved requisitions.

“Ahmed Farid

Operations General Manager

And Board Member

Paget

TENDER REQUEST FORM (TRF) / FOR SERVICES

PART (A) - INFORMATION

TENDER SUBJECT: ZB turbines control & excitation systems Upgrade

- REQUESTED STARTING DATE OF CONTRACT: 15.1. 2022.

- TYPE OF CONTRACT (LUMP SUM - UNIT RATE ~ etc...): |

- PROPOSED CURRENCY OF PAYMENT ( IF NOT INCLUDED IN E.GP.C LIST):

uu 8%

- IF ABACK UP CONTRACTOR IS REQUIRED: YES ~

-NO--- (IF YES PLS. JUSTIFY)

- IF A PERFORMANCE GUARANTEE IS REQUIRED: YES~—--- NO--

JUSTIFY)

~ (IF NO PLS. |

- IF ATECHNICAL EVALUATION IS REQUIRED: YES-----—- NO—

- EST COST OF THE TENDER: $ 1,600,000

PART (B) - SCOPE OF WORK AND SCHEDULE OF PRICES (BRIEF DESCRIPTION OF THE

| WORK AND / OR SERVICES TO BE UNDERTAKEN)

DETAILED SCOPE OF WORK AND SCHEDULE OF PRICES IS ATTACHED

(TO BE PREPARED AS AN ANNEX WHICH COULD BE USED AS AN INTEGRATED PART OF |

| THE CONTRACT)

}

i ee

a ie

g ge

ae

PART (C) - PROPOSED TENDERERS (FULL AND EXACT NAME)

4- Name: Siemens 2

Fax No.: 02 26143399

PART (D) - TENDER EVALUATION PLANE FOR TECHNICAL OFFERS — (IF ANY)

DETAILED PLAN IS ATTACHED (IF ANY)

PART (E) - SIGNATURES

we

T Deparment] OPERATIONS Dion,

‘ >. | Engineering Oepartmem

2B turbine control & excitation systems Upgrade [aaaaon Tp

Page: | Page 10f 13

Scope Of Work ss ge?

[Date

ZB turbines control & excitation systems

Upgrade

Part |: GT-1001D Control system Upgrade

Part Il: Manual Excitation replacement

Part Ill: GT-2502HPI Control system Upgrade

see

Beer

Page 1 of 13

7a T Department] OPERATIONS Dion

oo inerraDesormens |

2B turbine control & excitation systems Upgrade - a

| Revision: | 0

Page: | Page 20f32

Scope Of Work prose: _} Page?

ane : Date 3

1. Introduction

Suez oil company (SUCO) has a generating plant consists of four TB5000 Gas Turbines tagged “

GT-1001A/8/C/D" that drive a 3.3KV Generators at Zeit Bay field on the Red sea in Egypt “as

shown in Figure 1”.

0 Oo

ETL

Figure 1: 2/8 Power Station simplified Single Line Diagram

Three of those units have an upgraded control using Allen Bradley Control Logix PLC. Unit O still has the

original control from Ruston. All units have old manual excitation systems. The automatic excitation

system of each unit was upgraded to use CGCM device from Allen Bradley.

‘The PMS system was upgraded to use Allen Bradley PLC Control Logix as the PMS controller.

Please note that the power station has two sections bus bar (bus A and bus 8) with a bus coupler. The

power station works with the bus coupler closed that is one bus bar system. However, depends on the

operator's discretion, the power station can work with open bus coupler, that is two bus bars operation.

The CGCM devices are controlled and accessed by the PMS PLC via Control Net. The Redundant Control

Net cables were connected in daisy chain that is from the control room to unit A, to unit B, to unit C then

as|ast node unit D. as shown in Figure 2.

sie

Page 2 0f13

Separmang| PRIOR Dn i

- | egussy eect

2B turbine control & excitation systems Upgrade Taovaons te

Page: | Page3 of 13

Scope Of Work sg -

PLE RACK

Control Room

Unit € Excitation Unit D Excitation

Compartment Compartment

lerA0016 jort001D

Unit A Excitation

Compartment

or-s0018

or-t0018

Figure 2: old Control Net

Now, the philosophy is changed and CGCM is controlled directly through Turbine PLC , otherwise turbine “D”

is controlled by temporary Allen Bradly plc chassis installed in generator panel until execution of the turbine

Upgrade to add the logic to turbine controller, and the PMS controller and turbines’ PLC is communicating

through Ethernet network.

On other hand , six TBS000 Gas Turbines that drive centrifugal compressors are existing at the same

site “ Zeit Bay field” for gas injection & LPG production facilities , the turbine control upgrade for one

of these turbine units GT-2502 HPI “ high pressure compression unit “ is a part of this scope of work

2. System Description

2.1. Power Management System “PMS”

The old PMS, microprocessor-based system, was upgraded couple of years ago to PLC-based system.

‘The upgraded PMS is using Control Logix PLC to execute the PMS algorithms to manage & monitor the

operating of four generation ¢

Ee

Page 3 of 13

] - Department rneing Deparment

28 turbine control & excitation systems Upgrade [Revisions [0

P | Page of 3

Scope Of Work a = =

[Date

2.2. Power Generation Turbine Control

The unit sequence, starting, accelerating, loading and unloading, engine control, fuel control, unit protection,

etc. are managed by the Control Logix PLC in each unit (A, B and C). Unit D still has the original control system

from Ruston “the subject of upgrade”.

Each unit (A, 8 and C) has HMI located inside its control compartment. Each PLC and HMI has a dedicated IP

address,

2.3. Excitation System

‘The excitation system has two main parts, the automatic excitation part and the manual excitation part. The

automatic excitation part of the system was upgraded to Combined Generator Control Module (CGCM) from

Allen Bradley. The manual excitation part of the system still using the old components.

The excitation supply is a single-phase PMG that supplies both the Automatic Excitation and the Manual

excitation systems. Figure 3 shows the schematic of the current excitation system.

ge

Page 4 0f 13

‘OPERATIONS Division

nginering Deparment

oO

Page § of 13

Department]

ZB turbine control & excitation systems Upgrade

Scope Of Work

2.3.1 Manual Excitation System

The old manual excitation system is still in work. Its main function is to provide a back up to the automatic

excitation system in case of CGCM failure or if required by the operator (during system maintenance and/or

testing for example).

The manual excitation system is tracking the automatic excitation system so in case of losing the automatic

excitation system, in this case the CGCM device, the manual excitation system will keep the excitation at the

last value. The transition from the automatic to the manual is 2 bumpless. The operator can control the

excitation manually after the transfer to manual mode.

2.3.2 Automatic Excitation System

The excitation systems of all units were upgraded years ago to use Allen Bradley Combined Generator Control

Module (GCM)

‘The CGCM device is connected to the turbine PLC via a Control Net. All the operations of, reading from and

writing to the CGCM devices are controlled by the turbine’s PLC vie the Control Net. Figure3 Shows how the

automatic part and the manual part are interfaced to each other, to the generator and the control system.

Both parts (manual and automatic) are supplied from a single-phase PMG.

2.4 Gas Compression Turbine Control

GT-2502 HPI unit the subject of upgrade is one of eight units for gas injection & LPG facilities at Zeit

Bay field, It is the same model of the generation set "TB-5000” but drive two stage dresser centrifugal

compressors, the turbine package has the original Rustronic control system, which control & monitoring

the turbine in addition to monitoring the parameters of compressor like vibration & temperature levels

but the surge control of compressor is not included.

3. Scope of Work

The required scope of work has three parts as described below.

Part |: Unit D Control Upgrade

Upgrade the turbine control of unit 0 will be like other units. The new control must be Allen Bradley Control

Logix based system. Other types will not be accepted. Allen bradely HMI must also be provided.

“The following points summarize the required upgrade of unit-D upgrade’

1) The required system will be similar to pervious upgraded units, as in control system components guide

in the end of the scope of work

so

Ow

Page 5 of 13

‘OPERATIONS Dion

Engineering Department

0

= | Department

2B turbine control & excitation systems Upgrade

Revisioi

Page: | Page 6 of 13

Scope Of Work ae |

2) To guarantee the continuity and technical support of system hardware, the following will be taken in

consideration :

~The newest model of processor card will be accepted.

- The communication between PLC & I\Os Flex modules through Ethernet DLR instead of ControiNet

- The ControlNet module will kept for CGCM module, any other communication topology will be

subject of approval by SUCO and Rockwell.

= Any new offered component will be subject of contractor justification and SUCO acceptance &

approval.

3) The required upgrade system will replace the chassis from 1 through 6, A through C and the DC

Contactor Cabinet.

4) PLC software will be Allen Bradley RSLogix V20, HMI software is Factory-Talk View Studio V8

5) A new vibration system using Bentley Nevada 3500 system will replace the existing old vibration

system “Rochester system’. In addition to new barriers, sensors and new wiring might if required.

6) HMI Panel from Allen Bradley with Factory Talk Site edition is required for the Human Machine

Interface Project.

7) HMI screens will have two levels authorization for operating & maintenance and will be similar to unit

A\B.

8) A replacement of the old fire and gas system, including the gas and UV detectors through LON

network. SUCO requires the updated versions of the Detronics System.

9} To replace skid equipment and wiring as required to accommodate the new control system.

10) The new system must be of the same panel architecture as of units A through C.

11) A laptop must be supplied with all software packages and the final versions of the application

programs.

12) To Supply & install the required system (materials and software).

The installation of the next part will start after successfully completing the above part with satisfactory

operating performance.

Part ll: Manual Excitation Upgrade of All Units

Upgrade the manual excitation system. The following are the main required steps;

1) Provide a new design using up to date component “Basler Electric component is recommended “.

2) Demolition of the old excitation part.

3) Installation of the new manual excitation system.

4) All old components will be replaced including panel switches , Gauges, and pushbuttons , any old

component will be kept in the new design is subject of Contractor justification and SUCO approval

5) Interface the new manual excitation component to the automatic excitation component by doing a

complete wiring of the different component.

Qn

Page 60f 13.

re Department] OPERATIONS Dion

; Ensietig Depimens

2B turbine control & excitation systems Upgrade “Taaaao. Te

Page: | Page? ofi3

Scope Of Work & z

2 a eke : a Date

6) Check the wiring before powering up the system.

7), Power up the complete excitation system to check the voltages at different points.

8) Start up the generator and control its excitation manually.

9} Test the complete operation of the unit according to the approved test procedures.

The start-up & Commissioning of Part | & Il of scope are completed after achieving the following:

~ Running GT-1001D upgraded control system is running successfully.

= Running Manual Excitation systems successfully and switch

smoothly.

= Make all necessary modifications and tuning for all turbine units “A\B\C\D” governors to unify the

droop and MW share responses.

- Tuning turbines & PMS PLCs with CGCM units to achieve the best response for MVR share.

from Auto to Manual mode

Part Ill: GT-2502HPI Control system Upgrade

The control system package will be Allen Bradley control Logix PLC based which will be

built into a new control cabinet, and include fully configured Bentley Nevada BN3500, and

completed fire & gas system.

1) To apply the same points from 1 to 12 at part | of Scope, taking into account this unit

is drive a compressors in both hardware & software

2) The distance between the control room & turbine is about 70-80 meters, so supplying

any new required cables are contractor responsibility and any civil work will done by

SUCO.

4, SUCO Obligations

1) Full accommodation and local transportation of contractor personnel from/to SUCO job site.

2) First aid medical care for contractor personnel at SUCO job site.

3) All facilities required to perform the job at site excluded special tools and equipment.

5. Contractor Obligations

1) A site visit will be conducted prior to tendering for gathering all necessary details required in

‘the modification, Contractor shall provide preliminary project and vendor drawings of the

proposed changes for company review. Company will not be liable for any inaccurate

information that Contractor may gather.

2) Allist with numbers for each of the recommended spare parts and other consumables will be

prepared.

3) The new supplied products will be on-line product for next 5 years

ose

Page 7ofis

T OPERATIONS Dision

- Department apnesng Depart

2B turbine control & excitation systems Upgrade TRaaon TO

Page: Page 8 of 13, |

Scope Of Work Saar

op Date 1

4) The validity of spare parts and technical support of the new supplied system is to be confirmed

10-15 years.

5) The contractor will be responsible to check the supplied materials on site before starting the demolition

of the old system

6) All new wirings should be numbered & color coded, and all devices will be labeled.

7) The contractor shall observe all safety rules for work, which may be issued by company.

8) The contractor will be responsible of all of site work starting from demolition of the old system,

installing of the new system, cold loop checks, hot loop checks, start up, test run, training and

ending with the hand over.

9) A project schedule must be supplied, discussed and approved by SUCO.

10) Contractor will be responsible for performing all the tests required according to FAT & SAT

procedure:

Factory Acceptance Test:

* A factory acceptance test (FAT) shall be performed according to vendor test procedures.

* Acopy of the test procedure shall be sent to SUCO for approval.

Site Acceptance Test:

* A copy for test procedure shall be sent to SUCO for approval before system delivery and

prior to commissioning the system.

The site acceptance test (SAT) shall be done after system installation, commi

based on the actual approved SAT procedure.

¢ The SAT test report shall be included in the final site report as well as in the final system

documentations.

© The final site report will include any punch list items occurred during the SAT and

jing any found defect or problem, troubleshooting any found malfunction shall be

cleared and all system setting before the system handed over.

* All inspection procedures and tests shall be witnessed by (SUCO) representatives based

‘on the agreed procedures after SUCO representative review and approve.

11) The contractor has to run the system for a suitable period as a load running test to observe

the new control system performance. peas

aX

+

joning,

Page 8 of 13

‘OPERATIONS DWsion

T Tapa

= Engine Deparment

ZB turbine control & excitation systems Upgrade Taonaon Ps

Page: _| Page 9 of13

Scope Of Work ao Paes

6. Warranty

~ Hardware warranty

The contractor will warrants the hardware for one year starting from the date of start- up and not

related to the shipment date.

- Software warranty

The contractor warrants that all software free of defects in design and workmanship

,and will perform accord to specs, and obligates to perform any necessary modification remedy

system software bugs identified during two years starting from the date of start-up

In addition to there are no security keys \passwords are set by contractor could obstacle

the maintenance and\or has any bad impact on the operating of the system without SUCO

acceptance

7. Documentation

For each phase the contractor must provide the following main documents, where applicable

1), Project Master List. This document shows a detailed list of documents to be issue by the contractor.

2) Project Schedule, Kick-Off Meeting Information, time and agenda,

3) Project Progress Report.

4) System Architecture and System Input - Output List.

5) Control Panel Outlines and Wiring Schematics,

6) Control Narrative.

7) Vibration System Description (hardware and the configuration file)

8) Logic Source Code and HMI Source Code.

9) The Communication System Description, Schematic and list.

10) FAT & SAT test Procedures and Report.

11) Final “As Commissioned” Documentations.

S

a

a

we,

Page 9 of 13

= Depart raat ng Dea

2B turbine control & excitation systems Upgrade Fao iaon | ¢ °

eee Scope Of Work Page Pageioofis |

2 Date

Appendix

- PMS System Components Guide

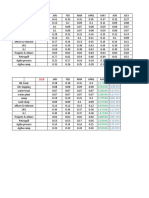

No. ~ Description Part Number

1_| Control Logix chassis 10 slots T756-A10

2 | Power supply 1756-PB72/8

3 | Control Logix Processor 5561 1756-161

4 | Dual Redundant Control Net 1756-CNBR

5 | Ethernet communication module 1756-ENBT

6 | Control Logix Digital Input 24 Vac, 16 channels 1756-1816

7 | Control Logix Digital Output 24 Vac, 16 channels 1756-OB16E

[8 | Controt Logix Analog Input, 16 channels 1756-1F16

[3 | Controt Logix Analog Output, 4 channels 1756-OF4

10 | Control Logix Analog Input, 8 channels 1756-1F8

11 | Control Logix Digital input 24 Vdc, 32 channels 1756-1832

42. | Flexi/O Communication Adapter 1794-ACNRIS

13. | Flex 1/0 Digital Input 24 Vdc, 16 channels 1794-1816

14 | Flex /0 Relay Output, 8 channels 1794-OW8

15 | Combination Generator Control Module 1407-CGeM

B. Gas turbine control system Components Guide

= Allen Bradley Control Logix PLC system.

No. Description Part Number

1 _| Control Logix chassis 7 slots 1756-87

osm

te:

Page 10 of 13

x a

| ZBturbine control & excitation systems Upgrade Fao a

Scope Of Work rege: _} Page tict

2 Power supply 1756-PB72/B

| 3 Control Logix Processor 5561 1756-L61

[a | Duat Redundant Control Net 1756-CNBR

5 Ethernet communication module 1756-ENBT

[6 | CFM frequency input module 1756-07

7 Flex |/O Analogue input 8 channels ‘1794-1E8

& [Thermocouple input 8 channels 1794-118

| RTDinput 8 channels 1790-188

10 | Isolated analogue output 1794-OF4L

11 | 24 Vdc Input 32 channels 1794-1832

12. | 24 Vde Output 32 channels 1794-0832 |

13 | XM-220 Dual speed module 1440-SPD02-01RB |

}

- Bentley Nevada vibration system.

No ‘Description Part Number

1 Rack 8 Slots

2 | Low voltage DC power supply 3500/15-04-00-01

3 Rack interface module 3500/20-01-02-01

4 Prox./seismic 4 channels 3500/42M-06-01

5 4 Channels relay module 3500/32-01-01

[| Communication gateway module 3500/92-04-01-01

7 | Internal barrier earthing module 2500/08

Qo

Page 11 of 13

]

Se

DBERATIONS Dison

Department|

iss Engineering SEpariment

ZB turbine control & excitation systems Upgrade

so

Scope Of Work

Page 32 of 13,

= Detronics fire and gas system.

Wo. Description Part Number

1 | EQ3001DCNW controller, DIN mount (007609-063

2 | €03730PW EDIO Module, Panel mount (009174-002

3 | EQ3700PW DCIO Module, Panel mount (007371-002

| Transmitter for 4-20 mA gas detector (006607-017

£022530CU standard digital communication unit

5 | Four UV detectors” Detronie multi-spectrum

infra-red UV"

© | Two gas sensors ” Det-ronic infra-red gas detector”

~The component of the panel.

No. Description Manufacturer | Part Number

1 | HMIPC (AB 1500P) ‘Allen Bradley | 6181P-15TSXP

2 _| Selector switches Allen Bradley |

3 _| Push buttons ‘Allen Bradley al

@ | Emergency stop push button (with guard) _| Allen Bradley

5 | Audible alarm ‘Allen Bradley

© _ | Digital indicators for PTE GG speed Yokogawa

7 | Ethernet Hub— 6 port N-TRON

3 _| Digital output interposing relay Phoenix

9 | Zener Barriers MTL

Sat

Te"!

Page 12 of 13

28 turbine control & excitation systems Upgrade

]

| Scope Of Work

8. Price Table

1. The Offer will be based on Lump Sum Basis.

2. The bidder to fil

commercial offer sealed envelope.

| Department]

‘OPERATIONS Dison

Engineering Depar MB

Revision: | 0

Page: Page 13 of 13

Date

the following table of prices and to be submitted only in the

Trem Description

Price

rer

T001D Control system Upgrade and

1 | Manual Excitation replacement

GT-2502HPI Control system Upgrade

Total

we

Page 13 of 13

OPERATIONS Dison

= Deparonen =

‘ater est

2B turbine control & excitation systems Upgrade govicion: | 0

[rage: | Page 13 of

Scope Of Work ne

8. Price Table:

1. The Offer will be based on Lump Sum Basis.

2. The bidder to fill in the following table of prices and to be submitted only in the

commercial offer sealed envelope.

Ttem Description Price

GT-1001D Control system Upgrade and

1 | Manual Excitation replacement

GT-2502HPT Control system Upgrade

Total

Page 13 of 13

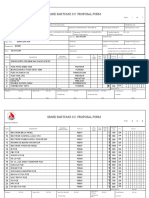

SUES OL COMPANY

Te S340

EAN 33038434 +3346

CH 198991

eg, NO : 1070001268

46792

oer

Tender Requisition

‘isthe. is eased t0 cover the cost of Power Generators Control Panels Vzrade

REQ. Date

30972022,

Ser, MESC DESCRIPTION Plant ay. fesm] unr Prorat

REQ price [VALLES

fi Povwsr Generators Control Panel Uae Zeit Bay fi ‘AU_| 200000.00 | 200000 00

Serial Service Deseription WBS / Cost Center ary [ory] Service | Curr

twit | Price

10 | Porner Generators Control Panels upgrale pause. 06.20 100 | av [2000000] usp

[ “Total Value 200000,00 LSD.

assed dine of ora

Fila Diekin ] CNRODNISON | FamserDanie | wns] MATERIALS FeRCINSNG

Divistox

Requester ‘Cou Acswum ED | Badgerconmt | When Applicable | Coding DEFT Paras Mer

Pity ata me

oa — ‘tats ty |) 2| omalitange | Do Teer

Ew Ae Om

n

fa | ies bee

Dee

TSOFORSINO: | Dining Ge ee Sp pe PONS

warsratanoa | peg Ort whe “ ayer

r)

Suez ou conpany

PO, BOX 2522CA1RO ARE

Tet 3M66a77.33460023

ia7sas-s3asso09

FAX 003604 3460971

Tender Requisition

Rog. NO : 1070001262 REQ Date: 15/09/2022

{his Reg. is Raised to Cover the Cost of GT-1001D Contrl Stem Upgrade

Sen] MESC DESCRIPTION Plant an. Jes] ex | torar

REQ sice |vauves

t {G-1001D Cont sestem upgrade Zeit Bay 1 ati | gon00n 00 ona 00

Seriat Service Deseription WBS / Cost Center cary [ary] Service | Curr.

Unit | Price

ie 1001 Contra stem apes DAIS. 06.15| 100 Tau [ooonooe [esp

Tol V ‘qo0n.00 CS

wwojeat fochaimen append

Fad Divsien | CAIRODINISION | Finance Divhion MDs MATERIALS PURCHASING

a DIVISION

Tae Guacwns COLT alga Crmd | When Apptcabts | Coding beri. | Porc er

at bas

Daren Deparment send 26/9]p2 | Comat Nimes | Dae Texter

oe bat

Con nes Gon Mar PPPS tek Lng SwckCommat | Fign

Ke Ease Pate

Ta OR on iD HANAN Dat lal

a

TSOFORMNG: | Dion Gu Ne | F wel PON

MATETA.NO1018 ae Bue

ait [22

* PO BUX 262.CAIROARE

TEA S34677-34467022-33479080

SMTRISSMOS0

AN 33035434 334

CR: 198891 Cairo

Rea. NO + 1070001832,

This Requsition is raised for HP 1 Gi

Tender Requisition

502 Control System Upgrade

REQ. Date: 19/10/2022

Ser. MESC DESCRIPTION Plant ary. [ox] unr [tora

REQ PRICE_| VALUES

1 LHP 1 FT=2502 Control system Lpgrade Zeit Bay 1 AUT scuonn 00 [sono00.00

Serial Service Description WBS / Cost Center ary [ary] service | Curr.

Unit | Price

io 502 Conical System upgrade D.073-01,06-40 100 [av [sooo [uso

“Total Value 500000,00 USD

silaye uk Fechadimas af PO

Field Divison MDS MATERIALS PURCHASING

DIVISION

Roweser Com proomt When Applicable [Colin DPE. | Poche Mer.

bafta tas Fine Date

Deponee Peer Geral Ra ea Dav Tender

i lol 2» Do

Cont Ase ‘Gon Mer er THR a ‘Sek Control Fors

Uhre | Qs Date

Tiel MGR oa FD ini | Da Leal

We Dus

180 FORM NO: Fl Bo darnahs PON

MATA=74.1401-018, Hiine, [26/401 2022 Bee

pote

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Battery Charger SOWDocument4 pagesBattery Charger SOWzakalyNo ratings yet

- 6 - OMX37013 - Block Diagrams RTBDocument17 pages6 - OMX37013 - Block Diagrams RTBzakalyNo ratings yet

- CT7N Bimetallic OverloadsDocument1 pageCT7N Bimetallic OverloadszakalyNo ratings yet

- Quote Suez Oil Apr 30 rfq2Document2 pagesQuote Suez Oil Apr 30 rfq2zakalyNo ratings yet

- CA7 Contactors 3Document2 pagesCA7 Contactors 3zakalyNo ratings yet

- CA7 Contactors AccessoriesDocument2 pagesCA7 Contactors AccessorieszakalyNo ratings yet

- Programmable High Frequency Charger: OWM-CBC-261006Document19 pagesProgrammable High Frequency Charger: OWM-CBC-261006zakalyNo ratings yet

- GPL + GLU ManualDocument58 pagesGPL + GLU ManualzakalyNo ratings yet

- Courses ObjectivesDocument33 pagesCourses ObjectiveszakalyNo ratings yet

- SPH Io en 0514 HR Protected.Document4 pagesSPH Io en 0514 HR Protected.zakalyNo ratings yet

- SPH NicdDocument7 pagesSPH NicdzakalyNo ratings yet

- 04 Day #2 - WorkShop 02 Energy Intensity SheetDocument2 pages04 Day #2 - WorkShop 02 Energy Intensity SheetzakalyNo ratings yet

- Book1 - Power ConsumptionDocument2 pagesBook1 - Power ConsumptionzakalyNo ratings yet

- Book1 - POWER CONSUMPTIONDocument2 pagesBook1 - POWER CONSUMPTIONzakalyNo ratings yet

- E-12 Maint & Material AdminDocument46 pagesE-12 Maint & Material AdminzakalyNo ratings yet

- E-1 Safety - Aug 2011Document31 pagesE-1 Safety - Aug 2011zakalyNo ratings yet

- Jcb193080 Parallel DC Ups 100vdc 50aDocument10 pagesJcb193080 Parallel DC Ups 100vdc 50azakalyNo ratings yet

- Basic Concept of GeneratorsDocument120 pagesBasic Concept of GeneratorszakalyNo ratings yet

- DC Dual Battery Chargers SOWDocument1 pageDC Dual Battery Chargers SOWzakalyNo ratings yet

- Air Strip GeneratorDocument1 pageAir Strip GeneratorzakalyNo ratings yet

- Gas Pant Ups ProposalDocument3 pagesGas Pant Ups ProposalzakalyNo ratings yet

- Spare Part List Modified StampedDocument1 pageSpare Part List Modified StampedzakalyNo ratings yet

- Cairo HSEQ P 15 PDFDocument5 pagesCairo HSEQ P 15 PDFzakalyNo ratings yet

- Spare Part List Modified Stamped - 2Document1 pageSpare Part List Modified Stamped - 2zakalyNo ratings yet

- Gas Pant Ups ProposalDocument3 pagesGas Pant Ups ProposalzakalyNo ratings yet

- Cairo HSEQ P 11 PDFDocument11 pagesCairo HSEQ P 11 PDFzakalyNo ratings yet

- الاستجابة التردديه للنظمDocument20 pagesالاستجابة التردديه للنظمzakalyNo ratings yet

- Overhead Transmission Line INSULATORSDocument4 pagesOverhead Transmission Line INSULATORSzakalyNo ratings yet

- Procedure For Issue of Work Permits: Suez Oil CompanyDocument30 pagesProcedure For Issue of Work Permits: Suez Oil CompanyzakalyNo ratings yet

- Cairo HSEQ P 09 PDFDocument14 pagesCairo HSEQ P 09 PDFzakalyNo ratings yet