Professional Documents

Culture Documents

E-12 Maint & Material Admin

Uploaded by

zakalyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

E-12 Maint & Material Admin

Uploaded by

zakalyCopyright:

Available Formats

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

MAINTENANCE & MATERIAL

ADMINISTRATION

MODULE E-12

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 1

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

Tasks:

E-12.1 Demonstrate understanding of the requirements of the MWI and raising a MIV

(material issue voucher).

E-12.2 Demonstrate utilisation of appropriate engineering and Manufacturer’s

documentation.

E-12.3 Identify the equipment needed for the job.

E-12.4 Identify spares and materials required for the job.

E-12.5 Identify and select the qualified staff for the job

E-12.6 Demonstrate maintaining of records and logbooks.

E-12.7 Receiving Materials

E-12.8 Demonstrate raising a material requisition, an AFE and write-off form.

E-12.9 Demonstrate raising a Material Cargo Manifest

E-12.10 Demonstrate raising and closing of MWI’s.

E-12.11 Demonstrate input and retrieving of equipment data.

E-12.12 Demonstrate verification of material availability through Material stock

management system.

E-12.13 Liaise work requirements with other sections and contractors.

E-12.14 Demonstrate writing of a job summary report.

E-12.15 Demonstrate verbal summary reports to the supervisor.

E-12.16 Demonstrate completing a stock proposal forE- spare parts.

E-12.17 Demonstrate completing a material return voucher.

E-12.18 Demonstrate logging and recording of equipment historical data.

E-12.20 Check, co- ordinate and follow- up on spare parts ordered.

E-12.21 Locate required spare parts from Electronic Material Administration list, identify

by part number.

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 2

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

MODULE No.: E-12, Maintenance Control and Material Administration

TASK No.: E-12.1 Demonstrate understanding of the requirements

of the MWI and raise the required paperwork.

Reference: Refer to attached

Requirements By Trainee:

Trainee should understand the requirements of the maintenance work instructions.

MWI means ‘Maintenance Work Instruction’ all planned jobs i.e., monthly service, 6

monthly, 12 monthly, etc. have the detailed work written on a sheet of paper for the

particular type of job.

This MWI has to be attached to the work order and should be in the possession of

permit holder who will execute the job. He has to see that all points in the MWI have

been covered. All work done has to be written in the work order form, where space

for the same is given. It should be returned to the supervisor after filling in.

There are two types of Workorders, Planned Maintenance Workorders which are

periodically generated by the Electronic Maintenance Management System called

`GMS´ or Unplanned Workorders to rectify breakdowns or malfunctions etc., these

can be generated by other departments such as for instance Production or PED and

others. See attached examples.

Example of a MWI for equip. Two Yearly Maintenance of Crude oil storage tank

mixer motors.

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 3

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

Task No. E-12.1 Continued

Maintenance Work Instruction for Planned Maintenance Example

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 4

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

Task No. E-12.1 Continued

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 5

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

Task No. E-12.1 Continued

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 6

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

Task No. E-12.1 Continued

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 7

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

Task No. E-12.1 Continued

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 8

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

Task No. E-12.1 Continued.

Work request for Unplanned Maintenance

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 9

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

Task No. E-12.1 Continued

Example of executing a Maintenance work instruction.

A. Raise the required Permits to Work as described in Module E-1

B. Prepare the correct tools for the job

C. Obtain the required material from the store via MIV or PO

D. Raise a special permit if material has to be transported outside ZB

E. Inform production supervisor about works to be carried out.

Requirements By Trainee:

Trainee to be capable of completing this task clearly and correctly.

A material issue voucher or MIV is issued to procure any item from the warehouse

that is listed in the store inventory and has a MESC Number (Material equipment

standard code).

Trainee should understand the form of material issue voucher, and how to fill and

sign.

Material issue voucher to be completed with account No, Date, material

description, quantity issued, MESC, balance, receiving and approval.

Inspect the received material, and check for specifications and quantity. Accept

and sign the material issue voucher.

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 10

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

Task No. E-12.1 Continued

Task Detail. MATERIAL ISSUE VOUCHER

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 11

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

Task No. E-12.1 Continued

FORM TO TRANSPORT EQUIPMENT/TOOLS/PARTS OUTSIDE ZB

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 12

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

MODULE No.: E-12 Maintenance Control and Material Administration

TASK No.: E-12.2 Demonstrate utilization of appropriate engineering

and manufacturer’s documentation.

Reference: Vendor manuals

Requirements By Trainee:

Trainee should understand the use of the appropriate documentation.

After going through the MWI if still doubt, refer to the manufacturer manual where

the engineering drawing and detailed work instructors are given. These assist you

further in doing a job properly and safely. The cut sectional drawings help in

identifying the different parts, method and direction of dismantling. The

manufacturer documentation helps you in the step by step dismantling & assembling

procedure. It also the various clearance and tolerance that have to be maintained are

given.

Always refer to the manufacturer manual before you start a job for the first time or

you are not familiar with.

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 13

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

MODULE No.: E-12 Maintenance Control and Material Administration

TASK No.: E-12.3 Identify the equipment needed for the job.

Reference: Job on hand

Requirements By Trainee:

Trainee should understand the work and the equipment needed to do the work

You have to describe in detail the tools and equipment needed for a particular job.

For example you have to carry out a repair of a 3.3 KV cable.

Now let us list what tools and equipment are needed (Example):

1. Cable Joint Kit (2 X) suitable for cable size

2. Armored CU cable as the same size not less than 30 meter

3. Hot air gun

4. Hydraulic cutter

5. Hydraulic press

6. Megger tester 5000 V

Similarly a different job will need different tools and equipment. Let us see what

tools are needed for the overhaul of an electric motor.

1. Spanners (Open & Socket type)

2. Ratchet spanner

3. Pullers (2 legs or 3 legs)

4) Bearings, heaters (Induction heaters & oil bath)

5) AVO Electrical Testing

6) Pliers

7) Greases

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 14

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

MODULE No: E-12 Maintenance Control and Material Administration.

TASK No.: E-12.4 Identify spares and materials required for the job.

Reference: Vendor manual

Requirements By Trainee:

Trainee to identify spares by part number, machine type.

Identify equipment required to remove the motor.

Before starting the job make a rough estimate of the spares and material needed for a

particular job. Check in the warehouse if these are available. If they are available than

only proceed with the job.

Let us see for example what equipmen/spares may be needed for an electric motor

overhaul:

Equipment

1. Crane

2. Chain blocks

3. Slings

4. Spanners (Open & Socket type)

5. Ratchet spanner

Spares/consumables

1) Greases

2) Bearings

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 15

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

MODULE No.: E-12 Maintenance Control and Material Administration

TASK No.: E-12.5 Identify and select the qualified staff for the job

Reference:

Requirements By Trainee:

Trainee to discuss with his Mentor.

Every job is not the same, it may need less experienced Technician/Engineer for

small jobs and experienced Technician/Engineer for major jobs. This requires a

certain amount of experience to judge the people working for you so that their

competencies are known to you.

Small routine jobs can be given to technicians but major jobs, troubleshooting should

be given to Senior Technician/Engineers in this way you balance your manpower

according to the job availability.

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 16

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

MODULE No.: E-12 Maintenance Control and Material Administration

TASK No.: E-12.6 Demonstrate maintaining of records and logbooks.

Reference: Refer to attached.

SUCO procedures

Requirements By Trainee:

Trainee should understand SUCO procedures for completing this task.

When you have completed the job, all details pertaining to the job have to be

recorded for future reference there are different means of recording 1. Logbook for

daily work 2 equip. Data sheet for each equipment 3 work order details of the job

done has to be recorded in the space provided, this is stored in the ‘GMS’ system in

the computer. These can be referred to when job history of particular equipment is

needed.

Time sheets of 3rd Parties

When work is executed by 3rd parties’ time sheets must be completed reflecting

the duration of the work on site.

There are 2 types on time sheets in use, namely one for local Contractors and one

for foreign Contractors.

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 17

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

Task No. E-12.6 Continued

Time sheet for 3rd Party Local Contractors

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 18

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

Task No. E-12.6 Continued

Time sheet for 3rd Party Foreign Contractors

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 19

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

MODULE No.: E-12, Maintenance Control and Material Administration

TASK No.: E-12.7 Receiving Material

Reference: Vendor manuals

SUCO procedures

Requirements By Trainee:

Trainee should understand the task.

Trainee must know the relevant forms in use by the Material Department to

receive ordered material.

The following forms are relevant to Maintenance Department when receiving

Material from the Material Department

1) Material Purchase order

2) Material Receiving Report

3) Receiving advice

4) Material Discrepancy Report

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 20

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 21

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

Task No. E-12.7 Continued

Receiving advice form used to advice that one or more spare parts are sent incorrectly

by the supplier via one or more purchase order related to our raised requisition. For

instance when the part numbers or properties differ from the spares we ordered.

Depending on this technical advice material sector will raise the material discrepancy

to the supplier preparing to send these spares back or to replace it with the suitable

spares.

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 22

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

Task No. E-12.7 Continued

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 23

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

Task No. E-12.7 Continued

Below is an example of a purchase order and material receiving report forms. These

forms which are produced by the Material department give all required information

about the materials ordered via the requisition(s) and the accepted offer(s), like part

numbers, quantity, price, requisition number, supplier, delivery date, …….etc.

Review the listed material in the material receiving report and compare it with the

material you actually receive. If you find everything is correct and identical you can

sign for acceptance. The materials can then be transported from the warehouse to the

workshop spares container.

Prepare a list for the missing materials that you ordered and were not sent via the

purchase order. If there are no missing materials you will then be able to prepare to

commence the job or expedite vendor arrival (If required).

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 24

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

Task No. E-12.7 Continued

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 25

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

MODULE No.: E-12, Maintenance Control and Material Administration.

TASK No.: E-12.8 Demonstrate raising a material requisition, an AFE

and a Write Off Form.

Reference: Refer to forms attached.

Requirements By Trainee:

Trainee to understand and perform the task to SUCO procedures.

A material requisition is also known as ‘MR.’ for short. It is used for ordering

equipment or items which are not kept as stock items. These items are called “Direct

Charge Items”. Direct charge items are used for instance for the overhaul of Turbines

and Compressors.

The MR. has to be filled and send to field cost account, there it will be checked

against available budget and send to O-40 (Operation Cost Control). From O-40 it

will be send to Material department after the approval of O-1 and O-1D has been

obtained.

The MR must contain all required information to purchase the material i.e.,

Manufacturers address, price, equipment detail, purpose required for, required on site

date, required quantity, description etc.

Note: A Requisition is Not only used for ordering material but can also be used to get

services or repair jobs.

If a MR is raised for Capital Items (fixed assets) then an AFE form Authority for

Expenditure has to be attached to the MR. This AFE form must include a valid

justification to explain why we need a new equipment or why we need to replace the

aged/out of service equipment (in the latter case you are also required to provide the

write off form for equipment needing replacement).

Capital requisition may be raised to cover high price overhauls that depend on

materials and vendor rep cost for example Turbines and Ajax compressors overhauls.

Note: Do not forget to put a cross in capital budget box that found in requisition form.

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 26

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

Task No. E-12.8 Continued

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 27

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

Task No. E-12.8 Continued

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 28

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

Task No. E-12.8 Continued

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 29

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

Task No. E-12.8 Continued

Material and services can also be arranged via a WO (Work Order). The limitation of

the Work Order is that its value may not exceed LE 1000. It is primarily used to

purchase small items on the local market or to cover services / repair jobs that can’t

be performed by ZB maintenance staff and can be found in the local market

workshops.

Note: W.O. used to purchase items from the local market with a max value of

LE 1000 has to be filled and sent to ware house for approval to ensure that the

items are not available in stock prior to going to the local market.

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 30

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

MODULE No.: E-12, Maintenance Control and Material Administration

TASK No.: E-12.9 Demonstrate raising a Material Cargo Manifest.

Reference: Refer to forms attached.

SUCO procedures

Requirements By Trainee:

Trainee should understand the requirement for a Material Cargo Manifest

You have to describe in detail when a Material Cargo Manifest is required and

complete the form.

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 31

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

Task No. E-12.9 Continued

A Material Cargo Manifest form is used when we need to send any equipment or any

piece of equipment outside the company site for repair or any other purpose.

For example: motors rewinding, crankshaft refurbishment and fans/rotors shafts

rebalancing…..etc.

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 32

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

MODULE No.: E-12, Maintenance Control and Material Administration

TASK No.: E-12.10 Demonstrate raising and closing of MWIs, work

order including man-hours spent.

Reference: Technical training program

Mentor

Planner

Requirements By Trainee:

Trainee to become proficient in computer skills, with assistance from the Mentor

trainer and planner.

Trainee to understand SUCO procedures.

Demonstrate raising and closing of work order (including man-hour spent).

First you will have to fill form starting the job to be carried out, equipment. No. Item

description, type of job area code, priority, job from dept ‘A’ to dept ‘B’.

Hand over this form to the planner who will then prepare a work order which will

than have to be signed by the section head.

After completion of job the work order has to be filled in.

1. Man hours: The top right side of the no is for the hours to be filled by each

dept. Like mech., elect, inst., others, and travel time.

Multiply the numbers of personnel on the job with the time taken

from start to finish for the job. Than add the travel time. This gives

you the total time or total man hours.

2. Report details of work done and history comments below: All the work carried

out for that particular job should be mentioned in details including

clearances measured and spare parts used.

3. Work completion: Name of person leading the job, start date & time. Sech. Head

signature.

4. Defect analysis: Type of defect. What is the cause for defect and action taken.

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 33

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

MODULE No.: E-12, Maintenance Control and Material Administration

TASK No.: E-12.11 Demonstrate input and retrieving of

equipment data.

Reference: Technical training program

Mentor

Planner

Requirements By Trainee:

Trainee to study and perform the task with assistance from the Mentor and

planner.

Trainee to follow SUCO procedures.

Mentor to assign a sample maintenance work (work should be familiar to trainee).

Trainee assisted by planner will retrieve from computer system.

a) Work order for the sample work.

b) MWI for sample work.

Trainee will write job summary report on sample work order (trainee to use his

past experience to provide details of work). And close the same.

Trainee will update data, on bases of the sample work order, (data to include

requirements of comac/ empower computer maintenance system.

Trainee to demonstrate ability to conduct Material Management System search.

a) Part by description.

b) Part by part no.

c) Part by mesc no.

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 34

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

MODULE No.: E-12, Maintenance Control and Material Administration

TASK No.: E-12.12 Demonstrate verification of material availability

through MMS, (Material Management System).

Reference: Technical training program

Mentor

Planner

Requirements By Trainee:

Trainee to study and perform the task with assistance from the MENTOR trainer

and planner.

Trainee to follow SUCO procedures.

MMS is a network system connecting central store with almost all of the field

computers of assigned section heads.

MMS system organize, up data and make the necessary balance situation of all

spare parts used in the fields, through which you can verify the availability of

certain part no. Spare part, its current stoke and its MESC no.

So to get mesc. No. Of any item, get the part No. From machine catalogue then

give the No. To your section head to get MESC No. Then you can raise MIV to get

the needed part from store.

Keep the stock balance for the spare parts between min. and max. Levels.

Make material requisition to adopt the balance.

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 35

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

MODULE No.: E-12, Maintenance Control and Material Administration.

TASK No.: E-12.13 Liaise work requirements with other sections and

contractors.

Reference:

Requirements By Trainee:

Trainee to inform Mentor and planner.

Trainee should understand why this helps in safely and efficiently performing the

work.

For proper planing and safe working atmosphere you have to know which

department is involved with you in the job for example may be electrical dept is

doing a job for a motor of the same equipment you are doing PM for it (pump,

mixer, etc).

Proper Co-operation is needed especially when the job started or near to be

completed to ensure safe maintenance job done.

Another example if you need to excavate a trench you will need help from civil

dept as well as a certification from others department to avoid damaging any

buried cable or piping or drainage systems.

So liaising and Co-operation is necessary of safe working.

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 36

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

MODULE No.: E-12, Maintenance Control and Material Administration.

TASK No.: E-12.14 Demonstrate writing of a job summary report.

Reference: None

Requirements by Trainee:

Trainee to report in his task diary, and approved by Mentor trainer.

Trainee to write clearly and concisely to ensure other people reading this

information have a complete understanding of the task.

To write technical report it should contain the following items.

Date : write report date.

To : write name of person you are raising report to and this position

From : write your name and your position.

Subject: write name or title of subject you need to report keep in mind it should be in

one line only.

Start by giving brief description about the subject.

Give details of action taken.

Give conclusion of report and your comment.

Any recommendation.

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 37

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

MODULE No.: E-12, Maintenance Control and Material Administration

TASK No.: E-12.15 Demonstrate verbal summary reports to the

supervisor.

Reference: Mentor trainer

SUCO procedures

Requirements By Trainee:

Mentor to communicate with the trainee, to ensure that all task summary reports

are clear, concise and understood.

Mentor trainer to ask trainee to repeat the information in his own words, this

ensure understanding.

Mentor to assign a sample task and ask trainee to write verbal summary report for

the sample job.

The report should include details like parts requirement, tools requirement,

procedures followed, checks and inspections carried out safety measures and

problems faced, the trainee should indicate the current status of the job.

He should identify the problems occurred on carrying out the job, and say reasons

and solution.

He should assure that the safety precaution has been followed.

Also, after the equipment repaired, delivered to operation, closed work permit and

work order.

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 38

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

MODULE NO.: E-12, Maintenance Control and Material Administration

TASK NO. : E-12.16 Demonstrate completing a stock proposal form-

spare parts.

Reference: - SUCO, Material Control.

Materials: - Stock proposal form.

Equipment & Tools: - None

Conditions: - None

Requirement – By Trainees:

Trainee should understand the stock proposal form.

Stock control at the warehouse will issue this form to balance the stock.

This from will be signed and issued by the material control.

The stock balance should be updated when minimum stock level is reached

automatically.

Stock proposal form including material part no. MESC, quantity, date, and

receiving date.

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 39

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

Task No. E-12.16 Continued

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 40

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

MODULE NO. : E-12 Maintenance Control and Material Administration

TASK NO. : E-12.17 - Demonstrate completing a material return voucher.

Reference: - SUCO, Material Control.

Materials: - None

Equipment & Tools: - None

Conditions: -None

Requirement – By Trainees:

Trainee should understand the form of material return voucher.

This form will be issued in case of materials returned.

The material is returned to the ware house if the material has not been used, for

instance when parts are withdrawn from stock and not used, or when spare parts

are repaired after use and returned to the ware house in which case they are

registered as condition “B”.

He will sign the material return voucher to the material control.

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 41

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

Task No. E-12.17 Continued

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 42

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

MODULE NO. : E-12 Maintenance Control and Material Administration

TASK NO. : E-12.18 - Demonstrate logging and recording of equipment

historical data.

Reference: - SUCO, Material Control.

Materials: - None

Equipment & Tools: - None

Conditions: -None

Requirement – By Trainees:

Trainee should understand the task and perform it himself.

He should prepare a log sheet for every machine recording tag No. machine name,

serial No. location, lube oil and grease types and spare parts consumed.

He should record the date of material and spare parts consumed and quantity in

the log sheet.

The log sheet will be used to check whether material consumption is normal, and

analyze the machine problem.

To compare the rate of consumption with similar machine, define causes and

modify.

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 43

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

MODULE NO. : E-12 Maintenance Control and Material Administration

TASK NO. : E-12.19 - Attend a site-planning meeting..

Reference: - SUCO, Material Control.

Materials: - None

Equipment & Tools: - None

Conditions: -None

Requirement – By Trainees:

Trainee should understand the task and perform it.

The meeting room, the subject of meeting: material control planning.

He will discuss consumption of spare parts, minimum and maximum stock, stock

control and budget.

He will listen to any question from the attendees and answer carefully.

Draw the curve of machine failure against calendar days to show failure frequency

and spare parts consumption. Analyses the problem and how to correct.

The priority of the machine, the maintenance time and economical study should

be. Reviewed.

Any modifications and suggestions to be discussed.

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 44

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

MODULE NO. : E-12 Maintenance Control and Material Administration

TASK NO. : E-12.20 - Check, co- ordinate and follow- up on spare parts

ordered.

Reference: - SUCO, Material Control.

Materials: - None

Equipment & Tools: - None

Conditions: -None

Trainee should understand the task and perform it.

He should make communication with purchasing department and stock control.

On receiving spare parts, inspect for acceptance using Material Receiving advice

(MRA) and Material receiving Report (MRR). If some spares are not accepted,

issue a material return discrepancy report (MDR).

He should inform his section head when materials are not accepted.

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 45

SUCO PETROLEUM COMPANY TASK DETAILING MANUAL

MODULE NO. : E-12 Maintenance Control and Material Administration

TASK NO. : E-12.21 - Locate required spare parts from Electronic Material

Administration list, identify by part number.

Reference: - SUCO, Material Control.

Materials: - None

Equipment & Tools: - None

Conditions: -None

- Trainee should understand the task and perform it.

- On ordering spare parts, he should have the following:

1. Vendor name, addresses and fax.

2. Machine name, tag No. Serial No. and location.

3. Spare parts drawing No., and No. of each one on the drawing.

4. Part number and /or misc. No.

5. No. of ordered parts or sets.

6. Minimum and maximum stock.

O-74 MODULE – E-12 (Rev.0) March 2012 Page - 46

You might also like

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsFrom EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsRating: 5 out of 5 stars5/5 (5)

- Manual Electronically Controlled Transmission Caterpillar H Series Motor GradersDocument48 pagesManual Electronically Controlled Transmission Caterpillar H Series Motor GradersGanapati Hegde94% (32)

- Basic Concept of GeneratorsDocument120 pagesBasic Concept of GeneratorszakalyNo ratings yet

- CSS - 9 - Written Assessment With Tos & BetaDocument8 pagesCSS - 9 - Written Assessment With Tos & BetaJevan Hope BaltazarNo ratings yet

- SIPOC Process ImprovementDocument32 pagesSIPOC Process Improvementmaxbrad0No ratings yet

- AURTTK102 Student Assessment - TheoryDocument9 pagesAURTTK102 Student Assessment - TheoryDeymon Alejandro Pinzon NaranjoNo ratings yet

- Compressor Manual PDFDocument90 pagesCompressor Manual PDFNiramai Werawut50% (2)

- M06Testing & Const.L& SDocument126 pagesM06Testing & Const.L& SgmnatigizawNo ratings yet

- Electrical Method Statement GN 8Document5 pagesElectrical Method Statement GN 8Chandree BoonzaaierNo ratings yet

- Modular Procedural AutomationDocument24 pagesModular Procedural Automationsahil4INDNo ratings yet

- TOOLKIT For MPDS-UpdatedMarch11Document13 pagesTOOLKIT For MPDS-UpdatedMarch11Tamsin VenterNo ratings yet

- Up and Running with Autodesk Inventor Simulation 2011: A Step-by-Step Guide to Engineering Design SolutionsFrom EverandUp and Running with Autodesk Inventor Simulation 2011: A Step-by-Step Guide to Engineering Design SolutionsNo ratings yet

- Internship Report - Fauji Fertilizer Company (FFC)Document49 pagesInternship Report - Fauji Fertilizer Company (FFC)Muhammad Aqeel Ashraf75% (8)

- Fabrication Presentation Slide by FahmiDocument82 pagesFabrication Presentation Slide by FahmiSharifah HafidhaNo ratings yet

- CDU II Operating ManualDocument562 pagesCDU II Operating ManualRajeshwar Telang91% (11)

- Transformer Testing ProceduresDocument13 pagesTransformer Testing ProceduresVENKATESAN R100% (7)

- Pump AssignmentDocument5 pagesPump AssignmentFikri RahimNo ratings yet

- Slides Plant Description (From PFD & P&IDs) E.HDocument47 pagesSlides Plant Description (From PFD & P&IDs) E.HRobert Waters100% (1)

- ESCL-SOP-016, Work Instruction For WorkShop OperatorsDocument5 pagesESCL-SOP-016, Work Instruction For WorkShop OperatorsadiqualityconsultNo ratings yet

- Sector:: Automotive/Land Transport SectorDocument20 pagesSector:: Automotive/Land Transport SectorVedin Padilla Pedroso92% (12)

- Static Equipment InstallationDocument21 pagesStatic Equipment Installationnike_y2k100% (1)

- Manual Motor Diesel 1135386, 1135389, 1135411, 1135412, 1135413, 1135414, 1135415, 1135416 - 2Document316 pagesManual Motor Diesel 1135386, 1135389, 1135411, 1135412, 1135413, 1135414, 1135415, 1135416 - 2Lasse HansenNo ratings yet

- Assistant Driller Module Trainee BookletDocument102 pagesAssistant Driller Module Trainee BookletJonathan50% (6)

- LITERATURE REVIEW: FAKTOR YANG MEMPENGARUHI PENERIMAAN OPINI GOING CONCERNDocument17 pagesLITERATURE REVIEW: FAKTOR YANG MEMPENGARUHI PENERIMAAN OPINI GOING CONCERNSuci OktamirzaNo ratings yet

- 08 FS EtpDocument18 pages08 FS EtpKatamaneni KoteswararaoNo ratings yet

- Man PDFDocument37 pagesMan PDFvamsiarangi100% (1)

- Successful Instrumentation and Control Systems Design, Second EditionFrom EverandSuccessful Instrumentation and Control Systems Design, Second EditionRating: 4.5 out of 5 stars4.5/5 (10)

- Leather Industry of BDDocument30 pagesLeather Industry of BDsams zeesha100% (1)

- Tanabe Main Air Compressor ManualDocument103 pagesTanabe Main Air Compressor Manualmy printNo ratings yet

- CTS Central AC Plant Mech. - CTS - NSQF-5Document62 pagesCTS Central AC Plant Mech. - CTS - NSQF-5Syed tahirNo ratings yet

- Hydraulics Advanced Level: Workbook TP 502Document44 pagesHydraulics Advanced Level: Workbook TP 502Jyotirmoy BarmanNo ratings yet

- Revised Standard Grade Pneumatic SystemsDocument91 pagesRevised Standard Grade Pneumatic SystemsHafiezul Hassan0% (1)

- Bomba CPKDocument20 pagesBomba CPKPatricio Andres Silva SanzanaNo ratings yet

- Project1 Part1Document1 pageProject1 Part1Yousef AlmomenNo ratings yet

- Basics of Mechanical Engineering Course CodeDocument13 pagesBasics of Mechanical Engineering Course CodeVipul SolankiNo ratings yet

- Automobile Professional Practice-1Document11 pagesAutomobile Professional Practice-1vanjarvijay7No ratings yet

- Algeria in Amenas Project: Rotating Equipment Job PlanDocument2 pagesAlgeria in Amenas Project: Rotating Equipment Job PlanKama Bena BenarousNo ratings yet

- Aut 116-05 8wk Revised 1-11 FinalDocument13 pagesAut 116-05 8wk Revised 1-11 FinalJsy LangNo ratings yet

- TOOLKIT For MPDS-August12 PDFDocument13 pagesTOOLKIT For MPDS-August12 PDFdjtj89No ratings yet

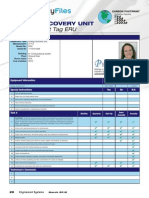

- TITLE Energy Recovery Unit Maintenance ChecklistDocument1 pageTITLE Energy Recovery Unit Maintenance ChecklistsajuhereNo ratings yet

- 63H34E05Document24 pages63H34E05Lo Shun Fat100% (1)

- UntitledDocument36 pagesUntitledJan Bryan EslavaNo ratings yet

- Lean Manufacturin and Six SegmaDocument9 pagesLean Manufacturin and Six Segmashahid_ali21No ratings yet

- SEM-1-AE-Auto Trade Practice-GTU-22-09-2021Document11 pagesSEM-1-AE-Auto Trade Practice-GTU-22-09-2021Darshan GohelNo ratings yet

- Use Case StudiesDocument54 pagesUse Case Studiesjkguru75No ratings yet

- 912 Installation Manual d04967 PDFDocument199 pages912 Installation Manual d04967 PDFZENAIRSTOLCH701No ratings yet

- Method Statement Template N GuidelinesDocument2 pagesMethod Statement Template N Guidelinesmkashkooli_scribdNo ratings yet

- LT-42 52 65Document228 pagesLT-42 52 65seregeNo ratings yet

- Assignment - Een1046 - Electronic - III - t3 2012 - 2013 Balachandran CDocument5 pagesAssignment - Een1046 - Electronic - III - t3 2012 - 2013 Balachandran Cdaneil303No ratings yet

- MPP1Document257 pagesMPP1Messias CastroNo ratings yet

- 627477473Document2 pages627477473sumitNo ratings yet

- Per ManualDocument144 pagesPer ManualMovith CrastoNo ratings yet

- Basic Practical Logbook SampleDocument22 pagesBasic Practical Logbook SamplemegamachNo ratings yet

- HP ProBook 6570b Disassembly InstructionsDocument16 pagesHP ProBook 6570b Disassembly InstructionsLoyd BronneNo ratings yet

- Maintenance Technician Job DescriptionDocument1 pageMaintenance Technician Job DescriptionMesfin THaimanotNo ratings yet

- (Jurutera Dalam Masyarakat) : EUP222 - Engineers in SocietyDocument13 pages(Jurutera Dalam Masyarakat) : EUP222 - Engineers in SocietySaiful MunirNo ratings yet

- MoM SOC Zubair 2 RehabilitationDocument5 pagesMoM SOC Zubair 2 RehabilitationniginpNo ratings yet

- US Air Force - AFQTP - 3E1X1-12 - Heating, Ventilation, Air Conditioning (HVAC), Refrigeration PDFDocument28 pagesUS Air Force - AFQTP - 3E1X1-12 - Heating, Ventilation, Air Conditioning (HVAC), Refrigeration PDFAsif iqbalNo ratings yet

- MR 11plct Frevzfeb12Document496 pagesMR 11plct Frevzfeb12charles_boyle_3No ratings yet

- Aircraft Maintenance Manual Aircraft Maintenance Manual Aircraft Maintenance Manual Aircraft Maintenance ManualDocument173 pagesAircraft Maintenance Manual Aircraft Maintenance Manual Aircraft Maintenance Manual Aircraft Maintenance ManualMohammad JaleelNo ratings yet

- TPLM30 IG Col33Document17 pagesTPLM30 IG Col33ahmedwwwNo ratings yet

- Government launches new Refrigeration and Air Conditioning Technician courseDocument63 pagesGovernment launches new Refrigeration and Air Conditioning Technician coursePrabhas RanaNo ratings yet

- MR 15plct Frevtfeb12Document476 pagesMR 15plct Frevtfeb12charles_boyle_3No ratings yet

- CTS Ref. and Air Conditioning Tech - NSQF-5Document72 pagesCTS Ref. and Air Conditioning Tech - NSQF-5sandeepfoxNo ratings yet

- Battery Charger SOWDocument4 pagesBattery Charger SOWzakalyNo ratings yet

- CT7N Bimetallic OverloadsDocument1 pageCT7N Bimetallic OverloadszakalyNo ratings yet

- Quote Suez Oil Apr 30 rfq2Document2 pagesQuote Suez Oil Apr 30 rfq2zakalyNo ratings yet

- Block diagrams of an RTB rectifier systemDocument17 pagesBlock diagrams of an RTB rectifier systemzakalyNo ratings yet

- AC Coil Three Pole Contactor Series CA7Document2 pagesAC Coil Three Pole Contactor Series CA7zakalyNo ratings yet

- Programmable High Frequency Charger ManualDocument19 pagesProgrammable High Frequency Charger ManualzakalyNo ratings yet

- 04 Day #2 - WorkShop 02 Energy Intensity SheetDocument2 pages04 Day #2 - WorkShop 02 Energy Intensity SheetzakalyNo ratings yet

- SPH NicdDocument7 pagesSPH NicdzakalyNo ratings yet

- CA7 Contactors AccessoriesDocument2 pagesCA7 Contactors AccessorieszakalyNo ratings yet

- SPH Io en 0514 HR Protected.Document4 pagesSPH Io en 0514 HR Protected.zakalyNo ratings yet

- Book1 - POWER CONSUMPTIONDocument2 pagesBook1 - POWER CONSUMPTIONzakalyNo ratings yet

- GPL + GLU ManualDocument58 pagesGPL + GLU ManualzakalyNo ratings yet

- Courses ObjectivesDocument33 pagesCourses ObjectiveszakalyNo ratings yet

- DC Dual Battery Chargers SOWDocument1 pageDC Dual Battery Chargers SOWzakalyNo ratings yet

- E-1 Safety - Aug 2011Document31 pagesE-1 Safety - Aug 2011zakalyNo ratings yet

- Gas Pant Ups ProposalDocument3 pagesGas Pant Ups ProposalzakalyNo ratings yet

- Oil and Water Treatment Energy Consumption 2017-2018Document2 pagesOil and Water Treatment Energy Consumption 2017-2018zakalyNo ratings yet

- Air Strip GeneratorDocument1 pageAir Strip GeneratorzakalyNo ratings yet

- Dse-All Can Guide En2 PDFDocument4 pagesDse-All Can Guide En2 PDFzakalyNo ratings yet

- TestingDocument6 pagesTestingEngr ShahidNo ratings yet

- الاستجابة التردديه للنظمDocument20 pagesالاستجابة التردديه للنظمzakalyNo ratings yet

- Spare Part List Modified Stamped - 2Document1 pageSpare Part List Modified Stamped - 2zakalyNo ratings yet

- Gas Pant Ups ProposalDocument3 pagesGas Pant Ups ProposalzakalyNo ratings yet

- Cairo HSEQ P 10Document12 pagesCairo HSEQ P 10eng20072007No ratings yet

- New UPS Tender for Zeit Bay Gas PlantDocument1 pageNew UPS Tender for Zeit Bay Gas PlantzakalyNo ratings yet

- Overhead Transmission Line INSULATORSDocument4 pagesOverhead Transmission Line INSULATORSzakalyNo ratings yet

- Cairo HSEQ P 15 PDFDocument5 pagesCairo HSEQ P 15 PDFzakalyNo ratings yet

- International Business Plan PDFDocument5 pagesInternational Business Plan PDFC MDNo ratings yet

- PPP EnglishDocument8 pagesPPP Englishសុគន្ធី កែវNo ratings yet

- Seferiadis 2018 PDFDocument88 pagesSeferiadis 2018 PDFOleksandrNo ratings yet

- India Property: CLSA India Real Estate Access DayDocument21 pagesIndia Property: CLSA India Real Estate Access DayManideep KumarNo ratings yet

- UDYAM REGISTRATION FORM - For Those Already Having Registration As UAMDocument5 pagesUDYAM REGISTRATION FORM - For Those Already Having Registration As UAMCa Nishikant mishraNo ratings yet

- RR No. 26-2002 Staggered FilingDocument5 pagesRR No. 26-2002 Staggered FilingCkey ArNo ratings yet

- The Peak HiLo IndicatorDocument10 pagesThe Peak HiLo IndicatorRonald DubeNo ratings yet

- Organization Profile: Wednesday, August 4, 2021 12:12 PMDocument1 pageOrganization Profile: Wednesday, August 4, 2021 12:12 PMCARLONo ratings yet

- CV HSE Officer Ratheesh VTDocument5 pagesCV HSE Officer Ratheesh VTDavid Pawon ObrikiNo ratings yet

- Kpi Aa Ip 2023Document10 pagesKpi Aa Ip 2023Poppy FitraNo ratings yet

- CER TAXUD - Surv-DATADocument481 pagesCER TAXUD - Surv-DATACiuri TVNo ratings yet

- Quote Ref JOLIVA28828 - GEL PIG PERENCO GABONDocument2 pagesQuote Ref JOLIVA28828 - GEL PIG PERENCO GABONMay'Axel RomaricNo ratings yet

- RT-11036-60-2023-MVL Dated 24-07-2023001Document4 pagesRT-11036-60-2023-MVL Dated 24-07-2023001Abhi Corleone BallackNo ratings yet

- Self Compacting ConcreteDocument18 pagesSelf Compacting ConcreteShamsUlislamNo ratings yet

- 4-6 7001A 2-16 A 7 Constraints Time Traps UoC7001A - 91558NSW CLRDocument15 pages4-6 7001A 2-16 A 7 Constraints Time Traps UoC7001A - 91558NSW CLRImran HakimNo ratings yet

- Evaluation 1: Toeicsv - We Are A Big FamilyDocument8 pagesEvaluation 1: Toeicsv - We Are A Big FamilyThanh LâmNo ratings yet

- Ms Sanna Masood payments 2016-21Document22 pagesMs Sanna Masood payments 2016-21aasan shinaNo ratings yet

- Strategic Cost ManagementDocument19 pagesStrategic Cost Managementraven345No ratings yet

- The barbaric history of sugar and how it fueled the slave tradeDocument12 pagesThe barbaric history of sugar and how it fueled the slave tradeultramarinezachNo ratings yet

- Certificate of Incorporation Post Change of NameDocument1 pageCertificate of Incorporation Post Change of NameBR BalachandranNo ratings yet

- Productivity Measurement in Malaysia ShipbuildingDocument75 pagesProductivity Measurement in Malaysia ShipbuildingYusop MDNo ratings yet

- Commodities Backed Finance Project ReportDocument74 pagesCommodities Backed Finance Project Reportkamdica100% (2)

- Commercial Invoice - Dedi IrwanDocument1 pageCommercial Invoice - Dedi IrwandharmawanNo ratings yet

- EBOOK6131f1fd1229c Unit 3 Ledger Posting and Trial Balance PDFDocument44 pagesEBOOK6131f1fd1229c Unit 3 Ledger Posting and Trial Balance PDFYaw Antwi-AddaeNo ratings yet

- JNK Profile Brochure - English (06!04!2020) - FinalDocument6 pagesJNK Profile Brochure - English (06!04!2020) - FinalPreetam SaranNo ratings yet

- Annex 8 Program Registration Forms 2Document60 pagesAnnex 8 Program Registration Forms 2Jemar Sultan FernandezNo ratings yet

- Beyond BenefitsDocument6 pagesBeyond BenefitsHasan GilaniNo ratings yet