Professional Documents

Culture Documents

Press Tool Design

Uploaded by

shivsagar sharma0 ratings0% found this document useful (0 votes)

20 views3 pagesDetail study on press tool

Original Title

Press tool design

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDetail study on press tool

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

20 views3 pagesPress Tool Design

Uploaded by

shivsagar sharmaDetail study on press tool

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

e-ISSN: 2582-5208

International Research Journal of Modernization in Engineering Technology and Science

( Peer-Reviewed, Open Access, Fully Refereed International Journal )

Volume:04/Issue:07/July-2022 Impact Factor- 6.752 www.irjmets.com

REVIEW ON BENDING OF METAL SHEET

Mr. Sayyed Qasim*1, Miss. Shete Vaibhavi*2, Mr. Shinde Vinod*3

*1,2,3Students Of Mechanical Engineering At Deogiri College, Aurangabad, Maharashtra, India.

ABSTRACT

Sheet metal are necessary and play role in industrial area widespread range of products, mechanical

engineering, electronic engineering, medical engineering. Demand growing in currently days in developing and

developed nations. Bending operation on sheet metal has been mostly used in industries for mass production of

automobile parts, tools etc. Through bending Sheet metal can be shaped in required shape and size. Bending is

most common formation operation. There are different types of bending operation Techniques in Sheet metal

bending.

Keywords: Sheet Metal, Bending Operation, Forming Techniques, Manufacturing Process.

I. INTRODUCTION

The most common sheet metal forming process is the bending process this also called as metal working

manufacturing process. Through sheet metal bending operation we can manufacture or produce U-shaped

component, V-shaped products of Sheet metal also L-shaped components can be produced.

Bending can be defined as

“Bending is Producing method within which metal is plastically misshapen into desired form and size

below the action of external load. ’’

Bending can be done in different manner for example bending along a straight line or path in which most

common type is sheet metal forming. Bending of sheet metal can be done in a variety of processes such as

Wiping, folding or flanging using special type of mechanism and machinery having different type of hard metal

Dies. Bending is most common Sheet metal forming operation. Many products like Automobile parts, its body

parts and component, home appliances, paper clips and metal doors are shaped by bending process.

II. LITERATURE SURVEY

Researcher showing that sheet metal forming that is bending of sheet metal has major role and contribution in

many mechanical industries especially automotive industries and transportation companies in terms of

improvement or development. The most common sheet metal forming process is the bending process this also

called as metal working manufacturing process.

All Researchers have been reported in sheet metal bending process are most common issue is spring back effect

in bending. Spring back define as After Bending due to elastic property of material try to regain its original

shape or position.

III. PROBLEM STATEMENT

Due to Spring back following six parameters are affecting

a) Bending radius

b) Bending angle

c) Bending force

d) Thickness

e) Punch Radius

f) Sheet metal material

There are two types of spring back effect one is positive spring back and another is negative spring back effect.

When measured bend angle after releasing load is larger than spring back effect called as positive. Whereas

measured bend angle is lower than spring back effect known as negative.

We can overcome spring back effect as follows,

1) In sheet metal bending operation over bending is the technique for getting desired bend angle.

2) Spring back effect can be minimized by Re-bending metal sheet.

3) To finding additional process that changes undesirable stress into less damaging stress.

4) By decreasing stress level which effect on parts used in bending operation.

www.irjmets.com @International Research Journal of Modernization in Engineering, Technology and Science

[1364]

e-ISSN: 2582-5208

International Research Journal of Modernization in Engineering Technology and Science

( Peer-Reviewed, Open Access, Fully Refereed International Journal )

Volume:04/Issue:07/July-2022 Impact Factor- 6.752 www.irjmets.com

IV. MANUFACTURING TECHNIQUES

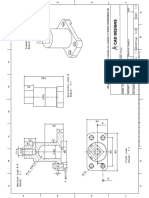

1] V- Bending: - In V-bending, sheet metal blank is bent between a v- shaped punch and die. Dies are simple

and in-expensive V- shaped component produced by this technique V-bending as shown in Figure (1).

Figure 1: V-Bending.

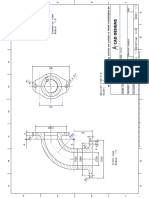

2] U- Bending: - In U-bending, sheet metal blank is bent between a U- shaped punch and die. Dies are simple

and in-expensive U- shaped component produced by this technique U-bending as shown in image.

Figure 2: U-Bending.

3] Edge Bending: - In Edge bending sheet to be held against the wipe die by a pressure pad. That is cantilever

support. By this method L-shaped component produced. Edge bending as shown in fig.

Figure 3: Edge -Bending.

4] Air-Bending: - In air bending metal blank not forced up to bottom end of die. Gap is always present in this

method between sheet metal and die.

5] Bottoming: - Bottoming is also called as Coining. Metal blank is completely forced up to bottom end of die.

www.irjmets.com @International Research Journal of Modernization in Engineering, Technology and Science

[1365]

e-ISSN: 2582-5208

International Research Journal of Modernization in Engineering Technology and Science

( Peer-Reviewed, Open Access, Fully Refereed International Journal )

Volume:04/Issue:07/July-2022 Impact Factor- 6.752 www.irjmets.com

V. CONCLUSION

We know, the metal bending is the huge industry in India .The especially for the mass production such as in

automotive engineering. According to our review, some basic part of bending like punched panel, die

workpieces from the research and the discussion we can conclude that the basic types of bending concludes V

bending as well as edge bending. Same other available bending types are air bending , flaming bending tube

bending these bending are not more useful as compare to V bending & edge bending V bending can be used for

larger sophisticated projects & edge bending can used for relatively small projects.

VI. REFERENCES

[1] https://www.sciencedirect.com/topics/engineering/pipe-manufacturing-process

[2] https://www.semanticscholar.org

[3] https://www.jstage.jst.go.jp/article

[4] Different Sheet Metal Bending Process - mech4study

[5] A Brief Overview of Bending Operation in Sheet Metal Forming (researchgate.net)

www.irjmets.com @International Research Journal of Modernization in Engineering, Technology and Science

[1366]

You might also like

- Industrial Origami A ReviewDocument5 pagesIndustrial Origami A ReviewIJIRAE- International Journal of Innovative Research in Advanced EngineeringNo ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Manufacturing of A Car Body: A Project Report For The Award of The Degree Bachelor of TechnologyDocument23 pagesManufacturing of A Car Body: A Project Report For The Award of The Degree Bachelor of TechnologyDHRUV SINGHALNo ratings yet

- MT Micro ProjectDocument9 pagesMT Micro ProjectJack SparrowNo ratings yet

- CLP PRODUCTION AND INDUSTRIAL ENGINEERING - Unit 1Document16 pagesCLP PRODUCTION AND INDUSTRIAL ENGINEERING - Unit 1jis mathewNo ratings yet

- V BendingDocument3 pagesV Bendingdawoodelahi1798No ratings yet

- Research Paper On Metal FormingDocument8 pagesResearch Paper On Metal Formingpeputaqlg100% (1)

- Icmmpe2019publishedpaper 5Document12 pagesIcmmpe2019publishedpaper 5aminiah alkhaerNo ratings yet

- MFP Unit Iv Univ QaDocument20 pagesMFP Unit Iv Univ QaMechanicalNo ratings yet

- Flow Forming of Tubes A Review PDFDocument11 pagesFlow Forming of Tubes A Review PDFKaustubh Joshi100% (1)

- An overview of forging processes and defectsDocument7 pagesAn overview of forging processes and defectsNagendra KumarNo ratings yet

- Design of Roll Forming Mill: Kondusamy V, Jegatheeswaran D, Vivek S, Vidhuran D, Harishragavendra ADocument19 pagesDesign of Roll Forming Mill: Kondusamy V, Jegatheeswaran D, Vivek S, Vidhuran D, Harishragavendra Ahasan devrimNo ratings yet

- Design and Fabrication of Hydraulic Zigzag Bending Machine IJERTCONV5IS07022Document4 pagesDesign and Fabrication of Hydraulic Zigzag Bending Machine IJERTCONV5IS07022praveen ajith100% (1)

- Defects in Welding MetallurgyDocument8 pagesDefects in Welding MetallurgyPradip ErandeNo ratings yet

- Bead Rolling MachineDocument7 pagesBead Rolling Machine5ch275pk7hNo ratings yet

- Rolling & Extrusion Case StudyDocument20 pagesRolling & Extrusion Case StudyMahmoud KassabNo ratings yet

- A Micro-Project On "Prepare Various Types of Welding Joints (With Metal Components) - Display Them On The WallboardDocument11 pagesA Micro-Project On "Prepare Various Types of Welding Joints (With Metal Components) - Display Them On The WallboardRohit BadguNo ratings yet

- PP PP PP PPDocument37 pagesPP PP PP PPJagdish Kolte100% (1)

- Defectsin WeldingmetallurgyDocument8 pagesDefectsin WeldingmetallurgylmotejauskasNo ratings yet

- Sheet Metal ShopDocument5 pagesSheet Metal Shopprince prosaNo ratings yet

- Sheet Metalworking: ©2002 John Wiley & Sons, Inc. M. P. Groover, "Fundamentals of Modern Manufacturing 2/e"Document34 pagesSheet Metalworking: ©2002 John Wiley & Sons, Inc. M. P. Groover, "Fundamentals of Modern Manufacturing 2/e"Himanshu GuptaNo ratings yet

- Flow Forming of Tubes-A ReviewDocument11 pagesFlow Forming of Tubes-A Reviewdr_kh_ahmedNo ratings yet

- Bamboo SplitterDocument7 pagesBamboo SplitterDemeke Gezahegn TeseraNo ratings yet

- FormingDocument381 pagesFormingArjun RoyNo ratings yet

- Chapter 4 (Sheet Metal Fabrication) With VideoDocument71 pagesChapter 4 (Sheet Metal Fabrication) With VideoSamrat BhattaraiNo ratings yet

- Sheet Metal Forming Processes ExplainedDocument38 pagesSheet Metal Forming Processes ExplainedPriya ChilukuriNo ratings yet

- Advancing sheet metal forming with servo press technologyDocument8 pagesAdvancing sheet metal forming with servo press technologyWaqar DarNo ratings yet

- Metal Forging Is A Metal Forming Process That Involves Applying Compressive Forces To A Work Piece To Deform ItDocument8 pagesMetal Forging Is A Metal Forming Process That Involves Applying Compressive Forces To A Work Piece To Deform ItrabikmNo ratings yet

- Lecture - 1 Nptel FormingDocument12 pagesLecture - 1 Nptel Formingaghosh704No ratings yet

- Sheet Metal Forming Processes With Incremental ApproachDocument14 pagesSheet Metal Forming Processes With Incremental Approachstranger3333No ratings yet

- Manufacturing Technology I 2 MarksDocument69 pagesManufacturing Technology I 2 MarksVenkatesh VenkatNo ratings yet

- Unit - IV Drawing of Rods, Wires and TubesDocument13 pagesUnit - IV Drawing of Rods, Wires and TubesMaddipudi RamakrishnaNo ratings yet

- Sheet Metal BendingDocument30 pagesSheet Metal BendingZen P MonachanNo ratings yet

- (Kekasaranpermukaan) IJESIT201301 51 PDFDocument7 pages(Kekasaranpermukaan) IJESIT201301 51 PDFMuhammad Tatma'inul QulubNo ratings yet

- Experimental Investigation On Spinning of Aluminum Alloy 19500 CupDocument7 pagesExperimental Investigation On Spinning of Aluminum Alloy 19500 CupArifat Ridho DionNo ratings yet

- CLP Production and Industrial EngineeringDocument69 pagesCLP Production and Industrial Engineeringjis mathewNo ratings yet

- Metal Forging Guide: Processes, Defects, DesignDocument17 pagesMetal Forging Guide: Processes, Defects, DesigncemekaobiNo ratings yet

- Recent Twomarks DocumentDocument6 pagesRecent Twomarks DocumentAravind PhoenixNo ratings yet

- Chapter 1 TO 5Document49 pagesChapter 1 TO 5nagisafurukawa122333No ratings yet

- Manufacturing Engineering and TechnologDocument17 pagesManufacturing Engineering and TechnologGilank GunawanNo ratings yet

- Summer Training Report CastingDocument29 pagesSummer Training Report CastingFaisal Bin Shabbir100% (1)

- Analysis of Different Types of Weld Joint Used For Fabrication of Pressure Vessel Considering Design Aspects With Operating ConditionsDocument13 pagesAnalysis of Different Types of Weld Joint Used For Fabrication of Pressure Vessel Considering Design Aspects With Operating ConditionsLiu YangtzeNo ratings yet

- Design of Welded Connections: Submitted To Prof. Berlanty Iskander byDocument17 pagesDesign of Welded Connections: Submitted To Prof. Berlanty Iskander byاحمد حمديNo ratings yet

- Study On Sheet Metal BendingDocument11 pagesStudy On Sheet Metal BendingmarcandreitraquenaNo ratings yet

- General Classification of Metal ProcessesDocument3 pagesGeneral Classification of Metal ProcessesRogen Darell AbanNo ratings yet

- Stamping (Metalworking) - WikipediaDocument5 pagesStamping (Metalworking) - Wikipediakirthi83No ratings yet

- ME 2201 MT 1 Short AnswersDocument40 pagesME 2201 MT 1 Short AnswersgurunathramNo ratings yet

- Review of die-less sheet metal forming methodsDocument5 pagesReview of die-less sheet metal forming methodsCarlos ArenasNo ratings yet

- Sheet Cutting PDFDocument10 pagesSheet Cutting PDFkolla satishNo ratings yet

- 1759 8536 1 PBDocument7 pages1759 8536 1 PBMohaiminul MimNo ratings yet

- Studies On Effect of Tool Pin Profiles and Welding Parameters On The Friction Stir Welding of Dissimilar Aluminium Alloys AA5052 & AA6063Document15 pagesStudies On Effect of Tool Pin Profiles and Welding Parameters On The Friction Stir Welding of Dissimilar Aluminium Alloys AA5052 & AA6063IJRASETPublicationsNo ratings yet

- Feedstock Technology for Reactive Metal Injection Molding: Process, Design, and ApplicationFrom EverandFeedstock Technology for Reactive Metal Injection Molding: Process, Design, and ApplicationNo ratings yet

- Modelling and Simulation of the Roll Forming ProcessDocument65 pagesModelling and Simulation of the Roll Forming ProcessMarco CruzNo ratings yet

- Intro To Die Casting PDFDocument116 pagesIntro To Die Casting PDFKmilo Giraldo100% (2)

- Friction Stir Weldingasa Joining ProcessthroughDocument6 pagesFriction Stir Weldingasa Joining ProcessthroughSURESH KUMAR APNo ratings yet

- 1 Om Note 2017 (Final)Document34 pages1 Om Note 2017 (Final)civil MuskanNo ratings yet

- Blisk TechnologyDocument25 pagesBlisk TechnologyMichele AndreozziNo ratings yet

- Home Instruction for Sheet Metal Workers - Based on a Series of Articles Originally Published in 'Metal Worker, Plumber and Steam Fitter'From EverandHome Instruction for Sheet Metal Workers - Based on a Series of Articles Originally Published in 'Metal Worker, Plumber and Steam Fitter'No ratings yet

- Mechanical Practice Drawing Sheets For AutoCAD CATIA NX SOLIDWORKS and ProE WWW - Caddesigns.in - 09Document1 pageMechanical Practice Drawing Sheets For AutoCAD CATIA NX SOLIDWORKS and ProE WWW - Caddesigns.in - 09shivsagar sharmaNo ratings yet

- Mechanical Practice Drawing Sheets For AutoCAD CATIA NX SOLIDWORKS and ProE WWW - Caddesigns.in 10Document1 pageMechanical Practice Drawing Sheets For AutoCAD CATIA NX SOLIDWORKS and ProE WWW - Caddesigns.in 10shivsagar sharmaNo ratings yet

- Mechanical Practice Drawing Sheets For AutoCAD CATIA NX SOLIDWORKS and ProE WWW - Caddesigns.in - 21Document1 pageMechanical Practice Drawing Sheets For AutoCAD CATIA NX SOLIDWORKS and ProE WWW - Caddesigns.in - 21shivsagar sharmaNo ratings yet

- Mechanical Practice Drawing Sheets For AutoCAD CATIA NX SOLIDWORKS and ProE WWW - Caddesigns.in 03Document1 pageMechanical Practice Drawing Sheets For AutoCAD CATIA NX SOLIDWORKS and ProE WWW - Caddesigns.in 03shivsagar sharmaNo ratings yet

- Can You Divide A Millimeter Into 20 Equal Parts? Essentially, A Vernier Does That ExactlyDocument10 pagesCan You Divide A Millimeter Into 20 Equal Parts? Essentially, A Vernier Does That Exactlyshivsagar sharmaNo ratings yet

- Abstract Book ICRAM 2019-1Document1 pageAbstract Book ICRAM 2019-1shivsagar sharmaNo ratings yet

- Abstract Book ICRAM 2019Document47 pagesAbstract Book ICRAM 2019shivsagar sharmaNo ratings yet

- Servising and Procedure Catalog CF 10031 8-10 R01 en PDFDocument434 pagesServising and Procedure Catalog CF 10031 8-10 R01 en PDFphong100% (1)

- 6.hydraulic Structure Lab ManualDocument57 pages6.hydraulic Structure Lab ManualAmmar Ahmad EED100% (2)

- Chemical Engineering Science: T.L. Rodgers, L. Gangolf, C. Vannier, M. Parriaud, M. CookeDocument10 pagesChemical Engineering Science: T.L. Rodgers, L. Gangolf, C. Vannier, M. Parriaud, M. CookeYusrilNo ratings yet

- Introductory Chemistry An Atoms First Approach 1st Edition Burdge Solutions ManualDocument32 pagesIntroductory Chemistry An Atoms First Approach 1st Edition Burdge Solutions Manualduongvalerie9rkb3100% (31)

- RETAINING WALL DESIGN FOR BOUNDARYDocument4 pagesRETAINING WALL DESIGN FOR BOUNDARYaldert_pathNo ratings yet

- Astm D523Document5 pagesAstm D523CeliaNo ratings yet

- Bcs Written SyllabusDocument12 pagesBcs Written SyllabushamimisratNo ratings yet

- Class 10 - Physics - Refraction of Light at Plane Surfaces SolutionsDocument68 pagesClass 10 - Physics - Refraction of Light at Plane Surfaces SolutionsAndrik LalNo ratings yet

- Tuning of PID Controller: Dr. Sadeq Al-MajidiDocument11 pagesTuning of PID Controller: Dr. Sadeq Al-Majidijin kazamaNo ratings yet

- Pascua Project For Module 2 Problem Set With SolutionDocument14 pagesPascua Project For Module 2 Problem Set With SolutionDJ KillNo ratings yet

- Nomograph For RCF Determination: ExampleDocument2 pagesNomograph For RCF Determination: Exampleshikhasharma_85No ratings yet

- Design of R.C.C. Bridge PiersDocument12 pagesDesign of R.C.C. Bridge PiersPatel TosifNo ratings yet

- Pendulum Experiment: Trial Length of String (Centimeters) Time (Seconds)Document3 pagesPendulum Experiment: Trial Length of String (Centimeters) Time (Seconds)Shayan FarrukhNo ratings yet

- Fundamentals and Principles of Soil MechanicsDocument13 pagesFundamentals and Principles of Soil Mechanicshuhu heheNo ratings yet

- The 2020 Magnetism Roadmap: Journal of Physics D: Applied PhysicsDocument45 pagesThe 2020 Magnetism Roadmap: Journal of Physics D: Applied PhysicsFrancisco EstrellaNo ratings yet

- Topic 1: Forces On Materials: Types of LoadDocument8 pagesTopic 1: Forces On Materials: Types of LoadAdi SafwanNo ratings yet

- Electromagnetic Spectrum and Optics AssessmentDocument5 pagesElectromagnetic Spectrum and Optics AssessmentKenneth Roy MatuguinaNo ratings yet

- Bolt and Nut, FastenerDocument86 pagesBolt and Nut, FastenerSelviya AvaurumNo ratings yet

- Heat Transfer Enhancement of High Temperature Thermal Energy Storage Using Open Cell Metal Foam & Paraffin WaxDocument4 pagesHeat Transfer Enhancement of High Temperature Thermal Energy Storage Using Open Cell Metal Foam & Paraffin WaxHiba MhiriNo ratings yet

- 2.MEET 315LA MatScie Engineering ME Lab Module 2Document48 pages2.MEET 315LA MatScie Engineering ME Lab Module 2Cj TilamNo ratings yet

- Q2 - Module 1 PDFDocument33 pagesQ2 - Module 1 PDFdem dorothy bosqueNo ratings yet

- Accuracy and RepeatabilityDocument61 pagesAccuracy and Repeatabilityjustin cardinalNo ratings yet

- Air Track Gizmo - ExploreLearningDocument4 pagesAir Track Gizmo - ExploreLearningJeremy Gomez-RojasNo ratings yet

- MV March2018 EsasDocument9 pagesMV March2018 EsasMargo Isay EriveNo ratings yet

- Blue White Simple Copy Editor CVDocument3 pagesBlue White Simple Copy Editor CV188 - Anggita Pramestiarajati - FTTMNo ratings yet

- Triaxial Permeability 2023Document3 pagesTriaxial Permeability 2023Kim Yuen WongNo ratings yet

- Lecture 7Document30 pagesLecture 7faiz alshammariNo ratings yet

- ICSE Class 10 Maths Question Paper Solution 2018Document28 pagesICSE Class 10 Maths Question Paper Solution 2018COW GUPTANo ratings yet

- 10 PhysicsDocument4 pages10 PhysicsNicka Asereht MinaNo ratings yet

- ICU Medical Gas NeedsDocument4 pagesICU Medical Gas NeedsGamerBro IDNo ratings yet