Professional Documents

Culture Documents

Doc251222 25122022124503

Uploaded by

Abdul Wasay0 ratings0% found this document useful (0 votes)

37 views12 pagesS-PCM for Samsung

Original Title

DOC251222-25122022124503

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentS-PCM for Samsung

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

37 views12 pagesDoc251222 25122022124503

Uploaded by

Abdul WasayS-PCM for Samsung

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 12

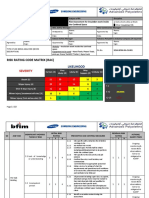

APPENDIX |

‘SPS0205ENN

REV. 5

PAGE 1 OF 78

S-PCM Minutes of Meeting eine

SUBJECT: S-PCM Kick Off Meeting: Insulation and | JOB NO.

Scaffolding Work

DATE OF MEETING: 2022/08/27 REPORT BY: Construction Manager. x

ATTENDENCE FROM SECL: ‘ATTENDENCE FROM SUBCONTRACTOR

Ore. JobTitle | Name | Signaturg) | Org. JobTitle [Name | Signature

sec. | Ping | sy tee erm | cam | Shh

Manager Prasann

' Bhavin

sect | Piping S/v | Richard BFIM PEC espe

SECL Insul |g. Ansing erm | acm | Jv Rven

Supervisor Relon

Paint’s/ - Joseph

sect | Pari e’ | 8. calayag Brim | HSEM | pico

HSE , Abdul

SEC | spanager | 'SKIM ef WIM | SL cal

HSE

SecL | Deputy | J. Crescini

Manager

Most critical hazard ssure shall b

Material Handling/Manual Unloading, Falling object/Personal injury/Pinch Point. | ¢[Y

No lifting of weights more than 18 kgs. WE

-No over stacking of materials.

-Proper signages and proper area for material staging.

‘Airborne Contaminants of insulation Materials (Rockwool).

Use of KN9S Mask. a

Hand Injury while handling cladding sheets / cutting of insulation ~ Cuts.

Use of Cut resistant gloves.

Confined Space Works. Proper illumination, permits, Confined space Training. WE

Working at scaffolds/Elevated Areas. sly

| Use of Full body Harness, Work at height training. 100% Tie Off : us

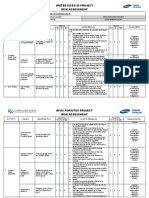

1 Work Overview

= __ Name of Work: Insulation Work and Scaffolding Work

= Work period (permitted period): 1" of September onward - approx. 18 Months

= _No. of workers: 170 Max.

= Heavy equipment: Forklift, Trailer Truck LAI

< Hazardous machine and tools: Drilling Machine (Battery operated),

Screwdriver, Tightener, hammer, compass, cutters, hole puncher, Ratchet,

material basket, pulley/gin wheel, manila, or nylon rope.

= Main materials: System Scaffold, Rockwool, PIR and Cladding

Relevant documents on the work plan

= Method Statements

= Drawings or photos relating to the work section in question —

= Construction/Commissioning, scaffolding plan, etc.

= Substance safety report (SDS)

= Ventilation plan with Calculation

= Scaffold Plan

= Irregular scaffold plan

= Manual Lifting Plan for Scaffolding and Insulation

Equipment to used and tools

= Forklift / boom truck / man lift / crane / truck / light vehicle / lighting tower

Power Tools ~ Drill Machine / Sheet Cutter

‘Manual tools ~ Cutters /tighteners

PPE

Night work Plan

= Proper Illumination Plan

Preparation of Job, Tools and Equipment; Un - Autho

Slip, Trip and Fall, Damaged tools and Equipment entry

;, Incompetence,

‘© NO PERMIT, NO WORK

+ Obtain required permit to work on daily basis and comply with permit to work

system and work method statement.

+ BFIM Scaffold inspector / supervisor qualified and certified by APOC ~ SESA shall

inspect the scaffold materials prior to entering the site. The scaffold material shall

be in accordance with SESA minimum requirements as per scaffold material

inspection checklist

‘+ S-PCM shall be discussed during the daily toolbox talk meeting prior to commence

the work, line supervision and HSE representative shall determine the associated

hazards and provide appropriate mitigation to avoid any accident/incident.

Properly wrap and te all loaded materials.

Ensure that sling/rope is not worn out and free from dete.

Safety Induction and necessary training forall by SESA EHSS Training Department.

Only trained and authorized personnel are allowed to perform the work

Ensure assigned workers are medically fit to work and are not acrophobic (is afraid

of heights)

Provide safe access, do not use shortcuts.

Ensure the accesses are free from obstruction

Removed unwanted materials, practice proper stacking of materials,

Barricade the working ares, post appropriate signage, and restrict entry to

authorized personnel only.

‘Hand tools shall inspected, and color coded only by authorized trained Personnel.

Power Tools shall be inspected only by authorized electrician and color code for the

month to be affixed. All ejected tools shall be removed from site immediately.

Material handling and manual lifting of light materials; Personal injury / pinch

point, Falling object

‘© Proper PPE shall be worn when handling the material. Use appropriate Hand Gloves,

(Impact Resistant Gloves). Be aware where hands are being placed and assess the

configuration of materials to be lifted

Keep fingers away from pinch point area, trapping point area,

Rolling Objects shall be blocked or wedged

Employees shall ensure that they have firm grip on the object being lifted

Follow Material Handling and Storage

Pay more attention to sharp edge and protruding part of the materials to avoid

injury. Ensure to provide protection for sharp edges and protruding parts

Heavy and awkward material shall be handled with non-powered mechanical such

8 pallet truck or additional manual support. Lift only 18kg by an individual,

Completely barricade and provide appropriate signages around manual lifting area,

Only authorized personnel to be located inside the lifting area,

Ensure personnel are not standing / located directed on the lifting trajectory.

Lifting of materials using inspected rope min. 18 mm and 3rd party certified pulley

and SWL marked canvass bag (50 ke).

* Ensure to check height limit for any manual lifting activity using gin pulley. Refer to

gin pulley information regarding maximum allowable height.

* When handling the material, make sure one piece each time to avoid the material

falling on the platform even to the ground,

‘+ Small pieces shall be in placed on box/container.

‘Material should not block the access at any time,

When handling the material from outside to inside through the man wey, both

people shall maintain focus on the work activity and on the material to avoid sudden

slipping and falling to someone,

‘+ Avoid placing excess materials at height. Only materials to be used for the day must

be placed and located on work area,

Working in confined Space; Fall, Poor illumination, Electric shock,

Suffocation toxic gases, Unauthorized personnel entry, Emergenc

‘* All employees going to work in confined space must have Confined space training

from the SESA EHSS Training department.

* Approved vertical ladder with intermediate platform scaffold which shall be in place

(inspected and with green tag) and shall be used as access to confined space,

‘* Inertia block shall be installed appropriately and shall be attached to personnel FBH

when accessing the ladder.

© When ascending or descending ladders and stairways always maintain three points

of contact,

* Full body harness shall be worn and ensure 100% tie-off compliance

© Scaffold should be as per standard and signed by competent person

* Minimum of 5 lux for General construction area and 110 lux or more illumination

light at workplace to be provided

* Illumination test using LUX meter shall be conducted to ensure proper and sufficient

lighting is provided.

* High visibility clothing / vest shall be provided and use,

Proper access to be provided,

Lights to be provided shall be maximum 12-24 volts rating.

Use double insulated power tools only.

All power tools shall be connected to GFCI/ELCB and anly max. 110V allowed.

Cable shall be routed thru magnetic cable hangers, elevated at least 2 meters high

and/or placed away from the access.

‘* Ensure Gas test conducted by certified gas tester using calibrated multi gas tester

Result to be recorded and filed.

+ SSA trained and certified attendant shall stay outside the man way and will keep

‘monitoring the condition and the status of the people working inside the confined

space.

(One out of four Entrant shall wear personal Oxygen monitor,

Proper ventilation shall be provided and keep running.

Oxygen concentration shall be between 19.8% and 23.5%.

Continuous monitoring to be conducted and to keep record at least every 2 hours

‘or as per permit requirements,

Buddy system shall be followed for working inside of confined space.

‘© Only confined space trained personnel are allowed to go inside the confined space

# Atrained and competent hole watch man to stand near the man way to monitor the

inside of the confined space all the time,

+ Personnel In/Out of the confined space must sign the log sheet. Stand by man to

counter check remaining entrants inside the space.

* CS.Job supervisor must be always available.

+ Prior to start the activity, Project ERT leader shall be informed of the confined space

work location

© Emergency contact details shall be posted nearby location

© Emergency rescue plan shall be attached to the work permit and shail be filled up

before starting the activity

‘+_Emergency assembly area must be informed to all workers.

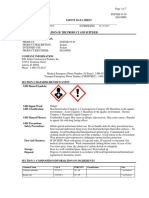

Surface preparation & sealant application; Health hazard, Personal injury,

Accumulation of Hazardous waste

* Only Trained / Competent person are allowed to perform the activity

# Understand and Follow the Manufacturer Recommendations of Chemicals for safe

handling and use, storage

Post adequate safety signage/ warning signs

Ensure $05 (Safety Date Sheet) for silicon sealant available at work location

ye wash station shell be available within the work area

First id kit shall be available and accessible to all those who work with pickling and

passivation

Work routines shall be carried out in 2 well-ventilated area,

Store the sealants in well ventilated areas.

Eating, Drinking & Smoking is not allowed at work location

Wear appropriate respirator during cleaning of Equipment & Piping.

Only trained and competent person for the job.

Observed proper positioning during execution of the job. Avoid overextending,

overreaching that can result in in personal injury

Remove defective tools immediately and place in quarantine box then removed

from site.

A hand tools must be inspected, and color coded forthe month

Only use the right tools for the job.

Homemade or fabricated tools are not allowed and must be disposed immediately

Use the appropriate PPE for the ob including hard helmet, safety glasses, steel-toed

safety shoes, and safety gloves.

‘+ Maximum of fifteen (15) workers and supervisor/s per layer allowed to work at the

same time, Rotation of workers to be ensured.

Any rags and clean-up waste material shall be properly stored in waste containers

designated for that purpose only. These items shall be stored in covered waste

containers until removed from the jobsite

Waste shall be segregated Hazardous and Non-Hazardous Waste and shall be placed

in suitable drum container with proper safety signs and containers / containments

shall free from damage

‘© Fallow the SDS for disposal of waste / chemicals

Follow local legislations regulations for disposal of hazardous waste.

Cutting of insulation materials and fabrication of cladding materials

(Perlite/Rockwool); Hand injury/Pinch point, Health hazards

* Proper working table and/or bench tobe provided while cutting Rockwool for fitting.

‘Work Area to be barricaded and signage's to be provided.

Ensure that only sel-retractable (spring type) knife shall be used

Keep away fingers and hands from pinch point.

‘Wear proper hand gloves as per EN 388:2016 cut standard with performance level

rating of 4/5, Personnel shall be provided

+ Involved personne! shall be trained in Hand & Power Tools Safety Training from SESA

EHSS training department

+ Use only rock wool with intact fiber; deteriorating fiber shall not be used,

+ Always wear clear safety glasses when handling rock wool

+ Use appropriate PPE as per MSDS such as disposable cover all, rubber coated gloves

‘and N95 respirator.

+ Discuss the potential hazards and PPES required for the work in TST prior to starting

the activity

+ SDS shall be at site and hazard to be discussed to work crew by the Supervisor

Installation of insulation; Fall from heights, fall of tools and materials; Skin

contact, may results skin irritation and rashes or allergies; Airborne Contaminants,

may results respiratory illness and breathing problems, Eye Contact, results eye

irritation and infections

‘+ Scaffold supervisor/inspector to ensure all scaffolds are inspected and tagged safe

for use prior to utilizing

+ Check the tag before climbing the scaffolding

+ Follow 100% tie off system while working from scaffolding

+ Do not alter or modify the scaffolding, Only scaffolding worker authorized to

perform scaffolding activity

‘+ All involved personnel must be trained in working at heights safety trainings from

HSS Training department.

+ Do not work on red tagged scaffolding

‘+ Asame means of entry and ext shall be provided and used whenever the elevated

work area is 1.8 meters and above or below working surface.

* Guard rails to be provided and ensured.

"Make sure the rungs of ladder are in good condition prior to use.

When climbing or descending, grip the horizontal rungs and maintain three points

of contact with free hands

* Ensure that working level is properly provided and no openings left un-covered.

+ Toe board shall be installed around the working platform to prevent the tools or

materials from falling,

# Tools shall be properly secured. All tools being used at elevated area must have

restraining rope to prevent falling from height

+ Barricade the area below into which objects can fall and not permitting workers to

enter the hazard area

+ Ensure that materials are not placed near the edge of the working platform.

+ Always flush with clean water after completing the job and wash hands thoroughly.

© If discomfort persists, inform the supervisor to seek medical attention.

‘Always wear proper PPEs such as coverall, disposable coverall and gloves at all times.

* Direct skin contact can be minimized by wearing long’sleeved shirts and long

trousers, a cap or hat, and standard duty gloves.

© Work clothes should be washed regularly and separately from other clothes.

Comfort sleeve gloves are recommended for improved comfort when handling and

installing Rockwool Insulation

+ Any symptoms and signs of ill-health are likely to be due to other causes. Can be

slightly itchy on prolonged contact with skin. Does not produce any acute or chronic

health effects. Treatment should be directed toward cleansing the skin and

symptomatic treatment as necessary. (Referred to MSDS)

* Wear appropriate respiratory protection such as dust mask (N95/3M) and or half

face mask respirator while working inside the confined space,

Shall ensure the warkers awareness of the hazards associated with this job,

Ventilation must be provided specially whilst working inside the confined space.

Work rotation to be considered to minimize exposure time,

Always flush with clean water after completing the job.

Always wear safety glass at all times,

Cladding works; Ergonomics, Falling of cladding materials, Hand injury/pinch

point/cut

* Proper manual handling technique to be used.

+ Manual lifting, maximum of 18 KGs of weight shall be allowed; ensure enough

workers are assigned for carrying bulk and large materials and use of non:

mechanical iting devices, when required

Proper work position to be maintained.

Regular housekeeping must be carried out in the working area.

Provide barricade in the working area and signage's to be posted.

Buddy system to be implemented. Co-worker will assist uring installation activity

Tools shall be secured with tool lanyard or lashing

Only Required quantity of insulation and cladding materials to be placed on the man

lift platform and loose materials shall be removed and placed on proper container

+ Ensure materials are manually hoisted at work area by 31d party approved gin wheel

with at least 18 mm nylon rope.

+ Constant supervision shall be in place and ensured

* Do not overload platform capacity, materials that were not used before

lunch/evening/morning break shall be lowered down to grade level

+ Retain from placing fingers and hands from pinch point area and sharp edges

+ Wear proper hand gloves as per EN 388:2016 cut standard with performance level

rating of 5. Personnel shall be provided

+ Involved personnel shall be trained in Hand & Power Tools Safety

Good housekeeping shall be conducted and maintained.

Scaffolding Preparation of Work Site/ Lifting & lowering / loading &

unloading of scaffolding materials; Unauthorized work, Untrained personnel,

Slip, trip and fall, Scaffolding Material Damage, Scaffolding Materials Falls from

height, Material damage, Ergonomics

‘© NO PERMIT, NO WORK

© Obtain required permit to work on daily basis and camply with permit to work

system and work method statement,

+ SPCM shall be discussed during the daily toolbox talk conduct before work

commences, line supervision and HSE representative shal determine the associated

hazards and provide appropriate mitigation to avoid any accident/incident

'* Joint inspection should be conducted prior to issue the permit by SECL approver &

certified WPR,

‘+ All necessary documents shall be attached with the work permit and shall be made

available at the work site

‘+ Involved personnel must attend Safety Induction and necessary trainings

‘* TBT meeting to be conducted by concerned supervisor and discuss the hazards

‘which can expect while performing the work, its reduction method and Preventive

action to be known to each employee.

Only trained and authorized personnel are allowed to perform the work

Ensure the accesses are free from obstruction.

Provide safe access, do not use shortcuts

Removed unwanted materials, practice proper stacking of materials

Barricade the working area, post appropriate signage, and restrict entry to

authorized personnel only

+ Tie with rope to both the ends of material to be lifted, so that the material does not

slip. Te the free end of the rope to structure during lifting / lowering

‘+ Material shall be firmly raised attached to the Gin wheel rope and shall not exceed

50 kgs (11016)

+ Full body harness and components shall be inspected and color code by authorized

personnel only.

Use Gin wheel, correct type, and size of rope to lft the materials

Gin whee! installation shal be inspected and color coded

Gin wheel to be 3rd party inspected. And chose suitable location for gin whee fixing.

Gin wheel should be fixed within 750mm from the end support.

Ensure work area is barricaded and no one willbe allowed to pass whilst lifting and

lowering of materials is in progress.

follow the scaffolding procedure

* Tie with rope to both the ends of material to be lifted, so thatthe material does not

slip. Tie the free end of the rope to structure during lifting / lowering

* Material shall be firmly raised attached to the Gin wheel rope and shall not exceed

50 kes (11016)

* Crane (if used) shall be SESA 3rd Party certified, operator to possess valid Saudi

Arabian license.

+ Rigger shall possess approved SESA certificates and be responsible to guide crane

‘operator in material movement

* During use of forkit, the operator shall have valid licenses and approved from SESA,

* Flag man shall complete the SESA trainings and be approved, flagman to be used

during loading / unloading.

+ Proper manual handling technique to be followed. Personnel shal be trained in the

Safe Manual Handling Technique.

* Manual lifting, maximum of 18 KGs of weight shall be allowed; ensure enough

workers are assigned for carrying bulk and large materials and use of non:

mechanical lifting devices, when required.

* Proper work position to be maintained.

Regular housekeeping must be carried out in the working area

‘Stacking & handling of scaffolding material; Slips, rips & falls, Congestion of Scaffold

materials and damage of material due to fall or insulficient protection, Ergonomics,

Unauthorized personnel entry

‘Avoid congestion of materials, make access ways free of any obstructions

‘Materials shall not store beyond height limit or storage space

Follow obstructions free pathways.

Allocate a designated stacking area for material.

Provide access ways for movement of lifting equipments,

Provide stacking area with physical barricade and appropriate signboards.

Segregate materials properly with usable and damage signages

Stack materials neatly and safely, consider the height and weight of stacking,

material to ensure stacking limit capacity, do not stack material at unstable height.

Band the scaffold tube and boards at both the end, and stack according to their

lengths

Provide proper access ways to remove and store materials,

Provide dunnage to mount all materials away from ground soll contamination.

Proper work position and posture to be maintained

Regular housekeeping must be carried out in the working area.

Work rotation to be implemented.

Personnel shall be trained and adhere to the Safe Manual Handling Technique.

Proper barticading of area

Post signage

10

‘Working at elevated location. (For Erection, modification, and Dismantle of

Scaffolding); Fall from height / incompetent person erection and dismantling,

Slips, trips & falls at same level, Exertion due to repetitive climbing to heights in hot

weather, Failure to retrieve injured personnel above scaffold platform, Drop objects

and fall of materials, Fall of material during movement on site or during erection &

dismantle, Access to scaffold during erection prior to Inspection handover & during

dismantle, Collapse of scaffold, Trips, slips and falls whilst moving around site,

Uneven ground, Head Injury due to fall of scaffold materials

‘All personnel involved in working at heights have attended Working at Heights

training and other required safety trainings.

‘© Ensure chin strap provided and used when working at height.

‘© Work shall be conducted in the constant presence of work supervisor

‘© Always wear tools belt to carry tools and secure with lanyard while working. on

height.

* condition of the floorboard shall be flat and shall not be slippery or uneven. The

ladder beams must be cleaned of any oil, grease and must not be applied in a wet

painted condition. Footwear to be used shall be in good condition and properly

laced,

# Tie material properly to loop all the sides, so that the material does not slip

Minimum 3 boards must be used by scaffolder to stand on an onboarded scaffold

Make sure ladders are properly secured at the top & also ensure that ladders have

proper non-slip feet, and iti supported on firm ground and must maintain 1:4 ratio

and ensure 100% Tie of

‘© All scaffold erectors shall maintain 100% Tie-off during erection, modification, and

dismantling,

‘© Ensure that the working platforms and ladders are neither wet nor have the slippery

surface.

Minimum PPE Such as Hard Hat, Safety Shoes, Safety Glasses must be worn always

Take periodic rest

Ensure to intake more water in regular interval

void taking drink ike Colas or drinks with high caffeine

Al scaffolding crew shall be trained and aware for possible incident scenario.

ERT shall be organized, trained and preparedness availabilty if incident occurs.

+ Rescue plan/procedure shall be developed, implemented, and well informed to all

involved parties.

‘Rescue retrieval equipment shall be available at all times using; Gin wheel pulley

(250 kgs) full-body harness, rigid ropes, Crane and mani.

‘+ All personal who are working at elevated area must use full body harness with 100%

tie-off all the times. ANSI 2359.1 with Suspension trauma kit to be followed and

make sure the anchoring point must be strong and safe

‘© Use material basket on Gin wheel pulley for hoisting and lowering of small objects,

materials, and tools.

Ensures toe board were completely fixed to prevent falling objects,

Isolate with barricades and signboard beneath working areas as exclusion zone.

All tools lke wrenches and leveler shall be fitted with lanyards

Follow SESA Scaffolding procedure, the area to be barriered off at ground level using

suitable means to prevent access. Material to be stored by suitable means to

prevent inadvertent movement ie., scaffold fittings to be bagged. Materials must

not be stored vertically unless they are prevented from falling. One employee to act

asa banksman when loading and unloading vehicle.

* On commencement of erection and dismantle an “incomplete” scaffold sign will be

displayed adjacent to the access routes. Physical barriers to be erected to prevent

+ Scaffolding erection must be maintained 1.5 meters from the edges of excavation.

* Ground level condition shall be inspected prior to scaffold erection,

+ 3rd party certified erector shall initiate erection of scaffold under supervision of

SESA/BFIM supervisor.

‘© Operatives to be aware of their surroundings do not stand on manhole covers,

censure you are looking where you are walking and working, do not step onto or over

debris, and avoid tripping or slipping hazards. Do not enter access routes or work

‘areas that are not adequately lit. Chose an access route or work area that is free

from hazard, Be aware of vehicle movements and maintain a safe distance. Report

any hazard to your supervisor

+ work area to be barriered off by suitable means to prevent access, storage of

materials within the work area will be subject to good housekeeping. Where itis not

possible to maintain barriered off areas storage of materials to be subject to good

housekeeping

‘+ All operatives should wear @ hard hat with chin straps during their working day.

'* Scaffold operatives are to erect Gin wheel framework which complies with

Scaffolding Procedure,

Scaffold tubes / boards are to be securely fastened using the following Roling hitch and

timber hitch knots. Scaffold tubes must be fastened twice using a half hitch knot

including the rolling hitch knot. Work area must have the required exclusion zone and

safety signs displayed to prevent any 3rd party operatives entering the work area whilst

material is being raised or lowered by Gin wheel. Gin Wheel must be marked with safe

working load

u

Working in extreme/ hot weather condition; Heat related iliness, Adverse

weather conditions. (High winds, hailstorm, and heavy rain)

‘© Pay attention to environmental board details and heat stress flagging system

Ensure to apply and implement work/rest rotation

In case anyone is affected with heat stress, shift that victim to a shaded area,

immediately inform Project ERT via Project Hotline number: 050-892-7264

Implement Buddy system, ensure that no one is allowed to work alone

‘Always provide sufficient cold drinking water and heat stress shelter with complete

requirements including informative signage, mist fan, ec. on work area. Put into

consideration that no water, no work since itis essential for the workers to be

hydrated as always to continue their work

Constant monitoring and supervision shall be implemented and carried out.

o not work at height if wind speed is more than 40.2 kph / 25 mph and in adverse

weather conditions. Refrain from lifting ifthe wind speed is more than 32 kph/20

rmph/9 m/s

Halt lifting activity if there is heavy rain, lighting and thunderstorm,

Wear appropriate clothing for various weather condition including weather

protection clothing

Supervisor to check weather conditions each day prior to work commencing and

throughout the jo.

Ensure rest shelters are provided in the work area

Supervisor should direct the workers to solid roof shaded area during heavy ain.

Make sure to attach tools and fasten when working at heights

Wa. OF Training Trating Howe

subeer.Tyoy name [signature [502 Yon [name [signature

ei Paoo| Fiperdd Oem Yee] ne

iim Saye |

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Heat Related IllnessesSTDocument19 pagesHeat Related IllnessesSTAbdul WasayNo ratings yet

- RA For Saddle AreasDocument6 pagesRA For Saddle AreasAbdul WasayNo ratings yet

- 10230-00-091-PD-0006 (Hip)Document247 pages10230-00-091-PD-0006 (Hip)Abdul WasayNo ratings yet

- Risk Assessment - Confined Space. SESA-BFIM-RA-CS-001Document13 pagesRisk Assessment - Confined Space. SESA-BFIM-RA-CS-001Abdul WasayNo ratings yet

- RA For Confined Space (Installation of Insulation & Cladding) - BFIMDocument9 pagesRA For Confined Space (Installation of Insulation & Cladding) - BFIMAbdul WasayNo ratings yet

- APOC RISK ASSESSMENT FORMAT - SESA-BFIM-RA-INS-002.Rev02Document7 pagesAPOC RISK ASSESSMENT FORMAT - SESA-BFIM-RA-INS-002.Rev02Abdul WasayNo ratings yet

- Apoc Risk Assessment Format - Sesa-Bfim-Ra-Cs-001Document11 pagesApoc Risk Assessment Format - Sesa-Bfim-Ra-Cs-001Abdul WasayNo ratings yet

- SDS Foster 95 50Document7 pagesSDS Foster 95 50Abdul WasayNo ratings yet

- APOC RISK ASSESSMENT FORMAT - SESA-BFIM-RA-INS-002.Rev01Document6 pagesAPOC RISK ASSESSMENT FORMAT - SESA-BFIM-RA-INS-002.Rev01Abdul WasayNo ratings yet

- Splitter - Risk Assessment Presentation. Revision 5Document8 pagesSplitter - Risk Assessment Presentation. Revision 5Abdul WasayNo ratings yet

- S-PCM APOC Insulation & Cladding WorksDocument11 pagesS-PCM APOC Insulation & Cladding WorksAbdul WasayNo ratings yet

- S-PCM Minutes of Meeting For Scaffolding & Insulation Work - Rev06Document80 pagesS-PCM Minutes of Meeting For Scaffolding & Insulation Work - Rev06Abdul WasayNo ratings yet

- S-PCM For Saddle AreaDocument10 pagesS-PCM For Saddle AreaAbdul WasayNo ratings yet

- Doc191222 19122022145112Document12 pagesDoc191222 19122022145112Abdul WasayNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)