Professional Documents

Culture Documents

Vibration Protection Procedure

Uploaded by

matam natarajOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vibration Protection Procedure

Uploaded by

matam natarajCopyright:

Available Formats

ENERGY LIMITED, VIJAYANAGAR

COMMON PROCEDURE - OH&S ISO 9001:2015,ISO 14001:2015,ISO 45001:2018 & ISO

50001:2018

DIN NO. Issue No./Date Rev.No/Date

03/16.04.2020 00/13.01.2023

Procedure for Vibration Protection

Revision status Record:

Revision Date Page Details of Changes Reason for

No. no. changes

Document Approval sheet:

Prepared by Core Team Member

Reviewed by Head-Safety

Approved by Head of Plant

Issued& Controlled MR

by

STANDARD OPERATING PROCEDURE Page 1 of 6

ENERGY LIMITED, VIJAYANAGAR

COMMON PROCEDURE - OH&S ISO 9001:2015,ISO 14001:2015,ISO 45001:2018 & ISO

50001:2018

DIN NO. Issue No./Date Rev.No/Date

03/16.04.2020 00/13.01.2023

1.0 Purpose

This Procedure approach to the management of OHS risks associated with managing

vibration and preventing related health risks. The purpose of this procedure is to outline

safe procedures to ensure that risks associated with activities that generate vibration are

adequately managed in order to minimise the risk of injury or harm to workers, contractors,

visitors and the public.

2.0 Scope

This procedure is applicable for all the employees of JSWEL & Contractors.

This procedure should be complied by the employees of JSWEL & Contractors that

undertake activities where they may be

3.0 Associated procedures:

----

4.0 Responsibility:

4.01 This procedure is prepared by Core team member, reviewed by HOD safety.

4.02 Management Representative will issue and control the procedure.

5.0 Procedure:

General safe work procedures:

Safety Helmet must be worn at all Long and loose hair must be avoided.

times in work place. Usage of Ear muff or Ear Plug whenever

required

Safety Shoes must be worn at all times Close fitting/protective clothing must be

in work areas. worn at all times in work areas. CSE,

LOTO & Height work permits if required.

Safety Goggles must be worn in work areas Use Anti vibration Hand gloves while

whenever required. using vibration generating tools

Rings & jewellery must not be worn & Ensure all flammable materials are

Mobiles to be turned Off. safely stored.

General environmental care:

STANDARD OPERATING PROCEDURE Page 2 of 6

ENERGY LIMITED, VIJAYANAGAR

COMMON PROCEDURE - OH&S ISO 9001:2015,ISO 14001:2015,ISO 45001:2018 & ISO

50001:2018

DIN NO. Issue No./Date Rev.No/Date

03/16.04.2020 00/13.01.2023

Segregate wastes at source ensure their

Ensure that there are no spillage

collection,storage and disposal as per

and leakages liquids.Store all

procedure for relevant type of waste. If

liquids in secondary

not sure,consult environmental

containments.

department.

Perfrom activities having

emissions/dust geenration in Ensure, relevant Common procedure is

secluded araes in way to contain follwed.

dust/smoke.

Switch off all lights.equipment While working keep in mind what can be

and other energy using systems reduced-reused and recycled –for better

where not required. environment.

6. Definition:

“daily exposure” means the quantity of mechanical vibration to which a worker is

exposed during a working day, which takes account of the magnitude and duration

of the vibration;

“Vibration” means a mechanical phenomenon where by oscillations occur about

equilibrium point. The oscillations may be periodic or random.

“high vibration” means any exposure greater than the exposure limit value and

action value specified in clause-7.

“exposure action value” means the level of daily exposure set out in clause-7 for any

worker which, if reached or exceeded, requires specified action to be taken to

reduce risk;

“exposure limit value” means the level of daily exposure for any worker which must

not be exceeded, as specified in sub clause -7

“hand-arm vibration” means mechanical vibration which is transmitted into the

hands and arms during a work activity;

“mechanical vibration” means vibration occurring in a piece of machinery or

equipment or in a vehicle as a result of its operation; and

“whole-body vibration” means mechanical vibration which is transmitted into the

body, when seated or standing, through the supporting surface, during a work

activity or as described in sub clause 7(b).

7. Exposure limit values and action values.

a) For hand-arm vibration - the daily exposure limit value is 5 m/s2 A(8);

b) For whole body vibration - the daily exposure limit value is 1.15 m/s2A(8);

STANDARD OPERATING PROCEDURE Page 3 of 6

ENERGY LIMITED, VIJAYANAGAR

COMMON PROCEDURE - OH&S ISO 9001:2015,ISO 14001:2015,ISO 45001:2018 & ISO

50001:2018

DIN NO. Issue No./Date Rev.No/Date

03/16.04.2020 00/13.01.2023

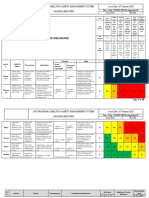

8. Assessment of risk to health due to vibration at the work place.

An occupier who carries out work which is liable to expose any worker from

vibration shall make a suitable and sufficient assessment of the risk created by that

work to the health and safety of those and the risk assessment shall identify the

control measures that need to be taken.

The risk assessment should be reviewed whenever it is felt the changes in the

process makes the earlier risk assessment no longer valid.

9. Engineering control measures

a) The occupier shall ensure that risk from the exposure of workers to vibration is either

eliminated at source or, where this is not reasonably practicable, reduced to as low a level

as is reasonably practicable.

b) Where it is not reasonably practicable to eliminate risk at source pursuant to paragraph

(a) and an exposure action value is likely to be reached or exceeded, the employer shall

reduce exposure to as low a level as is reasonably practicable by establishing and

implementing a programme of engineering control measures which are appropriate to this

type of activity.

c) The occupier shall ensure that the workers are provided with the following measures.

work equipment of appropriate ergonomic design which, taking account of the

work to be done, produces the least possible vibration;

the provision of auxiliary equipment which reduces the risk of injuries caused by

vibration; and install appropriate maintenance programmes for work

equipment, the workplace and workplace systems;

d) The employer shall ensure that his employees are not exposed to vibration above an

exposure limit value; and shall take necessary to identify the reasons for the limit being

exceeded and take appropriate steps to reduce the exposure to vibration to below limit

value.

10. Medical Examination.

a) The occupier shall ensure that the workers who are likely to be exposed to vibration at

above exposure action value are subjected to periodical medical examination once in a year.

The medical examination shall include general and physical examination as well as special

test for Reynaud’s phenomenon.

b) The health record of workers shall be maintained by the occupier for a period of 5 years

from the date of last test and produce to the Inspector of Factories on demand.

c) If at any time the certifying Surgeon/Factory Medical Inspector is of the opinion that the

worker is no longer fit to work in the said process on the ground that continuance daring

STANDARD OPERATING PROCEDURE Page 4 of 6

ENERGY LIMITED, VIJAYANAGAR

COMMON PROCEDURE - OH&S ISO 9001:2015,ISO 14001:2015,ISO 45001:2018 & ISO

50001:2018

DIN NO. Issue No./Date Rev.No/Date

03/16.04.2020 00/13.01.2023

would involve danger to the health of the worker he shall make a record of his findings in

the said certificate and the health register. The entry of his findings in those documents

should also include the period for which he considers that the said person is unfit for work

in the said processes. The person declared unfit in such circumstances shall be provided

with alternate placement facility unless he is fully incapacitated in the opinion of the

Certifying Surgeon in which case the person affected shall be suitably rehabilitated.

11. Personal Protective equipment

a) The occupier shall ensure that the worker who are likely to be exposed to high level of

vibration are provided with appropriate PPE and protective clothing confirming to national

or international standards. Such Personal Protective Equipment should include hand gloves

and safety shoes. The protective clothing shall be able to protect the workers from cold and

dump.

b) The occupier shall ensure that workers are given periodical training in the use care and

maintenance of the Personal Protective Equipment

12. Administrative Control Measures

a) The occupier shall ensure that as far as reasonably practicable as all necessary control

measures are taken to ensure that the unwanted vibrations does not affect the health of

the workers employed in the process to which this part of schedule apply.

b) The occupier shall provide all workers with information instruction and training to be

adopted to limit the exposure limit values.

c) Without prejudice to the generality of paragraph (a), the information, instruction and

training provided under that paragraph shall include–

I.the exposure limit values.

II.safe working practices to minimise exposure to vibration; and

III.suitable and sufficient information and training for employees, such that work

equipment may be used correctly and safely, in order to minimise their exposure to

vibration;

IV. limitation of the duration and magnitude of exposure to vibration;

V. appropriate work schedules with adequate rest periods; and

d) The Occupier shall display pictorial cautionary notices/warning signs at conspicuous

places where there are possibilities of workers being exposed to undesired high

vibrations

13. Prohibition in employment of women, young persons and persons with disabilities.

No women or young person or persons with disabilities shall be employed in the process

covered by this part of the schedule

14. Exemptions

If in respect of any factory, the Chief Inspector is satisfied that owing to any exceptional

circumstances, or infrequently of the process, or for any other reason, application of all or

STANDARD OPERATING PROCEDURE Page 5 of 6

ENERGY LIMITED, VIJAYANAGAR

COMMON PROCEDURE - OH&S ISO 9001:2015,ISO 14001:2015,ISO 45001:2018 & ISO

50001:2018

DIN NO. Issue No./Date Rev.No/Date

03/16.04.2020 00/13.01.2023

any of the provisions of this schedule is not necessary for the protection of the persons

employed in such factory, he may by an order in writing which he may at his discretion

revoke, exempt such factory from all or any of the provisions on such conditions and for

such period as he may specify in the said matter.

Ref:

Karnataka Factories Rules, 1969

Factories act-1948

https://dgfasli.gov.in/en/model-rules-part-ii/operations-involving-high-noise-and-

vibration-levels

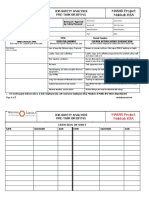

15. Records

Medical report of employee and associate employee

Regular inspection of High noise area

IH reports

STANDARD OPERATING PROCEDURE Page 6 of 6

You might also like

- Jha Atr, WHB, SD Field HydrotestingDocument3 pagesJha Atr, WHB, SD Field HydrotestingarunmirandaNo ratings yet

- He0Alth, Safety and Environment Ola/Uber/Cab Drivers: Submitted byDocument22 pagesHe0Alth, Safety and Environment Ola/Uber/Cab Drivers: Submitted byRohan NandiNo ratings yet

- JP Jo Interview QuestionsDocument10 pagesJP Jo Interview QuestionsMuhammad MehboobNo ratings yet

- ADIS Question Paper Exam Guide for Safety ManagementDocument2 pagesADIS Question Paper Exam Guide for Safety ManagementvikasNo ratings yet

- Government of India Prospectus for Advanced Diploma in Industrial SafetyDocument16 pagesGovernment of India Prospectus for Advanced Diploma in Industrial SafetyEHS Plant6No ratings yet

- Oisd 179Document27 pagesOisd 179Devashish SharmaNo ratings yet

- Industrial Safety ManegmentDocument132 pagesIndustrial Safety ManegmentAdilsha shaikhNo ratings yet

- IGN 07 Working at Height and Working at Height Rescue PlanDocument75 pagesIGN 07 Working at Height and Working at Height Rescue Planin123No ratings yet

- Indian Standard - Method For Computation of Frequency and Severity Rates For Industrial Injuries and Classification of Industrial AccidentsDocument29 pagesIndian Standard - Method For Computation of Frequency and Severity Rates For Industrial Injuries and Classification of Industrial AccidentsKunal JaiswalNo ratings yet

- Hot Work PermitDocument1 pageHot Work PermitvarunstuffNo ratings yet

- Central Labour InstituteDocument15 pagesCentral Labour InstituteSmita KNo ratings yet

- EHS Observation Report FormatDocument1 pageEHS Observation Report FormatDore101No ratings yet

- Action Plan Jalalabad FinalDocument75 pagesAction Plan Jalalabad FinalLimra TravelsNo ratings yet

- Mock Drill Observer Feedback Form Rev-01Document1 pageMock Drill Observer Feedback Form Rev-01Mohammad ArifNo ratings yet

- FUSHAN TECH SAFETY PROCEDUREDocument11 pagesFUSHAN TECH SAFETY PROCEDUREhoangmtbNo ratings yet

- HSE Site Instruction For Contractor FormDocument2 pagesHSE Site Instruction For Contractor Formابو محمد علي100% (1)

- Site Hse Inspection Report: SECB Supervision ProjectsDocument2 pagesSite Hse Inspection Report: SECB Supervision ProjectsRakesh SidhuNo ratings yet

- Mom For Table To Drill MeetingDocument2 pagesMom For Table To Drill MeetingChaudhary Wasim MurtazaNo ratings yet

- Weekly Safety Management Walkthrough Report: Gas Compression Project DepartmentDocument6 pagesWeekly Safety Management Walkthrough Report: Gas Compression Project DepartmentMuhammad TariqNo ratings yet

- 185 Eng PDFDocument1 page185 Eng PDFHaleem Ur Rashid BangashNo ratings yet

- HSEDocument2 pagesHSEPanchdev KumarNo ratings yet

- Chemical Process Safety Management QuestionsDocument1 pageChemical Process Safety Management QuestionsmkkamarajNo ratings yet

- Chirag Barad-EHSDocument4 pagesChirag Barad-EHSChirag BaradNo ratings yet

- Safety Weekly Stats Report Upto 02-Oct - 2021Document1 pageSafety Weekly Stats Report Upto 02-Oct - 2021Sabre AlamNo ratings yet

- Ambulance ChecklistDocument43 pagesAmbulance ChecklistRatnaSuryatiNo ratings yet

- Osh Communication: Document ID: MSP-005Document7 pagesOsh Communication: Document ID: MSP-005Kingsley AhanonuNo ratings yet

- Safe Work Method For Peb Work: Procedure Possible Hazards Control MeasuresDocument35 pagesSafe Work Method For Peb Work: Procedure Possible Hazards Control Measuressandip patilNo ratings yet

- Effluent Discharge Mock Emergency and Evalaution ReportDocument3 pagesEffluent Discharge Mock Emergency and Evalaution Reportremember0% (1)

- Pera JackhammerDocument7 pagesPera Jackhammerjumansyahamid1988No ratings yet

- GGC-HSEF 037 Site Daily ObservationDocument1 pageGGC-HSEF 037 Site Daily ObservationAmjadNo ratings yet

- Job Safety Analysis - Work SheetDocument4 pagesJob Safety Analysis - Work Sheetrickie7809No ratings yet

- ECO - Electrical Shock Emergency Mock DrillDocument4 pagesECO - Electrical Shock Emergency Mock DrillBoluwatife Elisha100% (1)

- HSE Formats (9508 - Part1)Document50 pagesHSE Formats (9508 - Part1)Paras Jani100% (1)

- HSE RequirementDocument10 pagesHSE Requirementyudiyana16No ratings yet

- What is a risk assessmentDocument18 pagesWhat is a risk assessmentKhizar HayatNo ratings yet

- Monthly Safety Inspection 2.3Document6 pagesMonthly Safety Inspection 2.3makaranthNo ratings yet

- SPI HSE FR 01 Foundation ChecklistDocument1 pageSPI HSE FR 01 Foundation ChecklistChandan KumarNo ratings yet

- Part Submission WarrantDocument4 pagesPart Submission WarrantSam AnuNo ratings yet

- 0400E-CHB - Sulfuric AcidDocument1 page0400E-CHB - Sulfuric AcidVeralord De VeraNo ratings yet

- CV - Praveen Kodiganti - HSE OfficerDocument3 pagesCV - Praveen Kodiganti - HSE OfficerAzher AismtcNo ratings yet

- A List of Tested QuestionsDocument6 pagesA List of Tested QuestionsVijay Raj100% (1)

- EOT Crane PermitDocument1 pageEOT Crane PermitHimanshu KumarNo ratings yet

- MOG-HSEQ-P-xxx Rev P1 PPE ManagementDocument47 pagesMOG-HSEQ-P-xxx Rev P1 PPE ManagementSamerNo ratings yet

- SPI HSE FR 02 Tower Erection ChecklistDocument1 pageSPI HSE FR 02 Tower Erection ChecklistChandan KumarNo ratings yet

- PROJECT IMS QEHS PLAN LEGAL REGISTERDocument4 pagesPROJECT IMS QEHS PLAN LEGAL REGISTERPriyanka JNo ratings yet

- Night Work NotificationDocument1 pageNight Work NotificationSreekumarNo ratings yet

- Health, Safety and Environment Policy ManualDocument3 pagesHealth, Safety and Environment Policy ManualVikas SinghNo ratings yet

- Emergency Response Approved.Document24 pagesEmergency Response Approved.Danny SardiniaNo ratings yet

- OSH Risk Register - 01Document28 pagesOSH Risk Register - 01M.usmanNo ratings yet

- 24-Hours Near Miss ReportDocument1 page24-Hours Near Miss ReportHaleemUrRashidBangashNo ratings yet

- L&T Chennai Metro Noise Monitoring ReportDocument1 pageL&T Chennai Metro Noise Monitoring Reportsalman farisNo ratings yet

- HSE Interview Questions & AnswersDocument12 pagesHSE Interview Questions & AnswersPraveen PrabhuNo ratings yet

- WK No.53 (December) 2021 Sepdc-Central - Weekly Kpi - (Ss 8358 Misk ABC) - RevDocument6 pagesWK No.53 (December) 2021 Sepdc-Central - Weekly Kpi - (Ss 8358 Misk ABC) - RevShafie ZubierNo ratings yet

- Noise and Hearing Conservation TrainingDocument1 pageNoise and Hearing Conservation TrainingRabialtu SulihahNo ratings yet

- Environment and Social Policy of NABARD FORMATDocument4 pagesEnvironment and Social Policy of NABARD FORMATMinatiBindhaniNo ratings yet

- Safety QuizDocument2 pagesSafety Quizfirojaga13No ratings yet

- Acf-Mra-063 - UaDocument1 pageAcf-Mra-063 - UaFateh AliyaNo ratings yet

- Workshop Inspection ChecklistDocument10 pagesWorkshop Inspection ChecklistVikas Singh100% (1)

- JHA for Unloading Product from Ship at Port of SalalahDocument4 pagesJHA for Unloading Product from Ship at Port of SalalahSreekumar100% (1)

- TR - Dressmaking NC IIDocument62 pagesTR - Dressmaking NC IIvenieroseNo ratings yet

- Material Safety Data Sheet: 1 Product and Company Identification Air PurifierDocument6 pagesMaterial Safety Data Sheet: 1 Product and Company Identification Air PurifierGusti IchsanNo ratings yet

- C&D MSDSDocument10 pagesC&D MSDSDhiraj KapoorNo ratings yet

- AHB Hong KongDocument46 pagesAHB Hong KongPraveen SankaranNo ratings yet

- EN - MC Blance Drum-Antifriction Bearing-40,50,80 - Rev02Document65 pagesEN - MC Blance Drum-Antifriction Bearing-40,50,80 - Rev02Ping KSomsupNo ratings yet

- Lesson 1 - 1.1-1.3Document16 pagesLesson 1 - 1.1-1.3Rye Rye LasorNo ratings yet

- Compliance ChecklistDocument4 pagesCompliance ChecklistjpNo ratings yet

- Working Effectively in An Information Technology EnvironmentDocument22 pagesWorking Effectively in An Information Technology EnvironmentFloyd GayleNo ratings yet

- ISO 45001 - 2018 ChecklistDocument16 pagesISO 45001 - 2018 ChecklistSanjeev VermaNo ratings yet

- Contractor Management Action Guide CPCCBC5005ADocument7 pagesContractor Management Action Guide CPCCBC5005AAmit SahniNo ratings yet

- Job Safety Analysis Pre-Task Briefing: MASAR Project Makkah KSADocument2 pagesJob Safety Analysis Pre-Task Briefing: MASAR Project Makkah KSAmahammed saleem100% (2)

- HEMPADUR TIE 4718825150 en-USDocument11 pagesHEMPADUR TIE 4718825150 en-USAnuar SalehNo ratings yet

- Fundamentals of Safety Management Rev.2.aDocument20 pagesFundamentals of Safety Management Rev.2.aEhs RolandNo ratings yet

- 4) 7.0 - AD EHS Professional Entity Registration Mechanism v5 31 May 2012Document43 pages4) 7.0 - AD EHS Professional Entity Registration Mechanism v5 31 May 2012Rasheed AhmadNo ratings yet

- BKW Group Code of ConductDocument10 pagesBKW Group Code of ConductNina Adrovic FridauNo ratings yet

- JobDesc - Training Supervisor - Health & SafetyDocument4 pagesJobDesc - Training Supervisor - Health & SafetyTLK ChannelNo ratings yet

- Install 11KV HV Switchgear Panel Method StatementDocument7 pagesInstall 11KV HV Switchgear Panel Method Statementsyed fazluddin67% (3)

- 3 Work Place Risk Assessment 12Document49 pages3 Work Place Risk Assessment 12IgorToporskyNo ratings yet

- SAP EHS Solution Overview - L0 - S4Document21 pagesSAP EHS Solution Overview - L0 - S4c cNo ratings yet

- Occupational Outlook Handbook FormDocument7 pagesOccupational Outlook Handbook Formapi-241519869No ratings yet

- SMS TemplateDocument44 pagesSMS TemplateNazirAhmadBashiriNo ratings yet

- Unit 1: Safe Operations - An IntroductionDocument52 pagesUnit 1: Safe Operations - An IntroductionBukenya RaymondNo ratings yet

- New Labour Codes 2020Document81 pagesNew Labour Codes 2020Jayendra GaurNo ratings yet

- HSE TrainingDocument12 pagesHSE Trainingpaeg6512100% (1)

- Objectives: Lesson 1: Introduction To Cake MakingDocument18 pagesObjectives: Lesson 1: Introduction To Cake MakingMarj MagalongNo ratings yet

- SACHE Text PDFDocument19 pagesSACHE Text PDFeirinaNo ratings yet

- Safety and Health Programs v-03!01!17Document54 pagesSafety and Health Programs v-03!01!17gintangsulungNo ratings yet

- Auto Body Repair Step-By-StepDocument76 pagesAuto Body Repair Step-By-StepMarko Bregovec100% (1)

- G.R. No. 187950 CRISTINA BARSOLO, Petitioner, Social Security System, Respondent. Decision Leonen, J.Document25 pagesG.R. No. 187950 CRISTINA BARSOLO, Petitioner, Social Security System, Respondent. Decision Leonen, J.Moachi SianenNo ratings yet

- Diesel SDS V2Document14 pagesDiesel SDS V2francisNo ratings yet