Professional Documents

Culture Documents

4.CNC and Robotics Lab

Uploaded by

NIKHIL ASOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4.CNC and Robotics Lab

Uploaded by

NIKHIL ASCopyright:

Available Formats

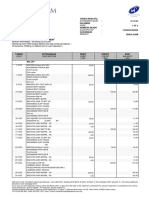

Government of Karnataka

Department of Technical Education

Board of Technical Examinations, Bengaluru

Course Title: CNC & Robotics Lab Course Code: 15MC64P

Mode (L:T:P) : 0:2:4 Credits:3 Core/ Elective: Core

Type of Course: Tutorials and Practical’s Total Contact Hours: 78

CIE- 25 Marks SEE- 50 Marks

Pre-requisites: knowledge of CNC structure, programming of CNC and Basics of Robotics

Course Objectives: To write CNC programs for simple mechanical parts involving milling,

drilling & turning operations and to write program to move Robot elements

Course Outcomes: At the end of the course, students should be able to

1. Develop Programming skills to create a component as per drawing, Simulate the prepared

part programme using available simulation software’s.

2. Develop programming skills to move robotic elements

Cognitive Linked Teaching

Course Outcome

Level with PO Hours

Develop Programming skills to create an

CO1 component for required drawing, Simulate the A 2,3,4 48

prepared part programme using available

simulation software’s.

Develop programming skills to move robotic

CO2 elements A 2,3,4 30

Total sessions 78

Legend: R; Remember, U: Understand A: Application

Mapping of Course Outcomes with Program Outcomes

Course Programme Outcomes

1 2 3 4 5 6 7 8 9 10

CNC & Robotics Lab - 3 3 3 - - - - - -

Directorate of Technical Education Karnataka State 15MC64P Page 1

Contents

Unit-I

CNC Lathe Turning Exercises

1

Develop a part program for step turning and simulate

2 Develop a part program for taper turning and simulate

3 Develop a part program for circular interpolation and simulate

4 Develop a part program for multiple turning operation and simulate

5 Develop a part program for thread cutting, grooving and simulate

6 Develop a part program for internal drills, boring and simulate

CNC Milling Exercises

1 Develop a part program for grooving and simulate

2 Develop a part program for drilling (canned cycle) and simulate

3 Develop a part program for mirroring with subroutines and simulate

Develop a part program for rectangular and circular pocketing and

4

simulate

Unit-II

Robot Programming Exercises

1 Develop and execute a program for the movement of ARM

2 Develop and execute a program for the rotation of BASE

3 Develop and execute a program for the movement of WRIST

4 Develop and execute a program for the movement of ELBOW

5 Develop and execute a program for the movement of SHOULDER

6 Develop and execute a program for PICK & PLACE movement

Directorate of Technical Education Karnataka State 15MC64P Page 2

7 Develop and execute a program for the continuous movement of all the

above

8 Develop and execute a program for the movement of END GRIPPER

9 Develop and execute a program for the identification of colour

10 Develop and execute a program for the segregation of metal and non-

metal parts

Contents linked with CO and PO

Sl No Contents CO PO

1 1 2,3,4

Develop a part program for step turning and simulate

2 Develop a part program for taper turning and simulate 1 2,3,4

3 Develop a part program for circular interpolation and simulate 1 2,3,4

4 Develop a part program for multiple turning operation and simulate 1 2,3,4

5 Develop a part program for thread cutting, grooving and simulate 1 2,3,4

6 Develop a part program for internal drills, boring and simulate 1 2,3,4

7 Develop a part program for grooving and simulate 1 2,3,4

8 Develop a part program for drilling (canned cycle) and simulate 1 2,3,4

9 Develop a part program for mirroring with subroutines and simulate 1 2,3,4

10 Develop a part program for rectangular and circular pocketing and 1 2,3,4

simulate

11 Develop and execute a program for the movement of ARM 2 2,3,4

12 Develop and execute a program for the rotation of BASE 2 2,3,4

13 Develop and execute a program for the movement of WRIST 2 2,3,4

14 Develop and execute a program for the movement of ELBOW 2 2,3,4

15 Develop and execute a program for the movement of SHOULDER 2 2,3,4

16 Develop and execute a program for PICK & PLACE movement 2 2,3,4

17 Develop and execute a program for the continuous movement of all 2 2,3,4

the above

18 Develop and execute a program for the movement of END GRIPPER 2 2,3,4

19 Develop and execute a program for the identification of colour 2 2,3,4

20 Develop and execute a program for the segregation of metal and non- 2 2,3,4

metal parts

Student Activity

Activity No. Description of the Student Activity

1 Develop CNC part programming for a turning component having step turning,

taper turning, thread cutting, Knurling operations

2 Develop CNC part programming for a milling component having mirroring,

pocketing, contour milling operations etc.

Directorate of Technical Education Karnataka State 15MC64P Page 3

3 Present a report on materials used for CNC tooling’s( Hand written 2 0r 3

pages)

4 Present a report on inserts used in CNC cutting tools

5 Develop a CNC program for a simple component by using APT language.

6 Prepare a report on various CAM software

Note:

1. Group of max four students should above activity or any other similar

activity related to the course COs and get it approved from concerned Teacher and HOD.

2. No group should have activity repeated or similar

3. Teacher should asses every student by using suitable Rubrics approved by HOD

Sample Rubrics

Dimension

Exemplary Accomplished Developing Beginning Roll No. of the Student

5/4 3 2 1 1 2 3 4 5

Organization Information Information in Difficult to Cannot Ex:

presented in logical follow understand 2

logical, sequence presentation-- presentation--

interesting student jumps no sequence

sequence around of

information

Subject Demonstrates At ease with Uncomfortable Does not 3

Knowledge full expected with have a grasp

knowledge by answers to information of the

answering all questions but and is able to information.

class does not answer only Cannot

questions with elaborate rudimentary answer

explanations questions questions

and about subject

elaborations

Graphics Explain and Relate to text Occasionally Uses 4

reinforce and uses graphics superfluous

screen text presentation that rarely graphics or

and support text no graphics

presentation and

presentation

Oral Maintains eye Maintains eye Occasionally Reads with 5

Presentation contact and contact most of uses eye no eye

pronounces all the time and contact, mostly contact and

terms pronounces reading incorrectly

precisely. All most words presentation, pronounces

audience correctly. Most and incorrectly terms. Speaks

members can audience pronounces too quietly

hear members can terms.

hear Audience

presentation members have

difficulty

hearing

Total Score=(2+3+4+5)=14/4=3.5=4

Directorate of Technical Education Karnataka State 15MC64P Page 4

Course Assessment Pattern

Particulars Max Evidence Course

Marks outcomes

Direct Assessment CIE Two tests 10 Blue books 1,2,

(Average of

Two tests)

Practical 10 Practical 1,2,

record record

Student 05 Student 1,2,

Activity Activity

Sheets

SEE End of the 50 Answer scripts 1,2,

course at BTE

Indirect Assessment Student Middle of the Feedback 1

Feedback course forms

on course End of the Feedback 1,2

course forms

*CIE – Continuous Internal Evaluation *SEE – Semester End Examination

Note:

1. I.A. test shall be conducted as per SEE scheme of valuation. However obtained marks

shall be reduced to 10 marks. Average marks of two tests shall be rounded off to the next

higher digit.

2. Rubrics to be devised appropriately by the concerned faculty to assess Student activities.

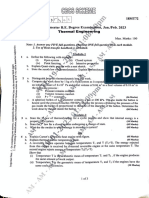

Scheme of valuation for SEE

Sl. No. Performance Max Marks

1 Writing any one CNC program (Turning/Milling) , execution and 10+10+5

simulation

2 Developing and executing any one robot movement 10+05

3 Viva Voce 10

TOTAL 50

Directorate of Technical Education Karnataka State 15MC64P Page 5

You might also like

- Learn to Program with Kotlin: From the Basics to Projects with Text and Image ProcessingFrom EverandLearn to Program with Kotlin: From the Basics to Projects with Text and Image ProcessingNo ratings yet

- Using Aspect-Oriented Programming for Trustworthy Software DevelopmentFrom EverandUsing Aspect-Oriented Programming for Trustworthy Software DevelopmentRating: 3 out of 5 stars3/5 (1)

- 20me702 - Process Planning and Cost Estimation Unit 4 2023-24Document64 pages20me702 - Process Planning and Cost Estimation Unit 4 2023-24CAD With RaoNo ratings yet

- 6.CAD LabDocument5 pages6.CAD LabNIKHIL ASNo ratings yet

- 20me702 - Process Planning and Cost Estimation Unit 5 2023-24Document65 pages20me702 - Process Planning and Cost Estimation Unit 5 2023-24CAD With RaoNo ratings yet

- Lab Manual Soft Engg Odd Sem VDocument84 pagesLab Manual Soft Engg Odd Sem Vrachitsharma4096No ratings yet

- 20me702 - Process Planning and Cost Estimation Unit 1 2023-24Document61 pages20me702 - Process Planning and Cost Estimation Unit 1 2023-24CAD With RaoNo ratings yet

- Mechatronics Digital Material RMK Unit I PDFDocument57 pagesMechatronics Digital Material RMK Unit I PDFRajmchzNo ratings yet

- 29 - MiniProject - ONLINE VOTING SYSTEMDocument23 pages29 - MiniProject - ONLINE VOTING SYSTEMRupesh Roshan0% (1)

- Computer Aided Manufacturing Laboratory: Lab ManualDocument29 pagesComputer Aided Manufacturing Laboratory: Lab ManualdeepakNo ratings yet

- CD Lab ManualDocument83 pagesCD Lab ManualPriyanshu GoutamNo ratings yet

- E Learning Website AngularDocument56 pagesE Learning Website AngularABHIMAT PANDEYNo ratings yet

- SS & OS LAB Manual-1 PDFDocument73 pagesSS & OS LAB Manual-1 PDFhemanthNo ratings yet

- EE220L DLD Lab Manual Fall 2022Document104 pagesEE220L DLD Lab Manual Fall 2022Shoaib MushtaqNo ratings yet

- OODP Mini ProjectDocument19 pagesOODP Mini ProjectMOHIL CHATURVEDI (RA2111003010889)100% (1)

- DHRUV BHASIN (RA2111003011395) : (2018 Regulation)Document18 pagesDHRUV BHASIN (RA2111003011395) : (2018 Regulation)Dhruv BhasinNo ratings yet

- C PrograamingDocument76 pagesC PrograamingPawanNo ratings yet

- Oslp r16 Labmanual FinalDocument80 pagesOslp r16 Labmanual Finalch MahendraNo ratings yet

- OODP Project FinalDocument26 pagesOODP Project FinalDhruv AtriNo ratings yet

- CADCAM Course File May 2016 - CMRDocument371 pagesCADCAM Course File May 2016 - CMRGGRNo ratings yet

- Summer Training Report On COMMERCIAL SURVEILLANCE SYSTEM USING COMPUTER VISIONDocument56 pagesSummer Training Report On COMMERCIAL SURVEILLANCE SYSTEM USING COMPUTER VISIONNaira RajputNo ratings yet

- DL LabmanualDocument54 pagesDL Labmanualtanay.bhor3No ratings yet

- Btech - Cse - Sem 41: Subject Unit Course Department SemesterDocument21 pagesBtech - Cse - Sem 41: Subject Unit Course Department SemesterJashmitha Sai KakavakamNo ratings yet

- Practical PLC Programming - On-LineDocument4 pagesPractical PLC Programming - On-LineJerome LIKIBINo ratings yet

- PDF Microproject PDFDocument10 pagesPDF Microproject PDFTAJKAZINo ratings yet

- EE8591 DSP Unit 1 Notes FinalDocument81 pagesEE8591 DSP Unit 1 Notes Final5047- MUTHINENI AGNIVESHNo ratings yet

- S4 & S5-EEE-Designing of PCB Using Proteus - FinalDocument4 pagesS4 & S5-EEE-Designing of PCB Using Proteus - FinalSaif HassanNo ratings yet

- FlowchartDocument224 pagesFlowchartmubin.pathan765No ratings yet

- Oodp Project Report Ra2111028010068Document26 pagesOodp Project Report Ra2111028010068Dhruv AtriNo ratings yet

- Ec8552-Cao Unit 5Document72 pagesEc8552-Cao Unit 5Anonymous c75J3yX33No ratings yet

- Grade - 9 Computer Engineering - C-ProgrammingDocument77 pagesGrade - 9 Computer Engineering - C-ProgrammingArpan sapkotaNo ratings yet

- MIC (22415) Misroproject FormatDocument12 pagesMIC (22415) Misroproject FormatRohi shewalkarNo ratings yet

- Ta Assignments: Problem Question From TA1 (q1 and q4)Document38 pagesTa Assignments: Problem Question From TA1 (q1 and q4)Iam anonymousNo ratings yet

- Computer Programming Research ContentDocument7 pagesComputer Programming Research ContentFrancis BehingNo ratings yet

- Manual de CNC Torno PDFDocument147 pagesManual de CNC Torno PDFGamaliel Delacruz IntocableNo ratings yet

- Operating Systems: Lab ManualDocument49 pagesOperating Systems: Lab ManualAaneill CrestNo ratings yet

- 7.project work-II On Design of Mechatronics System and Industrial VisitsDocument7 pages7.project work-II On Design of Mechatronics System and Industrial VisitsNIKHIL ASNo ratings yet

- EE4455 Embedded Systems - OBTLDocument6 pagesEE4455 Embedded Systems - OBTLAaron Tan100% (1)

- IT5103 Graphics Gaming TechnologiesDocument8 pagesIT5103 Graphics Gaming TechnologiesIT2025Chinmay KamlaskarNo ratings yet

- 3330705Document5 pages3330705Jigar SoniNo ratings yet

- Linux Basic BLP Msbte Manual Msbte StoreDocument109 pagesLinux Basic BLP Msbte Manual Msbte Storemalisanskruti8No ratings yet

- It-Dl Instructor Manual 17 18 Mdk1Document85 pagesIt-Dl Instructor Manual 17 18 Mdk1Likhith ReddyNo ratings yet

- Template EditedDocument71 pagesTemplate EditedThamizh ArasiNo ratings yet

- ITL202 - Ktu QbankDocument5 pagesITL202 - Ktu QbankManoj KumarNo ratings yet

- EE 353 Computer Networks-Fall 2022Document81 pagesEE 353 Computer Networks-Fall 2022Muhammad TalhaNo ratings yet

- Pcap Cse 3263 Lab Manual 2023Document70 pagesPcap Cse 3263 Lab Manual 2023Kumar AdityaNo ratings yet

- Amc CG 18cs67Document92 pagesAmc CG 18cs67Ama AkhtarNo ratings yet

- 18CS45Document4 pages18CS45technovision22coNo ratings yet

- North South University: Tanzilur - Rahman@northsouth - EduDocument5 pagesNorth South University: Tanzilur - Rahman@northsouth - EduZahidul IslamNo ratings yet

- Sem Vi Csdlo6023 Erp Lessonplan 2018-2019Document13 pagesSem Vi Csdlo6023 Erp Lessonplan 2018-2019Asep JoniNo ratings yet

- Computing7155 Y24 SyDocument17 pagesComputing7155 Y24 Sye9715231No ratings yet

- Faculty of Engineering & Technology: Ganpat UniversityDocument3 pagesFaculty of Engineering & Technology: Ganpat UniversityBLACK彡PANDAA GamingNo ratings yet

- 2024 - Project Report WritingDocument5 pages2024 - Project Report WritingsunmatesurajNo ratings yet

- Java Programming-II - CM4109Document55 pagesJava Programming-II - CM4109G1003 Amit PatilNo ratings yet

- Fundamental of Software DevelopmentDocument8 pagesFundamental of Software DevelopmentSocialNo ratings yet

- Digital Design and Computer Organization - BCS302 - LAB MANUALDocument67 pagesDigital Design and Computer Organization - BCS302 - LAB MANUALZaidaanShiraz50% (6)

- Civil Engineering: Category L T P Credit Year ofDocument4 pagesCivil Engineering: Category L T P Credit Year ofdipinnediyaparambathNo ratings yet

- Digital Design Lab ManualDocument39 pagesDigital Design Lab ManualDhananjayaNo ratings yet

- C4320702 PDFDocument9 pagesC4320702 PDFRISHABH BHALODIANo ratings yet

- 18MT72 Jan Feb 2023Document3 pages18MT72 Jan Feb 2023NIKHIL ASNo ratings yet

- 03 - COLLOBRATIVE ROBOT FOR INDUSTRIAL APPLICATION - ProcessingFeeDocument1 page03 - COLLOBRATIVE ROBOT FOR INDUSTRIAL APPLICATION - ProcessingFeeNIKHIL ASNo ratings yet

- PreviewpdfDocument49 pagesPreviewpdfNIKHIL ASNo ratings yet

- Final - Project - Wokwi ESP32, STM32, Arduino Simulator-2Document1 pageFinal - Project - Wokwi ESP32, STM32, Arduino Simulator-2NIKHIL ASNo ratings yet

- Automative Electronics and Hybrid VehicleDocument34 pagesAutomative Electronics and Hybrid VehicleNIKHIL ASNo ratings yet

- KSCT Project ProposalDocument7 pagesKSCT Project ProposalNIKHIL ASNo ratings yet

- WNC Certificate of Seminar ReportDocument13 pagesWNC Certificate of Seminar ReportNIKHIL ASNo ratings yet

- IV-II PLC Lab ManualDocument46 pagesIV-II PLC Lab ManualNIKHIL ASNo ratings yet

- FRA2020b DesigninginterconnectedhapticinterfacesDocument22 pagesFRA2020b DesigninginterconnectedhapticinterfacesNIKHIL ASNo ratings yet

- Lecture 19Document3 pagesLecture 19NIKHIL ASNo ratings yet

- Power Electronics VivaDocument7 pagesPower Electronics VivaAbhay Shankar Bharadwaj100% (1)

- 3 (A) - Medical Electronics (Elective)Document11 pages3 (A) - Medical Electronics (Elective)NIKHIL ASNo ratings yet

- How To Submit Interest in Skill HubDocument2 pagesHow To Submit Interest in Skill HubNIKHIL AS100% (1)

- Brief Note On Student PassDocument2 pagesBrief Note On Student PassSneha Sneha dollyNo ratings yet

- 5.python-Programming LabDocument7 pages5.python-Programming LabNIKHIL ASNo ratings yet

- 2.industrial ElectronicsDocument12 pages2.industrial ElectronicsNIKHIL ASNo ratings yet

- Ni Lab PrintsDocument23 pagesNi Lab PrintsNIKHIL ASNo ratings yet

- 6.in Plant TrainingDocument5 pages6.in Plant TrainingNIKHIL ASNo ratings yet

- 7.microcontroller and Interfacing LabDocument7 pages7.microcontroller and Interfacing LabNIKHIL ASNo ratings yet

- 5.industrial Electronics and DAS LabDocument5 pages5.industrial Electronics and DAS LabNIKHIL ASNo ratings yet

- Department of Technical EducationDocument10 pagesDepartment of Technical EducationNIKHIL ASNo ratings yet

- 3 (B) .Automotive Electronics (Elective)Document10 pages3 (B) .Automotive Electronics (Elective)NIKHIL ASNo ratings yet

- 7.project work-II On Design of Mechatronics System and Industrial VisitsDocument7 pages7.project work-II On Design of Mechatronics System and Industrial VisitsNIKHIL ASNo ratings yet

- How To PayDocument3 pagesHow To PayNIKHIL ASNo ratings yet

- DEPARTMENT OF MECHATRONICS ENGINEERING EditedDocument11 pagesDEPARTMENT OF MECHATRONICS ENGINEERING EditedNIKHIL ASNo ratings yet

- Python Lab PrintsDocument9 pagesPython Lab PrintsNIKHIL ASNo ratings yet

- Module-4 - Balancing of Rotating MassesDocument46 pagesModule-4 - Balancing of Rotating MassesNIKHIL ASNo ratings yet

- MST PPT1Document18 pagesMST PPT1NIKHIL ASNo ratings yet

- Malware DeveopmentDocument435 pagesMalware Deveopmentjjjabriyel jabriNo ratings yet

- Cooling System Electrolysis: Ron Davis Racing Products IncDocument2 pagesCooling System Electrolysis: Ron Davis Racing Products IncLazarus GutaNo ratings yet

- Final Final Mit SopDocument1 pageFinal Final Mit SopMd. Asaduzzaman NayonNo ratings yet

- EK Gladiator 80 Spec SheetDocument1 pageEK Gladiator 80 Spec SheetRafael JimenezNo ratings yet

- Are Social Networks An Advantage To Share Information or A Problem That Affects The Privacy of Each One?Document1 pageAre Social Networks An Advantage To Share Information or A Problem That Affects The Privacy of Each One?Rocio Peña ArdilaNo ratings yet

- Greenlightningai: An Efficient Ai System With Decoupled Structural and Quantitative KnowledgeDocument15 pagesGreenlightningai: An Efficient Ai System With Decoupled Structural and Quantitative Knowledgeyosamec917No ratings yet

- Exadata X10M Platform Overview Part 2Document3 pagesExadata X10M Platform Overview Part 2jonseverloveNo ratings yet

- Ornella Friggit CVDocument1 pageOrnella Friggit CVOrnella FriggitNo ratings yet

- Iffco Application FormDocument2 pagesIffco Application FormNur SkNo ratings yet

- Alumni Placment 2014 2021Document131 pagesAlumni Placment 2014 2021samyakNo ratings yet

- PLCDocument21 pagesPLCThiagoLiraNo ratings yet

- Kgisl Selected Students ListDocument4 pagesKgisl Selected Students ListNishanthNo ratings yet

- Project MajorDocument2 pagesProject MajorHarshNo ratings yet

- Sample ResumeDocument3 pagesSample ResumeJackkyNo ratings yet

- Datasheet FG2F009Document2 pagesDatasheet FG2F009hanswurstpeter12No ratings yet

- IO 550 ManualDocument850 pagesIO 550 ManualJimyToasaNo ratings yet

- E Waste Recyclers in GurgaonDocument2 pagesE Waste Recyclers in Gurgaonewaste gurgaonNo ratings yet

- Estatement-202310 20240118082918Document3 pagesEstatement-202310 20240118082918jooamir70No ratings yet

- SAMDocument19 pagesSAMOnita Dwi AgustinNo ratings yet

- Librerias ArduinoDocument4 pagesLibrerias ArduinoGustavo Adolfo Peña MarínNo ratings yet

- UL Series ManualV2Document12 pagesUL Series ManualV2AndrewJ73No ratings yet

- CSAP Job Description ASE GeneralDocument2 pagesCSAP Job Description ASE GeneralYossi HassonNo ratings yet

- OptiSystem 7.0 Release NotesDocument3 pagesOptiSystem 7.0 Release NotesRonald SaavedraNo ratings yet

- Notes 04 - Block ManipulationDocument2 pagesNotes 04 - Block ManipulationMan JaNo ratings yet

- Packaging and LabellingDocument32 pagesPackaging and LabellingVishal100% (1)

- Yelo Laser Diode Reliability Burn in and Lifetest For Photonic Devices PowerpointDocument19 pagesYelo Laser Diode Reliability Burn in and Lifetest For Photonic Devices PowerpointDavid SimmsNo ratings yet

- Esp32-S2 Datasheet enDocument45 pagesEsp32-S2 Datasheet enWesllen Dias SouzaNo ratings yet

- Outlines Profiles and SQL BaselinesDocument44 pagesOutlines Profiles and SQL BaselinesAshok ThiyagarajanNo ratings yet

- Remote Access - Students PDFDocument2 pagesRemote Access - Students PDFMae RupidoNo ratings yet

- Blinc 360 and Ajna TechDocument14 pagesBlinc 360 and Ajna TechAlkame IncNo ratings yet