100% found this document useful (12 votes)

18K views2 pagesPump Maintenance Checklist Template

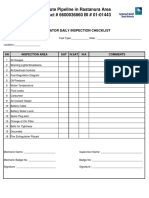

The pump maintenance checklist summarizes the key points to check during pump maintenance. These include inspecting electrical connections and insulation, measuring motor windings and voltage supply, checking amperage draw and thermal protection, examining shaft seals and impeller condition, draining and replacing oil, and verifying correct operation of level controls, valves, and rotation. The technician signs off after completing checks and any necessary maintenance.

Uploaded by

Nishanth GabrielCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

100% found this document useful (12 votes)

18K views2 pagesPump Maintenance Checklist Template

The pump maintenance checklist summarizes the key points to check during pump maintenance. These include inspecting electrical connections and insulation, measuring motor windings and voltage supply, checking amperage draw and thermal protection, examining shaft seals and impeller condition, draining and replacing oil, and verifying correct operation of level controls, valves, and rotation. The technician signs off after completing checks and any necessary maintenance.

Uploaded by

Nishanth GabrielCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

- Pump Maintenance Checklist