Professional Documents

Culture Documents

US2823701

Uploaded by

Ator Vastatin0 ratings0% found this document useful (0 votes)

6 views3 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views3 pagesUS2823701

Uploaded by

Ator VastatinCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

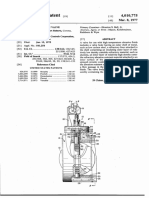

Feb. 18, 1958 M. S.

BURK 2,823,701

EXPANSION LOOF AND BEND FOR UNDERGROUND

HEATING PIPE SYSTEM

Filed Feb 6, 1956

2-R

3.

4.

2

22.2% 2

2.

55.5

32s6 & 2.É. &r

%šŠ3 v S INVENTOR

SSSS

8

(h) r

BY

Fig. 3 -*. (2444.

AT TORNEY

United States Patent Office 2,823,701

Patented Feb. 18, 1958

2

easily slipped over a bend in a heating pipe and then

Seal the split and the joints between sections of the tubes

2,823,70. with tape or mastic to provide a Waterproof expansion

EXPANSON LOOP AND BEND FOR UNDER. void in the insulation or insulating concrete for the heat

GROUND HEATENG PEPE SYSTEM ing pipe. These elbows can be pre-formed in one piece

or put together in mitered sections, and can be of any

Morris S. Burk, Miami Beach, Fla. length and size required.

Application February 6, 1956, Serial No. 563,745 it is also an object of my invention to employ the

O

usual insulation or insulating concrete used in the regular

4. Claims. (C. 138-48) Section for the heating pipes for the construction of my

novel loops and bends wherein employ encasements

of elliptical cross section in place of round paper encase

The present invention relates to a method and means Inent commonly used in this art. The balance of the

for constructing a loop or bend whereby room is pro 5

materials and work is exactly the same for the expansion

vided for the proper expansion and contraction of pipes loops and bends as it is for the straight runs of heating

transmitting fluids or steam at high temperatures. pipe. Thus, no special forms nor concrete chamber con

Heretofore it has been the practice to provide under Structions are needed. Also, the waterproofing continues

ground heating installations with a pocket or chamber, in exactly the same manner for both the straight runs

at intervals of about 300 feet, which chamber would 20 of conduit and for the loops and bends.

'contain U-shaped or elbow-shaped pipe sections of a It is a further object of the invention to provide a posi

size depending on the required expansion of the heating tive and accurately positioned void in the insulating con

(pipes and upon the distances between these chambers. Crete conduit so as to obviate the necessity of building

Such chambers were constructed of concrete and re an expansion chamber, resulting in a saving in excava

quired both waterproofing and insulating of the heat tion and in the cost of concrete encasement; furthermore,

ing pipes within the chamber so as to permit free move changes in direction and length of the heating pipes,

ment of the pipes within the chamber. This method bends, and loops can be made to meet site conditions

required a chamber of considerable length, and hence and overcome obstructions with little cr no loss of time

the expense and the time consumed in constructing the and with little additional expense.

chamber made each expansion joint many times more 30 With these and other objects and features in view, the

costly than the regular and typical length of insulated invention consists in the method of making expansion

heating pipe. joints for installation of underground conduits and in the

Another method heretofore used was to wrap the pipe construction and arrangement of the parts hereinafter

with glass Wool or with some other compressible mate more fully described. The novel features that are con

rial and then encase the pipe and wrapping in insulating 35 sidered characteristic of the invention are set forth with

concrete of a lesser strength or density than the concrete particularity in the appended claims. The invention it

used for typical pipe sections. Such method also has not Self, however, both as to its organization and its method

proven very satisfactory for the following reasons: of operation, together with additional objects and advan

(1) The compressible material would get saturated with tages thereof will best be understood from the following

ceneni and water from the insulating concrete poured 40 description of a specific embodiment when read in con

around it and would lose its compressibility. The ex nection with the accompanying drawings, wherein like

pansion of the heating pipe was then resisted by the reference numerals indicate like parts throughout the

insulating concrete, and cracking or other damage to several figures and in which:

the insulation would result, thereby reducing the value Figure 1 is a central cross sectional view of the ex

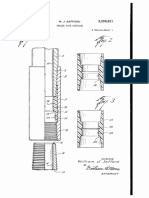

of the insulation in these loops and bends. (2) Since the 45 pansion loop constructed in accordance with my inven

Waterproofing is done on the inside of the concrete cham tion with the heating pipe shown in elevation.

ber, where heat from the pipes and steam formed from Figure 2 is an isometric view of a portion of the loop

possible leaks can attack the asphaltic material normally taken on line 2-2 of Fig. 1.

used, there is usually more trouble with the loops than Figure 3 is a cross section of a portion of the loop taken

there is in standard sections of pipes where the water 50 on line 3-3 of Fig. 1.

proofing is outside the insulation. (3) The concrete ex Figure 4 is an isometric view of a bend in a heating

terior of the loops has to be built as a separate opera pipe installation showing the split elbow in position.

tion, thus consuming additional time resulting in a delay Figure 5 is an isometric view of a bend in a heating

in laying the heating pipes. (4) The concrete type cham pipe installation showing the elliptical elbow in position

ber is very expensive in comparison to the standard sec 55 and sealed with tape, and also showing conical transi

tions of conduit. tion tubes connecting the elliptically-sectioned elbow with

it is therefore an object of my invention to provide typical round cardboard tubes, and

the necessary area for expansion of the heating pipes Figure 6 is a central cross-sectional view of a bend in

by the use of a paper tube of elliptical cross section the heating pipe installation with the pipe shown in ele

which is properly positioned around the pipe and which 60 vation.

is then surrounded with insulated concrete. Referring now to the drawing in detail and more

A further object of the invention is to provide proper specifically to Figures 2 to 5 inclusive, 7 represents the

room for changes in direction of heating pipes contained structural concrete base slab on which all parts and ele

in insulating concrete so as to both prevent binding of ments of the heating system rest. A waterproofing media

the pipe in the concrete and to provide the necessary 65 8 is poured on the slab, which media later embraces or

area for expansion and contraction of the pipe. envelops all the elements of the loop structure. Heating

It is a further object of the invention to provide an pipes 9, 9 are positioned on insulating blocks 0 which

easy and rapid means of installing expansion loops and rest on the base slab 7.

bends in insulating concrete conduits. To prevent the pipes 9 from Sticking to the insulating

Another object of my invention is to provide a split concrete 11, which is poured around them, it is customary

elbow-shaped fitting made of heavy paper or cardboard to wrap each pipe with cardboard or heavy paper.

having an elliptical cross section, which fitting could be employ tubular members 12 which are split longitudinally

2,823,701.

3 4

and hence are easily applied on the heating pipes. The What I claim is:

splits are then sealed with tape or mastic 13. 1. In an underground heating system, a pipe for con

To provide for the expansion and contraction of the ducting fluid or steam under high temperature, a bend in

heating pipes of the underground installation pipes, loops said pipe, means to provide an expansion chamber for

or bends 14 are used, as the case may be, at distances of 5 said pipe comprising tubular members surrounding the

about 300 feet apart. Each loop or bend 14 is provided straight portions of said pipe, an elbow-shaped fitting

with an elbow fitting 15 made of paper or cardboard. Surrounding the bend of said pipe and having an elliptical

This fitting is split at 16 to provide for its easy positioning cross-section to provide space for the proper expansion

around the bend 4 of pipe 9, as clearly shown in Fig. of said pipe in two directions, and transition members

4. Elbow 5 is elliptical in cross-section as shown at O connecting the ends of the fitting with the tubular mem

7 in Figs. 2, 3 and 4. This is done to provide a proper bers, and insulating media encasing said pipe and the

space for the expansion and contraction of the heating means which provide the expansion chamber; said tu

pipe 9 in two directions, shown at right angles to each bular members, elbow-shaped fitting, and transition mem

other in Figs. 4 and 5. A conical transition split tube bers being of flexible heat insulating material of a strength

18 connects one section of the elbow fitting 5 with the to withstand the pressure of the insulating media placed

round tube 2, as shown in Figs. 1, 5, and 6. The joints or poured over said pipe and the means which provide the

between said sections are sealed with tape or mastic 13. expansion chamber and being split longitudinally for easy

After the pipes 9 are fully encased in the cardboard or application over the pipe and bend, and means for sealing

paper tubular sections 2, 5, and 18, the insulation the split of said members and fitting.

means or lightweight concrete 1 is placed or poured 20 2. The device as set forth in claim 1, said members

around the enclosed heating pipes. The waterproofing and fitting being of spirally-wound heavy paper.

media 8 is then applied to cover or envelop the insulation 3. Means for providing space for the expansion and

to complete the section of the heating system. contraction of a fluid carrying pipe in an underground

The following result from my invention: (1) A better heating system encased in heat insulating concrete, said

void to provide for expansion and contraction of the pipe having straight portions joined by a bend or loop,

heating pipe is obtained; (2) a greater flexibility in the tubular members closely embracing the straight portions

construction of the underground heating system is ob of said heating pipe, an elbow-shaped fitting surrounding

tained, since changes in the length and direction of bends the bend of said pipe and being elliptical in cross-section

in the heating pipe can be easily, quickly, and inex to provide space for expansion of said pipe at the bend

pensively made in the field; (3) it is not necessary to use in two directions, and transition members connecting the

insulation of a different quality or type in the areas of ends of the fitting with the tubular members; said tubular

loops and bends than that used in the rest of the installa members, elbow-shaped fitting, and transition members

tion; (4) the waterproofing method and final results are being of flexible heat insulating material of a strength

more satisfactory outside the conduit in my present sys to withstand the pressure of the concrete poured over

ten than the waterproofing done inside the expansion 35 said pipe encased in said flexible heat insulating material.

chamber in the existing systems; (5) the overall time of 4. The means as set forth in claim 3, wherein the

construction is greatly reduced by the use of my method; tubular members, elbow-shaped fitting, and transition

(6) it is easier to install the heating pipes in the bends members are provided with a longitudinal split for easy

and loops in my system and hence the quality of the work application over the pipe and bend, and means for seal.

is better; and (7) the overall cost of installing heat lines 40 ing said split.

is greatly reduced by my system.

Thus, by the simple and practical method described, References Cited in the file of this patent

any number of conduits and expansion joints may be UNITED STATES PATENTS

efficaciously and economically laid. Moreover, com 45 340,073 Ainsworth ------------- Apr. 20, 1886

plete, Sure, and perfect expansion joints and waterproofing 727,786 Grace ----------------- May 12, 1903

means are provided for enclosing the underground high 891,855 Pearce ----------------- June 30, 1908

temperature, under pressure pipe distribution system. 2,081,867 Gysing --------------- May 25, 1937

Although a certain specific embodiment of the inven 2,355,966 Goff------------------- Aug. 15, 1944

tion has been shown and described, it is obvious that 50

many modifications thereof are possible. The invention, FOREIGN PATENTS

therefore, is not to be restricted except insofar as is 165,185 Germany -------------- Nov. 29, 1905

necessitated by the prior art and by the spirit of the

appended claims.

You might also like

- Manual Caterpillar d5m d6m d6r Track Type Tractors Power Train Control System Components Diagrams PDFDocument12 pagesManual Caterpillar d5m d6m d6r Track Type Tractors Power Train Control System Components Diagrams PDFBruno Cecatto86% (21)

- Original: FiledDocument4 pagesOriginal: FiledwcaskeyNo ratings yet

- 'I Ini: March 28, l1961 .1. E. Dalgleish 2,976,679Document5 pages'I Ini: March 28, l1961 .1. E. Dalgleish 2,976,679ShameekaNo ratings yet

- Us2691508 PDFDocument4 pagesUs2691508 PDFKhan ArshiNo ratings yet

- US3420058Document5 pagesUS3420058moonstarNo ratings yet

- Leszózezetail Healts: 3 SeasDocument3 pagesLeszózezetail Healts: 3 SeasVansala GanesanNo ratings yet

- By A? Re.: June 8, 1971 ... I. M. MILLER 3,584,106Document4 pagesBy A? Re.: June 8, 1971 ... I. M. MILLER 3,584,106Vansala GanesanNo ratings yet

- Boiler Heating SurfacesDocument12 pagesBoiler Heating SurfacesHai NguyenNo ratings yet

- United States Patent To 11, 4,010,775: 54 High Temperature Walve Primary Examiner-Houston S. Bell, JRDocument11 pagesUnited States Patent To 11, 4,010,775: 54 High Temperature Walve Primary Examiner-Houston S. Bell, JRThai VoNo ratings yet

- Retubing Experience SRU - WHBDocument5 pagesRetubing Experience SRU - WHBMurugan RangarajanNo ratings yet

- Us3266821 PDFDocument5 pagesUs3266821 PDFDiogo CorreaNo ratings yet

- PWHT For T 23 PanelDocument12 pagesPWHT For T 23 PanelSrinivasaNo ratings yet

- Method For Drilling Cooling HolesDocument7 pagesMethod For Drilling Cooling HolesAbdulaziz AlrawiNo ratings yet

- Energy Piles in ScotlandDocument8 pagesEnergy Piles in ScotlandMilena MurariNo ratings yet

- Method of Manufacturing Regeneratively Cooled Rocket Combustion ChambersDocument5 pagesMethod of Manufacturing Regeneratively Cooled Rocket Combustion ChambersAbhi KrishNo ratings yet

- Chapter 6 - Waste Heat Recovery DevicesDocument37 pagesChapter 6 - Waste Heat Recovery DevicesArshavin Watashi WaNo ratings yet

- CTI Feed WaterheaterDocument9 pagesCTI Feed WaterheaterИринаNo ratings yet

- United States Patent (191: BroylesDocument8 pagesUnited States Patent (191: BroylesbikarexpansionjointsNo ratings yet

- Heating CoilsDocument26 pagesHeating CoilsTrần Tuấn VũNo ratings yet

- Us 3554792Document9 pagesUs 3554792Burag HamparyanNo ratings yet

- Us 2104393Document6 pagesUs 2104393tseeree1 palam1No ratings yet

- United States Patent (19) 11 4,023,782: Eifer (45) May 17, 1977Document16 pagesUnited States Patent (19) 11 4,023,782: Eifer (45) May 17, 1977liNo ratings yet

- Nov. 25, 1941. J. C. Keaney 2,263,848: Filed Jan, Ill, 194l 2 Sheets-Sheet 1Document7 pagesNov. 25, 1941. J. C. Keaney 2,263,848: Filed Jan, Ill, 194l 2 Sheets-Sheet 1EZEQUIELNo ratings yet

- 07-003 Capillary IHXDocument5 pages07-003 Capillary IHXAndrii KuzmenkoNo ratings yet

- BR 1938 PDFDocument4 pagesBR 1938 PDFashok KumarNo ratings yet

- Heating With Coils and JacketsDocument14 pagesHeating With Coils and Jacketsibal_machine100% (1)

- Cooling Technology for ElectronicsDocument29 pagesCooling Technology for ElectronicsNikhil ShahNo ratings yet

- Basic Boiler Construction: Front Fired Studded Wall Refractory Covered BoilerDocument12 pagesBasic Boiler Construction: Front Fired Studded Wall Refractory Covered BoilerAnand JinoNo ratings yet

- Basic Boiler Construction GuideDocument8 pagesBasic Boiler Construction GuideIonescu FlorinNo ratings yet

- US Pat. 3693731Document10 pagesUS Pat. 3693731GaleriaTechniki.PLNo ratings yet

- Basic Boiler ConstructionDocument37 pagesBasic Boiler ConstructionSudarmarine SudharNo ratings yet

- Analysis of A Heat Pipe Assisted Heat SinkDocument6 pagesAnalysis of A Heat Pipe Assisted Heat SinkBALAMUGUNDANNo ratings yet

- Inspection of Double Tube Sheet Exch - Presentation1Document37 pagesInspection of Double Tube Sheet Exch - Presentation1Asad Bin Ala QatariNo ratings yet

- Shell BoilerDocument12 pagesShell BoilerMochamad Fajar RamdaniNo ratings yet

- Vibration-Free Rod-Baffle Design of TubeDocument5 pagesVibration-Free Rod-Baffle Design of Tubehwang2No ratings yet

- Modern Boiler ConstructionDocument7 pagesModern Boiler ConstructionMeghanath AdkonkarNo ratings yet

- Damage To Bottom Ash Handling SysDocument6 pagesDamage To Bottom Ash Handling SyssanjeevchhabraNo ratings yet

- US1983934Document4 pagesUS1983934Erin GokNo ratings yet

- Perry H. Gentzel and Foster Engineering Company v. Manning, Maxwell & Moore, Inc., 230 F.2d 341, 2d Cir. (1956)Document6 pagesPerry H. Gentzel and Foster Engineering Company v. Manning, Maxwell & Moore, Inc., 230 F.2d 341, 2d Cir. (1956)Scribd Government DocsNo ratings yet

- Filed May 7, 1953: J. D. Nesbitt Eta Fast Heat and Soak Furnace For ExtrusionDocument8 pagesFiled May 7, 1953: J. D. Nesbitt Eta Fast Heat and Soak Furnace For Extrusionأبو محمدNo ratings yet

- 11.6 Longitudinal Finned Double-Pipe ExchangersDocument14 pages11.6 Longitudinal Finned Double-Pipe Exchangersvatsal07No ratings yet

- Basic Boiler ConstructionDocument8 pagesBasic Boiler ConstructionLuthfi Yulian FikriNo ratings yet

- Lightweight ceramic-lined rocket motor with unprotected tail coneDocument5 pagesLightweight ceramic-lined rocket motor with unprotected tail coneLeo LonardelliNo ratings yet

- United States Patent (19) : Patent Number: (45) Date of PatentDocument10 pagesUnited States Patent (19) : Patent Number: (45) Date of PatentMichael JordanNo ratings yet

- Simulation and Thermal Analysis of Copper Heat Pipe With Various Wick Structures Using CFX 14 241Document11 pagesSimulation and Thermal Analysis of Copper Heat Pipe With Various Wick Structures Using CFX 14 241MaheshNo ratings yet

- Refinery Based Case Study of A Novel Gasket Designed For Use in Problematic Shell and Tube Heat Exchangers - Change GasketDocument19 pagesRefinery Based Case Study of A Novel Gasket Designed For Use in Problematic Shell and Tube Heat Exchangers - Change GasketAlbertoNo ratings yet

- Boiler OverhaulDocument9 pagesBoiler OverhaulHemant PatilNo ratings yet

- US3768541Document5 pagesUS3768541Ronak shahNo ratings yet

- Labyrinth Packer Lowers Costs For Steam-Injection Wells: Completions TodayDocument2 pagesLabyrinth Packer Lowers Costs For Steam-Injection Wells: Completions TodayraifelmbNo ratings yet

- Induction heating flat metal by transverse fluxDocument5 pagesInduction heating flat metal by transverse fluxAnonymous hQ0bP5Fg8INo ratings yet

- Heat Exchange Core Patent DetailsDocument7 pagesHeat Exchange Core Patent DetailsRadnumNo ratings yet

- US8033754Document10 pagesUS8033754Ator VastatinNo ratings yet

- Cracking and Corrosion of Composite Tubes in Black PDFDocument48 pagesCracking and Corrosion of Composite Tubes in Black PDFFrancisco Luciano Valdespino Mejia100% (1)

- BoilerDocument48 pagesBoilerAbdallah Mansour100% (2)

- US Pat. 3881777Document6 pagesUS Pat. 3881777GaleriaTechniki.PLNo ratings yet

- Cook Stove Terra - CETADocument14 pagesCook Stove Terra - CETAPierre799esNo ratings yet

- Boiler Types and Components OverviewDocument48 pagesBoiler Types and Components OverviewSubramanian Ravishankar100% (1)

- United States Patent: (55% Mini ) : Calanog' 3,603,383 A 9/1971 MichaelDocument11 pagesUnited States Patent: (55% Mini ) : Calanog' 3,603,383 A 9/1971 MichaelaegosmithNo ratings yet

- US8033754Document10 pagesUS8033754Ator VastatinNo ratings yet

- US20090076318A1Document16 pagesUS20090076318A1Ator VastatinNo ratings yet

- Reliable Dual Loop Cooling System Automatically Separates on Leak DetectionDocument9 pagesReliable Dual Loop Cooling System Automatically Separates on Leak DetectionAtor VastatinNo ratings yet

- US8376928Document17 pagesUS8376928Ator VastatinNo ratings yet

- US6142068Document6 pagesUS6142068Ator VastatinNo ratings yet

- US4906484Document14 pagesUS4906484Ator VastatinNo ratings yet

- US8398905Document9 pagesUS8398905Ator VastatinNo ratings yet

- Particle Board Panel Production Method and ApparatusDocument10 pagesParticle Board Panel Production Method and ApparatusAtor VastatinNo ratings yet

- US20120217671A1Document9 pagesUS20120217671A1Ator VastatinNo ratings yet

- ANALYSIS OF STEAM CYCLESDocument4 pagesANALYSIS OF STEAM CYCLESahmedytxzNo ratings yet

- STUDENT DATABASEDocument34 pagesSTUDENT DATABASEReeta ShuklaNo ratings yet

- Detailed-Lesson-Plan Empowerment TechnologyDocument3 pagesDetailed-Lesson-Plan Empowerment TechnologykaryawarxNo ratings yet

- FEM SyllabusDocument2 pagesFEM SyllabuscodieNo ratings yet

- Datasheet M 900ib 700Document1 pageDatasheet M 900ib 700oscar AlvaradoNo ratings yet

- TS-832PX, TS-832PXU-RP, TS-832PXU Compare Products - QNAPDocument12 pagesTS-832PX, TS-832PXU-RP, TS-832PXU Compare Products - QNAPAkram M. AlmotaaNo ratings yet

- Sukeerthi ResumeDocument3 pagesSukeerthi ResumesushmaNo ratings yet

- Fabric filters efficiently remove fine particlesDocument4 pagesFabric filters efficiently remove fine particlesPraphulJainNo ratings yet

- Brochure2-Mobil Greases PDFDocument2 pagesBrochure2-Mobil Greases PDFPedro PerezNo ratings yet

- Inte 314 ExamsDocument4 pagesInte 314 ExamsskipchirchirNo ratings yet

- Agilent 7890GC Firmware Bulletin B.02.05.03 and A.01.16Document35 pagesAgilent 7890GC Firmware Bulletin B.02.05.03 and A.01.16infinity1200No ratings yet

- Entice CatalogueDocument12 pagesEntice Cataloguebharath sNo ratings yet

- SodapdfDocument8 pagesSodapdfpedrohatake755No ratings yet

- Avante True ECG Plus: Cost-Effective Machine For Hospitals, Family Practices and Emergency RespondersDocument1 pageAvante True ECG Plus: Cost-Effective Machine For Hospitals, Family Practices and Emergency RespondersNellyoneTVNo ratings yet

- Fundamentals of Computers: Reema TharejaDocument39 pagesFundamentals of Computers: Reema TharejaYash SharmaNo ratings yet

- ISL95829CHRTZDocument74 pagesISL95829CHRTZJavier Marcelo BastetNo ratings yet

- LogDocument2 pagesLogBormeyNo ratings yet

- Instructions for assembling paper craft coffee valveDocument8 pagesInstructions for assembling paper craft coffee valveJofre Giovanny Apaza MoyaNo ratings yet

- Math108x Doc CHECKPOINTpredictionsDocument2 pagesMath108x Doc CHECKPOINTpredictionsJackson LumbasioNo ratings yet

- The Android Arsenal - Dialogs - Spots Progress DialogDocument8 pagesThe Android Arsenal - Dialogs - Spots Progress DialogRudolfNo ratings yet

- UTD-SOP-Workshop GuideDocument57 pagesUTD-SOP-Workshop GuideAvez AhmedNo ratings yet

- AirScale RNC Product DescriptionDocument46 pagesAirScale RNC Product Descriptionsamir YOUSIF100% (1)

- Kumulative Dissertation Uni WienDocument8 pagesKumulative Dissertation Uni WienWebsitesThatWritePapersForYouSingapore100% (1)

- Ambani Outpaces Biyani (Reliance Buying Big Bazaar) : Presented byDocument8 pagesAmbani Outpaces Biyani (Reliance Buying Big Bazaar) : Presented byAkash B.No ratings yet

- Study of IT Systems at Ashok LeylandDocument3 pagesStudy of IT Systems at Ashok LeylandSiddhant SalilNo ratings yet

- 100 MCQ Questions For Operating Systems MCQ Sets PDFDocument29 pages100 MCQ Questions For Operating Systems MCQ Sets PDFghodkeshital291150% (4)

- A Study of Consumer Satisfaction On After Sales Service of Electronic ProductsDocument37 pagesA Study of Consumer Satisfaction On After Sales Service of Electronic ProductsKaran VarmaNo ratings yet

- UniFi - Getting StartedDocument6 pagesUniFi - Getting StartedRachwandiNo ratings yet

- 4364 Ie3 Fs 90 180 MM Manual enDocument34 pages4364 Ie3 Fs 90 180 MM Manual enSilviu TichieruNo ratings yet