Professional Documents

Culture Documents

pc20tk 1 44 32

Uploaded by

Ryan LeeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

pc20tk 1 44 32

Uploaded by

Ryan LeeCopyright:

Available Formats

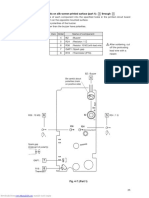

Stand

About 20 ˚ Mounting

Panel screw M3 x 22

for rear case

Rear case

Fig. 4-18: Assembling the panel with the rear case

3. Checking the readout (1 through 6)

Once the reading is assembled properly, it functions as shown in the right column in accordance

with the respective position of the Function switch.

Check Order Position of Function switch Function

All the display elements are illuminated (see Fig. 1-3)

1 V / and then AUTO RS232C xxx.x mV is displayed (xxx.x

is not constant; it always varies)

2 Ω/ / AUTO RS232C O.L MΩ is displayed.

AUTO RS232C xx.xx nF is displayed (xx.xx is not constant;

3

it is a value approximately within the range of 00.10-00.35)

4 400 • 4000 µA / AUTO RS232C 000.0 µA is displayed.

5 40 • 400 mA / AUTO RS232C 00.00 mA is displayed.

40 • 400 mA / • The buzzer sounds.

6

(Press the SELECT switch once.) • AUTO RS232C 00.00 mA is displayed.

Caution: If any of the display elements, which should be illuminated on the LCD in order 1, is missing, it is

attributable to a contact failure due to foreign matter included somewhere between the LCD, the

zebra-striped connector and the printed circuit board (large). Perform the steps in 4-9 again (page 27).

4-12 Adjustments

1. Adjustment environment Screwdriver for DCV Function

adjustment use

Choose an indoor location where temperature is

18-28 °C and relative humidity 75 % maximum Adjustment hole

without exposure to direct sunlight. (DCV ADJ)

After the adjustment,

2. Order of adjustments close the adjustment

hole with the oval seal.

The PC20TK is designed to show any of the readings

within the accuracy shown in "2-3 Specification" after

the DCV adjustment has been completed.

Fig. 4-19:

(1) Set the Function switch to / .

DCV adjustment

(2) Apply 3.8 VDC output from the voltage generator

between the negative (COM) and positive connectors of the PC20TK.

(3) Vertically insert the insulated screwdriver (*) for adjustment use through the DCV adjustment

hole (DCV • ADJ) in the panel surface and fit it into the slot in the pre-set resistor located

inside. Slowly turn the screwdriver clockwise or counterclockwise so that the reading falls

within the range of 3.799-3.801 V. Turning the screwdriver counterclockwise will decrease the

reading, while turning it clockwise will increase the reading.

* Applicable blade of screwdriver: 2.3 in width x 0.4-0.5 mm in thickness; shaft: 4.2 mm

max. in diameter and 15 mm min. in length

(4) After the adjustment, close the adjustment hole with the oval seal (one seal is provided for spare use).

If a standard voltage generator with high accuracy is not available, make connections

as shown in (1) in Fig. 5-1 and then make an adjustment by matching the reading on the

PC20TK with that of the voltmeter used as standard.

30

Downloaded from www.Manualslib.com manuals search engine

You might also like

- MCS100 Check Synch RelayDocument15 pagesMCS100 Check Synch RelayAdetunji TaiwoNo ratings yet

- MN Comp6e 03Document19 pagesMN Comp6e 03baksof3843No ratings yet

- List of Abbreviations-A320Document58 pagesList of Abbreviations-A320Midun Mohan100% (1)

- Cs Imaging v7 System RequirementsDocument4 pagesCs Imaging v7 System RequirementsJimmy GarzonNo ratings yet

- Experiment 6Document11 pagesExperiment 6Real MadridNo ratings yet

- Application Note An-985: Six-Output 600V Mgds Simplify 3-Phase Motor DrivesDocument12 pagesApplication Note An-985: Six-Output 600V Mgds Simplify 3-Phase Motor DrivesTaufik InsaniNo ratings yet

- DPM 1As-Bl: Product DescriptionDocument4 pagesDPM 1As-Bl: Product DescriptionFane PelinNo ratings yet

- Regeltek 213Document15 pagesRegeltek 213Muhammad FatihNo ratings yet

- MAX1702EDocument5 pagesMAX1702ERafael HurtadoNo ratings yet

- 74C922Document18 pages74C922Gunnar GodaraNo ratings yet

- EE-SX461-P11: Photomicrosensor (Transmissive)Document106 pagesEE-SX461-P11: Photomicrosensor (Transmissive)Daniel NicholasNo ratings yet

- DPM 1as-BlDocument4 pagesDPM 1as-BlNarendra BholeNo ratings yet

- En-Ee Sx4235a p2Document2 pagesEn-Ee Sx4235a p2zakreaNo ratings yet

- COMPANO 100 Whats New V2 - 40Document17 pagesCOMPANO 100 Whats New V2 - 40startservice.cpsNo ratings yet

- Voltmeter Using 7106+Document4 pagesVoltmeter Using 7106+MahadevNo ratings yet

- AN650 - Max038 PDFDocument15 pagesAN650 - Max038 PDFbetodias30No ratings yet

- 5.1.3 Operating Manual - RDI 3000VA-110VDC-230VACDocument22 pages5.1.3 Operating Manual - RDI 3000VA-110VDC-230VACdinh quoc baoNo ratings yet

- DVR Pre-Commissioning and CommissioningDocument65 pagesDVR Pre-Commissioning and CommissioningPMG Bhuswal ProjectNo ratings yet

- DS1802Document17 pagesDS1802roNo ratings yet

- LM 2901Document20 pagesLM 2901Aaron IbarraNo ratings yet

- Iga 18 1Document10 pagesIga 18 1Klaus AllowsNo ratings yet

- Touch Screen Controller TipsDocument9 pagesTouch Screen Controller TipsArchana N AmbarishNo ratings yet

- MC34063AB, MC34063AC, MC34063EB, MC34063EC: DC-DC Converter Control CircuitsDocument23 pagesMC34063AB, MC34063AC, MC34063EB, MC34063EC: DC-DC Converter Control CircuitsZettabyte ZettaNo ratings yet

- Foto Diodo DatasheetDocument4 pagesFoto Diodo DatasheetJajiwebNo ratings yet

- Daewoo Cn150 Chassis Dtq14p1fc TV SMDocument35 pagesDaewoo Cn150 Chassis Dtq14p1fc TV SMzxcvbnm12548796No ratings yet

- Waveform Generator Circuit Explain PDFDocument37 pagesWaveform Generator Circuit Explain PDFMio2008No ratings yet

- Minor Project Report by Ayush AnandDocument12 pagesMinor Project Report by Ayush AnandMukul RanaNo ratings yet

- DC 2317 AfaDocument10 pagesDC 2317 AfavictorhugoseNo ratings yet

- Chapter One Controlling The Operation of Wind-Solar Hybrid Power System Using Arduino-Based Hybrid MPPT ControllerDocument48 pagesChapter One Controlling The Operation of Wind-Solar Hybrid Power System Using Arduino-Based Hybrid MPPT ControllerOdebunmi NathanielNo ratings yet

- B Precision K: Instruction ManualDocument43 pagesB Precision K: Instruction Manualedgartepe4324No ratings yet

- Edc Manual RoseDocument48 pagesEdc Manual RoseRagabindu GuruNo ratings yet

- M XxuywDocument13 pagesM XxuywRenganathan KrishnanNo ratings yet

- Imprimir Datasheet 1Document14 pagesImprimir Datasheet 1Randy Siancas VelezNo ratings yet

- Lab10 2011Document5 pagesLab10 2011Venkat RamananNo ratings yet

- ZXSC410 420Document12 pagesZXSC410 420Catalin TirtanNo ratings yet

- 1MRK513001-BEN-En DC-DC Converter With Regulated Output Voltage RXTUG 22HDocument4 pages1MRK513001-BEN-En DC-DC Converter With Regulated Output Voltage RXTUG 22Hsalekojic5332No ratings yet

- EE21 Design of Closed Loop Controlled Ac Voltage Regulator Using TRIACDocument3 pagesEE21 Design of Closed Loop Controlled Ac Voltage Regulator Using TRIACSatishkumar KundrapuNo ratings yet

- Microcontrollers and TRIAC-Based Dimmers-CD00003820Document11 pagesMicrocontrollers and TRIAC-Based Dimmers-CD00003820Dan EsentherNo ratings yet

- G-40-22 TAC Forta M400: Actuator For Valves 20 Nov 2006Document6 pagesG-40-22 TAC Forta M400: Actuator For Valves 20 Nov 2006denitoNo ratings yet

- DC-DC Boost Converter For Custom Application by LeenaDocument4 pagesDC-DC Boost Converter For Custom Application by LeenaRekhamtrNo ratings yet

- Instrukcja - en BM233 2016-05-06 1Document24 pagesInstrukcja - en BM233 2016-05-06 1Szigyarto MihaiNo ratings yet

- Tenderable Specification For Samast Compliant ABT - MeterDocument12 pagesTenderable Specification For Samast Compliant ABT - MeterSristi MitraNo ratings yet

- EDN Design Ideas 1999Document201 pagesEDN Design Ideas 1999chag1956100% (5)

- M54649LDocument5 pagesM54649LAllan AlexNo ratings yet

- AEG DC 2000 Mat 37204601Document2 pagesAEG DC 2000 Mat 37204601mauriceauNo ratings yet

- Ec2-512 Condensing Unit Controller With Ethernet and Webserver FunctionDocument4 pagesEc2-512 Condensing Unit Controller With Ethernet and Webserver FunctionNikolas ChionasNo ratings yet

- P 2010 6 WeDocument22 pagesP 2010 6 WeJosue MatuNo ratings yet

- Service ManualDocument24 pagesService ManualYoReth AndrEea HernAndezzNo ratings yet

- LMB (X) 24-SR (-T) : Proportional, Non-Spring Return, 24 V, For 2 To 10 VDC or 4 To 20 MaDocument2 pagesLMB (X) 24-SR (-T) : Proportional, Non-Spring Return, 24 V, For 2 To 10 VDC or 4 To 20 Majose javier bravo paezNo ratings yet

- SM7020Document17 pagesSM7020BenoitDeCoomanNo ratings yet

- An 477Document28 pagesAn 477radaresNo ratings yet

- VICIDocument6 pagesVICIhaoNo ratings yet

- Triac Dimmer Schematic Diagram-6Document12 pagesTriac Dimmer Schematic Diagram-6elektropaulNo ratings yet

- ABB TRIO-20.0-27.6 - BCD.00379 - EN - RevG PDFDocument4 pagesABB TRIO-20.0-27.6 - BCD.00379 - EN - RevG PDFCristian MenesesNo ratings yet

- Dual Output Voltage Regulator With Power Saving: BA44W12SATDocument10 pagesDual Output Voltage Regulator With Power Saving: BA44W12SATBeatris Medellin MendozaNo ratings yet

- Datasheet - HK Es51922 4700752Document35 pagesDatasheet - HK Es51922 4700752Wagner MirandaNo ratings yet

- Re30242 2020-07Document12 pagesRe30242 2020-07JuanNo ratings yet

- LT366 Demo ManualDocument8 pagesLT366 Demo ManualParasaram SrinivasNo ratings yet

- VIPower: 10W POWER SMPS USING VIPer22A FOR AIR-CONDITIONER APPLICATIONDocument8 pagesVIPower: 10W POWER SMPS USING VIPer22A FOR AIR-CONDITIONER APPLICATIONLullaby summerNo ratings yet

- Project Title: Distribution Transmission Line Voltage Monitoring and Alert SystemDocument34 pagesProject Title: Distribution Transmission Line Voltage Monitoring and Alert SystemyashNo ratings yet

- Specification: 46" HDTV-Panel T460HW01Document27 pagesSpecification: 46" HDTV-Panel T460HW01Matt KuoNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- THP SL eDocument2 pagesTHP SL eRyan LeeNo ratings yet

- pc20tk 1 44 34Document1 pagepc20tk 1 44 34Ryan LeeNo ratings yet

- pc20tk 1 44 30Document1 pagepc20tk 1 44 30Ryan LeeNo ratings yet

- Goldhofer: Main FeaturesDocument1 pageGoldhofer: Main FeaturesRyan LeeNo ratings yet

- Are Your Employees Stealing From YouDocument27 pagesAre Your Employees Stealing From YouGeorge JosephNo ratings yet

- pc20tk 1 44 31Document1 pagepc20tk 1 44 31Ryan LeeNo ratings yet

- pc20tk 1 44 33Document1 pagepc20tk 1 44 33Ryan LeeNo ratings yet

- pc20tk 1 44 22Document1 pagepc20tk 1 44 22Ryan LeeNo ratings yet

- pc20tk 1 44 28Document1 pagepc20tk 1 44 28Ryan LeeNo ratings yet

- pc20tk 1 44 29Document1 pagepc20tk 1 44 29Ryan LeeNo ratings yet

- pc20tk 1 44 26Document1 pagepc20tk 1 44 26Ryan LeeNo ratings yet

- pc20tk 1 44 27Document1 pagepc20tk 1 44 27Ryan LeeNo ratings yet

- pc20tk 1 44 25Document1 pagepc20tk 1 44 25Ryan LeeNo ratings yet

- pc20tk 1 44 24Document1 pagepc20tk 1 44 24Ryan LeeNo ratings yet

- pc20tk 1 44 23Document1 pagepc20tk 1 44 23Ryan LeeNo ratings yet

- pc20tk 1 44 14Document1 pagepc20tk 1 44 14Ryan LeeNo ratings yet

- pc20tk 1 44 21Document1 pagepc20tk 1 44 21Ryan LeeNo ratings yet

- pc20tk 1 44 18Document1 pagepc20tk 1 44 18Ryan LeeNo ratings yet

- pc20tk 1 44 20Document1 pagepc20tk 1 44 20Ryan LeeNo ratings yet

- pc20tk 1 44 15Document1 pagepc20tk 1 44 15Ryan LeeNo ratings yet

- pc20tk 1 44 17Document1 pagepc20tk 1 44 17Ryan LeeNo ratings yet

- pc20tk 1 44 19Document1 pagepc20tk 1 44 19Ryan LeeNo ratings yet

- pc20tk 1 44 10Document1 pagepc20tk 1 44 10Ryan LeeNo ratings yet

- pc20tk 1 44 12Document1 pagepc20tk 1 44 12Ryan LeeNo ratings yet

- pc20tk 1 44 13Document1 pagepc20tk 1 44 13Ryan LeeNo ratings yet

- pc20tk 1 44 11Document1 pagepc20tk 1 44 11Ryan LeeNo ratings yet

- pc20tk 1 44 8Document1 pagepc20tk 1 44 8Ryan LeeNo ratings yet

- pc20tk 1 44 9Document1 pagepc20tk 1 44 9Ryan LeeNo ratings yet

- pc20tk 1 44 6Document1 pagepc20tk 1 44 6Ryan LeeNo ratings yet

- pc20tk 1 44 7Document1 pagepc20tk 1 44 7Ryan LeeNo ratings yet

- Frequency DoublerDocument4 pagesFrequency DoublerprakashroutNo ratings yet

- Molchanov A 2014Document7 pagesMolchanov A 2014mayuri sritharanNo ratings yet

- Icom IC-703 Instruction ManualDocument112 pagesIcom IC-703 Instruction ManualYayok S. AnggoroNo ratings yet

- User Manual PE-6000Document32 pagesUser Manual PE-6000kaung kyel zin aung zaw moeNo ratings yet

- Sensing Products: Quick Product GuideDocument5 pagesSensing Products: Quick Product GuideWMONTOYA4897No ratings yet

- Digsilent Powerfactory: Relay Model DescriptionDocument10 pagesDigsilent Powerfactory: Relay Model DescriptionjdhajhaFDJHJNo ratings yet

- Ampeg - svt-3 User ManualDocument14 pagesAmpeg - svt-3 User ManualVeciti ApsolventNo ratings yet

- Ekinox Series LeafletDocument6 pagesEkinox Series LeafletSaripudin GonNo ratings yet

- Article - Cost and Beneifts of Harmonic Current ReductionDocument9 pagesArticle - Cost and Beneifts of Harmonic Current ReductionHemendraJaniNo ratings yet

- LINTASARTA BROCHURE CONNECTIVITY-compressed PDFDocument7 pagesLINTASARTA BROCHURE CONNECTIVITY-compressed PDFDio AnandaNo ratings yet

- The Summing and Difference AmplifierDocument7 pagesThe Summing and Difference Amplifierموسى سعد لعيبيNo ratings yet

- 01AUL SG 17d SymbolicCircuitAnalysisDocument33 pages01AUL SG 17d SymbolicCircuitAnalysisLuca CorNo ratings yet

- Chapter 4Document85 pagesChapter 4HOD EEENo ratings yet

- Mekatronika: Oleh: Liman Hartawan Jurusan Teknik Mesin Fakultas Teknologi Industri Institut Teknologi NasionalDocument22 pagesMekatronika: Oleh: Liman Hartawan Jurusan Teknik Mesin Fakultas Teknologi Industri Institut Teknologi NasionalYuneo NurcahyaNo ratings yet

- American Industrial Revolution: Morse Code by Yeliz Camacho PerezDocument6 pagesAmerican Industrial Revolution: Morse Code by Yeliz Camacho PerezYeliz Camacho PerezNo ratings yet

- ACS 600 MultiDrive Control Electronics LED IndicatorsDocument6 pagesACS 600 MultiDrive Control Electronics LED IndicatorsEvandro PavesiNo ratings yet

- Pocket ZX Handheld ZX SpectrumDocument15 pagesPocket ZX Handheld ZX SpectrumDavid ClodeNo ratings yet

- Syllabus For Entrance ExaminationDocument4 pagesSyllabus For Entrance ExaminationmaheshvahaniNo ratings yet

- Product Specifications: Beta 58A Supercardioid Dynamic Vocal MicrophoneDocument1 pageProduct Specifications: Beta 58A Supercardioid Dynamic Vocal MicrophoneIva RenićNo ratings yet

- Lenovo C440 AIO Service Manual PDFDocument81 pagesLenovo C440 AIO Service Manual PDFMatt BushnellNo ratings yet

- Spendor A5-A6 Product InformationDocument2 pagesSpendor A5-A6 Product InformationAnonymous vQewJPfVXaNo ratings yet

- Matlab/Simulink Exercise: Digital Filter Design: 2 KHZ 3 KHZ R R FDocument6 pagesMatlab/Simulink Exercise: Digital Filter Design: 2 KHZ 3 KHZ R R Fapi-19804922No ratings yet

- Afdx - Arinc 664. TutorialDocument30 pagesAfdx - Arinc 664. Tutorialsdgpass2585100% (1)

- Dr. Y. Raja Rao: EducationDocument3 pagesDr. Y. Raja Rao: EducationnavecNo ratings yet

- ChamSys Touchscreen SupportDocument2 pagesChamSys Touchscreen SupportKayla PadillaNo ratings yet

- Thesis Example For Electronics EngineeringDocument5 pagesThesis Example For Electronics Engineeringafabfetiu100% (2)

- Laptop ShemaDocument104 pagesLaptop ShemamustapmaNo ratings yet

- Avionics Magazine - Aerospace Abbreviation GuideDocument25 pagesAvionics Magazine - Aerospace Abbreviation Guidefernandoabel01No ratings yet