Professional Documents

Culture Documents

"Pop-Action" Pressure Relief Valves: A8434 and A8436 Series

Uploaded by

shuzaoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

"Pop-Action" Pressure Relief Valves: A8434 and A8436 Series

Uploaded by

shuzaoCopyright:

Available Formats

“Pop-Action” Pressure Relief Valves

General Information

The “Pop-Action” design permits the RegO® Pressure Relief Valve to

open slightly to relieve moderately excessive pressure in the container. Relief valves in this catalog are only intended for use in LP-Gas or

When pressure increases beyond a predetermined point, the valve is anhydrous ammonia service. Do not use any relief valve contained in

designed to “pop” open to its full discharge capacity, reducing excess this catalog with any other service commodity. If you have an appli-

pressure quickly. This is a distinct advantage over ordinary valves which cation other than conventional LP-Gas or anhydrous ammonia

open gradually over their entire range, allowing excessive pressure to service, contact Engineered Controls International, Inc. before pro-

develop before the relief valve is fully open. All RegO® internal, semi- ceeding.

internal, and external relief valves incorporate this “Pop-Action” design.

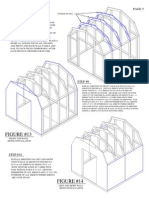

Fully Internal “Pop-Action” Pressure Relief Valves for

Transports and Delivery Trucks

A8434 and A8436 Series

Application

A

C Designed specifically for use as a primary relief valve in ASME transports

and delivery trucks with 2" and 3" NPT couplings.

Features

• Low profile design assures maximum protection against sheering or

distortion.

• All functioning parts are located below the level of the container con-

nection to reduce the possibility of damage or tampering.

• Longer spring size designed to minimize stress cracking in service.

• Use of two different materials for stem and guide minimizes the pos-

sibility of stem seizure which may occur when similar materials are

B used.

• Internal octagonal wrenching broach assures easy installation and

removal.

• ASME approved for use with LP-Gas and anhydrous ammonia.

Materials

Body .............................................................................. Stainless Steel

Spring ............................................................................ Stainless Steel

Stem ............................................................................. Stainless Steel

Stem Bushing ................................................... 17-4PH Stainless Steel

Seat Disc ..................................................... Resilient Synthetic Rubber

UL

®

Ordering Information

Flow Capacity SCFM/Air

C

Start To B Height UL ASME Suitable for

Discharge A Overall Above (At 120% (At 120% Tanks with Protective

Part Setting Container Height Coupling of Set of Set Surface Area Cap

Number PSIG Connection (Approx.) (Approx.) Pressure) Pressure) Up To:* (Included)

A8434N 265 3659

2" M. NPT 9 1⁄16" 12

⁄" 3700 175 Sq. Ft. A8434-11B

A8434G 250 3456

A8436N 265 9839

3" M. NPT 17 7⁄8" 34

⁄" 10210 602 Sq. Ft. A8436-11B

A8436G 250 9598

* Per NFPA Pamphlet #58, Appendix D. Area shown is for UL or ASME flow rating—whichever is larger.

PRODUCTS

D10

You might also like

- 3.3 Over Head Sign BoardDocument4 pages3.3 Over Head Sign BoardBilal A Barbhuiya100% (3)

- Fib Bulletin 65 ContentsDocument7 pagesFib Bulletin 65 ContentsMarko ĆećezNo ratings yet

- Process Plant Estimating StandardsDocument15 pagesProcess Plant Estimating StandardsCarl Williams75% (4)

- SBV-SBVD Eng 120724 1Document6 pagesSBV-SBVD Eng 120724 1SeresdfrtNo ratings yet

- Semi-Internal "Pop-Action" Pressure Relief Valves For ASME ContainersDocument1 pageSemi-Internal "Pop-Action" Pressure Relief Valves For ASME ContainersshuzaoNo ratings yet

- CNG Relief Valve v5.1 PDFDocument2 pagesCNG Relief Valve v5.1 PDFDavid EspinozaNo ratings yet

- Data Sheets Type 4130 Atmospheric Pressure Relief Valves Anderson Greenwood en en 5197938Document8 pagesData Sheets Type 4130 Atmospheric Pressure Relief Valves Anderson Greenwood en en 5197938CarlosAlbertoBerbeoMurallasNo ratings yet

- Gates WP Catalog 4312061 2016 LRDocument335 pagesGates WP Catalog 4312061 2016 LRDiego AvendañoNo ratings yet

- Catalog F84L F88Document16 pagesCatalog F84L F88lix0123No ratings yet

- Captura de Pantalla 2022-11-07 A La(s) 9.13.21Document34 pagesCaptura de Pantalla 2022-11-07 A La(s) 9.13.21HubertNo ratings yet

- PK Valve Page-13-17Document5 pagesPK Valve Page-13-17ICASA IngenieríaNo ratings yet

- Oil Guns and Gas Firing Equipment PDFDocument24 pagesOil Guns and Gas Firing Equipment PDFPravin KumarNo ratings yet

- PSV PDFDocument3 pagesPSV PDFKasnowo DiponegoroNo ratings yet

- Manual Book Pompa 104G5Document7 pagesManual Book Pompa 104G5Ardi 4791No ratings yet

- Durco Plug Valve Dimensions PDFDocument28 pagesDurco Plug Valve Dimensions PDFjtai1983No ratings yet

- Crosby Series BP OMNI-TRIM Pressure Relief Valves For Applications Involving Variable Back PressureDocument12 pagesCrosby Series BP OMNI-TRIM Pressure Relief Valves For Applications Involving Variable Back PressureGanda PrajaNo ratings yet

- Control Valves Two PortDocument16 pagesControl Valves Two Portwendelreis19746883100% (1)

- 1050 Pump Data SheetDocument4 pages1050 Pump Data SheetRery Dwi SNo ratings yet

- SCP Series Technical DataDocument8 pagesSCP Series Technical DataJaldhij PatelNo ratings yet

- Ace Main Catalogue en 04 2009 PDFDocument164 pagesAce Main Catalogue en 04 2009 PDFKrishna TiruvedulaNo ratings yet

- Valves, Fittings and Tubing: Medium and High Pressure Condensed CatalogDocument20 pagesValves, Fittings and Tubing: Medium and High Pressure Condensed CatalogEnrique AssmannNo ratings yet

- Ball Valve - CameronDocument36 pagesBall Valve - CameronMeet JaniNo ratings yet

- Biffi Atuador PneumaticoDocument4 pagesBiffi Atuador PneumaticoAnderson SiqueiraNo ratings yet

- Deareador C.B. Mod. SM PDFDocument34 pagesDeareador C.B. Mod. SM PDFElmer MendozaNo ratings yet

- Cabezotes Gardner DenverDocument8 pagesCabezotes Gardner DenverChristian CardenasNo ratings yet

- Yarway Wye Type Pipeline StrainersDocument12 pagesYarway Wye Type Pipeline StrainersLuis CartageneaNo ratings yet

- Gas Control: VAREC 7100B SeriesDocument8 pagesGas Control: VAREC 7100B SeriesWilson Ramirez ZuniniNo ratings yet

- Welded Pressure Vessel CalculationDocument7 pagesWelded Pressure Vessel CalculationClark Ivan TorresNo ratings yet

- AHLSTAR™ Process Pumps: The Heart of Your ProcessDocument15 pagesAHLSTAR™ Process Pumps: The Heart of Your ProcessFerry AndriansyahNo ratings yet

- Type T Hydraulic Deadweight Tester: RessureDocument8 pagesType T Hydraulic Deadweight Tester: RessureHector MoragaNo ratings yet

- Cameron Fully Welded Ball Valves PDFDocument36 pagesCameron Fully Welded Ball Valves PDFCARLOSNo ratings yet

- Lead Free: Cast Carbon & Alloy Steel Flanged & Butt Weld End Y StrainersDocument2 pagesLead Free: Cast Carbon & Alloy Steel Flanged & Butt Weld End Y StrainersRockny2011No ratings yet

- CNG Solenoid Valve v5.0 PDFDocument1 pageCNG Solenoid Valve v5.0 PDFDavid EspinozaNo ratings yet

- INH InstaLock Brochure LRDocument8 pagesINH InstaLock Brochure LRviniciusNo ratings yet

- KombatDocument8 pagesKombatjesus_manrique2753No ratings yet

- Farris Relief ValvesDocument24 pagesFarris Relief ValvesOtto DonisNo ratings yet

- Viking Q4195 1Document14 pagesViking Q4195 1arbiNo ratings yet

- CAT 2531 Pump Manual.Document4 pagesCAT 2531 Pump Manual.Armando VelardeNo ratings yet

- Maximizing Uptime for Petrochemical PumpsDocument6 pagesMaximizing Uptime for Petrochemical PumpsZainal MuzidNo ratings yet

- PLN-1200-3.07-01, Iss 01 - Product Catalogue PDFDocument12 pagesPLN-1200-3.07-01, Iss 01 - Product Catalogue PDFsakscribNo ratings yet

- Precision Globe Valves for Reliable PerformanceDocument12 pagesPrecision Globe Valves for Reliable PerformancesakscribNo ratings yet

- D Series Installation&Maintenance PDFDocument56 pagesD Series Installation&Maintenance PDFPablo GarcíaNo ratings yet

- Severn 1200 Series V1.2 1Document9 pagesSevern 1200 Series V1.2 1Thắng Trần QuangNo ratings yet

- Product Bulletin: Model Osg Ansi ProcessDocument6 pagesProduct Bulletin: Model Osg Ansi ProcessDomingo DíazNo ratings yet

- Finetrol Rotary Control Valve: Added SecurityDocument14 pagesFinetrol Rotary Control Valve: Added SecurityAmine KhNo ratings yet

- HX HN Compressors Brochure 2015 0318 LRDocument20 pagesHX HN Compressors Brochure 2015 0318 LRAlbert Paco GoytiaNo ratings yet

- Relief Valve DimensionsDocument12 pagesRelief Valve DimensionsPTC Phils.100% (1)

- Technical Bulletine G Series ActuatorsDocument8 pagesTechnical Bulletine G Series Actuatorsarif_setyaw4nNo ratings yet

- 3 2 4 - LC - D Series PDFDocument8 pages3 2 4 - LC - D Series PDFBrLuxy1952No ratings yet

- Es Lf288a DMDocument2 pagesEs Lf288a DMjituplanojrNo ratings yet

- Series 65-72 Ball Valve 2019 - v4 - FinalDocument8 pagesSeries 65-72 Ball Valve 2019 - v4 - FinalPrathamesh Pradeep MashilkarNo ratings yet

- Stainless Steel Standard Knife Gate ValvesDocument18 pagesStainless Steel Standard Knife Gate ValvescmontminyNo ratings yet

- D-Series Rack & Pinion Pneumatic ActuatorsDocument6 pagesD-Series Rack & Pinion Pneumatic ActuatorsJandri JacobNo ratings yet

- Right ItemDocument1 pageRight ItemLPG Equipment Consulting and ServicesNo ratings yet

- Perar Compact Ball ValvesDocument16 pagesPerar Compact Ball ValvesshamekhalmaamariNo ratings yet

- 6240 SpecDocument2 pages6240 SpecCarlos Miguel Barrena TorresNo ratings yet

- Captura de Tela 2023-11-29 À(s) 20.19.42Document44 pagesCaptura de Tela 2023-11-29 À(s) 20.19.42Julio SantosNo ratings yet

- NelesfinetrolDocument14 pagesNelesfinetrolsan21No ratings yet

- Carver Catalog 212CDocument16 pagesCarver Catalog 212CAhmadNo ratings yet

- WKM 370d4 Trunnion Mounted Ball Valves Brochure PDFDocument40 pagesWKM 370d4 Trunnion Mounted Ball Valves Brochure PDFAdhie WaelacxhNo ratings yet

- PM PRO Non-AdjustableDocument26 pagesPM PRO Non-AdjustableKarimZianiNo ratings yet

- Vessel Bottom Disc Valves for Full Flow and Dead Space Free DesignDocument8 pagesVessel Bottom Disc Valves for Full Flow and Dead Space Free DesignMahesh KumarNo ratings yet

- Experimental Research On The Dynamic Instability CDocument13 pagesExperimental Research On The Dynamic Instability CshuzaoNo ratings yet

- Rosenthal 2012Document16 pagesRosenthal 2012shuzaoNo ratings yet

- External "Pop-Action" Pressure Relief Valves For ASME Containers and Bulk Plant InstallationsDocument1 pageExternal "Pop-Action" Pressure Relief Valves For ASME Containers and Bulk Plant InstallationsshuzaoNo ratings yet

- Fully Internal "Pop-Action" Pressure Relief Valve For DOT Fork Lift CylindersDocument1 pageFully Internal "Pop-Action" Pressure Relief Valve For DOT Fork Lift CylindersshuzaoNo ratings yet

- Fully Internal "Pop-Action" Pressure Relief Valves For Motor Fuel ContainersDocument1 pageFully Internal "Pop-Action" Pressure Relief Valves For Motor Fuel ContainersshuzaoNo ratings yet

- Chart A - Minimum Required Rate of Discharge For LP-Gas Pressure Relief Valves Used On ASME ContainersDocument1 pageChart A - Minimum Required Rate of Discharge For LP-Gas Pressure Relief Valves Used On ASME ContainersshuzaoNo ratings yet

- Requirements For Pressure Relief ValvesDocument1 pageRequirements For Pressure Relief ValvesshuzaoNo ratings yet

- Foreword: Caution NoticeDocument1 pageForeword: Caution NoticeshuzaoNo ratings yet

- Safety Warning - LP-Gas Pressure Relief Valves: PurposeDocument1 pageSafety Warning - LP-Gas Pressure Relief Valves: PurposeshuzaoNo ratings yet

- Safety Information - Relief Valves Don't Last Forever: Part Number ExplanationDocument1 pageSafety Information - Relief Valves Don't Last Forever: Part Number ExplanationshuzaoNo ratings yet

- SampleDocument1 pageSampleshuzaoNo ratings yet

- Limited Warranty and Limitation of Liability: ProductsDocument1 pageLimited Warranty and Limitation of Liability: ProductsshuzaoNo ratings yet

- Inspect Regularly: ProductsDocument1 pageInspect Regularly: ProductsshuzaoNo ratings yet

- Civil Engineering: Mrs. JohnsonDocument10 pagesCivil Engineering: Mrs. Johnsontiffjandraughn100% (1)

- Micro Mechanical Behaviour of LaminaDocument65 pagesMicro Mechanical Behaviour of LaminaRajdeep GuptaNo ratings yet

- DME - Expansion Joint - Catalog PDFDocument19 pagesDME - Expansion Joint - Catalog PDFsammar_10No ratings yet

- Ahmedabad Center-10Document2 pagesAhmedabad Center-10RenieNo ratings yet

- Welded Steel Pipes SCH 40 PIPESDocument1 pageWelded Steel Pipes SCH 40 PIPESCorporativo InstacomNo ratings yet

- Schedule D From Section 7Document53 pagesSchedule D From Section 7gowtham reddyNo ratings yet

- Aveng Manufacturing Infrastructure BrochureDocument55 pagesAveng Manufacturing Infrastructure BrochureSravanPolepalliNo ratings yet

- Composite Construction Method PDFDocument38 pagesComposite Construction Method PDFChristopher JarvinNo ratings yet

- Heat ExchangerDocument34 pagesHeat ExchangerducanhbkNo ratings yet

- Final Box Culvert Segment 4 RFI - Inspection of St. Dennis Box Culvert Rebar ArrangementDocument12 pagesFinal Box Culvert Segment 4 RFI - Inspection of St. Dennis Box Culvert Rebar Arrangementpeter njugunaNo ratings yet

- Municipality/City Disposal Facility DF Location DF Status DF RehabilitationDocument5 pagesMunicipality/City Disposal Facility DF Location DF Status DF RehabilitationsorbisorbiNo ratings yet

- AGRU Tech Info eDocument105 pagesAGRU Tech Info ejavierNo ratings yet

- ETABS 17.0.1 Steel Frame Design Strength SummaryDocument2 pagesETABS 17.0.1 Steel Frame Design Strength SummaryJose David CastroNo ratings yet

- Fulltext1 PDFDocument3 pagesFulltext1 PDFvinothNo ratings yet

- NCC2E'2021 Abd Elmalik GOUFIDocument5 pagesNCC2E'2021 Abd Elmalik GOUFIFaklish LoufiNo ratings yet

- 99% Design Narrative of Qalat Distribution LineDocument9 pages99% Design Narrative of Qalat Distribution Linesm.kdh.nsNo ratings yet

- Analysis & Design of Multi-Story Building Using Staad Pro and E-TabsDocument7 pagesAnalysis & Design of Multi-Story Building Using Staad Pro and E-Tabsharish babu aluruNo ratings yet

- Ductility Test On BitumenDocument10 pagesDuctility Test On BitumenMAHESH KCNo ratings yet

- Valente 2017Document14 pagesValente 2017Ahmed KhalilNo ratings yet

- Signage Costing Concrete Text 0192893Document3 pagesSignage Costing Concrete Text 0192893Jeremy BuelbaNo ratings yet

- Case Study of EPS Geofoam Lightweight Fill For Settlement Control at Bridge Approach EmbankmentDocument10 pagesCase Study of EPS Geofoam Lightweight Fill For Settlement Control at Bridge Approach EmbankmentBao TruongNo ratings yet

- BVBVBVBVBBDocument9 pagesBVBVBVBVBBpspNo ratings yet

- 01-SAMSS-034 PDF Download - RTR (Fiberglass) Pressure Pipe and FittingsDocument4 pages01-SAMSS-034 PDF Download - RTR (Fiberglass) Pressure Pipe and FittingsZahidRafiqueNo ratings yet

- Ewat B - D Eimac01706 18en - IomDocument32 pagesEwat B - D Eimac01706 18en - IomPhilip WattNo ratings yet

- Astm C 11 - 05Document5 pagesAstm C 11 - 05Felipe Bateman BuenoNo ratings yet

- In?uence of Curvature Geometry of Laminated FRP Composite Panelson Delamination Damage in Adhesively Bonded Lap Shear JointsDocument10 pagesIn?uence of Curvature Geometry of Laminated FRP Composite Panelson Delamination Damage in Adhesively Bonded Lap Shear Joints615513No ratings yet

- BRIDGE DESIGN MANUALDocument49 pagesBRIDGE DESIGN MANUALdulancivil100% (11)