Professional Documents

Culture Documents

External "Pop-Action" Pressure Relief Valves For ASME Containers and Bulk Plant Installations

Uploaded by

shuzaoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

External "Pop-Action" Pressure Relief Valves For ASME Containers and Bulk Plant Installations

Uploaded by

shuzaoCopyright:

Available Formats

External “Pop-Action” Pressure Relief Valves

for ASME Containers and Bulk Plant Installations

AA3126, AA3130, 3131, 3132, 3133, 3135, AA3135, and A3149 Series

Application

3135-10

Designed for use as a primary relief valve on ASME above ground and

underground containers, bulk plant installations and skid tanks. The 3131

Series may also be used as a primary or secondary relief valve on DOT

cylinders, or as a hydrostatic relief valve.

All working components of these relief valves are outside the container

connection, so the valves must be protected from physical damage.

Features

B

• “Pop-action” design keeps product loss at a minimum.

• Relief valve designed to automatically reseat firmly after discharge.

• Resilient seat disc provides “bubble-tight” seal. C

• 3149 relief valves incorporate integral pipeaway adapter with break off

groove that protects the valve from piping stress damage.

A

• Optional pipeaway adapters have grooves that will break off to pro-

tect the relief valve from damage should excess stress be applied to 3135 A3149

the piping.

• 3149 relief valves include weep hole deflectors, installed to guard

against flame impingment on adjacent containers.

• Most are ASME rated for use with LP-Gas and anhydrous ammonia.

Materials 3132-10

3131, 3132 AA3126

Description 3133, 3135 AA3130 AA3135 A3149

Upper-Cold Rolled Steel

Body Brass Aluminum Rod*

Lower-Ductile Iron

Liner None Stainless Steel

Spring Stainless

Brass Aluminum

Guide Steel

Corrosion

Stainless Stainless Steel

Spring Resistant

Steel or Coated Steel

Steel UL

®

Seat Disc Resilient Synthetic Rubber

* A special coating is applied to the inlet threads to minimize possibility of electrolytic

action between the valve and steel coupling.

AA3135

W3132G

Ordering Information

Flow Capacity SCFM/Air (a) Accessories

Start To A B C UL ASME Suitable for Pipeaway Adapter

Discharge Container Overall Wrench (At 120% (At 120% Tanks with Weep

Part Setting Connection Height Hex of Set of Set Surface Area Protective Part Outlet Hole

Number PSIG M. NPT (Approx.) Section Pressure) Pressure) Up To: (e) Cap Number Size Delfector

AA3126L030 30 1⁄2" 2 3⁄8" 7⁄8" (b) — — 7545-40 AA3126-10 12

⁄ " M. NPT —

A3149L050 50 2600(c) — 113 Sq. Ft.

2 1⁄2" 10 1⁄2" 41⁄8" 3149-40 (h) Included (j)

A3149L200 200 8770 (c) — 500 Sq. Ft.

AA3126L250 1⁄2" 2 3⁄8" 78

⁄" 277 (c) — 23 Sq. Ft. (f) 7545-40 AA3126-10 12

⁄ " M. NPT

3131G 34

2060 1939 85 Sq. Ft. 3131-40 (g) — —

⁄" 3 7⁄16" 13⁄4"

AA3130UA250 2045 1838 249 Sq. Ft. (f) AA3130-40P AA3131-10 1" F. NPT

W3132G 1" 3340 — 154 Sq. Ft. 3132-10 11⁄4" F. NPT

3132G 4130 — 200 Sq. Ft. —

6 1⁄32" 2 3⁄8" 3132-54 (g)

T3132G 250 3790 — 180 Sq. Ft. 3132-10 11⁄4" F. NPT

MV3132G 11⁄4" 3995 — 190 Sq. Ft. — 3133-11B

3135G 11 16 11 16

5770 — 300 Sq. Ft. 3135-54 (g) 3135-10

6 ⁄ " 2 ⁄ "

AA3135UA250 6430 5080 (d) 1010 Sq. Ft. (f) AA3135-40PR AA3135-10 2" F. NPT

3133G 11⁄2" 5 15⁄16" 3 1⁄8" 6080 — 320 Sq. Ft. 3133-40 (g) 3133-10

A3149G 2 1⁄2" 10 1⁄2" 41⁄8" 10390 9153 613 Sq. Ft. 3149-40 (h) Included (j)

AA3130UA265 3⁄4" 3 7⁄16" 13⁄4" 2125 1912 261 Sq. Ft. (f) AA3130-40P AA3131-10 1" F. NPT —

265

AA3135UA265 11⁄4" 6 11⁄16" 2 11⁄16" 6615 5370 (d) 1045 Sq. Ft. (f) AA3135-40PR AA3135-10 2" F. NPT 3133-11B

AA3126L312 312 1⁄2" 2 3⁄8" 7⁄8" 330 (c) — 27 Sq. Ft. (f) 7545-40 AA3126-10 1⁄2" M. NPT —

(a) Flow rates shown are for bare relief valves. Adapters and pipeaways will (f) Per ANSI K61.1-1972, Appendix A.

reduce flow as discussed in forewording information. (g) Cap supplied with chain.

(b) Not UL or ASME rated. .059 square inch effective area. (h) Outlet 31⁄2-8N (F) thread, will accept 3" M. NPT pipe thread.

(c) Not UL or ASME rated. ECII® rated at 120% of set pressure. (j) Weep hole deflector is Part No. A3134-11B.

(d) Rated at 110% of set pressure.

(e) Per NFPA Pamphlet #58, Appendix D. Area shown is for UL or ASME flow

rating—whichever is larger.

PRODUCTS

D14

You might also like

- Machining Design GuideDocument7 pagesMachining Design GuideSagarias AlbusNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Company Profile (ACE VALVE)Document20 pagesCompany Profile (ACE VALVE)DDFSFNo ratings yet

- Patterson Material List PDFDocument8 pagesPatterson Material List PDFViệt Đặng XuânNo ratings yet

- Valves Reference PDFDocument35 pagesValves Reference PDFJulio RodriguezNo ratings yet

- Selective Laser SinteringDocument21 pagesSelective Laser SinteringSreedhar PugalendhiNo ratings yet

- Powder Metallurgy (ISE)Document107 pagesPowder Metallurgy (ISE)likydo100% (1)

- Filter Aid FiltrationDocument8 pagesFilter Aid FiltrationcatalinvsuNo ratings yet

- Ultra Filtration Manual and Line Diagram (Kanin)Document6 pagesUltra Filtration Manual and Line Diagram (Kanin)marksion exchangeNo ratings yet

- Astm A564Document10 pagesAstm A564chetan_thakur4278100% (1)

- CD 45Document1 pageCD 45LPG Equipment Consulting and ServicesNo ratings yet

- Fire HydrantsDocument22 pagesFire HydrantsRaduNo ratings yet

- RegO NH3 AA3130 and AA3135 Series Pressure Relief ValvesDocument1 pageRegO NH3 AA3130 and AA3135 Series Pressure Relief ValvesdoniebaskoroNo ratings yet

- KennedyDocument18 pagesKennedyHimat KhimaniNo ratings yet

- Guardian K81D Hydrant Meets AWWA and UL/FM StandardsDocument18 pagesGuardian K81D Hydrant Meets AWWA and UL/FM Standardsvicvic34No ratings yet

- 04 Mobile Foam Cart CMFCDocument6 pages04 Mobile Foam Cart CMFCuki12345No ratings yet

- Quick Sheet: API 602 Forged Steel Gate ValveDocument3 pagesQuick Sheet: API 602 Forged Steel Gate ValveNaresh ANo ratings yet

- Specifications, Applications, Service Instructions & Parts: AW300H Butt Weld Angle ValveDocument20 pagesSpecifications, Applications, Service Instructions & Parts: AW300H Butt Weld Angle ValveGabriel Rincón RodríguezNo ratings yet

- Aermotor A SuperSubDocument12 pagesAermotor A SuperSubnle_16948No ratings yet

- General Service Solenoid Valves: FeaturesDocument4 pagesGeneral Service Solenoid Valves: FeaturesMar SolNo ratings yet

- Jetcontrol 600-S UK 17072014Document4 pagesJetcontrol 600-S UK 17072014Zeko AmeenNo ratings yet

- FP 700 EngineeringDocument8 pagesFP 700 EngineeringCarlos Alberto VargasNo ratings yet

- DEPA Air Driven Diaphragm Pumps Series M Cast MetalDocument22 pagesDEPA Air Driven Diaphragm Pumps Series M Cast MetalJesús GamboaNo ratings yet

- GLT Ball Valve FLoatingDocument12 pagesGLT Ball Valve FLoatingKIMNo ratings yet

- 14B Overhead SwitchesDocument28 pages14B Overhead SwitchesRhiannon HaynesNo ratings yet

- Pneumatically Operated With Manual Reset Deluge Valve For Freshwater and Seawater ServiceDocument2 pagesPneumatically Operated With Manual Reset Deluge Valve For Freshwater and Seawater ServicedmitosNo ratings yet

- CA10230E - 14B Hookstick Operated SwitchesDocument28 pagesCA10230E - 14B Hookstick Operated SwitchesMelvin Enoc Chavarría ZelayaNo ratings yet

- W.1.29.01 Butterfly Control ValveDocument2 pagesW.1.29.01 Butterfly Control ValveCarlos RodriguezNo ratings yet

- Check Valve - Position IndicatorDocument2 pagesCheck Valve - Position Indicatorunibalaji_05No ratings yet

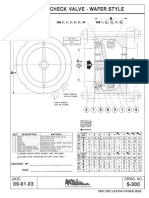

- Silent Check Silent Check Silent Check Silent Check Silent Check V V V V VAL AL AL AL Alve - VE-VE - VE - Ve - W W W W Wafer Style Afer Style Afer Style Afer Style Afer StyleDocument2 pagesSilent Check Silent Check Silent Check Silent Check Silent Check V V V V VAL AL AL AL Alve - VE-VE - VE - Ve - W W W W Wafer Style Afer Style Afer Style Afer Style Afer Styletanvir04169No ratings yet

- Bomba Goulds 3888 D3Document4 pagesBomba Goulds 3888 D3Juanpablo OXNo ratings yet

- AVK Gate Valve Maintenance-Free Design ConceptDocument8 pagesAVK Gate Valve Maintenance-Free Design ConceptRakesh Sasidharan PillaiNo ratings yet

- Resilient Seated Gate Valve: Design Connection Face To Face Marking Tests Corrosion ProtectionDocument6 pagesResilient Seated Gate Valve: Design Connection Face To Face Marking Tests Corrosion ProtectionMohamed RaafatNo ratings yet

- Operation & Maintenance ManualDocument19 pagesOperation & Maintenance ManualDnyaneshwarNo ratings yet

- Watsonmcdaniel WLD600 - WLD601 - LiquidDrainTrapDocument2 pagesWatsonmcdaniel WLD600 - WLD601 - LiquidDrainTrapbudi utomoNo ratings yet

- LR C515 RS Gate Vale R0Document6 pagesLR C515 RS Gate Vale R0Gilberto YoshidaNo ratings yet

- Data Sheet - TVS1200 CD Rev 1Document2 pagesData Sheet - TVS1200 CD Rev 1bhaskarbabaiNo ratings yet

- Flanged Series: Flow-TekDocument8 pagesFlanged Series: Flow-Teklcs2006mvNo ratings yet

- Goulds 3316 BulletinDocument12 pagesGoulds 3316 BulletinJesús DeveraNo ratings yet

- ILL Technical Book - 3180 Deming PumpDocument8 pagesILL Technical Book - 3180 Deming PumpfzamudiolNo ratings yet

- Avk Swing Check Valve, Resilient Seated Pn10/16 41/60-003: With Free Shaft End, DN50-300Document2 pagesAvk Swing Check Valve, Resilient Seated Pn10/16 41/60-003: With Free Shaft End, DN50-300DanielSchwaskiNo ratings yet

- Shield Alarm Check ValveDocument6 pagesShield Alarm Check ValveMd. Mominul IslamNo ratings yet

- Transparent Level Gauge Series 2000: Product Data Sheet No. 7Document1 pageTransparent Level Gauge Series 2000: Product Data Sheet No. 7Alfonso BlancoNo ratings yet

- Compressed Air Fittings & Equipment Catalogue: Importers and Direct Sellers of Quality Hand ToolsDocument18 pagesCompressed Air Fittings & Equipment Catalogue: Importers and Direct Sellers of Quality Hand ToolsVin KenNo ratings yet

- Anti-friction Fire Hydrant FeaturesDocument4 pagesAnti-friction Fire Hydrant FeaturesYury Isasi RosasNo ratings yet

- CTS Plunger TipsDocument2 pagesCTS Plunger TipsAlson LeeNo ratings yet

- ABB Series V Expulsion Dropout FusesDocument4 pagesABB Series V Expulsion Dropout FusesmrhomNo ratings yet

- Manual Valvula de Alivio RciDocument3 pagesManual Valvula de Alivio RciGonzalo DominguezNo ratings yet

- Butterfly Valve AR1Document4 pagesButterfly Valve AR1Robi KeiNo ratings yet

- Vc d v Kea Kfa Kla Spira Trol Ti d413 03Document8 pagesVc d v Kea Kfa Kla Spira Trol Ti d413 03Rinto SilalahiNo ratings yet

- Brochure Pressure Reducing Valve RYUKODocument7 pagesBrochure Pressure Reducing Valve RYUKOPandyNo ratings yet

- ButterflyValves PDFDocument4 pagesButterflyValves PDFmkiani2No ratings yet

- 84-90-001 Avk002ax Eni 432447Document3 pages84-90-001 Avk002ax Eni 432447Gotica ManagementNo ratings yet

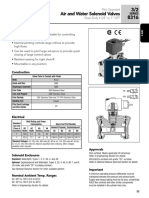

- Asco Series 316 Air Water CatalogDocument4 pagesAsco Series 316 Air Water CatalogekoNo ratings yet

- Asco 8325Document4 pagesAsco 8325Aletz AlegríaNo ratings yet

- Tomacorriente 20amp Appleton CompletoDocument6 pagesTomacorriente 20amp Appleton CompletoFex FexNo ratings yet

- 84-93-001 Avk002ax Eni 432477Document3 pages84-93-001 Avk002ax Eni 432477Gotica ManagementNo ratings yet

- Bermad: FP/FS 400Y Torrent Valve Engineering DataDocument12 pagesBermad: FP/FS 400Y Torrent Valve Engineering Dataeitan-daliaNo ratings yet

- Goulds 3316 BulletinDocument12 pagesGoulds 3316 BulletinKEOPSS03No ratings yet

- 3-Way General Service Solenoid ValvesDocument31 pages3-Way General Service Solenoid ValvesJuan Carlos Pardo RimachiNo ratings yet

- Armstrong 4012Document4 pagesArmstrong 4012visitabhinavNo ratings yet

- Data Sheet - UPRV R2-5Document4 pagesData Sheet - UPRV R2-5vipulsingh130No ratings yet

- Product Brochure Kennedy Guardian k81d K81a and K81am 3b54a01cDocument1 pageProduct Brochure Kennedy Guardian k81d K81a and K81am 3b54a01cAmjed HNo ratings yet

- Wilo Triple Duty Valve / Triple Service Valve: Technical BulletinDocument4 pagesWilo Triple Duty Valve / Triple Service Valve: Technical BulletinilieoniciucNo ratings yet

- Semi-Internal "Pop-Action" Pressure Relief Valves For ASME ContainersDocument1 pageSemi-Internal "Pop-Action" Pressure Relief Valves For ASME ContainersshuzaoNo ratings yet

- Experimental Research On The Dynamic Instability CDocument13 pagesExperimental Research On The Dynamic Instability CshuzaoNo ratings yet

- Rosenthal 2012Document16 pagesRosenthal 2012shuzaoNo ratings yet

- "Pop-Action" Pressure Relief Valves: A8434 and A8436 SeriesDocument1 page"Pop-Action" Pressure Relief Valves: A8434 and A8436 SeriesshuzaoNo ratings yet

- Fully Internal "Pop-Action" Pressure Relief Valve For DOT Fork Lift CylindersDocument1 pageFully Internal "Pop-Action" Pressure Relief Valve For DOT Fork Lift CylindersshuzaoNo ratings yet

- Chart A - Minimum Required Rate of Discharge For LP-Gas Pressure Relief Valves Used On ASME ContainersDocument1 pageChart A - Minimum Required Rate of Discharge For LP-Gas Pressure Relief Valves Used On ASME ContainersshuzaoNo ratings yet

- Fully Internal "Pop-Action" Pressure Relief Valves For Motor Fuel ContainersDocument1 pageFully Internal "Pop-Action" Pressure Relief Valves For Motor Fuel ContainersshuzaoNo ratings yet

- Safety Information - Relief Valves Don't Last Forever: Part Number ExplanationDocument1 pageSafety Information - Relief Valves Don't Last Forever: Part Number ExplanationshuzaoNo ratings yet

- Requirements For Pressure Relief ValvesDocument1 pageRequirements For Pressure Relief ValvesshuzaoNo ratings yet

- Inspect Regularly: ProductsDocument1 pageInspect Regularly: ProductsshuzaoNo ratings yet

- Safety Warning - LP-Gas Pressure Relief Valves: PurposeDocument1 pageSafety Warning - LP-Gas Pressure Relief Valves: PurposeshuzaoNo ratings yet

- Foreword: Caution NoticeDocument1 pageForeword: Caution NoticeshuzaoNo ratings yet

- Limited Warranty and Limitation of Liability: ProductsDocument1 pageLimited Warranty and Limitation of Liability: ProductsshuzaoNo ratings yet

- SampleDocument1 pageSampleshuzaoNo ratings yet

- Rolling Mill - Foundry AuctionDocument10 pagesRolling Mill - Foundry AuctionGogyNo ratings yet

- ASTM E3 Standard Guide For Preparation of Metallographic SpecimensDocument12 pagesASTM E3 Standard Guide For Preparation of Metallographic SpecimensNestor Leonardo Ayasta LevanoNo ratings yet

- Chemical Reaction Engineering - O. LevenspielDocument89 pagesChemical Reaction Engineering - O. LevenspielJack1123qNo ratings yet

- Quiz - Thermochem PRACTICE ANSWERSDocument2 pagesQuiz - Thermochem PRACTICE ANSWERSliana.mirlohi4No ratings yet

- m3 Charge Port Housing AssemblyDocument20 pagesm3 Charge Port Housing AssemblyWilliam SouzaNo ratings yet

- US6855191Document11 pagesUS6855191امين الدينNo ratings yet

- For Public Comment: Draft Malaysian StandardDocument60 pagesFor Public Comment: Draft Malaysian StandardKeith ChooNo ratings yet

- Chapter 23 - Reaction KineticsDocument11 pagesChapter 23 - Reaction KineticsnuofanxiaNo ratings yet

- Visbreaking, Thermal Cracking, and Coking: Mercaptan ExtractionDocument4 pagesVisbreaking, Thermal Cracking, and Coking: Mercaptan ExtractionChetan CherryNo ratings yet

- Shearing Tools GuideDocument21 pagesShearing Tools Guideメルヴリッ クズルエタNo ratings yet

- Full download book Manufacturing Engineering And Technology Pdf pdfDocument41 pagesFull download book Manufacturing Engineering And Technology Pdf pdfmelinda.wilson841100% (14)

- Jotafloor Coating: Technical Data SheetDocument5 pagesJotafloor Coating: Technical Data SheetWilliam SukyonoNo ratings yet

- 00APR40Document7 pages00APR40Claudinei MayerNo ratings yet

- Horizontal Airflow Carbonization MachineDocument3 pagesHorizontal Airflow Carbonization MachineTintin HaberNo ratings yet

- CVD and PVD Processes for Thin Film DepositionDocument24 pagesCVD and PVD Processes for Thin Film DepositionMahesh N 22MVD0090No ratings yet

- Application Guide Penguard MidcoatDocument6 pagesApplication Guide Penguard MidcoatSyeikhabil AsshoqofiNo ratings yet

- QW-482 WELDING PROCEDURE SPECIFICATIONS (WPSDocument1 pageQW-482 WELDING PROCEDURE SPECIFICATIONS (WPSlinaNo ratings yet

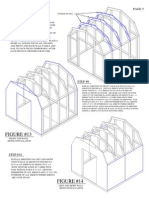

- Construction internship reportDocument8 pagesConstruction internship reportJo NeNo ratings yet

- Specification for Welded Copper and Copper-Alloy Heat Exchanger TubeDocument11 pagesSpecification for Welded Copper and Copper-Alloy Heat Exchanger TubeJason LimNo ratings yet

- Sus904l 158Document1 pageSus904l 158rinthusNo ratings yet

- ECE5-014 - A4 - Productsheet REXNORD CHAINDocument2 pagesECE5-014 - A4 - Productsheet REXNORD CHAINTRMNo ratings yet

- Ke ProfileDocument4 pagesKe Profilekermech21607No ratings yet

- Advantages of Open Die ForgingDocument5 pagesAdvantages of Open Die ForgingAjith KumarNo ratings yet

- Toleranc e FitsDocument39 pagesToleranc e FitsIvan SilvaNo ratings yet