Professional Documents

Culture Documents

Output Summary for Refrigerant Condenser

Uploaded by

ahmad santosoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Output Summary for Refrigerant Condenser

Uploaded by

ahmad santosoCopyright:

Available Formats

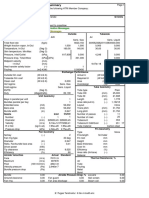

Output Summary Page 1

Released to the following company:

4hM4ds4nT0z0

Xist 7.3.2 25/01/2023 16:46 SN: 46639- SI Units

Rating - Horizontal Countercurrent Flow TEMA BEM Shell With Single-Segmental Baffles

No Data Check Messages.

See Runtime Message Report for Warning Messages.

Process Conditions Hot Shellside Cold Tubeside

Fluid name REF-2 WAT-1

Flow rate (kg/s) 1,0500 * 11,667 *

Inlet/Outlet Y (Wt. frac vap.) 1,0000 0,0000 0,0000 0,0000

Inlet/Outlet T (Deg C) 81,35 46,84 25,00 30,12

Inlet P/Avg (kPa) 1256,0 1255,2 400,00 393,74

dP/Allow. (kPa) 1,580 34,474 12,531 68,948

Fouling (m2-K/W) 0,000176 0,000035

Exchanger Performance

Shell h (W/m2-K) 1452,4 Actual U (W/m2-K) 664,05

Tube h (W/m2-K) 2312,9 Required U (W/m2-K) 444,72

Hot regime (--) Gravity Duty (MegaWatts) 0,2065

Cold regime (--) Sens. Liquid Eff. area (m2) 21,602

EMTD (Deg C) 21,5 Overdesign (%) 49,32

Shell Geometry Baffle Geometry

TEMA type (--) BEM Baffle type Single-Seg.

Shell ID (mm) 336,55 Baffle cut (Pct Dia.) 30

Series (--) 1 Baffle orientation (--) Perpend.

Parallel (--) 1 Central spacing (mm) 300,00

Orientation (deg) 0,00 Crosspasses (--) 7

Tube Geometry Nozzles

Tube type (--) Plain Shell inlet (mm) 77,927

Tube OD (mm) 19,050 Shell outlet (mm) 77,927

Length (m) 2,438 Inlet height (mm) 14,394

Pitch ratio (--) 1,2500 Outlet height (mm) 14,394

Layout (deg) 30 Tube inlet (mm) 102,26

Tubecount (--) 151 Tube outlet (mm) 102,26

Tube Pass (--) 1

Thermal Resistance; % Velocities; m/s Flow Fractions

Shell 45,72 Min Max A 0,149

Tube 36,87 Tubeside 0,46 0,47 B 0,596

Fouling 14,70 Crossflow 5,93e-2 0,55 C 0,157

Metal 2,71 Window 5,51e-2 0,86 E 0,098

F 0,000

D:\Refrigerant Condenser_25_01_2023 16 PM.htri

Run Log Page 2

Released to the following HTRI Member Company:

4hM4ds4nT0z0

Xist 7.3.2 25/01/2023 16:46 SN: 46639- SI Units

Rating - Horizontal Countercurrent Flow TEMA BEM Shell With Single-Segmental Baffles

Beginning Run

Running Xist Unit 1, 100

Condensate exit temperature = 43.7 C ( 110.7 F)

Run Completed. Solution Reached in 00:01.

D:\Refrigerant Condenser_25_01_2023 16 PM.htri

Final Results Page 3

Released to the following company:

4hM4ds4nT0z0

Xist 7.3.2 25/01/2023 16:46 SN: 46639- SI Units

Rating - Horizontal Countercurrent Flow TEMA BEM Shell With Single-Segmental Baffles

Process Data Hot Shellside Cold Tubeside Shellside Performance

Fluid name REF-2 WAT-1 Nom vel, X-flow/window 0,44 / 0,80

Fluid condition Cond. Vapor Sens. Liquid

Total flow rate (kg/s) 1,0500 * 11,667 * Flow fractions for vapor phase

Weight fraction vapor, In/Out (--) 1,0000 0,0000 0,0000 0,0000 A=0,1488 B=0,5964 C=0,1573 E=0,0976 F=0,0000

Temperature, In/Out (Deg C) 81,35 46,84 25,00 30,12

Skin temperature, Min/Max (Deg C) 36,22 42,94 32,85 38,64 Shellside Heat Transfer Corrections

Wall temperature, Min/Max (Deg C) 33,95 40,05 33,43 39,38

Pressure, In/Average (kPa) 1256,0 1255,2 400,00 393,74 Total Beta Gamma End Fin

Pressure drop, Total/Allowed (kPa) 1,580 34,474 12,531 68,948 0,976 0,920 1,061 0,932 1,000

Velocity, Mid/Max allow (m/s) 0,38 0,46 Pressure Drops (Percent of Total)

Mole fraction inert (--) 0,0000 Cross Window Ends Nozzle Shell Tube

Average film coef. (W/m2-K) 1452,4 2312,9 11,22 6,60 6,73 Inlet 67,23 9,17

Heat transfer safety factor (--) 1,0000 1,0000 MOMENTUM -3,04 Outlet 11,26 84,47

Fouling resistance (m2-K/W) 0,000176 0,000035 Two-Phase Parameters

Overall Performance Data Method Inlet Center Outlet Mix F

Overall coef., Reqd/Clean/Actual (W/m2-K) 444,72 / 778,48 / 664,05 RPM Sens Gas Gravity Gravity 0,9786

Heat duty, Calculated/Specified (MegaWatts) 0,2065 / 0,1720

Effective overall temperature difference (Deg C) 21,5 H. T. Parameters Shell Tube

EMTD = (MTD) * (DELTA) * (F/G/H) (Deg C) 21,51 * 0,9990 * 1,0000 Overall wall correction 1,021

Midpoint Prandtl no. 4,75

Midpoint Reynolds no. 5938 7858

See Runtime Messages Report for Bundle inlet Reynolds no. 40485 7503

warnings. Bundle outlet Reynolds no. 2660 8215

Fouling layer (mm)

Exchanger Fluid Volumes Thermal Resistance

Approximate shellside (L) 112,6 Shell Tube Fouling Metal Over Des

Approximate tubeside (L) 139,1 45,72 36,87 14,70 2,71 49,32

Shell Construction Information Total fouling resistance 2,21e-4

TEMA shell type BEM Shell ID (mm) 336,55 Differential resistance 7,43e-4

Shells Series 1 Parallel 1 Total area (m2) 22,032 Shell Nozzles Liquid

Passes Shell 1 Tube 1 Eff. area (m2/shell) 21,602 Inlet at channel end-No Inlet Outlet Outlet

Shell orientation angle (deg) 0,00 Number at each position 1 1 1

Impingement present No Diameter (mm) 77,927 77,927 52,502

Pairs seal strips 1 Passlane seal rods (mm) 0,000 No. 0 Velocity (m/s) 4,33 0,00 0,43

Shell expansion joint No Rear head support plate No Pressure drop (kPa) 1,062 0,000 0,178

Weight estimation Wet/Dry/Bundle 993,39 / 741,79 / 348,04 (kg/shell) Height under nozzle (mm) 14,394 14,394 14,394

Nozzle R-V-SQ (kg/m-s2) 954,10 0,00 208,80

Baffle Information Shell ent. (kg/m-s2) 1369,1 0,00

Type Perpend. Single-Seg. Baffle cut (% dia) 30

Crosspasses/shellpass 7 No. (Pct Area) (mm) to C.L Inlet Outlet Liquid

Central spacing (mm) 300,00 1 28,07 67,310 Tube Nozzle RADIAL RADIAL Outlet

Inlet spacing (mm) 445,19 2 0,00 0,000 Diameter (mm) 102,26 102,26 52,502

Outlet spacing (mm) 445,19 Velocity (m/s) 1,47 0,00 5,61

Baffle thickness (mm) 3,175 Pressure drop (kPa) 1,149 0,000 10,584

Use deresonating baffles No Nozzle R-V-SQ (kg/m-s2) 2089,6 0,00 30237

Tube Information Annular Distributor Inlet Outlet

Tube type Plain Tubecount per shell 151 Length (mm)

Overall length (m) 2,438 Pct tubes removed (both) Height (mm)

Effective length (m) 2,390 Outside diameter (mm) 19,050 Slot area (mm2)

Total tubesheet (mm) 47,625 Wall thickness (mm) 2,108 Diametral Clearances (mm)

Area ratio (out/in) 1,2842 Pitch (mm) 23,813 Ratio 1,2500 Baffle-to-shell Bundle-to-shell Tube-to-baffle

Tube metal Carbon steel Tube pattern (deg) 30 3,1750 20,082 0,7937

D:\Refrigerant Condenser_25_01_2023 16 PM.htri

Supplementary Results Page 4

Released to the following company:

4hM4ds4nT0z0

Xist 7.3.2 25/01/2023 16:46 SN: 46639- SI Units

Rating - Horizontal Countercurrent Flow TEMA BEM Shell With Single-Segmental Baffles

Externally Enhanced Tube Geometry Internally Enhanced Tube Geometry

Type Plain Type None

Fin density (fin/meter) Thickness (mm)

Fin height (mm) Pitch (L/D)

Fin thickness (mm)

Root diameter (mm)

Area/length (m2/m)

Mean Metal Temperatures

Mean shell temperature 50,69 (C)

Mean tube metal temperature in each tubepass, (C)

Tube Pass Inside Outside Radial

1 36,03 36,59 36,33

D:\Refrigerant Condenser_25_01_2023 16 PM.htri

Shellside Incremental Monitor Page 5

Released to the following company:

4hM4ds4nT0z0

Xist 7.3.2 25/01/2023 16:46 SN: 46639- SI Units

Rating - Horizontal Countercurrent Flow TEMA BEM Shell With Single-Segmental Baffles

Shellside Flow Region 1 1,0500 kg/s

Point number (--) 1 2 3 4 5 6 7 8 9

Shell pass (--) 1 1 1 1 1 1 1 1 1

Length from tube inlet (mm) 2390,4 2167,8 1795,2 1495,2 1195,2 895,19 595,19 222,59 0,000

Mass fraction vapor (--) 1,0000 1,0000 0,8884 0,7378 0,5878 0,4376 0,2891 0,1065 0,0000

Bulk temperature (C) 81,35 61,41 47,11 47,11 47,11 47,11 47,11 47,11 46,84

Skin temperature (C) 42,01 39,93 39,28 38,94 38,23 37,60 36,81

Wall metal temperature (C) 39,31 37,52 36,90 36,52 35,85 35,24 34,48

MTD (C) 29,1 18,4 19,0 19,6 20,2 20,9 21,6

Superheat for Onset of Nucleate Boiling (C)

Delta MTD correction (--) 0,9939 1,0000 1,0000 1,0000 1,0000 1,0000 1,0000

Pressure (kPa) 1256,0 1254,9 1254,8 1254,8 1254,7 1254,7 1254,7 1254,6 1254,4

Pressure drop (kPa) 1,062 0,074 0,052 0,044 0,035 0,045 0,058 0,032 0,178

Friction loss (kPa) 0,074 0,068 0,056 0,045 0,052 0,061 0,032

Static head loss (kPa) 0,000 0,000 0,000 0,000 0,000 0,000 0,000

Momentum loss (kPa) -3,9e-4 -0,015 -0,012 -0,010 -6,7e-3 -3,3e-3 1,40e-4

Crossflow velocity (m/s) 0,51 0,54 0,46 0,38 0,29 0,20 7,29e-2

Longitudinal velocity (m/s) 0,79 0,70 0,59 0,48 0,37 0,26 0,11

Shear stress at tube wall

Crossflow (Pa) 0,00 0,00 0,00 0,00 0,00 0,00 0,00

Longitudinal flow (Pa) 2,83e-2 0,00 0,00 0,00 0,00 0,00 0,00

Area (m2) 4,023 2,711 2,711 2,711 2,711 2,711 4,023

Cumulative area (m2) 4,023 6,734 9,445 12,156 14,867 17,579 21,602

Duty (MegaWatts) 0,0448 0,0254 0,0249 0,0253 0,0249 0,0247 0,0363

Cumulative duty (MegaWatts) 0,0448 0,0703 0,0951 0,1204 0,1454 0,1701 0,2064

Heat flux (W/m2) 11139 9385,8 9176,6 9323,9 9199,0 9122,3 9025,2

Calculated heat flux (W/m2) 15743 13197 12939 13151 12964 12852 12712

Critical heat flux (W/m2)

Overall U (W/m2-K) 587,08 751,55 718,71 708,07 674,91 648,41 618,81

Shellside h (W/m2-K) 1096,3 1903,5 1726,2 1684,0 1524,6 1409,4 1286,0

Sensible liquid h (W/m2-K) 0,00 0,00 0,00 0,00 0,00 0,00 0,00

Sensible vapor h (W/m2-K) 198,32 197,43 175,74 152,32 126,44 96,70 35,94

Condensate film h (W/m2-K) 1223,6 1906,2 1728,0 1685,5 1526,2 1411,1 1286,8

Vapor phase h (W/m2-K) 10536 1374075 1712883 1898484 1497161 1181687 2003383

Nucleate boiling h (W/m2-K) 0,00 0,00 0,00 0,00 0,00 0,00 0,00

Conv. boiling h (W/m2-K) 0,00 0,00 0,00 0,00 0,00 0,00 0,00

Film boiling h (W/m2-K) 0,00 0,00 0,00 0,00 0,00 0,00 0,00

Boiling thin film h (W/m2-K) 0,00 0,00 0,00 0,00 0,00 0,00 0,00

Natural convective h (W/m2-K) 0,00 0,00 0,00 0,00 0,00 0,00 0,00

Local Reynolds (--) 40485 44601 13366 7943,6 5938,0 4843,0 4145,1 3460,7 2659,9

Vapor Reynolds (--) 40485 51880 49171 40807 32338 23901 15555 5080,3 0,0000

Liquid Reynolds (--) 0,0000 18,060 419,89 916,38 1419,0 1919,8 2415,2 2939,1 2659,9

Vapor Prandtl (--) 0,8780 0,9099 0,9521 0,9521 0,9520 0,9520 0,9520 0,9520 0,9524

Liquid Prandtl (--) 4,7200 1,1792 4,7166 4,7165 4,7165 4,7165 4,7164 4,7154 4,7090

Flow regime param. (--) 0,0474 0,5027 0,8230 1,1527 1,5628 2,1848 6,5354

Condensate regime (--) Sens Gas Gravity Gravity Gravity Gravity Gravity Gravity

Boiling flow regime (--)

Boiling mechanism (--)

D:\Refrigerant Condenser_25_01_2023 16 PM.htri

Tubeside Incremental Monitor Page 6

Released to the following company:

4hM4ds4nT0z0

Xist 7.3.2 25/01/2023 16:46 SN: 46639- SI Units

Rating - Horizontal Countercurrent Flow TEMA BEM Shell With Single-Segmental Baffles

Point number (--) 1 2 3 4 5 6 7 8 9

Tube Pass (--) 1 1 1 1 1 1 1 1 1

Length from tube inlet (mm) 0,000 222,59 595,19 895,19 1195,2 1495,2 1795,2 2167,8 2390,4

Mass fraction vapor (--) 0,0000 0,0000 0,0000 0,0000 0,0000 0,0000 0,0000 0,0000 0,0000

Bulk temperature (C) 25,00 25,46 26,24 26,86 27,49 28,11 28,72 29,58 30,12

Skin temperature (C) 33,34 34,09 34,69 35,34 35,74 36,35 37,99

Wall metal temperature (C) 33,94 34,69 35,30 35,96 36,35 36,97 38,68

MTD (C) 21,6 20,9 20,2 19,6 19,0 18,4 29,1

Superheat for Onset of Nucleate Boiling (C)

Pressure (kPa) 400,00 398,74 398,63 398,56 398,48 398,40 398,32 398,22 387,47

Pressure drop (kPa) 1,201 0,124 0,079 0,079 0,079 0,079 0,078 0,123 10,688

Enhanced pressure drop mult (--)

Friction loss (kPa) 0,124 0,079 0,079 0,079 0,079 0,078 0,123

Static head loss (kPa) 0,000 0,000 0,000 0,000 0,000 0,000 0,000

Momentum loss (kPa) 0,000 0,000 0,000 0,000 0,000 0,000 0,000

Maximum velocity (m/s) 0,46 0,46 0,46 0,46 0,46 0,46 0,47

Average velocity (m/s) 0,46 0,46 0,46 0,46 0,46 0,46 0,47

Shear stress at tube wall (Pa) 0,98 0,98 0,98 0,97 0,97 0,97 0,97

Area (m2) 4,023 2,711 2,711 2,711 2,711 2,711 4,023

Cumulative area (m2) 4,023 6,734 9,445 12,156 14,867 17,579 21,602

Duty (MegaWatts) 0,0363 0,0247 0,0249 0,0253 0,0249 0,0254 0,0448

Cumulative duty (MegaWatts) 0,0363 0,0610 0,0860 0,1113 0,1361 0,1616 0,2064

Heat flux (W/m2) 9025,2 9122,3 9199,0 9323,9 9176,6 9385,8 11139

Calculated heat flux (W/m2) 12712 12852 12964 13151 12939 13198 15839

Critical heat flux (W/m2) 0,00 0,00 0,00 0,00 0,00 0,00 0,00

Overall U (W/m2-K) 618,81 648,41 674,91 708,07 718,71 751,55 587,08

Tubeside h (W/m2-K) 2228,5 2250,6 2278,4 2308,2 2335,1 2364,5 2427,4

Enhanced heat transfer mult (--)

Sensible liquid h (W/m2-K) 2228,5 2250,6 2278,4 2308,2 2335,1 2364,4 2425,9

Sensible vapor h (W/m2-K) 0,00 0,00 0,00 0,00 0,00 0,00 0,00

Condensate film h (W/m2-K) 0,00 0,00 0,00 0,00 0,00 0,00 0,00

Vapor phase h (W/m2-K) 0,00 0,00 0,00 0,00 0,00 0,00 0,00

Nucleate boiling h (W/m2-K) 0,00 0,00 0,00 0,00 0,00 0,00 0,00

Conv. boiling h (W/m2-K) 0,00 0,00 0,00 0,00 0,00 0,00 0,00

Film boiling h (W/m2-K) 0,00 0,00 0,00 0,00 0,00 0,00 0,00

Boiling thin film h (W/m2-K) 0,00 0,00 0,00 0,00 0,00 0,00 0,00

Natural convective h (W/m2-K) 0,00 0,00 0,00 0,00 0,00 0,00 0,00

Local Reynolds (--) 7503,0 7506,1 7641,1 7748,5 7857,5 7965,7 8073,6 8218,4 8215,0

Vapor Reynolds (--) 0,0000 0,0000 0,0000 0,0000 0,0000 0,0000 0,0000 0,0000 0,0000

Liquid Reynolds (--) 7445,1 7506,1 7641,1 7748,5 7857,5 7965,7 8073,6 8218,4 8287,9

Vapor Prandtl (--) 0,0000 0,0000 0,0000 0,0000 0,0000 0,0000 0,0000 0,0000 0,0000

Liquid Prandtl (--) 4,8599 4,8442 4,8070 4,7771 4,7464 4,7159 4,6853 4,6442 4,6094

Grashof (--) 309110 316123 323711 333480 332717 341351 395281

Richardson (--) 0,0055 0,0054 0,0054 0,0054 0,0052 0,0052 0,0059

Flow regime param. (--) 0,0000 0,0000 0,0000 0,0000 0,0000 0,0000 0,0000

Condensate regime (--)

Boiling flow regime (--) Sens Liq Sens Liq Sens Liq Sens Liq Sens Liq Sens Liq Sens Liq

Boiling mechanism (--) Sens Liq Sens Liq Sens Liq Sens Liq Sens Liq Sens Liq Sens Liq

D:\Refrigerant Condenser_25_01_2023 16 PM.htri

Vibration Analysis Page 7

Released to the following company:

4hM4ds4nT0z0

Xist 7.3.2 25/01/2023 16:46 SN: 46639- SI Units

Rating - Horizontal Countercurrent Flow TEMA BEM Shell With Single-Segmental Baffles

Shellside condition Cond. Vapor (Level 2,3000)

Axial stress loading (MPa) 0,000 Added mass factor 1,761

Beta 4,000

Position In The Bundle Inlet Center Outlet

Length for natural frequency (m) 0,745 0,600 0,745

Length/TEMA maximum span (--) 0,489 0,394 0,489

Number of spans (--) 4 4 4

Tube natural frequency (Hz) 140,4 139,0 114,5 +

Shell acoustic frequency (Hz) 220,0 + 0,0 0,0

Flow Velocities Inlet Center Outlet

Window parallel velocity (m/s) 1,36 0,73 6,15e-2

Bundle crossflow velocity (m/s) 0,48 0,39 2,17e-2

Bundle/shell velocity (m/s) 0,55 0,29 1,64e-2

Fluidelastic Instability Check Inlet Center Outlet

Log decrement HTRI 0,025 0,061 0,038

Critical velocity (m/s) 10,51 18,66 3,37

Baffle tip cross velocity ratio (--) 0,0460 0,0207 0,0065

Average crossflow velocity ratio (--) 0,0458 0,0206 0,0064

Acoustic Vibration Check Inlet Center Outlet

Vortex shedding ratio (--) 0,046 0,000 0,000

Chen number (--) 18548 0 0

Turbulent buffeting ratio (--) 0,034 0,000 0,000

Tube Vibration Check Inlet Center Outlet

Vortex shedding ratio (--) 0,041 0,032 0,002

Parallel flow amplitude (mm) 0,000 0,000 0,000

Crossflow amplitude (mm) 0,001 0,000 0,000

Tube gap (mm) 4,762 4,762 4,762

Crossflow RHO-V-SQ (kg/m-s2) 11,77 14,12 0,53

Bundle Entrance/Exit

(analysis at first tube row) Entrance Exit

Fluidelastic instability ratio (--) 0,044 0,000

Vortex shedding ratio (--) 0,110 0,000

Crossflow amplitude (mm) 0,00052 0,00000

Crossflow velocity (m/s) 1,30 0,00

Tubesheet to inlet/outlet support (mm) None None

Shell Entrance/Exit Parameters Entrance Exit

Impingement device None --

Flow area (m2) 3,98e-3 0,000

Velocity (m/s) 5,19 0,00

RHO-V-SQ (kg/m-s2) 1369,1 0,00

Shell type BEM Baffle type Single-Seg.

Tube type Plain Baffle layout Perpend.

Pitch ratio 1,2500 Tube diameter; (mm) 19,050

Layout angle 30 Tube material Carbon steel

Number U-Bend supports Elastic modulus; (MPa) 199592

Use deresonating baffles No Supports/baffle space 0

Program Messages

+ Frequency ratios are based upon lowest natural or acoustic frequency

* Items with asterisk exceed a conservative lower limit for vibration-free design. Review your case

using the procedure described in Online Help; You may find that a vibration problem is unlikely.

D:\Refrigerant Condenser_25_01_2023 16 PM.htri

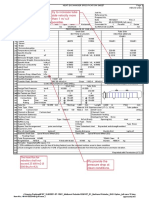

HEAT EXCHANGER RATING DATA SHEET Page 8

SI Units

Service of Unit Item No.

Type BEM Orientation Horizontal Connected In 1 Parallel 1 Series

Surf/Unit (Gross/Eff) 22,032 / 21,602 m2 Shell/Unit 1 Surf/Shell (Gross/Eff) 22,032 / 21,602 m2

PERFORMANCE OF ONE UNIT

Fluid Allocation Shell Side Tube Side

Fluid Name REF-2 WAT-1

Fluid Quantity, Total kg/s 1,0500 11,667

Vapor (In/Out) wt% 100,00 0,00 0,00 0,00

Liquid wt% 0,00 100,00 100,00 100,00

Temperature (In/Out) C 81,35 46,84 25,00 30,12

Density kg/m3 50,798 1126,6 965,65 960,44

Viscosity mN-s/m2 0,0145 0,2228 0,8904 0,7952

Specific Heat kJ/kg-C 1,0662 1,5445 3,3315 3,5810

Thermal Conductivity W/m-C 0,0177 0,0731 0,6110 0,6184

Critical Pressure kPa

Inlet Pressure kPa 1256,0 400,00

Velocity m/s 0,38 0,46

Pressure Drop, Allow/Calc kPa 34,474 1,580 68,948 12,531

Average Film Coefficient W/m2-K 1452,4 2312,9

Fouling Resistance (min) m2-K/W 0,000176 0,000035

Heat Exchanged 0,2065 MegaWatts MTD (Corrected) 21,5 C Overdesign 49,32 %

Transfer Rate, Service 444,72 W/m2-K Calculated 664,05 W/m2-K Clean 778,48 W/m2-K

CONSTRUCTION OF ONE SHELL Sketch (Bundle/Nozzle Orientation)

Shell Side Tube Side

Design Pressure kPaG 1310,0 517,11

Design Temperature C 110,00 60,00

No Passes per Shell 1 1

Flow Direction Downward

Connections In mm 1 @ 77,927 1 @ 102,26

Size & Out mm 1 @ 77,927 1 @ 102,26

Rating Liq. Out mm 1 @ 52,502 1 @ 52,502

Tube No. 151,00 OD 19,050 mm Thk(Avg) 2,108 mm Length 2,438 m Pitch 23,813 mm Tube pattern 30

Tube Type Plain Material Carbon steel Pairs seal strips 1

Shell ID 336,55 mm Kettle ID mm Passlane Seal Rod No. 0

Cross Baffle Type Perpend. Single-Seg. %Cut (Diam) 30 Impingement Plate None

Spacing(c/c) 300,00 mm Inlet 445,19 mm No. of Crosspasses 7

Rho-V2-Inlet Nozzle 954,10 kg/m-s2 Shell Entrance 1369,1 kg/m-s2 Shell Exit 0,00 kg/m-s2

Bundle Entrance 86,08 kg/m-s2 Bundle Exit 0,00 kg/m-s2

Weight/Shell 741,79 kg Filled with Water 993,39 kg Bundle 348,04 kg

Notes: Thermal Resistance, % Velocities; m/s Flow Fractions

Shell 45,72 Shellside 0,38 A 0,149

Tube 36,87 Tubeside 0,46 B 0,596

Fouling 14,70 Crossflow 0,44 C 0,157

Reported duty and flow rates include a user- Metal 2,71 Window 0,80 E 0,098

specified multiplier of 1,20. F 0,000

D:\Refrigerant Condenser_25_01_2023 16 PM.htri

HEAT EXCHANGER SPECIFICATION SHEET Page 9

SI Units

Job No.

Customer Reference No.

Address Proposal No.

Plant Location Date 25/01/2023 Rev

Service of Unit Item No.

Size 336,55 x 2438 mm Type BEM Horizontal Connected In 1 Parallel 1 Series

Surf/Unit (Gross/Eff) 22,032 / 21,602 m2 Shell/Unit 1 Surf/Shell (Gross/Eff) 22,032 / 21,602 m2

PERFORMANCE OF ONE UNIT

Fluid Allocation Shell Side Tube Side

Fluid Name REF-2 WAT-1

Fluid Quantity, Total kg/hr 3780,0 42000

Vapor (In/Out) 3780,0

Liquid 3780,0 42000 42000

Steam

Water

Noncondensables

Temperature (In/Out) C 81,35 46,84 25,00 30,12

Specific Gravity 1,1271 0,9661 0,9609

Viscosity mN-s/m2 0,0145 0,2228 0,8904 0,7952

Molecular Weight, Vapor

Molecular Weight, Noncondensables

Specific Heat kJ/kg-C 1,0662 1,5445 3,3315 3,5810

Thermal Conductivity W/m-C 0,0177 0,0731 0,6110 0,6184

Latent Heat kJ/kg 159,23 159,24

Inlet Pressure kPa 1256,0 400,00

Velocity m/s 0,38 0,46

Pressure Drop, Allow/Calc kPa 34,474 1,580 68,948 12,531

Fouling Resistance (min) m2-K/W 0,000176 0,000035

Heat Exchanged 206530 W MTD (Corrected) 21,5 C

Transfer Rate, Service 444,72 W/m2-K Clean 778,48 W/m2-K Actual 664,05 W/m2-K

CONSTRUCTION OF ONE SHELL Sketch (Bundle/Nozzle Orientation)

Shell Side Tube Side

Design/Test Pressure kPaG 1310,0 / 517,11 /

Design Temperature C 110,00 60,00

No Passes per Shell 1 1

Corrosion Allowance mm 3,175 3,175

Connections In mm 1 @ 77,927 1 @ 102,26

Size & Out mm 1 @ 77,927 1 @ 102,26

Rating Intermediate @ @

Tube No. 151 OD 19,050 mm Thk(Avg) 2,108 mm Length 2,438 m Pitch 23,813 mm

Tube Type Plain Material Carbon steel Tube pattern30

Shell Carbon steel ID 336,55 OD 355,60 mm Shell Cover

Channel or Bonnet Channel Cover

Tubesheet-Stationary Tubesheet-Floating

Floating Head Cover Impingement Plate None

Baffles-Cross Type Single-Seg. %Cut (Diam) 30 Spacing(c/c) 300,00 Inlet 445,19 mm

Baffles-Long Seal Type None

Supports-Tube U-Bend Type None

Bypass Seal Arrangement 1 pairs seal strips Tube-Tubesheet Joint Expanded (No groove)

Expansion Joint Type

Rho-V2-Inlet Nozzle 954,10 kg/m-s2 Bundle Entrance 86,08 Bundle Exit 0,00 kg/m-s2

Gaskets-Shell Side Tube Side

- Floating Head

Code Requirements TEMA Class R

Weight/Shell 741,79 kg Filled with Water 993,39 kg Bundle 348,04 kg

Remarks:

Note: Reported duty and flow rates include a user-specified multiplier of 1,20. Reprinted with Permission (v7,3.2)

D:\Refrigerant Condenser_25_01_2023 16 PM.htri

Properties Profile Monitor Page 10

Released to the following company:

4hM4ds4nT0z0

Xist 7.3.2 25/01/2023 16:46 SN: 46639- SI Units

Rating - Horizontal Countercurrent Flow TEMA BEM Shell With Single-Segmental Baffles

Physical Properties Profile: Hot Shellside (REF-2)

Property package User specified grid

Reference pressure; (kPa) (P1= 1246,0) (P2= 1251,0) (P3= 1256,0)

(P) 1 2 3 4 5 6 7 8 9 10

Temperature; (C) 1 81,35 78,47 75,60 72,72 69,85 66,97 64,09 61,22 58,34 55,47

2 81,35 78,49 75,62 72,76 69,90 67,03 64,17 61,31 58,45 55,58

3 81,35 78,50 75,65 72,80 69,95 67,10 64,25 61,40 58,55 55,70

Heat duty/flow rate; (kJ/kg) 1 0,0000 3,0452 6,1130 9,1814 12,273 15,341 18,433 21,524 24,639 27,777

2 0,0698 3,1144 6,1596 9,2280 12,296 15,364 18,433 21,524 24,616 27,730

3 0,1396 3,1609 6,2061 9,2512 12,320 15,364 18,433 21,501 24,592 27,707

Weight fraction vapor 1 1,0000 1,0000 1,0000 1,0000 1,0000 1,0000 1,0000 1,0000 1,0000 1,0000

2 1,0000 1,0000 1,0000 1,0000 1,0000 1,0000 1,0000 1,0000 1,0000 1,0000

3 1,0000 1,0000 1,0000 1,0000 1,0000 1,0000 1,0000 1,0000 1,0000 1,0000

Vapor Properties

Density; (kg/m3) 1 50,317 51,019 51,750 52,513 53,311 54,147 55,024 55,946 56,919 57,948

2 50,557 51,261 51,994 52,759 53,559 54,397 55,276 56,202 57,177 58,208

3 50,798 51,503 52,238 53,006 53,808 54,648 55,530 56,457 57,435 58,468

Viscosity; (mN-s/m2) 1 0,0145 0,0144 0,0143 0,0142 0,0141 0,0140 0,0138 0,0137 0,0136 0,0135

2 0,0145 0,0144 0,0143 0,0142 0,0141 0,0140 0,0139 0,0137 0,0136 0,0135

3 0,0145 0,0144 0,0143 0,0142 0,0141 0,0140 0,0139 0,0137 0,0136 0,0135

Thermal conductivity; (W/m-C) 1 0,0177 0,0175 0,0173 0,0171 0,0169 0,0167 0,0165 0,0163 0,0162 0,0160

2 0,0177 0,0175 0,0173 0,0171 0,0169 0,0167 0,0165 0,0164 0,0162 0,0160

3 0,0177 0,0175 0,0173 0,0171 0,0169 0,0167 0,0166 0,0164 0,0162 0,0160

Enthalpy; (kJ/kg) 1 0,0000 -3,063 -6,129 -9,198 -12,27 -15,35 -18,44 -21,54 -24,65 -27,77

2 0,0000 -3,052 -6,106 -9,164 -12,23 -15,30 -18,37 -21,46 -24,56 -27,67

3 0,0000 -3,040 -6,082 -9,129 -12,18 -15,24 -18,31 -21,38 -24,47 -27,57

Specific heat; (kJ/kg-C) 1 1,0647 1,0654 1,0665 1,0680 1,0700 1,0725 1,0756 1,0794 1,0839 1,0894

2 1,0655 1,0662 1,0673 1,0689 1,0709 1,0734 1,0766 1,0804 1,0850 1,0906

3 1,0662 1,0670 1,0682 1,0697 1,0718 1,0744 1,0776 1,0815 1,0861 1,0917

Liquid Properties

Density; (kg/m3) 1 1126,7 1126,7 1126,7 1126,7 1126,7 1126,7 1126,7 1126,7 1126,7 1126,7

2 1126,1 1126,1 1126,1 1126,1 1126,1 1126,1 1126,1 1126,1 1126,1 1126,1

3 1125,4 1125,4 1125,4 1125,4 1125,4 1125,4 1125,4 1125,4 1125,4 1125,4

Viscosity; (mN-s/m2) 1 0,2228 0,2228 0,2228 0,2228 0,2228 0,2228 0,2228 0,2228 0,2228 0,2228

2 0,2226 0,2226 0,2226 0,2226 0,2226 0,2226 0,2226 0,2226 0,2226 0,2226

3 0,2225 0,2225 0,2225 0,2225 0,2225 0,2225 0,2225 0,2225 0,2225 0,2225

Thermal conductivity; (W/m-C) 1 0,0732 0,0732 0,0732 0,0732 0,0732 0,0732 0,0732 0,0732 0,0732 0,0732

2 0,0731 0,0731 0,0731 0,0731 0,0731 0,0731 0,0731 0,0731 0,0731 0,0731

3 0,0730 0,0730 0,0730 0,0730 0,0730 0,0730 0,0730 0,0730 0,0730 0,0730

Enthalpy; (kJ/kg) 1 0,0000 -4,441 -8,882 -13,32 -17,76 -22,20 -26,65 -31,09 -35,53 -39,97

2 0,0000 -4,426 -8,851 -13,28 -17,70 -22,13 -26,55 -30,97 -35,40 -39,82

3 0,0000 -4,409 -8,818 -13,23 -17,64 -22,05 -26,45 -30,86 -35,27 -39,68

Specific heat; (kJ/kg-C) 1 1,5443 1,5443 1,5443 1,5443 1,5443 1,5443 1,5443 1,5443 1,5443 1,5443

2 1,5456 1,5456 1,5456 1,5456 1,5456 1,5456 1,5456 1,5456 1,5456 1,5456

3 1,5470 1,5470 1,5470 1,5470 1,5470 1,5470 1,5470 1,5470 1,5470 1,5470

Surface tension; (mN/m) 1 5,5826 5,5826 5,5826 5,5826 5,5826 5,5826 5,5826 5,5826 5,5826 5,5826

2 5,5630 5,5630 5,5630 5,5630 5,5630 5,5630 5,5630 5,5630 5,5630 5,5630

3 5,5433 5,5433 5,5433 5,5433 5,5433 5,5433 5,5433 5,5433 5,5433 5,5433

Critical temperature; (C) 1 101,03 101,03 101,03 101,03 101,03 101,03 101,03 101,03 101,03 101,03

2 101,03 101,03 101,03 101,03 101,03 101,03 101,03 101,03 101,03 101,03

3 101,03 101,03 101,03 101,03 101,03 101,03 101,03 101,03 101,03 101,03

D:\Refrigerant Condenser_25_01_2023 16 PM.htri

Properties Profile Monitor Page 11

Released to the following company:

4hM4ds4nT0z0

Xist 7.3.2 25/01/2023 16:46 SN: 46639- SI Units

Rating - Horizontal Countercurrent Flow TEMA BEM Shell With Single-Segmental Baffles

Physical Properties Profile: Hot Shellside (REF-2)

Property package User specified grid

Reference pressure; (kPa) (P1= 1246,0) (P2= 1251,0) (P3= 1256,0)

(P) 11 12 13 14 15 16 17 18 19 20

Temperature; (C) 1 52,59 49,72 46,84 46,84 46,84 46,84 46,84 46,84 46,84 46,84

2 52,72 49,86 46,99 46,99 46,99 46,99 46,99 46,99 46,99 46,99

3 52,85 50,00 47,15 47,15 47,15 47,15 47,15 47,15 47,15 47,15

Heat duty/flow rate; (kJ/kg) 1 30,915 34,076 37,261 53,206 69,152 85,098 101,04 116,99 132,91 148,86

2 30,869 34,006 37,191 53,113 69,059 84,982 100,90 116,83 132,75 148,67

3 30,822 33,960 37,121 53,044 68,943 84,865 100,76 116,69 132,59 148,51

Weight fraction vapor 1 1,0000 1,0000 1,0000 0,9000 0,8000 0,7000 0,6000 0,5000 0,4000 0,3000

2 1,0000 1,0000 1,0000 0,9000 0,8000 0,7000 0,6000 0,5000 0,4000 0,3000

3 1,0000 1,0000 1,0000 0,9000 0,8000 0,7000 0,6000 0,5000 0,4000 0,3000

Vapor Properties

Density; (kg/m3) 1 59,039 60,199 61,439 61,439 61,439 61,439 61,438 61,439 61,439 61,438

2 59,301 60,465 61,707 61,707 61,707 61,707 61,708 61,706 61,707 61,707

3 59,564 60,730 61,975 61,975 61,976 61,976 61,975 61,975 61,975 61,975

Viscosity; (mN-s/m2) 1 0,0134 0,0133 0,0132 0,0132 0,0132 0,0132 0,0132 0,0132 0,0132 0,0132

2 0,0134 0,0133 0,0132 0,0132 0,0132 0,0132 0,0132 0,0132 0,0132 0,0132

3 0,0134 0,0133 0,0132 0,0132 0,0132 0,0132 0,0132 0,0132 0,0132 0,0132

Thermal conductivity; (W/m-C) 1 0,0158 0,0156 0,0155 0,0155 0,0155 0,0155 0,0155 0,0155 0,0155 0,0155

2 0,0158 0,0156 0,0155 0,0155 0,0155 0,0155 0,0155 0,0155 0,0155 0,0155

3 0,0158 0,0157 0,0155 0,0155 0,0155 0,0155 0,0155 0,0155 0,0155 0,0155

Enthalpy; (kJ/kg) 1 -30,92 -34,08 -37,27 -37,27 -37,27 -37,27 -37,27 -37,27 -37,27 -37,27

2 -30,81 -33,96 -37,14 -37,14 -37,14 -37,14 -37,14 -37,14 -37,14 -37,14

3 -30,70 -33,84 -37,00 -37,00 -37,00 -37,00 -37,00 -37,00 -37,00 -37,00

Specific heat; (kJ/kg-C) 1 1,0960 1,1038 1,1130 1,1130 1,1130 1,1130 1,1130 1,1130 1,1130 1,1130

2 1,0972 1,1050 1,1144 1,1144 1,1144 1,1144 1,1144 1,1144 1,1144 1,1144

3 1,0984 1,1063 1,1157 1,1157 1,1157 1,1157 1,1157 1,1157 1,1157 1,1157

Liquid Properties

Density; (kg/m3) 1 1126,7 1126,7 1126,7 1126,7 1126,8 1126,8 1126,7 1126,7 1126,8 1126,7

2 1126,1 1126,1 1126,1 1126,1 1126,1 1126,1 1126,1 1126,1 1126,1 1126,1

3 1125,4 1125,4 1125,4 1125,4 1125,4 1125,4 1125,4 1125,4 1125,4 1125,4

Viscosity; (mN-s/m2) 1 0,2228 0,2228 0,2228 0,2228 0,2228 0,2228 0,2228 0,2228 0,2228 0,2228

2 0,2226 0,2226 0,2226 0,2226 0,2226 0,2226 0,2226 0,2226 0,2226 0,2226

3 0,2225 0,2225 0,2225 0,2225 0,2225 0,2225 0,2225 0,2225 0,2225 0,2225

Thermal conductivity; (W/m-C) 1 0,0732 0,0732 0,0732 0,0732 0,0732 0,0732 0,0732 0,0732 0,0732 0,0732

2 0,0731 0,0731 0,0731 0,0731 0,0731 0,0731 0,0731 0,0731 0,0731 0,0731

3 0,0730 0,0730 0,0730 0,0730 0,0730 0,0730 0,0730 0,0730 0,0730 0,0730

Enthalpy; (kJ/kg) 1 -44,41 -48,85 -53,29 -53,29 -53,29 -53,29 -53,29 -53,29 -53,29 -53,29

2 -44,25 -48,67 -53,10 -53,10 -53,10 -53,10 -53,10 -53,10 -53,10 -53,10

3 -44,09 -48,50 -52,91 -52,91 -52,91 -52,91 -52,91 -52,91 -52,91 -52,91

Specific heat; (kJ/kg-C) 1 1,5443 1,5443 1,5443 1,5443 1,5443 1,5443 1,5443 1,5443 1,5443 1,5443

2 1,5456 1,5456 1,5456 1,5457 1,5456 1,5456 1,5456 1,5457 1,5456 1,5456

3 1,5470 1,5470 1,5470 1,5470 1,5470 1,5470 1,5470 1,5470 1,5470 1,5470

Surface tension; (mN/m) 1 5,5826 5,5826 5,5826 5,5825 5,5827 5,5827 5,5825 5,5826 5,5828 5,5824

2 5,5630 5,5630 5,5630 5,5628 5,5630 5,5629 5,5631 5,5627 5,5630 5,5630

3 5,5433 5,5433 5,5433 5,5434 5,5434 5,5434 5,5432 5,5433 5,5433 5,5433

Critical temperature; (C) 1 101,03 101,03 101,03 101,03 101,03 101,03 101,03 101,03 101,03 101,03

2 101,03 101,03 101,03 101,03 101,03 101,03 101,03 101,03 101,03 101,03

3 101,03 101,03 101,03 101,03 101,03 101,03 101,03 101,03 101,03 101,03

D:\Refrigerant Condenser_25_01_2023 16 PM.htri

Properties Profile Monitor Page 12

Released to the following company:

4hM4ds4nT0z0

Xist 7.3.2 25/01/2023 16:46 SN: 46639- SI Units

Rating - Horizontal Countercurrent Flow TEMA BEM Shell With Single-Segmental Baffles

Physical Properties Profile: Hot Shellside (REF-2)

Property package User specified grid

Reference pressure; (kPa) (P1= 1246,0) (P2= 1251,0) (P3= 1256,0)

(P) 21 22 23 24

Temperature; (C) 1 46,84 46,84 46,84 --

2 46,99 46,99 46,99 --

3 47,15 47,15 47,15 46,84

Heat duty/flow rate; (kJ/kg) 1 164,80 180,75 196,69 --

2 164,62 180,54 196,46 --

3 164,41 180,31 196,23 196,69

Weight fraction vapor 1 0,2000 0,1000 0,0000 --

2 0,2000 0,1000 0,0000 --

3 0,2000 0,1000 0,0000 0,0000

Vapor Properties

Density; (kg/m3) 1 61,439 61,439 61,440 --

2 61,707 61,707 61,708 --

3 61,975 61,975 61,976 61,976

Viscosity; (mN-s/m2) 1 0,0132 0,0132 0,0132 --

2 0,0132 0,0132 0,0132 --

3 0,0132 0,0132 0,0132 0,0132

Thermal conductivity; (W/m-C) 1 0,0155 0,0155 0,0155 --

2 0,0155 0,0155 0,0155 --

3 0,0155 0,0155 0,0155 0,0155

Enthalpy; (kJ/kg) 1 -37,27 -37,27 -37,27 --

2 -37,14 -37,14 -37,14 --

3 -37,00 -37,00 -37,01 -37,35

Specific heat; (kJ/kg-C) 1 1,1130 1,1130 1,1131 --

2 1,1144 1,1144 1,1144 --

3 1,1157 1,1157 1,1157 1,1157

Liquid Properties

Density; (kg/m3) 1 1126,7 1126,8 1126,8 --

2 1126,1 1126,1 1126,1 --

3 1125,4 1125,4 1125,4 1126,8

Viscosity; (mN-s/m2) 1 0,2228 0,2228 0,2228 --

2 0,2226 0,2226 0,2226 --

3 0,2225 0,2225 0,2225 0,2228

Thermal conductivity; (W/m-C) 1 0,0732 0,0732 0,0732 --

2 0,0731 0,0731 0,0731 --

3 0,0730 0,0730 0,0730 0,0732

Enthalpy; (kJ/kg) 1 -53,29 -53,29 -53,29 --

2 -53,10 -53,10 -53,10 --

3 -52,91 -52,91 -52,91 -53,39

Specific heat; (kJ/kg-C) 1 1,5443 1,5443 1,5442 --

2 1,5456 1,5456 1,5456 --

3 1,5470 1,5470 1,5470 1,5440

Surface tension; (mN/m) 1 5,5826 5,5827 5,5829 --

2 5,5629 5,5630 5,5632 --

3 5,5434 5,5432 5,5436 5,5829

Critical temperature; (C) 1 101,03 101,03 101,03 --

2 101,03 101,03 101,03 --

3 101,03 101,03 101,03 101,03

D:\Refrigerant Condenser_25_01_2023 16 PM.htri

Properties Profile Monitor Page 13

Released to the following company:

4hM4ds4nT0z0

Xist 7.3.2 25/01/2023 16:46 SN: 46639- SI Units

Rating - Horizontal Countercurrent Flow TEMA BEM Shell With Single-Segmental Baffles

Physical Properties Profile: Hot Shellside (REF-2)

Property package User specified grid

Reference pressure; (kPa) (P1= 1246,0) (P2= 1251,0) (P3= 1256,0)

(P) 1 2 3 4 5 6 7 8 9 10

Liquid Properties

Critical pressure; (kPa) 1 4056,0 4056,0 4056,0 4056,0 4056,0 4056,0 4056,0 4056,0 4056,0 4056,0

2 4056,0 4056,0 4056,0 4056,0 4056,0 4056,0 4056,0 4056,0 4056,0 4056,0

3 4056,0 4056,0 4056,0 4056,0 4056,0 4056,0 4056,0 4056,0 4056,0 4056,0

Latent heat; (kJ/kg) 1 159,44 159,44 159,44 159,44 159,44 159,44 159,44 159,44 159,44 159,44

2 159,21 159,21 159,21 159,21 159,21 159,21 159,21 159,21 159,21 159,21

3 159,23 159,23 159,23 159,23 159,23 159,23 159,23 159,23 159,23 159,23

D:\Refrigerant Condenser_25_01_2023 16 PM.htri

Properties Profile Monitor Page 14

Released to the following company:

4hM4ds4nT0z0

Xist 7.3.2 25/01/2023 16:46 SN: 46639- SI Units

Rating - Horizontal Countercurrent Flow TEMA BEM Shell With Single-Segmental Baffles

Physical Properties Profile: Hot Shellside (REF-2)

Property package User specified grid

Reference pressure; (kPa) (P1= 1246,0) (P2= 1251,0) (P3= 1256,0)

(P) 11 12 13 14 15 16 17 18 19 20

Liquid Properties

Critical pressure; (kPa) 1 4056,0 4056,0 4056,0 4056,0 4056,0 4056,0 4056,0 4056,0 4056,0 4056,0

2 4056,0 4056,0 4056,0 4056,0 4056,0 4056,0 4056,0 4056,0 4056,0 4056,0

3 4056,0 4056,0 4056,0 4056,0 4056,0 4056,0 4056,0 4056,0 4056,0 4056,0

Latent heat; (kJ/kg) 1 159,44 159,44 159,44 159,44 159,47 159,45 159,43 159,46 159,23 159,42

2 159,21 159,21 159,21 159,21 159,47 159,21 159,23 159,19 159,25 159,22

3 159,23 159,23 159,23 159,23 158,99 159,22 158,97 159,24 158,98 159,22

D:\Refrigerant Condenser_25_01_2023 16 PM.htri

Properties Profile Monitor Page 15

Released to the following company:

4hM4ds4nT0z0

Xist 7.3.2 25/01/2023 16:46 SN: 46639- SI Units

Rating - Horizontal Countercurrent Flow TEMA BEM Shell With Single-Segmental Baffles

Physical Properties Profile: Hot Shellside (REF-2)

Property package User specified grid

Reference pressure; (kPa) (P1= 1246,0) (P2= 1251,0) (P3= 1256,0)

(P) 21 22 23 24

Liquid Properties

Critical pressure; (kPa) 1 4056,0 4056,0 4056,0 --

2 4056,0 4056,0 4056,0 --

3 4056,0 4056,0 4056,0 4056,0

Latent heat; (kJ/kg) 1 159,47 159,47 159,46 --

2 159,45 159,23 159,23 --

3 159,00 158,97 159,25 159,25

D:\Refrigerant Condenser_25_01_2023 16 PM.htri

Properties Profile Monitor Page 16

Released to the following company:

4hM4ds4nT0z0

Xist 7.3.2 25/01/2023 16:46 SN: 46639- SI Units

Rating - Horizontal Countercurrent Flow TEMA BEM Shell With Single-Segmental Baffles

Physical Properties Profile: Cold Tubeside (WAT-1)

Property package User specified grid

Reference pressure; (kPa) (P1= 375,00) (P2= 400,00)

(P) 1 2 3 4 5

Temperature; (C) 1 30,12 28,87 27,61 26,32 25,00

2 30,12 28,87 27,61 26,32 25,00

Heat duty/flow rate; (kJ/kg) 1 -15957 -15962 -15966 -15970 -15975

2 -15957 -15961 -15966 -15970 -15975

Weight fraction vapor 1 0,0000 0,0000 0,0000 0,0000 0,0000

2 0,0000 0,0000 0,0000 0,0000 0,0000

Liquid Properties

Density; (kg/m3) 1 960,44 961,70 962,99 964,30 965,65

2 960,44 961,70 962,99 964,30 965,65

Viscosity; (mN-s/m2) 1 0,7952 0,8169 0,8399 0,8643 0,8904

2 0,7952 0,8169 0,8399 0,8643 0,8904

Thermal conductivity; (W/m-C) 1 0,6184 0,6166 0,6148 0,6130 0,6110

2 0,6184 0,6166 0,6148 0,6130 0,6110

Enthalpy; (kJ/kg) 1 0,0000 -4,427 -8,854 -13,28 -17,71

2 0,0000 -4,427 -8,854 -13,28 -17,71

Specific heat; (kJ/kg-C) 1 3,5810 3,5236 3,4630 3,3990 3,3315

2 3,5810 3,5236 3,4630 3,3992 3,3315

Surface tension; (mN/m) 1 71,213 71,429 71,649 71,872 72,100

2 71,213 71,429 71,649 71,872 72,100

Critical temperature; (C) 1 374,15 374,15 374,15 374,15 374,15

2 374,15 374,15 374,15 374,15 374,15

Critical pressure; (kPa) 1 22120 22120 22120 22120 22120

2 22120 22120 22120 22120 22120

Latent heat; (kJ/kg) 1 0,0000 0,0000 0,0000 0,0000 0,0000

2 0,0000 0,0000 0,0000 0,0000 0,0000

D:\Refrigerant Condenser_25_01_2023 16 PM.htri

Stream Properties Page 17

Released to the following company:

4hM4ds4nT0z0

Xist 7.3.2 25/01/2023 16:46 SN: 46639- SI Units

Rating - Horizontal Countercurrent Flow TEMA BEM Shell With Single-Segmental Baffles

Hot Shellside Fluid Inlet Outlet

Fluid name REF-2

Temperature (C) 81,35 46,84

Pressure (kPa) 1256,0 1254,4

Weight fraction vapor (--) 1,0000 0,0000

Vapor Properties

Density (kg/m3) 50,798 61,891

Viscosity (mN-s/m2) 0,0145 0,0132

Conductivity (W/m-C) 0,0177 0,0155

Heat capacity (kJ/kg-C) 1,0662 1,1153

Molecular weight (--) -- --

Liquid Properties

Density (kg/m3) 1125,4 1126,6

Viscosity (mN-s/m2) 0,2225 0,2228

Conductivity (W/m-C) 0,0730 0,0731

Heat capacity (kJ/kg-C) 1,5470 1,5445

Molecular weight (--) -- --

Latent heat (kJ/kg) 159,23 159,24

Surface tension (mN/m) 5,5433 5,5767

Molar Composition Vapor Liquid K-Value Vapor Liquid K-Value

D:\Refrigerant Condenser_25_01_2023 16 PM.htri

Stream Properties Page 18

Released to the following company:

4hM4ds4nT0z0

Xist 7.3.2 25/01/2023 16:46 SN: 46639- SI Units

Rating - Horizontal Countercurrent Flow TEMA BEM Shell With Single-Segmental Baffles

Cold Tubeside Fluid Inlet Outlet

Fluid name WAT-1

Temperature (C) 25,00 30,12

Pressure (kPa) 400,00 387,47

Weight fraction vapor (--) 0,0000 0,0000

Vapor Properties

Density (kg/m3) -- --

Viscosity (mN-s/m2) -- --

Conductivity (W/m-C) -- --

Heat capacity (kJ/kg-C) -- --

Molecular weight (--) -- --

Liquid Properties

Density (kg/m3) 965,65 960,44

Viscosity (mN-s/m2) 0,8904 0,7952

Conductivity (W/m-C) 0,6110 0,6184

Heat capacity (kJ/kg-C) 3,3315 3,5810

Molecular weight (--) -- --

Latent heat (kJ/kg) -- --

Surface tension (mN/m) 72,100 71,213

Molar Composition Vapor Liquid K-Value Vapor Liquid K-Value

D:\Refrigerant Condenser_25_01_2023 16 PM.htri

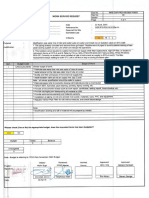

Drawings Page 19

Released to the following company:

4hM4ds4nT0z0

Xist 7.3.2 25/01/2023 16:46 SN: 46639- SI Units

Rating - Horizontal Countercurrent Flow TEMA BEM Shell With Single-Segmental Baffles

337

mm

2,438

m

TEMA type BEM Total tube inlet nozzles 1 Stream ID Shellside Tubeside

Shell diameter 336,55 mm Total tube outlet nozzles 1 Stream name REF-2 WAT-1

Tube length 2,438 m Total shell inlet nozzles 1 Flow, kg/s 1,0500 11,667

Dry weight 742 kg/shell Total shell outlet nozzles 1 Pressure drop, kPa 1,580 12,531

Wet weight 993 kg/shell Total shell liquid nozzles 1 Temperature, C 81,35 46,84 25,00 30,12

Bundle weight 348 kg/shell Wt. fraction vapor 1,0000 0,0000 0,0000 0,0000

Pressure, kPa 1256,0 1254,4 400,00 387,47

D:\Refrigerant Condenser_25_01_2023 16 PM.htri

Drawings Page 20

Released to the following company:

4hM4ds4nT0z0

Xist 7.3.2 25/01/2023 16:46 SN: 46639- SI Units

Rating - Horizontal Countercurrent Flow TEMA BEM Shell With Single-Segmental Baffles

TEMA type BEM

Shell ID 336,55 mm

77,927 mm Actual OTL 316,47 mm

Height under inlet nozzle 14,394 mm

Height under outlet nozzle 14,394 mm

Height under liq. outlet nozzle 14,394 mm

Tube type Plain

Tube OD 19,050 mm

Tube pitch 23,813 mm

Tube layout angle 30 deg

Tubes 151

Tube positions available 151

Tie rods 4

Seal strip pairs 1

Tube Passes 1

Baffle cut % diameter 30

TUBEPASS DETAILS

Pass Rows Tubes

1 15 151

SYMBOL LEGEND

Tube

Dummy Short Tube

Dummy Long Tube

Plugged Tube

Tie Rod

Seal Rod

Impingement Rod

77,927 mm 52,502 mm

D:\Refrigerant Condenser_25_01_2023 16 PM.htri

Drawings Page 21

Released to the following company:

4hM4ds4nT0z0

Xist 7.3.2 25/01/2023 16:46 SN: 46639- SI Units

Rating - Horizontal Countercurrent Flow TEMA BEM Shell With Single-Segmental Baffles

3187

mm

200 301 121 2042 301 612

mm mm mm mm mm mm

S1 T3

356

mm

T2

T1 S2 S3 Fixed Slotted

662 1454

mm mm

S1 T2

391 391

mm mm

391 391 419

mm mm mm

T1 T3 S2 S3

Front Channel Shell Rear Channel

Nozzles OD, mm Rating Design Shell Tube Weight kg Company

S1 Inlet 88,9 Pres (kPaG) 1310 517,11 Bundle 348 Customer Ref

S2 Outlet 88,9 Temp (C) 110 60 Dry 742 Item

S3 Outlet 60,325 Passes 1 1 Wet 993 Service

T1 Inlet 114,3 Thick (mm) 9,525 2,108 TEMA BEM Setting Plan

T2 Outlet 60,325 Date 25/01/2023 By

T3 Outlet 114,3 Diagram Rev

D:\Refrigerant Condenser_25_01_2023 16 PM.htri

Input Reprint Page 22

Released to the following company:

4hM4ds4nT0z0

Xist 7.3.2 25/01/2023 16:46 SN: 46639- SI Units

Rating - Horizontal Countercurrent Flow TEMA BEM Shell With Single-Segmental Baffles

Exchanger Data

Service type Generic shell and tube

TEMA type BEM

Run mode Rating

Hot fluid location Shellside

Unit orientation Horizontal

Number of shells in series 1

Number of shells in parallel 1

Flow in 1st tubepass Countercurrent

Train flow direction Countercurrent

Construction Data

Shell material Carbon steel

Tube material Carbon steel

Shellside design pressure 1310,0 kPaG

Tubeside design pressure 517,11 kPaG

Shellside vacuum pressure None

Tubeside vacuum pressure None

Shellside design temperature 110,00 C

Tubeside design temperature 60,00 C

Shellside corrosion allowance 3,175 mm

Tubeside corrosion allowance 3,175 mm

Shellside radiography None

Tubeside radiography None

TEMA class R

Shell outside diameter 355,60 mm

Shell inside diameter 336,55 mm

Shell wall thickness 9,525 mm

Front head outside diameter 355,60 mm

Front head inside diameter 336,55 mm

Front head thickness 9,525 mm

Rear head outside diameter 355,60 mm

Rear head inside diameter 336,55 mm

Rear head thickness 9,525 mm

Suppress mechanical calculations No

Tube Data

Tube type Plain

Tube outside diameter 19,050 mm

Tube wall thickness 2,108 mm

Tube pitch 23,813 mm

Tube pitch ratio 1,250

Tubepasses per shell 1

Tube pattern 30 degrees

Tube count method Rigorous

Tube length 2,438 m

Tube material Carbon steel

D:\Refrigerant Condenser_25_01_2023 16 PM.htri

Input Reprint Page 23

Released to the following company:

4hM4ds4nT0z0

Xist 7.3.2 25/01/2023 16:46 SN: 46639- SI Units

Rating - Horizontal Countercurrent Flow TEMA BEM Shell With Single-Segmental Baffles

Baffle Data

Baffle type Single segmental

Baffle orientation Perpendicular

Baffle cut percent 30,000 % shell ID

Adjust baffle cut No adjustment

Central baffle spacing 300,00 mm

Variable baffle spacing No

Window cut from baffles No

Use deresonating baffles No

Supports Data

Floating head support type None

Include inlet vibration support No

Include outlet vibration support No

Nozzle Data

Shellside

Nozzle standard 01-ANSI_B36_10.TABLE

Shell entrance type Add impingement if TEMA requires

Shell exit type Remove tubes if TEMA requires

Inlet Outlet Liq. Outlet

Nozzle outside diameter 88,900 88,900 60,325 mm

Nozzle schedule Sch 40 Sch 40 Sch 40

Nozzle inside diameter 77,927 77,927 52,502 mm

Number at this position 1 1 --

Tubeside

Nozzle standard 01-ANSI_B36_10.TABLE

Inlet Outlet Liq. Outlet

Nozzle outside diameter 114,30 114,30 60,325 mm

Nozzle schedule Sch 40 Sch 40 Sch 40

Nozzle inside diameter 102,26 102,26 52,502 mm

Number at this position 1 1 --

Nozzle Location Data

Radial position on shell inlet nozzle Program decides

Longitudinal position on shell of inlet nozzle At rear head

Radial position on shell outlet nozzle Program decides

Tubeside entry type Radial

Tubeside inlet position Front head

Tubeside exit type Same as inlet

Impingement Data

Impingement type Rods

Use tube positions to place rods No

Impingement rod rows 2

Impingement rod diameter 15,875 mm

Impingement rod pitch 23,813 mm

Impingement rods on centerline Program set

Impingement rod layout angle 30,00 deg

Rod row width to nozzle diameter 1,0000

D:\Refrigerant Condenser_25_01_2023 16 PM.htri

Input Reprint Page 24

Released to the following company:

4hM4ds4nT0z0

Xist 7.3.2 25/01/2023 16:46 SN: 46639- SI Units

Rating - Horizontal Countercurrent Flow TEMA BEM Shell With Single-Segmental Baffles

Tube Layout Data

Force symmetric layout No

Force continuous cleaning lanes No

Force uniform layout No

Align across primary passlanes No

Fill knock out area with dummy tubes Program set

Fill bundle periphery with dummy tubes Program set

Fill passlanes with dummy tubes Program Set

Shifted staggard layout Program set

Use crossed U-bends Program set

Minimum U-bend diameter 57,150 mm

Use tube layout drawing as input No

Clearance Data

Number of seal strip pairs Calculated

Block A stream No

Block E stream No

Block F stream No

Number of passlane seal rods Calculated

Tubes to remove for tie rods Calculated

Number of tie rods 4

Tie rod outside diameter 9,525 mm

Baffle to shell clearance 3,175 mm

Baffle clearance type TEMA

Optional Geometry Data

Small exchanger No

Double tubesheet No

Shell expansion joint No

Process Conditions Data Hot Fluid Cold Fluid

Phase condition Two phase Sensible liquid

Flow rate 0,8750 9,7222 kg/s

Inlet vapor fraction 1,0000 0,0000

Outlet vapor fraction 0,0000 0,0000

Inlet temperature 81,35 25,00 C

Outlet temperature 46,84 30,12 C

Inlet pressure 1256,0 400,00 kPa

Allowable pressure drop 34,474 68,948 kPa

Exchanger duty 0,1720 MegaWatts

Duty multiplier 1,2000

Process Fouling Data Hot Fluid Cold Fluid

Fouling resistance 1,76e-4 3,52e-5 m2-K/W

D:\Refrigerant Condenser_25_01_2023 16 PM.htri

Input Reprint Page 25

Released to the following company:

4hM4ds4nT0z0

Xist 7.3.2 25/01/2023 16:46 SN: 46639- SI Units

Rating - Horizontal Countercurrent Flow TEMA BEM Shell With Single-Segmental Baffles

Hot Fluid Property Data

Fluid name REF-2

Physical property method User specified grid

Temperature interpolation option Program

Flash type Integral

Quantity units Moles

Pure component condensation No

Heat release type Specific enthalpy

Hot Fluid Physical Property Data

Pressure Set, 1256,0 kPa

Vapor Vapor Vapor Vapor Liquid

Mass Vapor Dynamic Thermal Heat Liquid Dynamic

Temp. Enthalpy Fraction Density Viscosity Cond. Capacity Density Viscosity

C kJ/kg kg/m3 mN-s/m2 W/m-C kJ/kg-C kg/m3 mN-s/m2

81,35 -8744 1,0000 50,798 0,0145 0,0177 1,0662 -- --

78,50 -8747 1,0000 51,503 0,0144 0,0175 1,0670 -- --

75,65 -8750 1,0000 52,238 0,0143 0,0173 1,0682 -- --

72,80 -8753 1,0000 53,006 0,0142 0,0171 1,0697 -- --

69,95 -8756 1,0000 53,808 0,0141 0,0169 1,0718 -- --

67,10 -8759 1,0000 54,648 0,0140 0,0167 1,0744 -- --

64,25 -8763 1,0000 55,529 0,0139 0,0166 1,0776 -- --

61,40 -8766 1,0000 56,457 0,0137 0,0164 1,0815 -- --

58,55 -8769 1,0000 57,435 0,0136 0,0162 1,0861 -- --

55,70 -8772 1,0000 58,468 0,0135 0,0160 1,0917 -- --

52,85 -8775 1,0000 59,564 0,0134 0,0158 1,0984 -- --

50,00 -8778 1,0000 60,730 0,0133 0,0157 1,1063 -- --

47,15 -8781 1,0000 61,975 0,0132 0,0155 1,1157 1125,4 0,2225

47,15 -8797 0,9000 61,975 0,0132 0,0155 1,1157 1125,4 0,2225

47,15 -8813 0,8000 61,976 0,0132 0,0155 1,1157 1125,4 0,2225

47,15 -8829 0,7000 61,976 0,0132 0,0155 1,1157 1125,4 0,2225

47,15 -8845 0,6000 61,975 0,0132 0,0155 1,1157 1125,4 0,2225

47,15 -8861 0,5000 61,975 0,0132 0,0155 1,1157 1125,4 0,2225

47,15 -8877 0,4000 61,975 0,0132 0,0155 1,1157 1125,4 0,2225

47,15 -8893 0,3000 61,975 0,0132 0,0155 1,1157 1125,4 0,2225

47,15 -8909 0,2000 61,975 0,0132 0,0155 1,1157 1125,4 0,2225

47,15 -8924 0,1000 61,975 0,0132 0,0155 1,1157 1125,4 0,2225

47,15 -8940 0,0000 61,976 0,0132 0,0155 1,1157 1125,4 0,2225

46,84 -8941 0,0000 -- -- -- -- 1126,8 0,2228

Pressure Set, 1256,0 kPa

Liquid Liquid Liquid Liquid Liquid

Thermal Heat Surface Critical Critical

Temp. Cond. Capacity Tension Pressure Temp.

C W/m-C kJ/kg-C mN/m kPa C

81,35 -- -- -- -- --

78,50 -- -- -- -- --

75,65 -- -- -- -- --

72,80 -- -- -- -- --

69,95 -- -- -- -- --

D:\Refrigerant Condenser_25_01_2023 16 PM.htri

Input Reprint Page 26

Released to the following company:

4hM4ds4nT0z0

Xist 7.3.2 25/01/2023 16:46 SN: 46639- SI Units

Rating - Horizontal Countercurrent Flow TEMA BEM Shell With Single-Segmental Baffles

Hot Fluid Physical Property Data

Pressure Set, 1256,0 kPa

Liquid Liquid Liquid Liquid Liquid

Thermal Heat Surface Critical Critical

Temp. Cond. Capacity Tension Pressure Temp.

C W/m-C kJ/kg-C mN/m kPa C

67,10 -- -- -- -- --

64,25 -- -- -- -- --

61,40 -- -- -- -- --

58,55 -- -- -- -- --

55,70 -- -- -- -- --

52,85 -- -- -- -- --

50,00 -- -- -- -- --

47,15 0,0730 1,5470 5,5433 4056,0 101,03

47,15 0,0730 1,5470 5,5434 4056,0 101,03

47,15 0,0730 1,5470 5,5434 4056,0 101,03

47,15 0,0730 1,5470 5,5434 4056,0 101,03

47,15 0,0730 1,5470 5,5432 4056,0 101,03

47,15 0,0730 1,5470 5,5433 4056,0 101,03

47,15 0,0730 1,5470 5,5433 4056,0 101,03

47,15 0,0730 1,5470 5,5433 4056,0 101,03

47,15 0,0730 1,5470 5,5434 4056,0 101,03

47,15 0,0730 1,5470 5,5432 4056,0 101,03

47,15 0,0730 1,5470 5,5436 4056,0 101,03

46,84 0,0732 1,5440 5,5829 4056,0 101,03

Pressure Set, 1251,0 kPa

Vapor Vapor Vapor Vapor Liquid

Mass Vapor Dynamic Thermal Heat Liquid Dynamic

Temp. Enthalpy Fraction Density Viscosity Cond. Capacity Density Viscosity

C kJ/kg kg/m3 mN-s/m2 W/m-C kJ/kg-C kg/m3 mN-s/m2

81,35 -8744 1,0000 50,557 0,0145 0,0177 1,0655 -- --

78,49 -8747 1,0000 51,261 0,0144 0,0175 1,0662 -- --

75,62 -8750 1,0000 51,994 0,0143 0,0173 1,0673 -- --

72,76 -8753 1,0000 52,759 0,0142 0,0171 1,0689 -- --

69,90 -8756 1,0000 53,559 0,0141 0,0169 1,0709 -- --

67,03 -8759 1,0000 54,397 0,0140 0,0167 1,0734 -- --

64,17 -8763 1,0000 55,276 0,0139 0,0165 1,0766 -- --

61,31 -8766 1,0000 56,202 0,0137 0,0164 1,0804 -- --

58,45 -8769 1,0000 57,177 0,0136 0,0162 1,0850 -- --

55,58 -8772 1,0000 58,208 0,0135 0,0160 1,0906 -- --

52,72 -8775 1,0000 59,301 0,0134 0,0158 1,0972 -- --

49,86 -8778 1,0000 60,465 0,0133 0,0156 1,1050 -- --

46,99 -8781 1,0000 61,707 0,0132 0,0155 1,1144 1126,1 0,2226

46,99 -8797 0,9000 61,707 0,0132 0,0155 1,1144 1126,1 0,2226

46,99 -8813 0,8000 61,707 0,0132 0,0155 1,1144 1126,1 0,2226

46,99 -8829 0,7000 61,707 0,0132 0,0155 1,1144 1126,1 0,2226

46,99 -8845 0,6000 61,708 0,0132 0,0155 1,1144 1126,1 0,2226

46,99 -8861 0,5000 61,706 0,0132 0,0155 1,1144 1126,1 0,2226

D:\Refrigerant Condenser_25_01_2023 16 PM.htri

Input Reprint Page 27

Released to the following company:

4hM4ds4nT0z0

Xist 7.3.2 25/01/2023 16:46 SN: 46639- SI Units

Rating - Horizontal Countercurrent Flow TEMA BEM Shell With Single-Segmental Baffles

Hot Fluid Physical Property Data

Pressure Set, 1251,0 kPa

Vapor Vapor Vapor Vapor Liquid

Mass Vapor Dynamic Thermal Heat Liquid Dynamic

Temp. Enthalpy Fraction Density Viscosity Cond. Capacity Density Viscosity

C kJ/kg kg/m3 mN-s/m2 W/m-C kJ/kg-C kg/m3 mN-s/m2

46,99 -8877 0,4000 61,707 0,0132 0,0155 1,1144 1126,1 0,2226

46,99 -8893 0,3000 61,707 0,0132 0,0155 1,1144 1126,1 0,2226

46,99 -8909 0,2000 61,707 0,0132 0,0155 1,1144 1126,1 0,2226

46,99 -8925 0,1000 61,707 0,0132 0,0155 1,1144 1126,1 0,2226

46,99 -8941 0,0000 61,708 0,0132 0,0155 1,1144 1126,1 0,2226

Pressure Set, 1251,0 kPa

Liquid Liquid Liquid Liquid Liquid

Thermal Heat Surface Critical Critical

Temp. Cond. Capacity Tension Pressure Temp.

C W/m-C kJ/kg-C mN/m kPa C

81,35 -- -- -- -- --

78,49 -- -- -- -- --

75,62 -- -- -- -- --

72,76 -- -- -- -- --

69,90 -- -- -- -- --

67,03 -- -- -- -- --

64,17 -- -- -- -- --

61,31 -- -- -- -- --

58,45 -- -- -- -- --

55,58 -- -- -- -- --

52,72 -- -- -- -- --

49,86 -- -- -- -- --

46,99 0,0731 1,5456 5,5630 4056,0 101,03

46,99 0,0731 1,5457 5,5628 4056,0 101,03

46,99 0,0731 1,5456 5,5630 4056,0 101,03

46,99 0,0731 1,5456 5,5629 4056,0 101,03

46,99 0,0731 1,5456 5,5631 4056,0 101,03

46,99 0,0731 1,5457 5,5627 4056,0 101,03

46,99 0,0731 1,5456 5,5630 4056,0 101,03

46,99 0,0731 1,5456 5,5630 4056,0 101,03

46,99 0,0731 1,5456 5,5629 4056,0 101,03

46,99 0,0731 1,5456 5,5630 4056,0 101,03

46,99 0,0731 1,5456 5,5632 4056,0 101,03

Pressure Set, 1246,0 kPa

Vapor Vapor Vapor Vapor Liquid

Mass Vapor Dynamic Thermal Heat Liquid Dynamic

Temp. Enthalpy Fraction Density Viscosity Cond. Capacity Density Viscosity

C kJ/kg kg/m3 mN-s/m2 W/m-C kJ/kg-C kg/m3 mN-s/m2

81,35 -8744 1,0000 50,317 0,0145 0,0177 1,0647 -- --

78,47 -8747 1,0000 51,019 0,0144 0,0175 1,0654 -- --

75,60 -8750 1,0000 51,750 0,0143 0,0173 1,0665 -- --

D:\Refrigerant Condenser_25_01_2023 16 PM.htri

Input Reprint Page 28

Released to the following company:

4hM4ds4nT0z0

Xist 7.3.2 25/01/2023 16:46 SN: 46639- SI Units

Rating - Horizontal Countercurrent Flow TEMA BEM Shell With Single-Segmental Baffles

Hot Fluid Physical Property Data

Pressure Set, 1246,0 kPa

Vapor Vapor Vapor Vapor Liquid

Mass Vapor Dynamic Thermal Heat Liquid Dynamic

Temp. Enthalpy Fraction Density Viscosity Cond. Capacity Density Viscosity

C kJ/kg kg/m3 mN-s/m2 W/m-C kJ/kg-C kg/m3 mN-s/m2

72,72 -8753 1,0000 52,513 0,0142 0,0171 1,0680 -- --

69,85 -8756 1,0000 53,311 0,0141 0,0169 1,0700 -- --

66,97 -8759 1,0000 54,147 0,0140 0,0167 1,0725 -- --

64,09 -8763 1,0000 55,024 0,0138 0,0165 1,0756 -- --

61,22 -8766 1,0000 55,946 0,0137 0,0163 1,0794 -- --

58,34 -8769 1,0000 56,919 0,0136 0,0162 1,0839 -- --

55,47 -8772 1,0000 57,948 0,0135 0,0160 1,0894 -- --

52,59 -8775 1,0000 59,039 0,0134 0,0158 1,0960 -- --

49,72 -8778 1,0000 60,199 0,0133 0,0156 1,1038 -- --

46,84 -8781 1,0000 61,439 0,0132 0,0155 1,1130 1126,7 0,2228

46,84 -8797 0,9000 61,439 0,0132 0,0155 1,1130 1126,7 0,2228

46,84 -8813 0,8000 61,439 0,0132 0,0155 1,1130 1126,7 0,2228

46,84 -8829 0,7000 61,439 0,0132 0,0155 1,1130 1126,8 0,2228

46,84 -8845 0,6000 61,438 0,0132 0,0155 1,1130 1126,7 0,2228

46,84 -8861 0,5000 61,439 0,0132 0,0155 1,1130 1126,7 0,2228

46,84 -8877 0,4000 61,440 0,0132 0,0155 1,1131 1126,8 0,2228

46,84 -8893 0,3000 61,438 0,0132 0,0155 1,1130 1126,7 0,2228

46,84 -8909 0,2000 61,439 0,0132 0,0155 1,1130 1126,7 0,2228

46,84 -8925 0,1000 61,439 0,0132 0,0155 1,1130 1126,8 0,2228

46,84 -8941 0,0000 61,440 0,0132 0,0155 1,1131 1126,8 0,2228

Pressure Set, 1246,0 kPa

Liquid Liquid Liquid Liquid Liquid

Thermal Heat Surface Critical Critical

Temp. Cond. Capacity Tension Pressure Temp.

C W/m-C kJ/kg-C mN/m kPa C

81,35 -- -- -- -- --

78,47 -- -- -- -- --

75,60 -- -- -- -- --

72,72 -- -- -- -- --

69,85 -- -- -- -- --

66,97 -- -- -- -- --

64,09 -- -- -- -- --

61,22 -- -- -- -- --

58,34 -- -- -- -- --

55,47 -- -- -- -- --

52,59 -- -- -- -- --

49,72 -- -- -- -- --

46,84 0,0732 1,5443 5,5826 4056,0 101,03

46,84 0,0732 1,5443 5,5825 4056,0 101,03

46,84 0,0732 1,5443 5,5827 4056,0 101,03

46,84 0,0732 1,5443 5,5827 4056,0 101,03

46,84 0,0732 1,5443 5,5825 4056,0 101,03

D:\Refrigerant Condenser_25_01_2023 16 PM.htri

Input Reprint Page 29

Released to the following company:

4hM4ds4nT0z0

Xist 7.3.2 25/01/2023 16:46 SN: 46639- SI Units

Rating - Horizontal Countercurrent Flow TEMA BEM Shell With Single-Segmental Baffles

Hot Fluid Physical Property Data

Pressure Set, 1246,0 kPa

Liquid Liquid Liquid Liquid Liquid

Thermal Heat Surface Critical Critical

Temp. Cond. Capacity Tension Pressure Temp.

C W/m-C kJ/kg-C mN/m kPa C

46,84 0,0732 1,5443 5,5826 4056,0 101,03

46,84 0,0732 1,5443 5,5828 4056,0 101,03

46,84 0,0732 1,5443 5,5824 4056,0 101,03

46,84 0,0732 1,5443 5,5826 4056,0 101,03

46,84 0,0732 1,5443 5,5827 4056,0 101,03

46,84 0,0732 1,5442 5,5829 4056,0 101,03

Cold Fluid Property Data

Fluid name WAT-1

Physical property method User specified grid

Temperature interpolation option Program

Flash type Integral

Quantity units Moles

Pure component boiling No

Heat release type Specific enthalpy

Cold Fluid Physical Property Data

Pressure Set, 400,00 kPa

Vapor Liquid Liquid Liquid Liquid Liquid

Mass Liquid Dynamic Thermal Heat Surface Critical

Temp. Enthalpy Fraction Density Viscosity Cond. Capacity Tension Pressure

C kJ/kg kg/m3 mN-s/m2 W/m-C kJ/kg-C mN/m kPa

25,00 -15975 0,0000 965,65 0,8904 0,6110 3,3315 72,100 22120

26,32 -15970 0,0000 964,30 0,8643 0,6130 3,3992 71,872 22120

27,61 -15966 0,0000 962,99 0,8399 0,6148 3,4630 71,649 22120

28,87 -15962 0,0000 961,70 0,8169 0,6166 3,5236 71,429 22120

30,12 -15957 0,0000 960,44 0,7952 0,6184 3,5810 71,213 22120

Pressure Set, 400,00 kPa

Liquid

Critical

Temp. Temp.

C C

25,00 374,15

26,32 374,15

27,61 374,15

28,87 374,15

30,12 374,15

D:\Refrigerant Condenser_25_01_2023 16 PM.htri

Input Reprint Page 30

Released to the following company:

4hM4ds4nT0z0

Xist 7.3.2 25/01/2023 16:46 SN: 46639- SI Units

Rating - Horizontal Countercurrent Flow TEMA BEM Shell With Single-Segmental Baffles

Cold Fluid Physical Property Data

Pressure Set, 375,00 kPa

Vapor Liquid Liquid Liquid Liquid Liquid

Mass Liquid Dynamic Thermal Heat Surface Critical

Temp. Enthalpy Fraction Density Viscosity Cond. Capacity Tension Pressure

C kJ/kg kg/m3 mN-s/m2 W/m-C kJ/kg-C mN/m kPa

25,00 -15975 0,0000 965,64 0,8904 0,6110 3,3315 72,100 22120

26,32 -15970 0,0000 964,30 0,8643 0,6130 3,3990 71,872 22120

27,61 -15966 0,0000 962,99 0,8399 0,6148 3,4630 71,649 22120

28,87 -15962 0,0000 961,70 0,8169 0,6166 3,5236 71,429 22120

30,12 -15957 0,0000 960,44 0,7952 0,6184 3,5810 71,213 22120

Pressure Set, 375,00 kPa

Liquid

Critical

Temp. Temp.

C C

25,00 374,15

26,32 374,15

27,61 374,15

28,87 374,15

30,12 374,15

Control Methods Data

Shellside friction factor method Commercial

Tubeside friction factor method Commercial

Pure longitudinal flow No

Pure component condensation No

Condensing correlation HTRI Proration

Mole fraction inerts 0,0000

Momentum exclusion 0,0000 %

Pure component boiling No

Check film boiling Yes

Nucleate boiling method Physical property/theoretical boiling range

Component boiling method Nucleate and convective

Increments per baffle Calculated

Control User-Defined Methods Data

Add non-nucleate boiling Yes

D:\Refrigerant Condenser_25_01_2023 16 PM.htri

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- 23-HA-103 - Rating Case - 1Document11 pages23-HA-103 - Rating Case - 1yadav yadavNo ratings yet

- Output Summary: SI UnitsDocument42 pagesOutput Summary: SI UnitsAkhil JoseNo ratings yet

- See Runtime Message Report For Warning MessagesDocument1 pageSee Runtime Message Report For Warning MessagesAnonymous Q2hxfbghNo ratings yet

- Sekiro: See Runtime Message Report For Warning MessagesDocument1 pageSekiro: See Runtime Message Report For Warning MessagesĐinh Hoàng ViệtNo ratings yet

- Output Summary: SI UnitsDocument14 pagesOutput Summary: SI UnitsEduardoNo ratings yet

- Sekiro: See Runtime Message Report For Warning MessagesDocument1 pageSekiro: See Runtime Message Report For Warning MessagesĐinh Hoàng ViệtNo ratings yet

- Design E-100 GT PMB N GN Kemala 15 MM Main CaseDocument103 pagesDesign E-100 GT PMB N GN Kemala 15 MM Main Casewahyu hidayatNo ratings yet

- Output Summary: SI UnitsDocument1 pageOutput Summary: SI Unitsdaboo sanatNo ratings yet

- CO2 Condenser 02-03-2023-15 PMDocument37 pagesCO2 Condenser 02-03-2023-15 PMahmad santosoNo ratings yet

- HTRI Output Summary for Biogas Cooler DesignDocument1 pageHTRI Output Summary for Biogas Cooler Designkindi76_153423792No ratings yet

- Sekiro: See Runtime Message Report For Warning MessagesDocument1 pageSekiro: See Runtime Message Report For Warning MessagesĐinh Hoàng ViệtNo ratings yet

- Dawn of War II Manual - ENDocument45 pagesDawn of War II Manual - ENelmarcusIINo ratings yet

- GTB v6Document7 pagesGTB v6Chan Shiaw SyanNo ratings yet

- Jpf5-E-0022 - 17 08 22Document10 pagesJpf5-E-0022 - 17 08 22pradeep yadavNo ratings yet

- Idris Kris Shandy - 203303048Document1 pageIdris Kris Shandy - 203303048Idris KrisNo ratings yet

- LPG Amine Cooler-SummaryDocument15 pagesLPG Amine Cooler-SummaryJEEVITHANo ratings yet

- HTRI Output Summary for Multipass Shell and Tube Heat ExchangerDocument1 pageHTRI Output Summary for Multipass Shell and Tube Heat ExchangerGiulliano Enrique MucciNo ratings yet

- Output Summary: See Data Check Messages Report For Warning Messages. See Runtime Message Report For Warning MessagesDocument1 pageOutput Summary: See Data Check Messages Report For Warning Messages. See Runtime Message Report For Warning MessagesIdil FitriNo ratings yet

- Process Design Report SummaryDocument3 pagesProcess Design Report Summarymuhd.qasimNo ratings yet

- Design - Horizontal Countercurrent Flow TEMA BEM Shell With Single-Segmental BafflesDocument1 pageDesign - Horizontal Countercurrent Flow TEMA BEM Shell With Single-Segmental BafflesherNo ratings yet

- HTRI Heat Exchanger Rating SummaryDocument6 pagesHTRI Heat Exchanger Rating SummaryCami Vander MeyNo ratings yet

- OLOA 55531 - 0.75 sch40Document4 pagesOLOA 55531 - 0.75 sch40NILTON BERNALNo ratings yet

- See Runtime Message Report For Warning MessagesDocument1 pageSee Runtime Message Report For Warning MessagesainunNo ratings yet

- Output Summary: See Data Check Messages Report For Informative MessagesDocument1 pageOutput Summary: See Data Check Messages Report For Informative MessagesFilippo AlfendroNo ratings yet

- Diseño y fabricación de equipos de acuerdo a código ASMEDocument4 pagesDiseño y fabricación de equipos de acuerdo a código ASMENILTON BERNALNo ratings yet

- CH-RA3 Page 1Document1 pageCH-RA3 Page 1Sonya LoveraNo ratings yet

- Chocolatos 2Document1 pageChocolatos 2Hariyono Rudi NovantoNo ratings yet

- RicisDocument1 pageRicisHariyono Rudi NovantoNo ratings yet

- PramonnoDocument1 pagePramonnoHariyono Rudi NovantoNo ratings yet

- 100-Mc-417-Ra3-Hx-Ra3 - HDC Condensador Reactor PDFDocument2 pages100-Mc-417-Ra3-Hx-Ra3 - HDC Condensador Reactor PDFSonya LoveraNo ratings yet

- See Data Check Messages Report For Informative MessagesDocument54 pagesSee Data Check Messages Report For Informative MessagesCesar MarcosNo ratings yet

- Vibration analysis of heat exchangersDocument15 pagesVibration analysis of heat exchangersljv004No ratings yet

- Heat exchanger specification sheetDocument1 pageHeat exchanger specification sheetSonya LoveraNo ratings yet

- Simulation Summary of Horizontal EconomizerDocument1 pageSimulation Summary of Horizontal EconomizerHariyono Rudi NovantoNo ratings yet

- ChocolatosDocument1 pageChocolatosHariyono Rudi NovantoNo ratings yet

- Basic Weights Calc - ACHEDocument6 pagesBasic Weights Calc - ACHESiva ShankarNo ratings yet

- 7854-Hds-2e2301 Rev 8Document3 pages7854-Hds-2e2301 Rev 8SonNguyenNo ratings yet

- Reporte de Diseño de Aeroenfriador 18-10Document27 pagesReporte de Diseño de Aeroenfriador 18-10Luis AlexanderNo ratings yet

- DJM MBA PCS CA 007 Deethanizer Reboiler E 1401 Rev BDocument37 pagesDJM MBA PCS CA 007 Deethanizer Reboiler E 1401 Rev BDIANTORONo ratings yet

- Case 1 e 002 D - H Rev 0Document16 pagesCase 1 e 002 D - H Rev 0Oswaldo GuerraNo ratings yet

- Heat Stable Reactor Heater 1.5 KG - HR (9.24 MM ID Tube)Document38 pagesHeat Stable Reactor Heater 1.5 KG - HR (9.24 MM ID Tube)Ravindra BarangeNo ratings yet

- Output Summary for Air-Cooled Heat ExchangerDocument7 pagesOutput Summary for Air-Cooled Heat ExchangerVu TranNo ratings yet

- FS22-002-Process Calculation For Chiller - Rev.A-Bundle OptionDocument3 pagesFS22-002-Process Calculation For Chiller - Rev.A-Bundle OptionJason DoNo ratings yet

- Calculation Economizer - PL ProjectDocument12 pagesCalculation Economizer - PL ProjectXuan Man NguyenNo ratings yet

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdDocument4 pagesSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdSRINo ratings yet

- 1007 Ac Hex 001 R0Document5 pages1007 Ac Hex 001 R0züheyir nuralNo ratings yet

- Steam HXDocument1 pageSteam HXrajachemNo ratings yet

- Natural Gas Steam Heater SummaryDocument14 pagesNatural Gas Steam Heater SummarySivi NallamothuNo ratings yet

- 1523916823Document25 pages1523916823Thaís Dias ParteliNo ratings yet

- Design-Horizontal air-cooled heat exchanger forced draft countercurrent crossflowDocument25 pagesDesign-Horizontal air-cooled heat exchanger forced draft countercurrent crossflowLuis AlexanderNo ratings yet

- Tugas Take Home UTSDocument18 pagesTugas Take Home UTSdodikNo ratings yet

- Heat Exchanger Specification Sheet for Renewable Naphtha Product CoolerDocument2 pagesHeat Exchanger Specification Sheet for Renewable Naphtha Product Coolershahbaz akramNo ratings yet

- MULTI-V - INDOOR - 36k-48k - Common Exploded - View 2015.11.11 EU and LATDocument8 pagesMULTI-V - INDOOR - 36k-48k - Common Exploded - View 2015.11.11 EU and LATfhelfenstellerNo ratings yet

- 100-Mc-417-Ra3-Hx-Ra3 - HDB Condensador ReactorDocument1 page100-Mc-417-Ra3-Hx-Ra3 - HDB Condensador ReactorSonya LoveraNo ratings yet

- 240-05-DTS-010 V-400 Regenaration Gas SeperatorDocument20 pages240-05-DTS-010 V-400 Regenaration Gas SeperatorEmran NazirNo ratings yet

- 240-05-DTS-009 V-501 Air ReceiverDocument20 pages240-05-DTS-009 V-501 Air ReceiverEmran NazirNo ratings yet

- Intercambiador de Calor: Heat Exchanger Data SheetDocument6 pagesIntercambiador de Calor: Heat Exchanger Data SheetBRENDA VIVIANA ARANDA JURADONo ratings yet

- Electrical Data P532 258 012 10 (Series) P532 258 004 10 (Series) P532 258 004 10 (Parallel) P532 258 0.7 10 (Parallel)Document1 pageElectrical Data P532 258 012 10 (Series) P532 258 004 10 (Series) P532 258 004 10 (Parallel) P532 258 0.7 10 (Parallel)Anas SharholiNo ratings yet

- BB 1Document1 pageBB 1SaidFerdjallahNo ratings yet

- WSR-RTN-PRJ-19-013Rev.01 - Piping of GTC-A&B Sea Water Lube Oil Cooler UpdateDocument10 pagesWSR-RTN-PRJ-19-013Rev.01 - Piping of GTC-A&B Sea Water Lube Oil Cooler Updateahmad santosoNo ratings yet

- 1-2P-Flash Separator - SokaDocument27 pages1-2P-Flash Separator - Sokaahmad santosoNo ratings yet

- PG 2ph Test Sep 75%Document29 pagesPG 2ph Test Sep 75%ahmad santosoNo ratings yet

- Demister CalcDocument3 pagesDemister Calcahmad santosoNo ratings yet

- SEL-TBD-O-CA-001 R0 Process Simulation Report SignedDocument12 pagesSEL-TBD-O-CA-001 R0 Process Simulation Report Signedahmad santosoNo ratings yet

- Framework Pre FS DmeDocument4 pagesFramework Pre FS Dmeahmad santosoNo ratings yet

- SEL-TBD-O-CA-003 - R0 - Crude Oil Storage Tank Sizing-Signed PDFDocument16 pagesSEL-TBD-O-CA-003 - R0 - Crude Oil Storage Tank Sizing-Signed PDFahmad santosoNo ratings yet

- Resume-Chandra 2017 BurdamasDocument1 pageResume-Chandra 2017 Burdamasahmad santosoNo ratings yet

- SEL-TBD-O-CA-003 - R0 - Crude Oil Storage Tank Sizing-Signed PDFDocument16 pagesSEL-TBD-O-CA-003 - R0 - Crude Oil Storage Tank Sizing-Signed PDFahmad santosoNo ratings yet

- Fkie Business PlanDocument1 pageFkie Business Planahmad santosoNo ratings yet

- CO2 Condenser 02-03-2023-15 PMDocument37 pagesCO2 Condenser 02-03-2023-15 PMahmad santosoNo ratings yet

- FKIE Coal SummaryDocument18 pagesFKIE Coal Summaryahmad santosoNo ratings yet

- How Many Inches Can A Welder Weld Per DayDocument5 pagesHow Many Inches Can A Welder Weld Per Dayahmad santosoNo ratings yet

- CO2 Capture Liquefaction Process Stream AnalysisDocument72 pagesCO2 Capture Liquefaction Process Stream Analysisahmad santosoNo ratings yet

- NKGSB Int Com 001 A4 ADocument8 pagesNKGSB Int Com 001 A4 Aahmad santosoNo ratings yet

- PreFS Coal To DME - FKIE - Rev 3CDocument43 pagesPreFS Coal To DME - FKIE - Rev 3Cahmad santoso100% (1)

- Nkgsb-Prs-Cl-001-A4-C Tank Heater Duty Calculation Flow Chart-09-04-20Document3 pagesNkgsb-Prs-Cl-001-A4-C Tank Heater Duty Calculation Flow Chart-09-04-20ahmad santosoNo ratings yet

- Co2 Capture 23-1-23 PFDDocument1 pageCo2 Capture 23-1-23 PFDahmad santosoNo ratings yet

- Overfill ProtectionDocument4 pagesOverfill Protectionahmad santosoNo ratings yet

- Commissioning Fire Water TankDocument19 pagesCommissioning Fire Water Tankahmad santosoNo ratings yet

- YHSI-NK Minutes of MeetingDocument2 pagesYHSI-NK Minutes of Meetingahmad santosoNo ratings yet

- NKGSB-PRS-CL-007-A4-A Hydraulic Calculation and Line Sizing - Utility LineDocument8 pagesNKGSB-PRS-CL-007-A4-A Hydraulic Calculation and Line Sizing - Utility Lineahmad santosoNo ratings yet

- Case 7 - Tank Heat Loss LRDocument181 pagesCase 7 - Tank Heat Loss LRahmad santosoNo ratings yet

- Nkgsb-Prs-Cl-001-A4-C Tank Heater Duty Calculation Flow Chart-09-04-20Document3 pagesNkgsb-Prs-Cl-001-A4-C Tank Heater Duty Calculation Flow Chart-09-04-20ahmad santosoNo ratings yet

- DWG P&ID 19 DEC 19-ModelDocument1 pageDWG P&ID 19 DEC 19-Modelahmad santosoNo ratings yet

- NKGSB-PRS-DB-002-A4-A Process Description & Control Philosophy (11-18-2019)Document29 pagesNKGSB-PRS-DB-002-A4-A Process Description & Control Philosophy (11-18-2019)ahmad santoso100% (1)

- Microsoft PowerPoint - FKIE - DME-TEASER-FINALDocument33 pagesMicrosoft PowerPoint - FKIE - DME-TEASER-FINALahmad santosoNo ratings yet

- NKGSB-PRS-CL-007-A4-A Fire Water Demand Calculation2 (Autosaved-26-01-20)Document15 pagesNKGSB-PRS-CL-007-A4-A Fire Water Demand Calculation2 (Autosaved-26-01-20)ahmad santoso100% (1)

- Case 2 - Tank Heat LossDocument84 pagesCase 2 - Tank Heat Lossahmad santosoNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityShivam PanchalNo ratings yet

- Turbine Bypass SystemDocument20 pagesTurbine Bypass Systemamer_arauf100% (17)

- Determine Required Flushing Flow RateDocument9 pagesDetermine Required Flushing Flow Ratethomas_v501925No ratings yet

- Notes:: P&I Diagram Closed Cooling Water SystemDocument1 pageNotes:: P&I Diagram Closed Cooling Water SystemtuyencntnNo ratings yet

- Argon PDFDocument18 pagesArgon PDFPavan KumarNo ratings yet

- Tanks PresentationDocument29 pagesTanks Presentationkrish585100% (1)

- Refrigeration System DesignDocument8 pagesRefrigeration System DesignJustine BoqsNo ratings yet

- A869-6-44-0005 PMS For RevampDocument950 pagesA869-6-44-0005 PMS For RevampMastram HatheshNo ratings yet

- Performance Testing Asme 4.1Document42 pagesPerformance Testing Asme 4.1EnzoNo ratings yet

- Gas Turbine Compressor Cleaning SystemsDocument20 pagesGas Turbine Compressor Cleaning SystemsDoli MotorNo ratings yet

- Solved Problem 04Document8 pagesSolved Problem 04Abdullah SimpsonNo ratings yet

- Coke and Coal Gasification Plant 2 200 TPD 107Document1 pageCoke and Coal Gasification Plant 2 200 TPD 107osamaNo ratings yet

- Uniphos Kwiksense Digital Smart Gas Transmitter: Salient FeaturesDocument3 pagesUniphos Kwiksense Digital Smart Gas Transmitter: Salient Featuresraushan mishraNo ratings yet

- Catalogo 4WI-Boiler-Book-04-11Document56 pagesCatalogo 4WI-Boiler-Book-04-11Luis Anselmo CastilloNo ratings yet

- Flow Through PipesDocument31 pagesFlow Through PipesShyam Pandey50% (2)

- 27 6 14 16229 Compair Filters Brochure 02 Uk V2Document8 pages27 6 14 16229 Compair Filters Brochure 02 Uk V2Leonardo Tommy DacuNo ratings yet

- Peng-Robinson (PR) : Use of Equations of State and Equation of State Software PackagesDocument7 pagesPeng-Robinson (PR) : Use of Equations of State and Equation of State Software PackagesgeorgenzNo ratings yet

- D6378 10 (Reapproved 2016)Document14 pagesD6378 10 (Reapproved 2016)Cristhian Emmanuel Garrido100% (2)

- Construction and Performance Testing of The Hydraulic Ram PumpDocument7 pagesConstruction and Performance Testing of The Hydraulic Ram PumpGreen Action Sustainable Technology Group0% (1)

- NACA Airfoils Post Stall PDFDocument23 pagesNACA Airfoils Post Stall PDFEmilio BernyNo ratings yet

- Avoiding Pressure SurgeDocument33 pagesAvoiding Pressure SurgeManas KarnureNo ratings yet

- A New Model For Modern Production DeclinDocument14 pagesA New Model For Modern Production DeclinMinh NguyễnNo ratings yet

- P&ID Symbols Legend - LucidchartDocument10 pagesP&ID Symbols Legend - LucidchartkalvinpogiNo ratings yet

- Aerothermal Performance Measurements and AnalysisDocument8 pagesAerothermal Performance Measurements and Analysisraul19rsNo ratings yet

- 4me3 Fluid MechanicsDocument4 pages4me3 Fluid MechanicsGautam GunjanNo ratings yet

- API 12j Two Phase Separator Sizing - Api Rp520 Relief Valve SizingDocument13 pagesAPI 12j Two Phase Separator Sizing - Api Rp520 Relief Valve SizingOmer EkerNo ratings yet

- Pump Primer 2 AssDocument33 pagesPump Primer 2 AssGkou DojkuNo ratings yet

- Boiling and CondensationDocument12 pagesBoiling and CondensationKarthik SadasivuniNo ratings yet

- Nlewis65 115 124 Class and Home Problems Nasri 43 No 2 Spring 2009 CeeDocument10 pagesNlewis65 115 124 Class and Home Problems Nasri 43 No 2 Spring 2009 CeeMarilin NuñezNo ratings yet

- Fan Inlet System EffectsDocument4 pagesFan Inlet System EffectsEzrizal Yusuf100% (1)