Professional Documents

Culture Documents

Laser-Enabled Extremely-High Rate Technology For LED Assembly

Uploaded by

Tien TruongOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Laser-Enabled Extremely-High Rate Technology For LED Assembly

Uploaded by

Tien TruongCopyright:

Available Formats

52-4 / V. R.

Marinov

Laser-Enabled Extremely-High Rate Technology for µLED Assembly

Val R. Marinov

Uniqarta, Inc., Fargo, ND, USA

www.uniqarta.com

Abstract serial and parallel. In the serial (sequential) method, the µLEDs

We developed a complete wafer-to-panel technology for extremely are placed one-by-one on the panel. This is an implementation of

high rate assembly of µLEDs. The process involves transferring the conventional pick-place technology, which is not realistic

the µLEDs directly from the source epi-wafer to a quartz carrier when the number of assembled µLEDs is in the millions or tens

from where they are selectively transferred to the panel using our of millions.

Laser-Enabled Massively Parallel Transfer method with >100M Most of the parallel assembly methods are based on the Micro

units/hr. Transfer Printing (µTP) pick-and-place technique [7], variants of

Author Keywords which are under development by several companies. In essence,

µLED assembly; massively-parallel transfer; µLED display. µTP uses a stamp to pick up an array of µLEDs and transfer it to

a display substrate by “stamping” it. The advantage of this

1. Introduction technique is that it allows for the placement of a large number of

Micro-LEDs (µLEDs) are defined here as epi-layer, substrate-less dies over a large panel size at a high rate. However, the µTP

LEDs with dimensions of <100 µm/side and a thickness of about process requires a careful engineering of the stamp and the donor

5-7 µm. µLEDs have come into the spotlight after Apple and substrate. Using large stamps for high transfer rates may be

Oculus acquired µLED startups. There are currently no µLED problematic because of the pitch inconsistency resulting from

displays in mass production but the companies developing the manufacturing errors and the CTE mismatch between the stamp

technology believe that it has the potential to challenge OLED material (340 ppm/°C for PDMS), glass donor substrate (5-9

technology in the future [1]. Unlike OLEDs, µLEDs are typically ppm/°C) and the panel material. An ambient temperature change

based on III-nitride compound semiconductors which offer far of just 1°C will cause more than 30 µm mismatch between a 100

higher total brightness than OLED products [2], as much as 30 mm/side PDMS stamp and the µLEDs on a glass donor substrate.

times, as well as higher efficiency [3]. They also don’t suffer from This would render such a stamp useless. Also, planned

the shorter lifetimes of OLEDs. Another big benefit is their redundancy is required to mitigate the risks of dead pixels. Some

superior efficiency. solutions include placing two µLEDs at each subpixel [8], an

µLEDs are currently aimed at small, low-energy wearables such approach that essentially doubles the material cost of the display

as AR/VR headsets and smart watches. Another market entry are and still doesn’t guarantee the absence of dead subpixels. Another

large format display. The major reason µLED displays are not in question is the compatibility of the µTP process with

mass production yet is the lack of commercially viable interconnection methods other than thin film lithography. Yet

technology to place and interconnects the very large number of another issue is related to the need for redistributing the µLEDs

µLEDs required for these devices. This, according to many at a pitch greater than the pitch of the source wafer onto a stamp-

experts, is the major bottleneck that prevents the general ready support substrate with adhesive tethers, from where they

production cost of µLED displays from going down [4]. can be picked by the stamp, a step that complicates the production

process and increases production cost.

Presented is Uniqarta’s extremely high placement rate Massively

Parallel Laser-Enabled Transfer (MPLET) technology for µLED Uniqarta’s MPLET technology for extremely fast placement of

placement that is applicable to a wide range of panels sizes. µLED, described in the next section, is a comprehensive wafer-

MPLET is a truly disruptive technology with a potential to to-interconnected µLED assembly technique that addresses all the

revolutionize µLED and mini-LED display manufacturing. problems inherent to the µTP method.

2. State of the Art in µLED Assembly 3. MPLET Technology for Component

The two major methods currently considered for assembling Placement

µLEDs in displays are wafer bonding and die bonding. MPLET’s process flow is illustrated in Figure 1. The process

starts with transferring µLEDs grown on the epitaxial wafer to a

Wafer Bonding: The wafer bonding method is applied to create laser-transparent glass carrier which has a sacrificial layer

monolithic displays with integrated µLEDs on matrix- (Dynamic Release Layer, DRL) spin-coated on its surface. This

addressable substrates [e.g., 5]. In this approach, a standard LED transfer is done using an intermediate transfer tape to ensure that

wafer is etched to form µLEDs, which are then integrated with the dies end up oriented on the DRL carrier active side away from

the transistor back plane. Advantages of this method include a the glass substrate, ready for flip-chip assembly. Conversely, the

very small pixel size and a mass transfer capacity. The drawbacks µLED can be transferred directly to the DRL carrier, in which

include the small overall size of the display, which is limited by case their active side will face the DRL and they will be placed

the size of the µLED wafer, the need for the pitch of the donor on the receive substrate face up. In both cases the µLED are

array to match the pitch of the display, and the inability to exclude released from the source wafer using a laser liftoff (LLO) method.

bad and subpar µLEDs from the transferred array. Once placed on the DRL, the µLEDs are ready for laser transfer,

Die Bonding: In the die bonding approach, discrete µLEDs are accomplished using Uniqarta’s patented laser transfer process for

packaged on rigid or flexible substrates. One of the major ad- high-rate assembly of ultra-small and/or ultra-thin semiconductor

vantages of the discrete approach is the capacity to create a large dies [9] modified for µLED placement and illustrated in Figure 2.

area display [6]. Die bonding methods fall into two categories,

692 • SID 2018 DIGEST ISSN 0097-996X/18/4702-0692-$1.00 © 2018 SID

52-4 / V. R. Marinov

Figure 2. A schematic illustrating

Uniqarta’s laser transfer process.

Figure 1. Process flow in Uniqarta’s laser-

enabled extremely-high rate technology

for µLED assembly. SB-LEAP = single-

beam laser transfer process; MPLET

operates in a multi-beam mode, as

explained in the text. Figure 3. A schematic illustrating the MPLET concept. For simplicity, only a 3×3

beam array is shown although DOEs with much larger arrays are achievable. Note

that all dies on the wafer could be of the same type – the colors in this figure are

only used to indicate the subsequent die arrays transferred with one laser pulse.

In this process, the components to be transferred are bonded to Defect Management: A solution for managing defective

the DRL. During laser transfer, a portion of the DRL is ablated by µLED is an integral part of MPLET. Before laser transfer, the

a short UV laser pulse through the carrier substrate to generate DRL carrier is processed by the MPLET equipment operating in

gases that create a blister in the DRL without rupturing it. The a single-beam mode (the multi-beam to single-beam modification

force exerted by the expanding blister, in addition to the is simply done be removing the DOE from the optical train) and

gravitational force, initiates a transfer across a 10-300 µm gap programmed using a wafer map to remove the bad µLEDs (Step

onto a receive substrate where the die is interconnected to the rest 4 in Figure 1). Next, the panel is introduced and the system is

of the circuitry. By scanning the laser beam across the many dies operated in its multi-beam mode to rapidly place the remaining

of a wafer, this process can achieve very high placement rates of good µLEDs. Because of the previously removed bad dies, a

100K units/hr or higher. However, this single-beam transfer certain number of incomplete die arrays will be transferred. This

process is still not sufficient when a very large number of is dealt with in a final step in which MPLET is switched back to

components need to be assembled for applications such as the a single-beam mode and populates the empty subpixels using the

µLED displays, chip-on-board LED lighting, IoT nodes, etc. orphaned µLEDs left on the wafer from the previous step.

MPLET Technology: MPLET builds upon the single-beam A limiting factor in MPLET is the single-beam operation used in

laser-transfer process, extending its capability by transferring a the defect management step, which becomes predominant at

large array of dies with a single laser pulse (the transfer process lower wafer yields, as seen in Figure 4. Another important

takes < 50µs). Instead of being scanned by a single beam, the conclusion is that MPLET doesn’t necessarily require large beam

wafer in MPLET is scanned via an x-y laser scanner with an array arrays to achive extremely high placement rate. Smaller arrays

of “beamlets” diffracted from a single laser beam using a will help with better utilizing the round source wafers while still

Diffractive Optical Element (DOE) (Figure 3). Each beamlet providing placement rates in excess of 100M units/hr.

transfers one die, resulting in a placement rate equal to that of the Technology Demonstration: Uniqarta has demonstrated key

single-beam process multiplied by the number of beamlets. The elements of the MPLET process. Figures 5a and 5b show the

beam can be diffracted into tens of thousands of beamlets, limited results from transferring µLED from the source epi-wafer to the

only by the power of the laser.

SID 2018 DIGEST • 693

52-4 / V. R. Marinov

From a manufacturing standpoint, this requires the industry to

resolve several important issues and to integrate them in a

cohesive technology solution. This includes, but is not limited to:

a) a reliable method for placing and electrically

interconnecting millions to tens of millions of µLEDs

into an array configuration at a very high assembly rate

(>100M units/hr) at high precision;

b) solutions for µLED testing before and after assembly

and defect management after assembly;

c) at a wafer level, minimizing the component cost by

eliminating those preparation steps that are not

inherently required to fabricate an µLED.

Uniqarta’s MLET technology holds the promise of solving these

issues. Depending on the system configuration and panel size, the

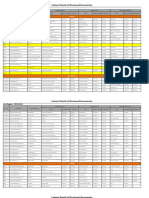

Figure 4. MPLET placement rate for different array placement rates in MPLET can exceed 100M units/hr for large

sizes as a function of wafer yield. The assembly times panels and 500M units/hr for small ones. Regarding placement

are estimates for a 70-in, 4K display. precision, according to some authors, currently the mass

manufacture of displays allows for a placement precision down to

DRL carrier. The transfer was performed using the transfer around ±34 µm, whereas µLED would require the precision to be

method described above. We have also successfully demonstrated narrowed down to around ±1.5 µm [10]. Recently, Uniqarta has

the single-beam laser transfer process’s ability to place 55×32×6 demonstrated laser transfer of 50×50×6 µm µLEDs with an

µm µLEDs on the receive substrate with solder bonding pads average placement error of 1.8 µm.

(Figure 5c). Figure 5d is a frame capture of a video showing the

parallel transfer of a 5×5 array of 42×42×6 µm dummy dies. Defect management is an integral part of MPLET with its ability

Figure 5e shows the probing of 55×32×6 µm µLEDs soldered to to screen out and replace defective µLEDs. Finally, MPLET

a test substrate. We are in the process of bringing all these process works with µLEDs transferred directly from the substrates for

components together with an objective demonstrating a demo epitaxial growth without the need to relocate µLEDs to a

µLED display later this year assembled with a placement rate of complementary source substrate as in the µTP methods.

more than 10M units/hour. 5. Impact

4. Discussion and Conclusions Uniqarta’s MPLET technology solves the problem of

To become commercially viable, the large area µLED display economically placing large quantities of µLEDs across a large

technology must be able to compete effectively with the existing area by increasing the placement rate of µLEDs to more than

display technologies (OLED and LCD) and to make a profit. 100M units/hr. This capability, which also includes the ability to

µLED wafer

DRL carrier (a)

transferred field in MPLET (b) (c)

(d) (e)

Figure 5. (a) A 2-in µLED wafer bonded to the DRL carrier, ready for laser transfer; (b) a close-up of the transferred

µLEDs on the DRL carrier; (c) 55×32×6 µm µLEDs laser placed on a test substrate’s bonding pads, ready for soldering

(pads are not visible in this photograph); (d) a screen shot from an MPLET video clip showing a 5×5 array of 42×42×6 µm

dummy dies immediately before laser transfer; (e) probing of soldered 55×32×6 µm µLEDs on a test substrate.

694 • SID 2018 DIGEST

52-4 / V. R. Marinov

pre-screen and replace non-functional/subpar LEDs, reduces Micro-LED Market Could Reach US$30~40 Billion If It

assembly times to minutes and enables market-compatible price Was to Supplant the Current Display Chain. 2017

points. This is a capability not commercially available today. [available from:

Other approaches for high-speed µLED placement are being http://press.trendforce.com/node/view/2801.html].

developed. However, none are reported to be capable of [5] Jeon, C., H. Choi, and M. Dawson, Fabrication of matrix-

placement rates matching Uniqarta’s solution nor deal efficiently addressable InGaN-based microdisplays of high array

with the problem of non-functional or subpar LEDs. density. IEEE Photonics Technology Letters, 2003. 15(11):

6. Acknowledgements p. 1516-1518.

Author wants to acknowledge the support received from NSF [6] Lee, V.W., N. Twu, and I. Kymissis, Frontline Technology

(Awards Nos. 1519514, 1632387, and 1745903). Micro-LED Technologies and Applications. Information

Display, December 2016, Iss. 6: p. 16-23.

7. References

[1] Larsen, R. An introduction to Micro LED; a new self- [7] Park, S.-I., et al., Printed assemblies of inorganic light-

emitting display technology. 2016 [available from: emitting diodes for deformable and semitransparent

http://www.flatpanelshd.com/focus.php?subaction=showful displays. Science, 2009. 325(5943): p. 977-981.

l&id=1477048275]. [8] Bibl, A., et al., LED display with redundancy scheme.

[2] Acharya, A.R., Group III–Nitride Semiconductors: 2014, LuxVue Technology Corporation.

Preeminent Materials for Modern Electronic and [9] Marinov, V., et al., Laser-Enabled Advanced Packaging of

Optoelectronic Applications. Himalayan Physics, 2015. 5: Ultrathin Bare Dice in Flexible Substrates. Components,

p. 22-26. Packaging and Manufacturing Technology, IEEE

[3] Peddie, J., Augmented Reality: Where We Will All Live. Transactions on, 2012. 2(4): p. 569-577.

2017: Springer. [10] Golightly, D. Tech Talk: Where Are All Of The Micro-

[4] Chu, R. Press Release: TrendForce Says Potential Scale of LED Displays? Android Headlines, October 17, 2017.

SID 2018 DIGEST • 695

You might also like

- CHAPTER ONE Structural GeologyDocument46 pagesCHAPTER ONE Structural GeologyAfolabi Eniola AbiolaNo ratings yet

- Ultra Low Latency MicrowaveDocument9 pagesUltra Low Latency MicrowaveMihaelNo ratings yet

- Refill Brand Guidelines 2Document23 pagesRefill Brand Guidelines 2Catalin MihailescuNo ratings yet

- CompressDocument14 pagesCompressAnonymous gfR3btyU0% (1)

- Maskless LithographyDocument8 pagesMaskless Lithographymarci_elgNo ratings yet

- Kompresi MobilDocument58 pagesKompresi Mobilfatah hamid100% (1)

- Cics Tutorial PDFDocument23 pagesCics Tutorial PDFNeelay KumarNo ratings yet

- XC3000 Series Motion Control System of Laser Cutting Commissioning Manual TextDocument138 pagesXC3000 Series Motion Control System of Laser Cutting Commissioning Manual Textgerardo.reynosoNo ratings yet

- Freelance Contract AgreementDocument10 pagesFreelance Contract AgreementGayathri Prajit100% (1)

- Concise Guide to OTN optical transport networksFrom EverandConcise Guide to OTN optical transport networksRating: 4 out of 5 stars4/5 (2)

- Sub-Wavelength Holographic Lithography (SWHL)Document15 pagesSub-Wavelength Holographic Lithography (SWHL)МРязанскийNo ratings yet

- DWDM Transmode GoodDocument89 pagesDWDM Transmode GoodSanjay YadavNo ratings yet

- Silicon Photonic Mode Multiplexers Based On Subwavelength Metamaterials and On-Chip Beam FormingDocument4 pagesSilicon Photonic Mode Multiplexers Based On Subwavelength Metamaterials and On-Chip Beam FormingAron RNo ratings yet

- ECTC2020 PaperNo.286 VfinalDocument8 pagesECTC2020 PaperNo.286 Vfinalgoutham ezhilarasuNo ratings yet

- CMOS-compatible Ultra-Compact Silicon Multimode Waveguide Bend Based On Inverse Design MethodDocument7 pagesCMOS-compatible Ultra-Compact Silicon Multimode Waveguide Bend Based On Inverse Design MethodTruong Cao DungNo ratings yet

- Light Emitting Polymer: Department of Electrical & Electronics, College of Engineering and Management Punnapra, AlappuzhaDocument27 pagesLight Emitting Polymer: Department of Electrical & Electronics, College of Engineering and Management Punnapra, AlappuzhaRagesh TrNo ratings yet

- Design and Demonstration of Glass Panel Embedding For 3d System Packages For Heterogeneous Integration ApplicationsDocument12 pagesDesign and Demonstration of Glass Panel Embedding For 3d System Packages For Heterogeneous Integration ApplicationsnanozordprimeNo ratings yet

- The Infrared Traffic Logger: Wavelength Division Multiplexing (WDM)Document3 pagesThe Infrared Traffic Logger: Wavelength Division Multiplexing (WDM)Athira VijayanandanNo ratings yet

- Preprints202304 0764 v1Document18 pagesPreprints202304 0764 v1ArturNo ratings yet

- Seminar ReportDocument24 pagesSeminar ReportNarender SinghNo ratings yet

- Alen Report 1Document16 pagesAlen Report 1Abhin AsNo ratings yet

- Light Emitting PolymersDocument11 pagesLight Emitting Polymerssridhar N SHASTRINo ratings yet

- Optical Ring Architecture Using 4-Nodes WDM Add/Drop Multiplexer Based SSMFDocument3 pagesOptical Ring Architecture Using 4-Nodes WDM Add/Drop Multiplexer Based SSMFDayannaNo ratings yet

- Enhanced Constraint-Based Optical Network For Improving OSNR Using ROADMDocument10 pagesEnhanced Constraint-Based Optical Network For Improving OSNR Using ROADMInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Double Patterning LithographyDocument1 pageDouble Patterning Lithographyrashmi sNo ratings yet

- Electronics: A Hidden DCT-Based Invisible Watermarking Method For Low-Cost Hardware ImplementationsDocument25 pagesElectronics: A Hidden DCT-Based Invisible Watermarking Method For Low-Cost Hardware ImplementationsARUN CHILUKURINo ratings yet

- Nonparaxial Mode-Size Converter Using An Ultracompact Metamaterial Mikaelian LensDocument7 pagesNonparaxial Mode-Size Converter Using An Ultracompact Metamaterial Mikaelian LensPaola GongoraNo ratings yet

- Optics and Laser TechnologyDocument10 pagesOptics and Laser TechnologyDuy Từ ĐàoNo ratings yet

- Behind The Light Show in Optical TransceiversDocument7 pagesBehind The Light Show in Optical TransceiversarmandobroncaNo ratings yet

- Proposal Simulation and Execution of Embedded Scheme Centred Dual Horn by Wireless TechnologyDocument5 pagesProposal Simulation and Execution of Embedded Scheme Centred Dual Horn by Wireless TechnologyKARTHIKNo ratings yet

- Multiple Signal Representation For PDA 00847764Document15 pagesMultiple Signal Representation For PDA 00847764jbusowiczNo ratings yet

- 04 1120 PoenningerDocument6 pages04 1120 PoenningerChristian HollaenderNo ratings yet

- ROADM - The Core of Agile Optical Networks: Passive Based SolutionDocument8 pagesROADM - The Core of Agile Optical Networks: Passive Based SolutionMARCO MANUEL ARANDA SULLCATANo ratings yet

- A Parametric Network For The Global Compensation of Physical Layer Linear Impairments in Coherent Optical CommunicationsDocument17 pagesA Parametric Network For The Global Compensation of Physical Layer Linear Impairments in Coherent Optical CommunicationsAlexandru FrunzaNo ratings yet

- IJEDR1701118Document7 pagesIJEDR1701118kesavanNo ratings yet

- 2013litho SummaryDocument6 pages2013litho SummaryAman kumarNo ratings yet

- Decoupling NetworkDocument10 pagesDecoupling NetworkVivek MukundanNo ratings yet

- 726 SadekDocument6 pages726 SadekSachin PetleNo ratings yet

- PDMS caracsDFDocument7 pagesPDMS caracsDFFarid MORABETNo ratings yet

- Applied Sciences: The Challenges of Advanced CMOS Process From 2D To 3DDocument32 pagesApplied Sciences: The Challenges of Advanced CMOS Process From 2D To 3DPramod Reddy RNo ratings yet

- Ultrafast Multi-Focus 3-D Nano-Fabrication Based On Two-Photon PolymerizationDocument7 pagesUltrafast Multi-Focus 3-D Nano-Fabrication Based On Two-Photon PolymerizationHan YangNo ratings yet

- In Situ 3D Nanoprinting of Free-Form Coupling Elements For Hybrid Photonics IntegrationDocument9 pagesIn Situ 3D Nanoprinting of Free-Form Coupling Elements For Hybrid Photonics IntegrationMiles FernsbyNo ratings yet

- LCD SLMDocument9 pagesLCD SLMVipin_Kumar_5649No ratings yet

- Electronics: From 32 NM To TFET Technology: New Perspectives For Ultra-Scaled RF-DC Multiplier CircuitsDocument14 pagesElectronics: From 32 NM To TFET Technology: New Perspectives For Ultra-Scaled RF-DC Multiplier Circuitssaeed gholamiNo ratings yet

- Final-Wlte-Full-Notes For UseDocument236 pagesFinal-Wlte-Full-Notes For UseChess ChanNo ratings yet

- Optical Computing Seminar ReportDocument25 pagesOptical Computing Seminar ReportManish PushkarNo ratings yet

- Recent Developments in Panel Level Packaging-IEEEDocument7 pagesRecent Developments in Panel Level Packaging-IEEEatulNo ratings yet

- Final Wlte Full NotesDocument236 pagesFinal Wlte Full NotesDeepak SharmaNo ratings yet

- Meet3 01Document4 pagesMeet3 01kraidonNo ratings yet

- DVR Based ThesisDocument5 pagesDVR Based Thesistinajordanhuntsville100% (1)

- Active Vs Passive Solutions White Paper PLDocument6 pagesActive Vs Passive Solutions White Paper PLGeorgi IlievNo ratings yet

- Grating Light Valve Display Technology (GLVT) - Muhammed Ismail PPDocument20 pagesGrating Light Valve Display Technology (GLVT) - Muhammed Ismail PPismailpp200863% (8)

- Suppression of Hot-Carrier Effects Facilitated by The Multimodal Thin-Film Transistor ArchitectureDocument8 pagesSuppression of Hot-Carrier Effects Facilitated by The Multimodal Thin-Film Transistor ArchitectureangelNo ratings yet

- Visvesvaraya Technological University, BELGAUM-590018: Dense Wavelength Division Multiplication (DWDM)Document21 pagesVisvesvaraya Technological University, BELGAUM-590018: Dense Wavelength Division Multiplication (DWDM)Namdev RathodNo ratings yet

- Interference in Lte Small CellsDocument27 pagesInterference in Lte Small CellsminhthangbkNo ratings yet

- Esmm 974Document19 pagesEsmm 974santanuNo ratings yet

- Performance Improvements of A VLC System, in A V2X Context, Using A Different Multiplexing TechniqueDocument11 pagesPerformance Improvements of A VLC System, in A V2X Context, Using A Different Multiplexing TechniqueTELKOMNIKANo ratings yet

- DWDM Technical ReportDocument25 pagesDWDM Technical ReportTareq QaziNo ratings yet

- Next Generation Lithographydthe Rise of Unconventional Methods?Document17 pagesNext Generation Lithographydthe Rise of Unconventional Methods?tameem Fahad tameemFahadNo ratings yet

- Interferometric Modulator Display (Trademarked Mirasol) .: - in Essence, IMODSDocument10 pagesInterferometric Modulator Display (Trademarked Mirasol) .: - in Essence, IMODSSrinjoy Nag ChowdhuryNo ratings yet

- 2006 A Generalized Memory Polynomial Model For Digital Predistortion of RF Power AmplifiersDocument9 pages2006 A Generalized Memory Polynomial Model For Digital Predistortion of RF Power Amplifiers9885842565No ratings yet

- Femtosecond Fiber Laser ThesisDocument12 pagesFemtosecond Fiber Laser Thesislisaolivenorthlasvegas100% (2)

- Switches .Of Course These Switches Are Cheap and Capable ofDocument17 pagesSwitches .Of Course These Switches Are Cheap and Capable ofK Murali KrishnaNo ratings yet

- 3D Printed AntennaDocument11 pages3D Printed AntennaGanga PandeyNo ratings yet

- 752-MHz Modulation Bandwidth of High-Speed Blue Micro Light-Emitting DiodesDocument6 pages752-MHz Modulation Bandwidth of High-Speed Blue Micro Light-Emitting DiodesasifnewazuccNo ratings yet

- Subcarrier Grouping OFDM For Visible-Light Communication SystemsDocument13 pagesSubcarrier Grouping OFDM For Visible-Light Communication SystemsghalzaiNo ratings yet

- 2022 Charge Transfer Observed in Light Activated Catalyst ParticlesDocument2 pages2022 Charge Transfer Observed in Light Activated Catalyst ParticlesTien TruongNo ratings yet

- Catalysts 08 00405Document19 pagesCatalysts 08 00405Tien TruongNo ratings yet

- PhysRevMaterials 1 022401Document6 pagesPhysRevMaterials 1 022401Tien TruongNo ratings yet

- 1 s2.0 S2213343719303021 MainDocument16 pages1 s2.0 S2213343719303021 MainTien TruongNo ratings yet

- Underfill ChipsDocument9 pagesUnderfill ChipsTien TruongNo ratings yet

- Wan 2005Document7 pagesWan 2005Tien TruongNo ratings yet

- Underfill Flip-Chip ReviewDocument19 pagesUnderfill Flip-Chip ReviewTien TruongNo ratings yet

- Photocatalytic Oxidation of Ammonia Via An Activated Carbon-Nickel Ferrite Hybrid Catalyst Under Visible Light IrradiationDocument9 pagesPhotocatalytic Oxidation of Ammonia Via An Activated Carbon-Nickel Ferrite Hybrid Catalyst Under Visible Light IrradiationTien TruongNo ratings yet

- Challenges in The Realm of MicroLEDDocument35 pagesChallenges in The Realm of MicroLEDTien TruongNo ratings yet

- 02 IG4K TechnologiesDocument47 pages02 IG4K TechnologiesM Tanvir AnwarNo ratings yet

- Talent Neuron NewsletterDocument2 pagesTalent Neuron NewsletterTalent NeuronNo ratings yet

- Thermister O Levels Typical QuestionDocument4 pagesThermister O Levels Typical QuestionMohammad Irfan YousufNo ratings yet

- Ariando Purba: Nov 2017-: CV. Mulia Abadi (Knitto Textiles) - Present System Development and ImplementationDocument3 pagesAriando Purba: Nov 2017-: CV. Mulia Abadi (Knitto Textiles) - Present System Development and ImplementationariandoNo ratings yet

- Annexure 3 Courtesy Car AgreementDocument3 pagesAnnexure 3 Courtesy Car AgreementManishNo ratings yet

- Neo Lighting Control Console: User Manual AddendumDocument14 pagesNeo Lighting Control Console: User Manual AddendumSamuelRômanceMuñozNo ratings yet

- Makalah MGR Promot - Clma Gravity - p2pd TmminDocument27 pagesMakalah MGR Promot - Clma Gravity - p2pd TmminSandi SaputraNo ratings yet

- Lect7 Grinding Advanced ManufacturingDocument33 pagesLect7 Grinding Advanced Manufacturingsirac topcuNo ratings yet

- Silverio Nuanez Verified ComplaintDocument10 pagesSilverio Nuanez Verified ComplaintMichael_Lee_RobertsNo ratings yet

- Roger Rabbit:, Forest Town, CA 90020Document3 pagesRoger Rabbit:, Forest Town, CA 90020Marc TNo ratings yet

- DocumentDocument2 pagesDocumentAddieNo ratings yet

- New Champlain Bridge: Final Report Summary (English)Document82 pagesNew Champlain Bridge: Final Report Summary (English)andyrigaNo ratings yet

- Nigeria Country Profile - 0Document4 pagesNigeria Country Profile - 0Nden SohbutNo ratings yet

- Istqb Agile Tester Learning Objectives SingleDocument3 pagesIstqb Agile Tester Learning Objectives SingleSundarNo ratings yet

- Divisional Sec. Contact Details 2019-03-01-UpdateDocument14 pagesDivisional Sec. Contact Details 2019-03-01-Updatedotr9317No ratings yet

- Finaldis2011 1Document4 pagesFinaldis2011 1syaiful.idzwanNo ratings yet

- How To Write The Introduction of An Action Research PaperDocument8 pagesHow To Write The Introduction of An Action Research Papergw1qjewwNo ratings yet

- Thousands of Relocation Jobs Await You Anytime, Anywhere!: About UsDocument3 pagesThousands of Relocation Jobs Await You Anytime, Anywhere!: About UsWeackson Guerrier100% (1)

- OCES 1001 - Final Exam Instructions (Please Read BEFORE The Exam)Document16 pagesOCES 1001 - Final Exam Instructions (Please Read BEFORE The Exam)Heihei ChengNo ratings yet

- Huawei Videoconferencing HD Endpoint TE50 Datasheet - 20140221Document2 pagesHuawei Videoconferencing HD Endpoint TE50 Datasheet - 20140221nuttylNo ratings yet

- Case Analysis: A Simple Strategy at Costco: Informative Background InformationDocument15 pagesCase Analysis: A Simple Strategy at Costco: Informative Background InformationFred Nazareno CerezoNo ratings yet

- Avast 2050 License Faker by ZeNiX 2014-03-14 enDocument1 pageAvast 2050 License Faker by ZeNiX 2014-03-14 enenteryourname5No ratings yet

- Sikaplan®-1652 Bonded VOC Gas Barrier: Product Data SheetDocument3 pagesSikaplan®-1652 Bonded VOC Gas Barrier: Product Data SheetKhin Sandi KoNo ratings yet