Professional Documents

Culture Documents

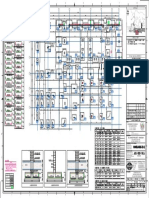

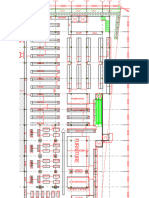

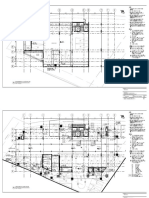

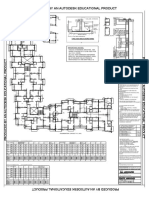

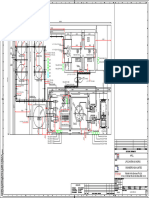

Power Layout Circuit-R1 (TRF)

Uploaded by

Electrical PCBL TeamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Power Layout Circuit-R1 (TRF)

Uploaded by

Electrical PCBL TeamCopyright:

Available Formats

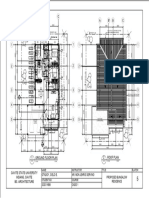

NOTES

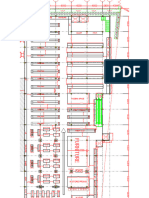

X1 X2 X3 X4 X5 X6 X7 X8 X9 X10 X11 X12 X13 X14 X15

49500

4150 3350 400 4950 2150 7075 1865 2885 2500 7500 6000 6000

425 250

R7 C

ALU LOUVER

Y1

SERVICE

3500

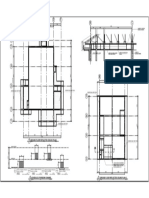

DUCT LIFT DUCT

Y2 SHAFT 3T

CAPACITY

+ 28.00 Lvl

SHAFT

1700

DN

1600

3200X3500mm

250

Y3

1525

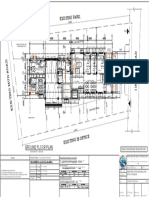

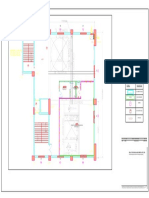

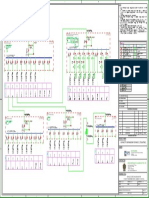

ELECTRICAL LEGEND FOR GENERAL POWER SOCKETS :

2095 4451

63A

5798 FIXTURE DESCRIPTION

WALK WAY

TRC SPDB-04/C14,15,16 SR.NO QTY.

SYMBOL

WALK WAY

1

7500

42 42 COVERED SHED

FAHU3 14900 CFM DEHUMIDIFIRE 2

AIR FLOW

OF

DIRECTION

3570 L X 2200W X 2050H EAHU2 45200 CFM

WEIGHT1731KG

5215

3900 L X 3400W X 3000H

TIER1 40

AIR FLOW

OF

DIRECTION

WEIGHT4492KG ℄ OF CASING 3

+ 28.00 Lvl TIER1

41 COVERED SHED

2147

2147

16A

AIR FITER 4

16A 1961

936

CASING R7

Y4 TRC SPDB-04/C13

38 5 63A

WALK WAY

DEHUMIDIFIER1 & 2 F.D. BLOWER

AHU3 22800 CFM AREA 886 Sq.m

5000 (L) x 1800 (W) x 2000 (H)

A 4830 L X 2800 W X 2050 H

WEIGHT2730KG

TIER1

FAHU2 52700 CFM

4400 L X 3400W X 3000H

A 01. ARCHITECTURAL

AIR FLOW

OF

DIRECTION

WEIGHT4736KG

02. STRUCTURAL

TIER1

03. HVAC

7500

39 5798

COVERED SHED STEAM 04. ELECTRICAL

RADIATOR THERMIC

1961 FLUID

5353

+ 28.00 Lvl HEATER 05. UTILITIES

33750

UP

WALK WAY

AIR FITER REFERENCE DRAWING

CASING 2050

300x300 FLOOR

2285

OPENING FOR

Y5

ELECTRICAL

R7

TRC SPDB-04/C7 TRC SPDB-04/C8 CHILLER1

2515

(WORKING)

100 TR 1378

16A WEIGHT2717KG 36 36 BLOWER

160kVA UPS CHILLER2 CHILLER2 ROOM

Y6 BATTERYTRC SPDB-04/C9 (WORKING) (WORKING) 6700X7820 mm

36 100 TR 100 TR + 28.00 Lvl

COMPRESSOR 1 & 2

WEIGHT2717KG WEIGHT2717KG

2335

43 43

I/O PANEL

R1 FOR REVIEW 09.02.2023 GKL GKL

UTILITY PDB 1

8420

F CHILLER SIZES

2596 (L) x 1336 (W) x R0 03.05.2022 M.M H.B

FOR REVIEW

Y7

F

TRC SPDB-04/C6 + 28.00 Lvl 1830 (H)

DRYER 37 37 REV DESCRIPTION DATE DRAWN CHECK

I/O PANEL

300kVA UPS DRYER 37

BATTERY

4115

F F AIR RECEIVER

3150

Dia 100mm 5310 FILTER

REVISION HISTORY

MCC WET END PANEL

+ 28.00 Lvl CLEANING AREA

4500X3500 PROJECT NAME :

1790

AREA 173 Sq.m 1000x800 WALL

OPENING FOR

Y8

R7

160kVA

63A

ELECTRICAL

CAPACITY EXPANSION FOR MCC ( 750 MTM)

UPS

F

16A ELEC MECH

TRC SPDB-04/C5 SHAFT SHAFT TRC SPDB-04/C10,11,12

CLIENT :

300kVA HVAC PANEL1 R7

UPS

F F

DFE PHARMA

7000

ELECTRICAL B‐4, SIPCOT Industrial Complex, Kudikadu,

ROOM Cuddalore

PIPING

Tamil Nadu ‐ 607005

SHAFT

TRC SPDB-04/C3

TRC SPDB-04/C4

F F

MCC DRY END HVAC PANEL 2

PANEL CONTRACTOR :

CRESCON PROJECTS & SERVICES PVT LTD

Y9 No.70 Second Floor, 8th Street

Sector No.2, KK Nagar

Chennai ‐ 78

TRC SPDB-04/C1 TRC SPDB-04/C2

TEL : 044 ‐ 23664945,

C Email : cresconproj@gmail.com

DRAWING TITLE :

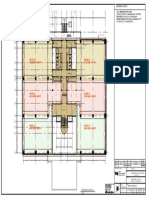

GENERAL POWER LAYOUT MCC

PLANT TERRACE FLOOR

DRAWN : M.M CHECKED : H.B APPROVED : A.B

SIGN : SIGN : SIGN :

SCALE : 1:100

DWG NO: DFE/B01/ELE/DWG/GPR/005 Rev. R1

SHEET NO: 01 CON'T. ON : 01 Size. A1

You might also like

- Dfe-B01-Ele-Dwg-Gpr-005 - General Power Layout For Terrace FloorDocument1 pageDfe-B01-Ele-Dwg-Gpr-005 - General Power Layout For Terrace FloorElectrical PCBL TeamNo ratings yet

- Dfe-B01-Ele-Dwg-Gpr-004 - General Power Layout For Third FloorDocument1 pageDfe-B01-Ele-Dwg-Gpr-004 - General Power Layout For Third FloorElectrical PCBL TeamNo ratings yet

- Dfe-B01-Ele-Dwg-Gpr-002 - General Power Layout For First Floor & Mezzanine FloorDocument1 pageDfe-B01-Ele-Dwg-Gpr-002 - General Power Layout For First Floor & Mezzanine FloorElectrical PCBL TeamNo ratings yet

- Dfe-B01-Ele-Dwg-Gpr-003 - General Power Layout For Second FloorDocument1 pageDfe-B01-Ele-Dwg-Gpr-003 - General Power Layout For Second FloorElectrical PCBL TeamNo ratings yet

- DFE-B01-ELE-DWG-LTG-003 - LIGHTING LAYOUT - MCC PLANT SECOND FLOOR (DB) - Copy-SF PLANDocument1 pageDFE-B01-ELE-DWG-LTG-003 - LIGHTING LAYOUT - MCC PLANT SECOND FLOOR (DB) - Copy-SF PLANElectrical PCBL TeamNo ratings yet

- Dfe-B01-Ele-Dwg-Gpr-006 - General Power Layout For Mumty TerraceDocument1 pageDfe-B01-Ele-Dwg-Gpr-006 - General Power Layout For Mumty TerraceElectrical PCBL TeamNo ratings yet

- Dfe-B01-Ele-Dwg-Gpr-001 - General Power Layout For Ground FloorDocument1 pageDfe-B01-Ele-Dwg-Gpr-001 - General Power Layout For Ground FloorElectrical PCBL TeamNo ratings yet

- Second Floor Plan: Schedule of Floor FinishesDocument1 pageSecond Floor Plan: Schedule of Floor FinishesMJian VergaraNo ratings yet

- Power Layout Circuit-R1 (MTRF)Document1 pagePower Layout Circuit-R1 (MTRF)Electrical PCBL TeamNo ratings yet

- DENAH LT.1-Model PDFDocument1 pageDENAH LT.1-Model PDFTri BudiNo ratings yet

- A6Document1 pageA6Lloyd MontalbanNo ratings yet

- Ground Floor Plan: Proposed Workshop and Warehouse - Davao City V.M.Jhek Builders 5 2Document1 pageGround Floor Plan: Proposed Workshop and Warehouse - Davao City V.M.Jhek Builders 5 2Victorino SantosNo ratings yet

- ROAD OVER BRIDGE DWG-Layout1Document1 pageROAD OVER BRIDGE DWG-Layout1Anjali M SNo ratings yet

- 2nd Floor Framing Strengting (Data Centre) 21!07!2023Document1 page2nd Floor Framing Strengting (Data Centre) 21!07!2023hamza 11No ratings yet

- Sukhani GA With Levels PDFDocument1 pageSukhani GA With Levels PDFHimal KafleNo ratings yet

- Ga HPHDocument1 pageGa HPHhanda ramadhanNo ratings yet

- SD-1 Copy-ModelDocument1 pageSD-1 Copy-ModelNOV2022 CELENo ratings yet

- Ilovepdf MergedDocument24 pagesIlovepdf MergedJADEL ALCANTARANo ratings yet

- Level 3Document1 pageLevel 3Khalid SherbiniNo ratings yet

- Bunaglow PlanDocument1 pageBunaglow PlanCielo OtadoyNo ratings yet

- 6-St-Ar-Mh-S&t-Det-001 (Sheet 1 of 2)Document1 page6-St-Ar-Mh-S&t-Det-001 (Sheet 1 of 2)Jacob FryeNo ratings yet

- Property & Supply Storage Room: Elev. ElevDocument1 pageProperty & Supply Storage Room: Elev. ElevBerlin Andrew SionNo ratings yet

- Pile & Pile Cap Reinforcement P11-P12-P13Document1 pagePile & Pile Cap Reinforcement P11-P12-P13Sayan SarkarNo ratings yet

- Floor Plan Roof Plan: Roof Eaves Line Roof Eaves LineDocument1 pageFloor Plan Roof Plan: Roof Eaves Line Roof Eaves LineJifty Parojinog Jr.No ratings yet

- Foundation PlanDocument1 pageFoundation PlanIbbe CaguiatNo ratings yet

- Existing Park: Ground Floor PlanDocument1 pageExisting Park: Ground Floor PlanManasNo ratings yet

- 2.appendix A - Floor PlanDocument2 pages2.appendix A - Floor PlanbarsathNo ratings yet

- Ground Floor Plan A Second Floor Plan B: Garage 2-CARSDocument1 pageGround Floor Plan A Second Floor Plan B: Garage 2-CARSArwin DeriNo ratings yet

- B C D A3 A5 A7 Section: C-C: Max. Static Floor Loading 50 N/CMDocument1 pageB C D A3 A5 A7 Section: C-C: Max. Static Floor Loading 50 N/CMAmine MetalbarzottiNo ratings yet

- Lift Differnt Sze DetailDocument1 pageLift Differnt Sze Detailsumant giriNo ratings yet

- Gambar Kerja Rev-Mode 1Document1 pageGambar Kerja Rev-Mode 1Orent Randa kelenNo ratings yet

- Priesma Architect: Mr. AntoniDocument1 pagePriesma Architect: Mr. AntoniRio AdistiaNo ratings yet

- Avesta Pharma-5tf Cre LayoutDocument1 pageAvesta Pharma-5tf Cre LayoutSaurabh KadamNo ratings yet

- HBC 2263 P2J Esa Va1 ST FL 2002 R1Document1 pageHBC 2263 P2J Esa Va1 ST FL 2002 R1MØhãmmed ØwięsNo ratings yet

- HBC 2263 P2J Esa Va1 ST FL 2002 R1Document1 pageHBC 2263 P2J Esa Va1 ST FL 2002 R1MØhãmmed ØwięsNo ratings yet

- Gambar Kerja Rev-Mode 2Document1 pageGambar Kerja Rev-Mode 2Orent Randa kelenNo ratings yet

- Deo BridgeDocument1 pageDeo Bridgemahendra prajapatiNo ratings yet

- 2 - DrainageDocument8 pages2 - DrainageDhanushka MadhushankaNo ratings yet

- SH 4-ModelDocument1 pageSH 4-ModelPaolo ValdezNo ratings yet

- Chintamani Habitat Column ScheduleDocument1 pageChintamani Habitat Column SchedulePiyush ShahaneNo ratings yet

- Drawing1 ModelDocument1 pageDrawing1 ModelNawfel ArafathNo ratings yet

- COLUMN SCHEDULE (7) - ModelDocument1 pageCOLUMN SCHEDULE (7) - ModelPiyush ShahaneNo ratings yet

- Ground Floor Plan: Schedule of Floor FinishesDocument1 pageGround Floor Plan: Schedule of Floor FinishesMJian VergaraNo ratings yet

- Schedule of Windows & Glazing: 1 W 2 W 3 W 4 W 5 WDocument1 pageSchedule of Windows & Glazing: 1 W 2 W 3 W 4 W 5 Walezandro del rossiNo ratings yet

- Mindship Bulk Carie-ModelDocument1 pageMindship Bulk Carie-ModelNguyễn Đức TựNo ratings yet

- Floor Plan 565Document1 pageFloor Plan 565Siva sangariNo ratings yet

- SH 5-ModelDocument1 pageSH 5-ModelPaolo ValdezNo ratings yet

- 5.VIE-PC01-STN-BHT-CRS-4001 (R2) SECTION A-Layout1Document1 page5.VIE-PC01-STN-BHT-CRS-4001 (R2) SECTION A-Layout1Ashish BhartiNo ratings yet

- Admin - Ground FloorDocument1 pageAdmin - Ground FloorParthi BanNo ratings yet

- Kolkata 700 001 7, Hare StreetDocument1 pageKolkata 700 001 7, Hare Streetkoushik42000No ratings yet

- Elevation Section: PMK International Consult LLCDocument1 pageElevation Section: PMK International Consult LLCAhsan KhanNo ratings yet

- Isl4 Storage Shelves PlanDocument1 pageIsl4 Storage Shelves Plansasikumarcivil1996No ratings yet

- Toilet Block: Disaster Resilience of Public School Infrastructure and Community (Dr-Psic)Document11 pagesToilet Block: Disaster Resilience of Public School Infrastructure and Community (Dr-Psic)Debendra Dev KhanalNo ratings yet

- E F D C B A E F D C B A E F D C B A: Ground Floor Plan Second Floor Plan Third Floor PlanDocument1 pageE F D C B A E F D C B A E F D C B A: Ground Floor Plan Second Floor Plan Third Floor Plankuya prexNo ratings yet

- Gua-Tra-078 - Shop Drawing Smoking ShelterDocument11 pagesGua-Tra-078 - Shop Drawing Smoking ShelterICEDA HumNo ratings yet

- Detail of C1F1: Foundation PlanDocument1 pageDetail of C1F1: Foundation PlanEury AlzagaNo ratings yet

- Electrical A4Document3 pagesElectrical A4John Tristan GonzalesNo ratings yet

- 01.PLUMBING SANITARY-ModelDocument1 page01.PLUMBING SANITARY-ModeldinNo ratings yet

- The Rough Guide to Beijing (Travel Guide eBook)From EverandThe Rough Guide to Beijing (Travel Guide eBook)Rating: 2 out of 5 stars2/5 (1)

- DFE-B01-ELE-DOC-DC-001 - R0 - Lighting Design CalculationDocument138 pagesDFE-B01-ELE-DOC-DC-001 - R0 - Lighting Design CalculationElectrical PCBL TeamNo ratings yet

- DFE-B01-ELE-DWG-LTG-005 - LIGHTING LAYOUT - MCC PLANT TERRACE FLOOR (DB) - Copy-TERRACE PLANDocument1 pageDFE-B01-ELE-DWG-LTG-005 - LIGHTING LAYOUT - MCC PLANT TERRACE FLOOR (DB) - Copy-TERRACE PLANElectrical PCBL TeamNo ratings yet

- DFE-B01-ELE-DWG-LTG-006 - LIGHTING LAYOUT - MCC PLANT MUMTY FLOOR (RCP) - MumtyDocument1 pageDFE-B01-ELE-DWG-LTG-006 - LIGHTING LAYOUT - MCC PLANT MUMTY FLOOR (RCP) - MumtyElectrical PCBL TeamNo ratings yet

- Dfe-B01-Ele-Dwg-Gpr-001 - General Power Layout For Ground FloorDocument1 pageDfe-B01-Ele-Dwg-Gpr-001 - General Power Layout For Ground FloorElectrical PCBL TeamNo ratings yet

- Dfe-B01-Ele-Dwg-Gpr-006 - General Power Layout For Mumty TerraceDocument1 pageDfe-B01-Ele-Dwg-Gpr-006 - General Power Layout For Mumty TerraceElectrical PCBL TeamNo ratings yet

- Power Layout Circuit-R1 (FF)Document1 pagePower Layout Circuit-R1 (FF)Electrical PCBL TeamNo ratings yet

- Dfe-B00-Ele-Dwg-Sld-002 - Single Line Diagram For LV Main DistributionDocument1 pageDfe-B00-Ele-Dwg-Sld-002 - Single Line Diagram For LV Main DistributionElectrical PCBL Team0% (1)

- Power Layout Circuit-R1 (MTRF)Document1 pagePower Layout Circuit-R1 (MTRF)Electrical PCBL TeamNo ratings yet

- Power Layout Circuit - R1Document1 pagePower Layout Circuit - R1Electrical PCBL TeamNo ratings yet

- Power Layout Circuit-R1 (3F)Document1 pagePower Layout Circuit-R1 (3F)Electrical PCBL TeamNo ratings yet

- Dfe-b00-Ele-dwg-sld-006 - Single Line Diagram For Process PCC Panel - 2a & 2b (Wet End)Document1 pageDfe-b00-Ele-dwg-sld-006 - Single Line Diagram For Process PCC Panel - 2a & 2b (Wet End)Electrical PCBL TeamNo ratings yet

- Dfe-B00-Ele-Dwg-Sld-003 - Single Line Diagram For Process PCC Panel - 1 (Dry End)Document1 pageDfe-B00-Ele-Dwg-Sld-003 - Single Line Diagram For Process PCC Panel - 1 (Dry End)Electrical PCBL Team100% (1)

- Dfe-B00-Ele-Dwg-Sld-001 - R0 - Single Line Diagram For MV DistributionDocument1 pageDfe-B00-Ele-Dwg-Sld-001 - R0 - Single Line Diagram For MV DistributionElectrical PCBL TeamNo ratings yet

- Dfe-B00-Ele-Dwg-Sld-004 - Single Line Diagram For Utility Distribution (Sheet 01 of 02)Document1 pageDfe-B00-Ele-Dwg-Sld-004 - Single Line Diagram For Utility Distribution (Sheet 01 of 02)Electrical PCBL TeamNo ratings yet

- Dfe-B00-Ele-Dwg-Sld-005 - Single Line Diagram For Utility Distribution (Sheet 02 of 02)Document1 pageDfe-B00-Ele-Dwg-Sld-005 - Single Line Diagram For Utility Distribution (Sheet 02 of 02)Electrical PCBL TeamNo ratings yet

- Department of Defense Design Criteria StandardDocument30 pagesDepartment of Defense Design Criteria StandardAlvaro Rojas AnzolaNo ratings yet

- 174B-MCC Boiler - As BuiltDocument33 pages174B-MCC Boiler - As BuiltDharun KumarNo ratings yet

- Datasheet MultiPlus II 120V ENDocument2 pagesDatasheet MultiPlus II 120V ENAlamdar HassnainNo ratings yet

- Limiting Values of Radionuclide Intake and Air Concentration EPA PDFDocument234 pagesLimiting Values of Radionuclide Intake and Air Concentration EPA PDFLeons Rixson SiahaanNo ratings yet

- 2019 - Roadmap OverviewDocument5 pages2019 - Roadmap OverviewClean Air BDNo ratings yet

- Jack Evans Police BLDGDocument2 pagesJack Evans Police BLDGcunhaleoNo ratings yet

- Cepci 2006-2014 PDFDocument2 pagesCepci 2006-2014 PDFIka Sulistyaningtiyas100% (1)

- Programmable Temperature ControllerDocument2 pagesProgrammable Temperature ControllerNaveenkumar RNo ratings yet

- Low Voltage 3-Phase Induction Motors 0.55kW To 500kW: RangeDocument12 pagesLow Voltage 3-Phase Induction Motors 0.55kW To 500kW: Rangealimoya13No ratings yet

- Smart Green Project Template PresentationDocument15 pagesSmart Green Project Template PresentationSwissFm Cleaning CaptainsNo ratings yet

- Polycab LDC HDC Composite CatalogueDocument7 pagesPolycab LDC HDC Composite CatalogueIon VairamuthuNo ratings yet

- VRV/VRF Variable Refrigerant Volume (Or Flow) Technology: April 2010Document2 pagesVRV/VRF Variable Refrigerant Volume (Or Flow) Technology: April 2010rijothomasv777No ratings yet

- The Techno City Project Trivandrum, Kerala, India Latest Technologies Report For MEP ServicesDocument28 pagesThe Techno City Project Trivandrum, Kerala, India Latest Technologies Report For MEP ServicesSyraj HamzaNo ratings yet

- Damodar Valley Corporation: Mejia Thermal Power StationDocument20 pagesDamodar Valley Corporation: Mejia Thermal Power StationFlying ColoursNo ratings yet

- Research Online Research OnlineDocument9 pagesResearch Online Research OnlineabdullaalakourNo ratings yet

- Btech Civil 7to8semDocument62 pagesBtech Civil 7to8semfanishNo ratings yet

- Manual Flowserve PumpsDocument32 pagesManual Flowserve PumpsDerry KurniawanNo ratings yet

- Jindal Group: A Training Report ONDocument22 pagesJindal Group: A Training Report ONKrish KarnNo ratings yet

- Intake DesignDocument2 pagesIntake DesignmanwarkhanNo ratings yet

- BC1Document12 pagesBC1gvaf1879No ratings yet

- Qatar Engineering & Construction Company WLL (Qcon)Document12 pagesQatar Engineering & Construction Company WLL (Qcon)Dan DumbravescuNo ratings yet

- 1.0 FUNDAMENTALS of VIBRATION 1.1 What Is Vibration? Mechanical VibrationDocument56 pages1.0 FUNDAMENTALS of VIBRATION 1.1 What Is Vibration? Mechanical VibrationLuis Balducci100% (1)

- Fluid Mechanics July 2013 PDFDocument3 pagesFluid Mechanics July 2013 PDFH S Vishwa NathNo ratings yet

- DF457D PDDocument3 pagesDF457D PDMihai MogaNo ratings yet

- EARTH SCIENCE Rossby Wave Lecture Chapter1 ADocument20 pagesEARTH SCIENCE Rossby Wave Lecture Chapter1 AdoraemonminiNo ratings yet

- EENG223 Second Midterm-Solutions PDFDocument5 pagesEENG223 Second Midterm-Solutions PDFRamoona LatifNo ratings yet

- Foamglas Technical Info PDFDocument2 pagesFoamglas Technical Info PDFfred chinonsoNo ratings yet

- P1 4 Generating Electricity Standard QuestionsDocument100 pagesP1 4 Generating Electricity Standard QuestionsjesudassajNo ratings yet