Professional Documents

Culture Documents

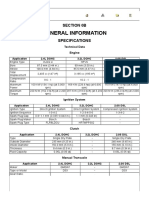

General Description and System Operation Engine

Uploaded by

David Wise-MannCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Description and System Operation Engine

Uploaded by

David Wise-MannCopyright:

Available Formats

Captiva

GENERAL DESCRIPTION AND SYSTEM OPERATION

Cylinder Block

The cylinder block is constructed from aluminium alloy with cast-in-place iron cylinder bore liners. Each of the four copper-infiltrated sintered steel main bearing caps are

attached to the cylinder block by six bolts. Along with two outer and two inner bolts, two side bolts are used in the deep skirt block for increased block stiffness. The

crankshaft thrust bearing is mounted in the third main bearing cap.

To prevent aeration, oil return from the valve train and cylinder heads is channelled away from the reciprocating components through oil drain back passages

incorporated into the cylinder heads and engine block. Pressure actuated piston oil cooling jets are mounted between opposing cylinders.

Cylinder Head

The cylinder heads are semi-permanent mould cast aluminium with powdered metal valve seat inserts and valve guides. Each cylinder head contains four valves per

cylinder. The valves are actuated by the rocker arms that pivot on stationary hydraulic lash adjusters, which are oil-fed to maintain valve / rocker lash.

The separate exhaust and intake camshafts are supported by four bearings machined into the cylinder head. The front camshaft bearing cap is used as a thrust control

surface for each camshaft.

A tube is pressed into each cylinder head in three places that shields each spark plug. An ignition coil assembly is mounted directly on each spark plug, through each

spark plug tube.

Crankshaft

The crankshaft is a forged steel design with four main bearings. The number three main bearing controls crankshaft thrust. A crankshaft position reluctor wheel is

pressed onto the rear of the crankshaft, in front of the rear main journal. The crankshaft is internally balanced with an integral oil pump drive machined into the nose in

front of the front main journal.

Piston and Connecting Rod Assembly

The piston assembly is fitted with two low tension compression rings and one multi-piece oil control ring. The top compression ring is plasma sprayed, while the second

compression ring is cast iron Napier.

The oil control ring incorporates a steel expander and two chrome plated steel rails.

The connecting rods are sinter forged steel and have full floating piston pins. The piston pins are a slip-fit type, into the bronze bushed connecting rods. Round wire

retainers are used to retain the piston pin into the piston.

The cast aluminium pistons incorporate a polymer coated skirt to reduce friction.

Chamshaft Drive System

Three timing chains are fitted (primary, right-hand secondary and left-hand secondary). The primary timing chain connects the crankshaft sprocket with the left-hand and

right-hand intermediate drive shaft sprockets.

Each oil pressure fed intermediate sprocket drives the secondary timing chains, which subsequently drive the respective cylinder head camshaft position actuators.

Two stationary timing chain guides and movable timing chain shoes control secondary timing chain backlash.

Each secondary timing chain shoe is under tension from an oil pressure hydraulically operated tensioner. To control backlash on the primary chain, two stationary timing

chain guides and an oil pressure hydraulically actuated tensioner with built in shoe are fitted.

The tensioners minimize timing chain noise and provide accurate valve action by keeping slack out of the timing chains, while continuously adjusting for timing chain

wear. The tensioners incorporate a plunger that adjusts outward with wear, minimizing backlash. The tensioners are equipped with oiling jets to spray oil onto the timing

components during engine operation. Each tensioner is sealed to the head or block using a rubber coated steel gasket. The gasket traps an adequate oil reserve to

ensure quiet start-up.

Camshaft Position Actuator Control System

A variable camshaft timing system is fitted that allows camshaft phasing changes within a range of 25 camshaft degrees as engine operating conditions vary.

Camshaft phasing optimizes engine performance and fuel economy without compromising overall engine response and driveability. Variable camshaft timing also

contributes to a reduction in exhaust emissions. The need for an exhaust gas recirculation (EGR) system is eliminated as exhaust and intake valve overlap is optimized.

A camshaft position actuator is fitted at the front of each camshaft that changes the camshaft lobe timing relative to the camshaft drive sprocket.

Intake Manifold

A dual-stage variable intake manifold is achieved through the use of an intake manifold tuning control (IMTC) valve. The engine control module controlled IMTC alters

the length and volume of the intake manifold plenum. Varying the intake manifold takes advantage of the natural pulse / pressure waves occurring in the manifold that

are created by the process of air induction into the cylinders.

Lubrication System

A structural diecast aluminium oil pan is fitted that incorporates an oil suction pipe, an oil deflector, an oil baffle and an oil level sensor. The oil suction pipe is bolted into

the oil pan and seals to the bottom of the cylinder block with a gasket. The oil deflector is bolted to the upper portion of the oil pan and ensures oil supply is maintained

under all conditions. The oil level sensor is mounted through the end of the oil pan.

A crankshaft driven gerotor oil pump is mounted to the front of the cylinder block. The pump, which incorporates an internal pressure-relief valve, draws oil from the oil

suction tube through the lower passage in the cylinder block. Oil is then directed through an upper passage to the left-hand side of the cylinder block where the oil filter

adapter is mounted.

The oil filter adapter incorporates a top-access, spin on style oil filter. The oil filter adapter housing incorporates a threaded oil pressure sender. Oil flows through a lower

passage within the oil filter adapter and through the oil filter. Filtered oil travels back through the upper passage of the adapter and into the engine block.

Oil is then directed up and across the front of the cylinder block, through several drilled passages. These front passages feed oil to each cylinder head, the passage for

the main bearings and piston oil jets, the right-hand and left-hand secondary idler sprockets and to the primary timing chain tensioner.

Each cylinder head passage directs oil into oiling circuits for the stationary hydraulic lash adjusters (SHLAs) and the camshaft bearing journals. Oil is also directed

through two passages, each with a spring-loaded check-ball valve, to the chambers where the camshaft position actuator solenoid valves are mounted. An additional

passage in the cylinder head also directs oil to the secondary timing chain tensioner.

The oil passage that supplies oil to the main bearings also supplies oil to pressure actuated piston cooling oil jets. Each oil jet is mounted between opposing cylinder

bores and directs oil to the two bores to provide extra cooling and control piston temperatures.

From the front passages, oil is directed to the front of the block where the right-hand and left-hand intermediate drive shaft sprockets and the primary timing chain

tensioner are mounted. Each camshaft timing chain tensioner relies on a gasket to maintain an oil reserve after the engine is turned off. All camshaft timing chain

tensioners incorporate a small oil jet to supply an oil spray onto the camshaft timing chain components.

Oil returns to the oil pan, either through the camshaft timing chain area or through the drain back passages on the outboard walls of the cylinder heads and cylinder

block.

© Copyright Chevrolet Europe. All rights reserved

You might also like

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- Engine MechanicalDocument175 pagesEngine MechanicalKevin BroussardNo ratings yet

- 058 - Engine Mechanical - 2.4L (LEA LUK) - Description and OperationDocument9 pages058 - Engine Mechanical - 2.4L (LEA LUK) - Description and OperationGedas Gvildys100% (1)

- Descripcion y OperacionDocument6 pagesDescripcion y OperacionCentro copiadoNo ratings yet

- Engine ConstructionDocument66 pagesEngine Constructionace ebradoNo ratings yet

- YanmarDocument202 pagesYanmarErman Erlertürk100% (1)

- Basic Engine System TrainingDocument19 pagesBasic Engine System TrainingEnang SundayNo ratings yet

- Reciprocating Compressor IIDocument66 pagesReciprocating Compressor IIAli O Dalki100% (1)

- Manual Corolla Engine 4A-FE 3S-GTE 5S-FEDocument311 pagesManual Corolla Engine 4A-FE 3S-GTE 5S-FEanto_jo95% (39)

- 09 Engine 2.9L Turbo Lubrication - Description and OperationDocument11 pages09 Engine 2.9L Turbo Lubrication - Description and Operationtwdz9s26vdNo ratings yet

- Reciprocating Compressor IIDocument59 pagesReciprocating Compressor IISagar NaduvinamaniNo ratings yet

- محركاتDocument20 pagesمحركاتYasmin RedaNo ratings yet

- Formula One EngineDocument9 pagesFormula One Engineლადო ჯიქურიNo ratings yet

- Running Gear of Diesel Engine ZZDocument26 pagesRunning Gear of Diesel Engine ZZAlaine Jan de Tablan100% (2)

- Fundamentals of Engine Construction and OperationDocument11 pagesFundamentals of Engine Construction and OperationBill Erick CastilloNo ratings yet

- Centrifugal Compressors OverviewDocument40 pagesCentrifugal Compressors OverviewMohamed BalbaaNo ratings yet

- Fundamentals of Engine Construction and Operation: Know These TermsDocument9 pagesFundamentals of Engine Construction and Operation: Know These TermsMarian Valentin MitreaNo ratings yet

- Motor 2.0 T Tsi InfoDocument56 pagesMotor 2.0 T Tsi InfoRicardo Rangel Posadas100% (2)

- 01.main Engine ManualDocument64 pages01.main Engine ManualwilfredNo ratings yet

- Engine Lubrication SystemDocument2 pagesEngine Lubrication SystemYemaneDibetaNo ratings yet

- Engine - Gtdi 2.0l Petrol - Description and OperationDocument43 pagesEngine - Gtdi 2.0l Petrol - Description and OperationroryNo ratings yet

- Aero Engines - Diesel - The Guiberson EngineDocument7 pagesAero Engines - Diesel - The Guiberson EngineAislan Souza100% (1)

- Engine Component 3Document8 pagesEngine Component 3anuradhaNo ratings yet

- Reciprocating Compressor IIDocument59 pagesReciprocating Compressor IIAbdussalamElhanashi50% (2)

- C100 Service Training Manual:: Engine Mechanical (2.0L Diesel)Document40 pagesC100 Service Training Manual:: Engine Mechanical (2.0L Diesel)sertex_jo100% (1)

- C and L Series Weekly ReportDocument13 pagesC and L Series Weekly Reportvoice of voicelessNo ratings yet

- Unit 7 Typical Marine Diesel Engines 3.1. DoxfordDocument7 pagesUnit 7 Typical Marine Diesel Engines 3.1. DoxfordBoldashNo ratings yet

- Basic Engine: Systems OperationDocument3 pagesBasic Engine: Systems OperationTri WahyuningsihNo ratings yet

- Lubricating Oil SystemDocument7 pagesLubricating Oil SystemLegen DaryNo ratings yet

- Engine Components: by Abhishek SharmaDocument16 pagesEngine Components: by Abhishek Sharmavik03223No ratings yet

- 2ZZGE Engine - Part of ManualDocument46 pages2ZZGE Engine - Part of ManualDavide Faelli100% (2)

- CPCBII 4B3.3 Engine Design FeaturesDocument26 pagesCPCBII 4B3.3 Engine Design FeaturesGowthaman NNo ratings yet

- Manual Reparación Turbo GARRETDocument24 pagesManual Reparación Turbo GARRETFelipe Lepe MattaNo ratings yet

- Basic Engine: Systems OperationDocument2 pagesBasic Engine: Systems OperationNay SoeNo ratings yet

- Lubrication System, Description: Service InformationDocument6 pagesLubrication System, Description: Service Informationwidanto0apriawanNo ratings yet

- Engines: Internal Combustion Engine Needs Fuel, Ignition and Compression in Order To RunDocument15 pagesEngines: Internal Combustion Engine Needs Fuel, Ignition and Compression in Order To RunrohitrockerNo ratings yet

- Engines: Internal Combustion Engine Needs Fuel, Ignition and Compression in Order To RunDocument15 pagesEngines: Internal Combustion Engine Needs Fuel, Ignition and Compression in Order To RunAbrar AbuNo ratings yet

- Engines: Internal Combustion Engine Needs Fuel, Ignition and Compression in Order To RunDocument15 pagesEngines: Internal Combustion Engine Needs Fuel, Ignition and Compression in Order To RunJayita AcharyyaNo ratings yet

- Engines: Internal Combustion Engine Needs Fuel, Ignition and Compression in Order To RunDocument15 pagesEngines: Internal Combustion Engine Needs Fuel, Ignition and Compression in Order To RunnandhinidishNo ratings yet

- Engines: Internal Combustion Engine Needs Fuel, Ignition and Compression in Order To RunDocument15 pagesEngines: Internal Combustion Engine Needs Fuel, Ignition and Compression in Order To RunjohnkirubaNo ratings yet

- Engines: Internal Combustion Engine Needs Fuel, Ignition and Compression in Order To RunDocument15 pagesEngines: Internal Combustion Engine Needs Fuel, Ignition and Compression in Order To Runjimi7No ratings yet

- Engines: Internal Combustion Engine Needs Fuel, Ignition and Compression in Order To RunDocument15 pagesEngines: Internal Combustion Engine Needs Fuel, Ignition and Compression in Order To Runpramodarya1No ratings yet

- An Introduction To Concepts of EnginesDocument15 pagesAn Introduction To Concepts of EnginesPrashanth PaiNo ratings yet

- All About Engines (PowertPoint)Document15 pagesAll About Engines (PowertPoint)mikogonzalveNo ratings yet

- Engines: Internal Combustion Engine Needs Fuel, Ignition and Compression in Order To RunDocument15 pagesEngines: Internal Combustion Engine Needs Fuel, Ignition and Compression in Order To RunCasey GreenNo ratings yet

- Engines: Internal Combustion Engine Needs Fuel, Ignition and Compression in Order To RunDocument15 pagesEngines: Internal Combustion Engine Needs Fuel, Ignition and Compression in Order To RunAnil NayakNo ratings yet

- Engines: Internal Combustion Engine Needs Fuel, Ignition and Compression in Order To RunDocument15 pagesEngines: Internal Combustion Engine Needs Fuel, Ignition and Compression in Order To RunVaratharaj MNo ratings yet

- PPD ReviewerDocument4 pagesPPD ReviewerMark Alvin CuyaNo ratings yet

- Swaraj Tractor EngineDocument7 pagesSwaraj Tractor EngineHarmanjit SinghNo ratings yet

- Engines: Internal Combustion Engine Needs Fuel, Ignition and Compression in Order To RunDocument15 pagesEngines: Internal Combustion Engine Needs Fuel, Ignition and Compression in Order To RunRavi MulimaniNo ratings yet

- Sistema de Lubricacion Emd 645Document21 pagesSistema de Lubricacion Emd 645Adriana Rojas VerasteguiNo ratings yet

- SKODA SSP 057 EngDocument44 pagesSKODA SSP 057 Engsorinenng100% (3)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Small Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsFrom EverandSmall Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsNo ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IiFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNo ratings yet

- DCV-ITS-002 Temp Ops ApprovalDocument2 pagesDCV-ITS-002 Temp Ops ApprovalDavid Wise-MannNo ratings yet

- Supplemental Inflatable Restraints (Sir)Document7 pagesSupplemental Inflatable Restraints (Sir)David Wise-MannNo ratings yet

- Steering Wheel and ColumnDocument27 pagesSteering Wheel and ColumnDavid Wise-MannNo ratings yet

- Suspension DiagnosisDocument4 pagesSuspension DiagnosisDavid Wise-MannNo ratings yet

- Abs General Description and System OperationDocument2 pagesAbs General Description and System OperationDavid Wise-MannNo ratings yet

- General InformationDocument23 pagesGeneral InformationDavid Wise-MannNo ratings yet

- Ac General Description and System OperationDocument2 pagesAc General Description and System OperationDavid Wise-MannNo ratings yet

- Lighting Maintenance & RepairDocument18 pagesLighting Maintenance & RepairDavid Wise-MannNo ratings yet

- General Engine Information - HFV6 3Document10 pagesGeneral Engine Information - HFV6 3David Wise-MannNo ratings yet

- Squeaks and RattlesDocument2 pagesSqueaks and RattlesDavid Wise-MannNo ratings yet

- Glass and MirrorsDocument27 pagesGlass and MirrorsDavid Wise-MannNo ratings yet

- OTC 5822 - Prediction of Motions and Loads For Crane Vessels During Heavy LiftsDocument11 pagesOTC 5822 - Prediction of Motions and Loads For Crane Vessels During Heavy LiftsDavid Wise-MannNo ratings yet

- Ac Maintenance and RepairDocument39 pagesAc Maintenance and RepairDavid Wise-MannNo ratings yet

- OTC 4165 - Analytical and Model Test Study of Platform and Jacket Tow in WavesDocument10 pagesOTC 4165 - Analytical and Model Test Study of Platform and Jacket Tow in WavesDavid Wise-MannNo ratings yet

- Paper CFD Wave MakingDocument7 pagesPaper CFD Wave MakingDavid Wise-MannNo ratings yet

- OTC 3517 - Model Tests On The Transportation of A Large Offshore Structure by Launching BargeDocument10 pagesOTC 3517 - Model Tests On The Transportation of A Large Offshore Structure by Launching BargeDavid Wise-MannNo ratings yet

- Validation of Added Resistance Computations by A Potential Flow Boundary Element MethodDocument10 pagesValidation of Added Resistance Computations by A Potential Flow Boundary Element MethodDavid Wise-MannNo ratings yet

- Heli OperationsDocument19 pagesHeli OperationsDavid Wise-MannNo ratings yet

- FOX Oil Levels Bicycle Suspension ServiceDocument7 pagesFOX Oil Levels Bicycle Suspension ServiceDavid Wise-MannNo ratings yet

- Prediction of Added Resistance of Ships by 3-D Green Function Method and Its Comparision With Semi-3-D and 2-D ApproachesDocument10 pagesPrediction of Added Resistance of Ships by 3-D Green Function Method and Its Comparision With Semi-3-D and 2-D ApproachesDavid Wise-MannNo ratings yet

- Class 3 Vessels Under 25mDocument4 pagesClass 3 Vessels Under 25mDavid Wise-MannNo ratings yet

- Equipment List.: Class F2 - Hire & Drive Motor Vessels (Up To Class D Waters) Length Equipment (NSCV, Part F, Section 2)Document3 pagesEquipment List.: Class F2 - Hire & Drive Motor Vessels (Up To Class D Waters) Length Equipment (NSCV, Part F, Section 2)David Wise-MannNo ratings yet

- MOSES Manual PDFDocument456 pagesMOSES Manual PDFseehariNo ratings yet

- CLD Exam Prep Guide EnglishDocument13 pagesCLD Exam Prep Guide Englishk_goulasNo ratings yet

- Module: Jet Propulsion: Course Code: UME501 Course Name: Applied ThermodynamicsDocument48 pagesModule: Jet Propulsion: Course Code: UME501 Course Name: Applied ThermodynamicskusNo ratings yet

- Perkins 1106D Parts Book PJ70704 PDFDocument235 pagesPerkins 1106D Parts Book PJ70704 PDFJuan Carlos Gomez Valderrama80% (5)

- ECU List 7 2 0 New Features ListDocument41 pagesECU List 7 2 0 New Features ListBishoy saad100% (1)

- Crane Starboard EngineDocument1 pageCrane Starboard EngineAPEXINDONo ratings yet

- 03-03MM Series Torque SpecsDocument4 pages03-03MM Series Torque SpecsJuan Pablo urria schwarzenbergNo ratings yet

- mf8240 160824142620 PDFDocument698 pagesmf8240 160824142620 PDFArgopartsNo ratings yet

- Itahydraulic Hydraulic Power UnitsDocument5 pagesItahydraulic Hydraulic Power UnitsLuis Nahuelhuaique LemusNo ratings yet

- Seat ValveDocument2 pagesSeat ValvelilikNo ratings yet

- Fundamentals Shop Safety Procedures Structures LabDocument3 pagesFundamentals Shop Safety Procedures Structures LabEric Hardy100% (1)

- Man S50me-C9 - 5Document385 pagesMan S50me-C9 - 5Carlos Sopas100% (1)

- Work Description-16-Litre Engine: Issue 3Document6 pagesWork Description-16-Litre Engine: Issue 3rewrwNo ratings yet

- Manual Husquarna 44Document5 pagesManual Husquarna 44Anker Pedersen100% (1)

- 1995 Mitsubishi Galant VR V6 OverheatingDocument2 pages1995 Mitsubishi Galant VR V6 OverheatingRoullete Santos ChipongianNo ratings yet

- Multiquip Model Qp-204H Gasoline Powered Centrifugal Pump: Parts ManualDocument46 pagesMultiquip Model Qp-204H Gasoline Powered Centrifugal Pump: Parts ManualНебојша РадићNo ratings yet

- Engine Overhaul : Group 11BDocument96 pagesEngine Overhaul : Group 11Bopa952ya.ruNo ratings yet

- Ramjet Engine Final ReportDocument25 pagesRamjet Engine Final ReportDhananjay Baviskar100% (2)

- FL 912 Marine enDocument2 pagesFL 912 Marine enZuskerNo ratings yet

- IR MSTS Files Update 29 April 2012Document40 pagesIR MSTS Files Update 29 April 2012RajeshKotian0% (1)

- EcDocument11 pagesEcFrancesca Ackumbur0% (1)

- 08 Emission Final PDFDocument33 pages08 Emission Final PDFAdinath UpadhyeNo ratings yet

- FT450 FT550 Ft550lite FT600Document170 pagesFT450 FT550 Ft550lite FT600weak nessNo ratings yet

- A Presentation On PumpsDocument34 pagesA Presentation On PumpsSajjad Rasool ChaudhryNo ratings yet

- Exhaust and Pollution Control SystemDocument24 pagesExhaust and Pollution Control SystemOne Love Jah LoveNo ratings yet

- GP-650 DatasheetDocument2 pagesGP-650 DatasheetYony MarcianoNo ratings yet

- en WHB Hatz W35 PDFDocument76 pagesen WHB Hatz W35 PDFpricopdaniel100% (3)

- 68DK-28 Parts List (Heavyl Fuel Oil)Document289 pages68DK-28 Parts List (Heavyl Fuel Oil)Ira PaschenkoNo ratings yet

- Failure Diagnosis: Turbocharger GuidelinesDocument1 pageFailure Diagnosis: Turbocharger GuidelinesTan KokkiangNo ratings yet

- A Review of Engine Downsizing and Its EffectsDocument6 pagesA Review of Engine Downsizing and Its EffectsMuhammad TaimoorNo ratings yet

- Massey Ferguson MF 1114 Tractor Service Parts Catalogue ManualDocument15 pagesMassey Ferguson MF 1114 Tractor Service Parts Catalogue Manualqlb898316No ratings yet