Professional Documents

Culture Documents

ASME Piping 2011 Ned Endres Final

Uploaded by

ahmadmortazaviOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASME Piping 2011 Ned Endres Final

Uploaded by

ahmadmortazaviCopyright:

Available Formats

Proceedings of the ASME 2011 Pressure Vessels and Piping Division Conference

PVP2011

July 17-21, 2011, Baltimore, Maryland, USA

PVP2011-57017

ACOUSTIC AND VIBRATION ANALYSIS OF FLUID INDUCED BLOWER AND

PIPING UNWANTED MOTION

Ned M. Endres, Senior MDS Representative

Metrix Instruments Corporation

Abstract high noise and vibration causing nausea and other medical

This paper presents investigational findings and a problems. Onsite vibration and sound measurements took place

discussion of recommendations relating to sound and vibration in March 2010. The vibration and sound data were acquired

measurements performed in connection with a fluid induced during steady state operating conditions of the blowers. During

vibration issue on two air blowers and attached exhaust piping these measurements only two blowers were operating, blower

at an industrial facility. These vibration and sound “B” and blower “C”.

measurements were prompted by recent check valve failures

for the air blower units, and unacceptable sound levels

emanating from these units and affecting nearby residents. This

data was acquired during steady state operating conditions of

the blowers under normal operating conditions. An FFT data

acquisition system, a piezoelectric microphone and three

piezoelectric triaxial accelerometers were used to collect

vibration measurements at each of the 70 locations on the

blowers, motors, blower bases, and exhaust piping, while

sound measurements were simultaneously acquired with the Damage

microphone. Piping and blower vibration readings were used to

construct an operating deflection shape analysis of the blowers,

foundations and attached piping system. The resulting vibration Damage

and sound analysis revealed that acoustic excitation of the

piping system appeared to be the likely source of the high

vibration, high sound pressure levels; piping cracks and check

valve failures. Corrective actions were implemented that

reduced the sound pressure levels, vibration levels, and

reduced/eliminate the piping damage and valve failures.

INTRODUCTION

Metrix was retained by plant management to provide

Photos 1 and 2: Check Valve Damage

vibration and acoustic diagnostics expertise to analyze elevated

noise and vibration levels of four air blowers. This project

Recent check valve failures and repair of cracked exhaust

encompasses sound and vibration measurements of aeration

piping were causing forced outages of the blower units and

blowers and attached exhaust piping for an MBBR wastewater

severely disrupting the water treatment process. Economic

treatment plant within a large industrial plant. This

impact of the potential cracked valves and piping while in

investigation was prompted by recent check valve component

service were causing waste treatment plant downtime and were

failures for these blower units, and unacceptable sound levels

estimated to be exceeding $100,000 for 2010. Potential

emanating from these blower units which potentially would

complaints about objectionable noise levels from nearby

affect nearby residents (photos 1 and 2). Plant maintenance

residents were also a concern. By correctly identifying root

workers were also hesitant to work around these units due to

1 Copyright © 2011 by ASME

cause(s) of the high vibration and noise levels, this cost was pressure pulsation in the exhaust of the blowers should be

avoided and a positive relationship with nearby residents was occurring at 3600 cpm (3600 rpm = 2x 1800 rpm drive speed)

maintained. which showed up in the sound spectra.

INSTRUMENTATION

Throughout the body of this paper, the following

conventions will be used; regarding sensor naming and

orientation. Blowers are “viewed” as being with the “X”

direction, or axial direction, along the shafts of the motors and

Blower B

blowers. The positive “X” direction is along the blower driven

Blower A

shaft from blower C towards blower B. Likewise, the “Y”

direction will be perpendicular to the “X” direction in the

horizontal plane, see figures 1 and 2. The “Z” direction is

vertical, perpendicular to both the “X” and “Y” directions;

+X Direction

forming a “right hand” coordinates system for these vibration

measurements. The triaxial accelerometer sensor directions

follow this same coordinate system. For instance, a vibration

measurement at location 1 in the vertical direction will be Blower C

referred to as a vibration amplitude (velocity and displacement)

“1Z” in the following vibration summary tables later in this Blower D

paper. +Y Direction

110 inch vertical pipe +X Direction

section

Location 22

+Z Direction

Figure 2: Vibration Measurement Coordinate System

At standard temperature and pressure, acoustic wavelength

of the 3600 cpm component would be about 225 inches, thus

too long to form a standing wave within the current piping

within the building, see photos 3, 4 and 5. The longest piping

length was approximately 180 inches for the vertical section of

Figure 1: Vibration Measurement Coordinate System blower D piping, which ran from the floor to the ceiling where

the piping exited the building. After the leaving the building,

A Data Physics Abacus data acquisition system and Data the piping took a horizontal turn to the wastewater tanks.

Physics Mobilyzer analysis software were used to collect However, the vertical piping runs of each blower from the floor

vibration measurements at each of 70 key locations on the to the crossover manifold pipe were about 110 inches, see

blowers, motors, blower bases, and exhaust piping. Three PCB figure 1. This run of pipe could feasibly accommodate a 1/2

triaxial accelerometers were used to capture vibration wavelength standing wave at 3600 cpm and a full wavelength

conditions at each selected location and a TMS 130P10 ICP standing wave at 7200 cpm form within the pipe [3,4], see table

microphone was used to capture sound readings adjacent to A. When these blowers were designed, piping lengths that

Blower C. match critical acoustic wavelengths as shown in table A should

have been avoided whenever possible.

SOUND MEASUREMENTS AND OBSERVATIONS

Sound pressure levels were measured during the vibration

measurements using a single microphone at 4 locations

adjacent to blower C. Measured sound pressure levels typically

reached 107-110 dBA with the highest sound component being

at 3600 cpm (60Hz) of about 104 dBA [1,2], see figure 3. The

predominate spectral components were 3600 cpm (60 Hz) and

harmonics of 3600 cpm, namely 7200cpm, 10,800 cpm, 14,400

cpm… There was also a smaller spectral peak at 1800 cpm,

which correlates with running speed of the blower. Since these

blowers have two lobes on the higher speed drive shaft,

2 Copyright © 2011 by ASME

a good initial solution; however examination of the blower

configurations revealed that this would likely require

significant modifications to the existing arrangement of

blowers and increase installation cost.

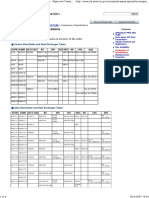

Frequency Velocity ¼λ ½λ λ 1.25λ 1.5λ

cpm in/sec in/cycle in/cycle in/cycle in/cycle in/cycle

1800 13500 112.50 225.00 450.00 562.50 675.00

3600 13500 56.25 112.50 225.00 281.25 337.50

5400 13500 37.50 75.00 150.00 187.50 225.00

7200 13500 28.13 56.25 112.50 140.63 168.75

9000 13500 22.50 45.00 90.00 112.50 135.00

10800 13500 18.75 37.50 75.00 93.75 112.50

12600 13500 16.07 32.14 64.29 80.36 96.43

14400 13500 14.06 28.13 56.25 70.31 84.38

16200 13500 12.50 25.00 50.00 62.50 75.00

Photo 3: Blowers A and B and piping 18000 13500 11.25 22.50 45.00 56.25 67.50

Table A

VIBRATION MEASUREMENTS & OBSERVATIONS

To evaluate mechanical condition of each blower, vibration

measurements were taken at each blower shaft bearing housing.

Vibration levels at each blower bearing were measured in

vertical, lateral (radial) and axial directions see tables 1 and 2.

Two PCB triaxial accelerometers and Data Physics Abacus

vibration data acquisition system were used to measure

vibration on each blower. Representative vibration spectra

from these measurements are shown in figures 4A through 4C.

Almost all of the vibratory energy occurs at running speed

(1800 cpm) of the blowers and harmonics (3600 cpm, 5400

cpm, 7200 cpm…) of this frequency. Vibration higher than 0.6

inches per second (ips) peak are considered by the blower

OEM to be elevated vibration levels, and these readings are

Photos 4 and 5: Vertical piping from each blower, highlighted in yellow. Elevated vibration levels in multi-lobe

each being approximately 100 inches long blowers can be due to a variety of sources (root causes):

120

S10, 10

X: 3.585k

Y: 104.5

Misalignment (coupling misalignment)

100 Impellers/lobes rubbing

80 Worn bearings and gears

Unbalance

dBMag, SPL_(A)

60

40 Blower looseness

20

Piping resonances (standing wave pressure

0

pulsations)

-20

Foreign material buildup

0 10k 20k

CPM

30k 40k

Casing strain

Figure 3: Sound Pressure Spectrum,

Adjacent to Blower C, 111 dBA Overall Vibration levels were consistently higher in the vertical

direction compared to the axial and lateral directions,

Since the blowers input shaft are turning at 1800 rpm and particularly for blower B. This appeared to be likely caused by

each shaft has 2 lobes, pressure pulsations from the exhaust of downward exhaust pressure pulsations (forces) in the exhaust,

these blowers occurred at 3600 cpm or 60 Hz. This naturally which exits downward from beneath each blower [5], vibrating

explains the high sound level component at 3600 cpm. both the blower and piping vertically. This motion was plainly

Unfortunately, this frequency also roughly matches the length visible in the operating deflection shape of each blower, seen in

of a ½ wavelength potential standing wave in the vertical pipe later section of this paper. These measurements also showed

section of each blower exhaust. To suppress these pressure that vibration frequency components at blower running speed

pulsations, a discharge (exhaust) silencer was considered to be (1800 rpm) and below were poorly correlated (low coherence)

3 Copyright © 2011 by ASME

with piping vibration in this frequency range, see figures 5 and

6. These measurements also indicated that blower vibration at 1.0

S4, 4

X: 1.800k

twice blower running speed (3600 rpm) and above did correlate Y: 125.9m

well with piping vibration and acoustic energy components in

100m

this frequency range. In short, blower vibration at running 10m

LogMag, in/s

speed, like blower unbalance…, was not responsible for the 1.0m

observed piping vibration.

100µ

Measurement Direction 10.0µ

Blower C Vertical Lateral Y Axial 1.0µ

Z (Radial) X

10k 20k 30k 40k

CPM

Locations ips Peak ips Peak ips Peak Figure 4A: Auto Power Spectrum, Blower B,

Coupling End, OA 0.693 0.368 0.342 Driven Shaft, Coupling End Bearing,

Drive Shaft Bearing Vibration Velocity in Axial Direction

Coupling End, 1X 0.018 0.091 0.045

Drive Shaft Bearing

Blind End, Drive OA 0.624 0.604 0.463 1.0

S5, 5

X: 1.800k

Shaft Bearing Y: 213.7m

Blind End, Drive 1X 0.033 0.193 0.043 100m

Shaft Bearing 10m

Coupling End, Idle OA 0.706 0.379 0.465

LogMag, in/s

Shaft Bearing 1.0m

Coupling End, Idle 1X 0.031 0.091 0.026

Shaft Bearing

100µ

Blind End, Idle OA 0.464 0.565 0.546 10.0µ

Shaft Bearing

Blind End, Idle 1X 0.044 0.190 0.032 1.0µ

10k 20k 30k 40k

CPM

Shaft Bearing

Figure 4B: Auto Power Spectrum, Blower B,

Notes:

OA = Overall Direct (unfiltered) vibration amplitude, Driven Shaft, Coupling End Bearing,

inches per second (ips) peak Vibration Velocity in Vertical Direction

1X = Synchronous (once-per-revolution) filtered vibration amplitude,

inches per second peak

S6, 6

Table 1 1.0 X: 1.800k

Y: 140.0m

100m

10m

LogMag, in/s

Measurement Direction 1.0m

Blower B Vertical Lateral Y Axial

Z (Radial) X 100µ

Locations ips Peak ips Peak ips Peak

10.0µ

Coupling End, Drive OA 0.845 0.509 0.558

Shaft Bearing 1.0µ

10k 20k 30k 40k

Coupling End, Drive 1X 0.214 0.140 0.126

CPM

Shaft Bearing Figure 4C: Auto Power Spectrum, Blower B,

Blind End, Drive Shaft OA 0.940 1.089 0.554 Driven Shaft, Coupling End Bearing,

Bearing Vibration Velocity in Lateral or Radial Direction

Blind End, Drive Shaft 1X 0.271 0.383 0.136

Bearing

Coupling End, Idle OA 0.814 0.463 0.709

Shaft Bearing

Coupling End, Idle 1X 0.241 0.137 0.248

Shaft Bearing

Blind End, Idle Shaft OA 0.825 1.108 0.714

Bearing

Blind End, Idle Shaft 1X 0.219 0.408 0.249

Bearing

Notes:

OA = Overall Direct (unfiltered) vibration amplitude, inches per second (ips)

peak

1X = Synchronous (once-per-revolution) filtered vibration amplitude, inches

Figure 5: Coherence Spectra, Coherence Between

per second peak

Table 2 Blower C at Reference Location

(−Y) Direction and Piping Location 22 (−X) Direction

4 Copyright © 2011 by ASME

deflections at each of the 70 locations (XYZ directions; see

sketch A and B below).

Reference Accelerometer Location

Figure 6: Coherence Spectra, Coherence Between

Blower C at Reference Location

(−Y) Direction and Microphone

OPERATING DEFLECTION SHAPE ANALYSIS

An operating deflection shape (ODS) is defined as the

deflection pattern or shape of a mechanical structure (machine

or machine components) at a particular frequency (typically at Photo 3: Reference Accelerometer Location on Blower C

operating speed). This shape is determined by measuring

dynamic deflections of a machine in response to operating Vibration data for operational deflection shape model was

forces at two or more locations on machine, while it is in acquired by collecting “point-by-point” data on the two

operation. This methodology is used to show the relative blowers and piping. This ODS data was collected while both

motion of machine components due to existing forces. As well, blower units were running at steady state operating conditions.

the ODS gives an intuitive representation of the synchronous This ODS was performed to characterize the relative motion of

(1X) motion (and other frequencies) of the blower units and blower components during “typical” vibration conditions of the

connected piping. When the frequency of the existing forces blowers. A twenty four-channel Data Physics Abacus vibration

coincides with natural frequencies of the machine, it will data acquisition system was used to capture the vibration data

resonate. When this occurs, the mode shape and ODS at that from the two roving triaxial accelerometers and reference

particular frequency will look similar. triaxial accelerometer. The vibration data acquisition system

captures the frequency responses functions (FRF) of each

To perform ODS measurements, a reference triaxial roving triaxial accelerometer channel relative to the reference

accelerometer was mounted to the “B” blower housing at a triaxial accelerometer signatures. The operating deflection

location and in an orientation where the response of the blower shape vibration deflections were then computed from these

to existing forces can be readily measured and are significant. measured FRF’s.

Typically, the location exhibiting the highest vibration level is

selected as the reference location. In this instance, a blower

housing outboard (blind side) bearing housing was selected

(see photo 3). Three triaxial accelerometers and Data Physics

Abacus vibration data acquisition system were used to measure

vibration on each blower and piping. This first triaxial

accelerometer was used as an amplitude and phase reference

for other measured locations. This sensor remained fixed at this

location throughout the ODS measurements. Two other triaxial

(3 orthogonal axes) accelerometers were used for measuring

the response of the two blowers “B” and “C” at other key

sensor locations in a manner to sufficiently define the motion

of the machines. Since radial vibration motion of the blower

appeared to be a direct source of rotational vibration energy, the

reference accelerometer was mounted to the higher speed shaft

side, blend end of the blower housing and orientated with its

axes in the radial (lateral, transverse) direction, axial direction,

and vertical direction of the blower. The ODS reference

vibration amplitude was measured using the radially orientated

triaxial accelerometer channel. As mentioned, two triaxial

accelerometers were used to acquire 3 dimensional vibration

Sketch A: ODS Geometry

5 Copyright © 2011 by ASME

and C moving slightly vertically up and down (out-of-phase

with each other) in what appears to be reaction to the exhaust

pulsations at 3600 cpm and piping motion. Coherence

measurements between blower and piping vibration showed

good correlation (> 0.7) between blower and piping vibration

at 3600 cpm. Sound measurements and blower vibration also

showed good correlation (> 0.7) at 3600 cpm. These coherence

levels (> 0.7) indicate a reasonable “cause and effect”

relationship between sound and blower vibration and between

piping and blower vibration (figure 15).

Sketch B: ODS Measurement Locations

To visualize the ODS deflections, a computer “model” of the

geometry of the measured points was generated; see sketch A

and B. ODS deflections for each measured location were Cracks

applied to matching points in the computer model. Since the

ODS deflections are very small compared to the dimensions on

the machine, the amplitudes of the ODS are scaled and Photo 4: Pipe Crack

animated so that the motion was clearly visible on the computer

screen. In other words, the ODS deflections in the model are Structural modal measurements on the exhaust piping were

greatly exaggerated to make them visually apparent; in short, attempted after acquisition of the ODS data. These

the deflections are not display at the scale of the models itself. measurements are useful in identifying whether structural

Hence, an ODS shows the relative motion and phase between natural frequencies coincide with vibration frequency

locations on the blower components, not absolute “scaled” components inherent with the blowers or piping resulting in a

deflections of the machine. In the ODS figures, the black dotted structural resonance. Resonant vibration typically amplifies the

lines are the undeformed ODS model shape. The solid lines are vibration response of a structure far beyond the design

the animated ODS shape. deflection levels predicted by computation based upon only

static loading.

The operating deflection shape was assembled from

vibration measurements acquired for 70 vibration measurement

locations. Figures 7 through 14 illustrate the operating

deflection shape at 60Hz, the frequency corresponding to the

fundamental tone. This ODS shape clearly showed significant

deflections occurring at piping sensor locations 9, 10, 19

through 28, and 65 with the motion being predominately

vertically in the Z direction and axially in the X direction. This

motion appears to be in reaction to pressure pulsations from the

two running blowers; however dynamic pressure measurements

would have to be performed to confirm this hypothesis. To

arrest the piping motion, the piping could be constrained by

pipe fixturing (snubber, pipe rolls, spring hangers…) or a tuned

damper; however it was believed that these actions would

probably not reduce noise levels appreciably. This solution

would help reduce piping vibration, cracks and other potential

fatigue damage (photo 4). The ODS also showed blowers B

6 Copyright © 2011 by ASME

Blower “B”

Blower “C”

Figure 7: Operating Deflection Shape at 3600 cpm Figure 10: Operating Deflection Shape at 3600 cpm

Isometric View Axial View

Blower “C”

Blower “B”

Figure 8: Operating Deflection Shape at 3600 cpm Blower “B” Blower “C”

Top View

Blower “B” Blower “C”

Figure 11: Operating Deflection Shape at 3600 cpm

Isometric View

Figure 9: Operating Deflection Shape at 3600 cpm

Lateral View (side view)

Since the blowers could not be shut down for more than 5 Blower “C”

minutes without compromising the bacteria in the process,

adequate modal measurements could not be performed to

identify any natural frequencies of the piping or blowers. This Blower “B”

was recommended as testing to be conducted during a future

outage.

Figure 12: Operating Deflection Shape at 3600 cpm

Top View

7 Copyright © 2011 by ASME

damage to the silencer or its welds; see photos 6 and 7.

Fortunately, this packing material was captured by a down

stream screen. The silencer OEM is pursuing a root cause for

the packing material issue and has deployed a differently

designed silencer. Dynamic pressure measurements were

Blower “B” recommended as further testing to be conducted during a future

Blower “C”

outage in order to measure pressure intensity of the acoustic

standing wave and to provide insight into silencer packing

issues.

Figure 13: Operating Deflection Shape at 3600 cpm 1.0

Lateral View (side view)

800m

C1, 6

X: 59.50

600m Y: 792.0m

Magnitude

400m

200m

Blower “B” 0

0 200 400 600 800

Hz

1.0

Blower “C” 800m

C1, 10

X: 59.50

600m Y: 835.0m

Magnitude

400m

200m

0

0 200 400 600 800

Figure 14: Operating Deflection Shape at 3600 cpm Hz

Axial View Figure 15: Coherence Spectra: Coherence

Between Blower C at Reference Location

In late March, the best initial solution to both the vibration (−Y) Direction and Piping Location 25

and noise problems appeared to be installing exhaust silencers (−X) direction (top), Coherence Between

on each blower. It was anticipated that reduced exhaust Blower C at Reference Location

pulsation should occur which should also reduce piping (−Y) Direction and Microphone

vibration and exhaust generated noise. An acoustic standing

wave due to blower exhaust pulsations appeared to be the root

cause, but dynamic pressure measurements would be needed to

confirm this conclusion.

Exhaust silencers were installed on each blower in April

2010, see photo 5. They had an immediate effect on sound

pressure levels both inside the blower room and in the

surrounding neighborhood. Sound pressure levels dropped at

least 20dBA inside and outside of the blower room, making for

a more pleasant environment for maintenance personnel. In-

house PdM vibration measurements revealed that blower Silencer installed

here.

vibration levels were reduced by more than 50%.

In July 2010, Blower C experienced problems with silencer Photo 5: Location of Installed Silencers

packing material escaping without any detectable mechanical

8 Copyright © 2011 by ASME

An acoustic analysis of the sound measurements suggested

that a potential acoustic standing wave might be present in a

vertical section of each blower exhaust piping. This

phenomenon suggested that exhaust silencers might be a

potential solution. An operating deflection shape analysis of the

vibration measurements clearly showed deflection patterns

which also indicated that deploying exhaust silencers on the

exhaust of each blower might reduce acoustic and vibration

levels of the piping. Exhaust silencers were deployed and noise

levels were significantly reduced, pipe cracking, check valve

damage were also eliminated. In fact, acoustic sound pressure

Photo 6: Silencer packing material levels were reduced by 20 dBA; thus avoiding nearby

retrieved from downstream screens resident’s complaints concerning noise and making the

prior to aeration tank immediate environment more pleasant for maintenance

activities.

Original blower installation plans did not take into account

the impact of acoustic standing waves occurring inside piping

sections that were not proper sized. These plans did not also

consider acoustic interaction of the blowers; which were to be

run in 2 and 3 blower configurations. A cursorily review of

piping section lengths and acoustical wavelengths would have

identified suspect piping sections, highlighted the need for

deploying silencers and resulted in piping design modifications

before hardware was purchased and installed.

Photo 7: Disassembled silencer showing Economic impact of the potential cracked valves and

loss of packing material without piping while in service causing waste treatment plant downtime

physical damage to silencer was estimated as exceeding $100,000 for 2010. Potential

complaints about noise levels from nearby residents were also

averted. By correctly identifying root cause(s) of the high

vibration and noise levels, this cost was avoided.

REFERENCES

1. ISO-3746, “Acoustic – Determination of Sound Power

Levels of Noise Sources Using Sound Pressure – Survey

Method Using an Enveloping Measurement Surface Over a

Reflecting Plane”, 1995-08-15.

2. ISO-16032, “Acoustic – Measurement of Sound Pressure

Level from Service Equipment in Buildings - Engineering

Method”, 2004.

3. Halliday, D., Resnick, R, “Physics: for Students of Science

and Engineering”, 1960, pg. 422-447.

Figure 16: New silencer design 4. Blevins, R.D., ”Formulas for Natural Frequency and Mode

Shape”, 2001, pg. 340.

SUMMARY

The above case history clearly shows that integration of 5. Yeon-Whan K, Young-Shin L., “Damage prevention design

sound and vibration measures along with an operating of branch pipe under pressure pulsation transmitted from main

deflection shape analysis and presentation of the vibration data steam header”, JMST, Volume 22, Number 4, Pg 647-652.

proved to be an effective methodology for solving piping

related issues. 6. Bently, D. E., Hatch, C. T., “Fundamentals of Rotating

Machinery Diagnostics”, 2002, pg. 1-19.

9 Copyright © 2011 by ASME

You might also like

- Coulomb's LawDocument4 pagesCoulomb's LawPeterCiezczakNo ratings yet

- Wave Equation WorksheetsDocument15 pagesWave Equation WorksheetsOmar ShamaylehNo ratings yet

- ECE485 Fa10 hw2Document3 pagesECE485 Fa10 hw2Ivan AvramovNo ratings yet

- Resonators Reduce Noise from Centrifugal BlowersDocument11 pagesResonators Reduce Noise from Centrifugal BlowersmaryaoannaNo ratings yet

- Numerical Calculation of Pressure Fluctuations in The Volute of A Centrifugal FanDocument11 pagesNumerical Calculation of Pressure Fluctuations in The Volute of A Centrifugal FanphineasphineNo ratings yet

- Noise Sources in Centrifugal PumpsDocument5 pagesNoise Sources in Centrifugal PumpsAnonymous r3MoX2ZMTNo ratings yet

- Source identification and noise reduction of a reciprocating compressorDocument9 pagesSource identification and noise reduction of a reciprocating compressorShashank Sudhakar PathakNo ratings yet

- Brief History of Control Valve Noise Prediction StandardsDocument3 pagesBrief History of Control Valve Noise Prediction StandardsMuhammad Adil KhanNo ratings yet

- De Paola 2018 J. Phys. Conf. Ser. 1110 012004Document10 pagesDe Paola 2018 J. Phys. Conf. Ser. 1110 012004teorikdeliNo ratings yet

- Piping Vibrations ConferenceDocument12 pagesPiping Vibrations ConferenceGustavo Espinosa MartinezNo ratings yet

- Centrifugal Compressor Case StudyDocument13 pagesCentrifugal Compressor Case Studybbmoksh100% (1)

- Cheung 2001Document7 pagesCheung 2001amirNo ratings yet

- Resolving Excessive Vibration in Steam and Feed-Water Piping at Loviisa Nuclear Power PlantDocument8 pagesResolving Excessive Vibration in Steam and Feed-Water Piping at Loviisa Nuclear Power PlantJose PradoNo ratings yet

- Articulo OriginalDocument4 pagesArticulo OriginalCesar Canales MinayaNo ratings yet

- PVP2014 28303Document10 pagesPVP2014 28303ammagdyamaNo ratings yet

- Effects of Tip Clearance On Rotor/Stator In-Teraction Tonal Noise of Axial FanDocument8 pagesEffects of Tip Clearance On Rotor/Stator In-Teraction Tonal Noise of Axial FanCanan DönmezNo ratings yet

- Vibration in Large Process ColumnDocument2 pagesVibration in Large Process ColumnHieuNo ratings yet

- Feed Pump Discge Line Vibration SolvedharDocument4 pagesFeed Pump Discge Line Vibration SolvedharPedro DiazNo ratings yet

- Numerical Calculation of Centrifugal Fan NoiseDocument11 pagesNumerical Calculation of Centrifugal Fan NoiseAnuj shuklaNo ratings yet

- Mollo Christensen1964Document17 pagesMollo Christensen1964Souhardya BanerjeeNo ratings yet

- 12 Axial FansDocument15 pages12 Axial FansPrashantNo ratings yet

- Chapter 12Document12 pagesChapter 12bhaskarNo ratings yet

- Stack Noice Control 01Document2 pagesStack Noice Control 01gechaves1No ratings yet

- DESIGN AND FABRICATION OF LOW COST DISDROMETER AND TURBULENCE SENSOR Morarka - GhaisasDocument4 pagesDESIGN AND FABRICATION OF LOW COST DISDROMETER AND TURBULENCE SENSOR Morarka - GhaisasMein samayNo ratings yet

- Fundamental Principles of Clamp-OnDocument6 pagesFundamental Principles of Clamp-OnBach Xuan NguyenNo ratings yet

- Sources and remedies for high-frequency piping vibrationDocument24 pagesSources and remedies for high-frequency piping vibrationSmith780512No ratings yet

- Cidra Sonartrac Flow Meters: An Alternative Flow Measurement TechnologyDocument15 pagesCidra Sonartrac Flow Meters: An Alternative Flow Measurement TechnologyMarcoNo ratings yet

- Velocity of sound in air determined using resonance columnDocument8 pagesVelocity of sound in air determined using resonance columnKaran TejwaniNo ratings yet

- Calculation and Design of Exhaust Noise Mufflers For Power Engineering EquipmentDocument10 pagesCalculation and Design of Exhaust Noise Mufflers For Power Engineering EquipmenthenrengNo ratings yet

- Asld PresentDocument50 pagesAsld PresentAakanksha GahlautNo ratings yet

- Ultra-Low-Noise Cavity-Stabilized Microwave Reference Oscillator Using An Air-Dielectric ResonatorDocument6 pagesUltra-Low-Noise Cavity-Stabilized Microwave Reference Oscillator Using An Air-Dielectric ResonatorwaikyqinNo ratings yet

- High Frequency Noise Reduction of Variable Speed Scroll Compressor via Transient CFD AnalysisDocument9 pagesHigh Frequency Noise Reduction of Variable Speed Scroll Compressor via Transient CFD AnalysisGokuNo ratings yet

- Noise Reduction in Ultrasonic Gas Flow MeasurementDocument9 pagesNoise Reduction in Ultrasonic Gas Flow MeasurementyasminaNo ratings yet

- Power FlowDocument11 pagesPower FlowKAMELNo ratings yet

- Acoustically Induced Vibration (Aiv) & Flow Induced Vibration (Fiv) Analysis For The High Pressure Reducing Systems Using Energy Institute GuidelinesDocument4 pagesAcoustically Induced Vibration (Aiv) & Flow Induced Vibration (Fiv) Analysis For The High Pressure Reducing Systems Using Energy Institute GuidelinesJournal 4 ResearchNo ratings yet

- Identification and Prediction of Piping System NoiseDocument7 pagesIdentification and Prediction of Piping System NoisejjirwinNo ratings yet

- A Technique For Estimating The Sound PowerDocument5 pagesA Technique For Estimating The Sound Powercarito1223No ratings yet

- Isc5 136Document7 pagesIsc5 136ghjtyuNo ratings yet

- Coriolis PDFDocument11 pagesCoriolis PDFdanielaNo ratings yet

- Uncertainty and Reproducibility Analysis of A Laboratorial Scaled Pipe ProverDocument8 pagesUncertainty and Reproducibility Analysis of A Laboratorial Scaled Pipe ProverOrlando GomezNo ratings yet

- Detection of Buckling in Steelpipeline and Column by Distributed Brillouin SensorDocument7 pagesDetection of Buckling in Steelpipeline and Column by Distributed Brillouin SensormanachemiaaNo ratings yet

- CD Paper Pag 373Document10 pagesCD Paper Pag 373Anonymous lEBdswQXmxNo ratings yet

- Flow-Induced Pulsations in Pipe Systems With Closed Side Branches: Study of The Effectiveness of Detuning As Remedial MeasureDocument6 pagesFlow-Induced Pulsations in Pipe Systems With Closed Side Branches: Study of The Effectiveness of Detuning As Remedial MeasureJose BijoyNo ratings yet

- Pressure Losses Across Trickle Irrigation Fittings and EmittersDocument6 pagesPressure Losses Across Trickle Irrigation Fittings and EmittersFrancisco OppsNo ratings yet

- Acoustic and Pressure Characteristics of A Ported Shroudturbocompressor Operating at Near Surge ConditionsDocument14 pagesAcoustic and Pressure Characteristics of A Ported Shroudturbocompressor Operating at Near Surge ConditionsSinan ÖrmeciNo ratings yet

- Effects Gas Flow ConditioningDocument6 pagesEffects Gas Flow ConditioningJOSE GONZALEZ VALERONo ratings yet

- Acoustic Fatigue Evaluation of Branch ConnectionsDocument8 pagesAcoustic Fatigue Evaluation of Branch ConnectionsShalihan MustafaNo ratings yet

- EDI No.25 - Nonsynchronous Forced Vibration in Centrifugal CompressorsDocument4 pagesEDI No.25 - Nonsynchronous Forced Vibration in Centrifugal CompressorsSamuel WeberNo ratings yet

- Full TextDocument6 pagesFull TextLaura SalasNo ratings yet

- Industrial compressor signal analysis for robust control under pulsationDocument6 pagesIndustrial compressor signal analysis for robust control under pulsationYurlevinson Espinosa CardenasNo ratings yet

- c74 PDFDocument9 pagesc74 PDFgunaNo ratings yet

- Optical VibrationDocument6 pagesOptical VibrationKarthick VelayuthamNo ratings yet

- Acoustic Fatigue Assessment of Piping System Components by FeaDocument13 pagesAcoustic Fatigue Assessment of Piping System Components by FeaTeknologi TermutakhirNo ratings yet

- Modifications of A Handheld Vacuum Cleaner For Noise ControlDocument7 pagesModifications of A Handheld Vacuum Cleaner For Noise ControlJason fuNo ratings yet

- Acoustically Induced Vibration Mitigations in Compressor Piping SystemsDocument10 pagesAcoustically Induced Vibration Mitigations in Compressor Piping SystemsaerosanthNo ratings yet

- Fatigue Life EstimationDocument7 pagesFatigue Life EstimationJomer J SimpsonNo ratings yet

- Noise Control Engineering Conference Paper EvaluationDocument2 pagesNoise Control Engineering Conference Paper EvaluationbehnazrzNo ratings yet

- Well Test Facility Specifications 40 X 40 LECMDocument10 pagesWell Test Facility Specifications 40 X 40 LECMDEDI ARDIANSYAH LUBISNo ratings yet

- Aeolian Conductor Vibration ControlDocument4 pagesAeolian Conductor Vibration ControlFeleki AttilaNo ratings yet

- Heat Recovery Steam Generator Noise AttenuationDocument13 pagesHeat Recovery Steam Generator Noise Attenuationkangsungjin100% (1)

- One-Dimensional Compressible Flow: Thermodynamics and Fluid Mechanics SeriesFrom EverandOne-Dimensional Compressible Flow: Thermodynamics and Fluid Mechanics SeriesNo ratings yet

- Engineering Vibroacoustic Analysis: Methods and ApplicationsFrom EverandEngineering Vibroacoustic Analysis: Methods and ApplicationsStephen A. HambricNo ratings yet

- Innovative Remediation Techniques To Compressor Foundation SystemsDocument8 pagesInnovative Remediation Techniques To Compressor Foundation SystemsahmadmortazaviNo ratings yet

- EFRC RD Report Foundation Anchor Bolts Grouting October 19th 2017Document210 pagesEFRC RD Report Foundation Anchor Bolts Grouting October 19th 2017ahmadmortazaviNo ratings yet

- Pulsimsuite2 LeafletDocument2 pagesPulsimsuite2 LeafletahmadmortazaviNo ratings yet

- Pulsation Studies 10.10Document4 pagesPulsation Studies 10.10ahmadmortazaviNo ratings yet

- Pulsation Analysis 4Document1 pagePulsation Analysis 4ahmadmortazaviNo ratings yet

- MISES User ManualDocument63 pagesMISES User ManualahmadmortazaviNo ratings yet

- Oscillator CircuitsDocument19 pagesOscillator Circuits21-08523No ratings yet

- Motovario MaintenanceDocument72 pagesMotovario Maintenancearachman297988No ratings yet

- Rds No. Standard Elementary System Size Pressure (Bar (G) )Document36 pagesRds No. Standard Elementary System Size Pressure (Bar (G) )Amit SharmaNo ratings yet

- Repair Welding of A Rotating Electrical Machine's Broken ShaftDocument7 pagesRepair Welding of A Rotating Electrical Machine's Broken ShaftLargyla Torres MendesNo ratings yet

- Geometric Design Chapter SummaryDocument90 pagesGeometric Design Chapter SummaryANup GhiMire100% (1)

- Dimensionality Reduction Using Principal Component AnalysisDocument32 pagesDimensionality Reduction Using Principal Component Analysissai varunNo ratings yet

- Characterization and Compact Modeling of Nanometer CMOS Transistors at Deep-Cryogenic TemperaturesDocument11 pagesCharacterization and Compact Modeling of Nanometer CMOS Transistors at Deep-Cryogenic Temperaturesrakshit yaNo ratings yet

- Lennox DLSC Heat Pump Product Brochure-1Document2 pagesLennox DLSC Heat Pump Product Brochure-1dgpetrov1977No ratings yet

- DENISON HYDRAULICS axial piston pump goldcup series service informationDocument65 pagesDENISON HYDRAULICS axial piston pump goldcup series service informationDanilo Perez HenaoNo ratings yet

- Exercise 26:: ∆ l=1 mω l AY m, A Y ∆ l ∝ωDocument21 pagesExercise 26:: ∆ l=1 mω l AY m, A Y ∆ l ∝ωAbhishek PathakNo ratings yet

- Micowave IntroductionDocument21 pagesMicowave Introductionniji mathewsNo ratings yet

- Frequency Control on an Evolving Island Power SystemDocument221 pagesFrequency Control on an Evolving Island Power SystemKing KingNo ratings yet

- PIPE AND TUBE - Comparison of SpecificationsDocument4 pagesPIPE AND TUBE - Comparison of Specificationsnate anantathatNo ratings yet

- Fundamentals of Nanotransistors Homework SolutionsDocument14 pagesFundamentals of Nanotransistors Homework SolutionsSuraj Singh YadavNo ratings yet

- Tutorial Chapter 7Document2 pagesTutorial Chapter 7Fareez SedakaNo ratings yet

- Problem Set-02Document2 pagesProblem Set-02linn.pa.pa.khaing.2020.2021.fbNo ratings yet

- Atwood Water Heater Manual PDFDocument41 pagesAtwood Water Heater Manual PDFferrofabNo ratings yet

- Mechanical Characteristics of Overhead LinesDocument13 pagesMechanical Characteristics of Overhead LinesMizanur RahmanNo ratings yet

- Electric Machines - Principles, Applications, and Control Schematics 2nd EditionDocument642 pagesElectric Machines - Principles, Applications, and Control Schematics 2nd EditionMirza MehanovićNo ratings yet

- UTeM Compressor TutorialDocument2 pagesUTeM Compressor Tutorialzul hilmiNo ratings yet

- IFE Level 4 Certificate in Fire Science and Fire SafetyDocument8 pagesIFE Level 4 Certificate in Fire Science and Fire SafetyDebayanbasu.juNo ratings yet

- C0636A×1000 Bench LatheDocument2 pagesC0636A×1000 Bench LatheAlireza KazemiNo ratings yet

- ! Theory of Surface Plasmons and Surface-Plasmon Polaritons PDFDocument54 pages! Theory of Surface Plasmons and Surface-Plasmon Polaritons PDFOlshansky OlegNo ratings yet

- SEO-Optimized Title for Seminar on Islanding TITLE"Seminar on Islanding Detection and Operator ActionsDocument16 pagesSEO-Optimized Title for Seminar on Islanding TITLE"Seminar on Islanding Detection and Operator ActionskishansaiNo ratings yet

- Viva Quastions SegwayDocument11 pagesViva Quastions SegwayEr Md AamirNo ratings yet

- BS 5295 Part 2 1989.enviro Cleanliness in Encl Spaces - Spec Clean Rooms & Clean Air DevicesDocument16 pagesBS 5295 Part 2 1989.enviro Cleanliness in Encl Spaces - Spec Clean Rooms & Clean Air DevicesRamiAl-fuqahaNo ratings yet

- ABB Technical Data Sheet Electrical Machines: No. Data Unit RemarksDocument8 pagesABB Technical Data Sheet Electrical Machines: No. Data Unit RemarksIngenieria DyconNo ratings yet