Professional Documents

Culture Documents

107.WI - Anodizing - EC 004 - Lower Receiver

Uploaded by

Rknight BOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

107.WI - Anodizing - EC 004 - Lower Receiver

Uploaded by

Rknight BCopyright:

Available Formats

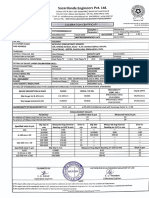

AMENDMENT

Rev No. Amendment Date Doc. Ref. No. Pages Modified Amendment deta

0 10.07.2020 ----- ------- New release

AIMPL/PRT/

1 11.08.2020 Page 1 Hole Masking a

WI/30

AIMPL/PRT/

2 14.09.2020 Page 2 Masking Remov

WI/31

3 03.10.2020 SURFACE ARE

MENDMENT DETAILS

Amendment details

New release

Hole Masking added

Masking Removed as per customer requirement.

SURFACE AREA FOR ANODIZE area row added

Ref No. :

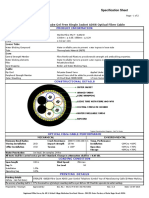

Work Instruction for Anodic Coating Rev. Date/No.:

AIMPL/CRC/WI/107

08.01.2021 / 01

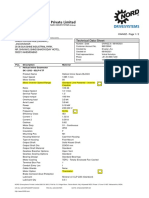

Process # OP-070 Location: Out Source Supplier Name

Part Number EC- 004 Process Name HARD ANODIC COATING

Coating

Part Name Lower Receiver 25 ± 10 μ (0.015 - 0.035 mm)

Thickness

Coating

Material AL-7075-T6

Specification

HARD ANODIC COATING PER MIL-A-8625F, TYPE III, CLASS 2, THICKNESS

COLOR MATTE DARK BLACK NO. 37030 TO NO. 37038 OF 1. Glass bead prior to surface finish SURFACE AREA FOR

Color Special Note 532.77 sq cm.

FED STD-595B 2. Masking not required ANODIZE

Input Parts Processed Parts

Visual Criteria Instructions

White patches are not acceptable anywhere on the part.

i) After process parts should look BLACK in MATTE DARK color.

ii) Do not dump the parts. Stage properly after processing.

Pit marks or wipe off are not accepted anywhere on the part.

iii) Glass Bead Blasting prior to finish.

iv) Wrap the part with strech wrap after Anodizing.

There should be no dust accumulation on the part

Prepared by Approved by

Subhasish Tushar Kanti

Document available 7 of 7 AIMPL/QMS/F/09 REV No. 00 Date 01.08.2018

\\192.168.1.150\Quality\QMS\AS 9100\Documents\3. WI\PRJ

You might also like

- List of Construction Material Prices in The Philippines 2018 - PHILCON PRICESDocument16 pagesList of Construction Material Prices in The Philippines 2018 - PHILCON PRICESHamza82% (11)

- Muhammad WaqasDocument1 pageMuhammad WaqasthehitechmultanNo ratings yet

- RT Report Imran ShahzadDocument1 pageRT Report Imran ShahzadthehitechmultanNo ratings yet

- RT Report Muhammad ImranDocument1 pageRT Report Muhammad ImranthehitechmultanNo ratings yet

- Edc Abo RuduisDocument5 pagesEdc Abo Ruduislemuel bacsaNo ratings yet

- Muhammad AsifDocument1 pageMuhammad AsifthehitechmultanNo ratings yet

- DAQ1-0092Q Regulations Exterior Defects Management (17) en (1) 1Document43 pagesDAQ1-0092Q Regulations Exterior Defects Management (17) en (1) 1yeucongnghemoiNo ratings yet

- Gre Pipe Technical Documents PDFDocument64 pagesGre Pipe Technical Documents PDFSunriseNo ratings yet

- CPP HT Pipeline ReportDocument301 pagesCPP HT Pipeline ReportAbdulkaderNo ratings yet

- 212-10153208 - APL-6324 - 31-03-2021 Eje TRASERODocument26 pages212-10153208 - APL-6324 - 31-03-2021 Eje TRASEROLucas ScioscioliNo ratings yet

- Failure Analysis Report: Information - 01Document4 pagesFailure Analysis Report: Information - 01Budi ArtantoNo ratings yet

- Product Technical Specification: Power CableDocument6 pagesProduct Technical Specification: Power CableGanabathi NadarajooNo ratings yet

- Specification For ADSS CableDocument2 pagesSpecification For ADSS Cablepalani.djpNo ratings yet

- Application Note 1060Document19 pagesApplication Note 1060essen999No ratings yet

- Samples Spection Report Signify Fio Sólido Vermelho 0,50mm2 440610001241Document1 pageSamples Spection Report Signify Fio Sólido Vermelho 0,50mm2 440610001241Moises NogueiraNo ratings yet

- 1280a4-8430-Ds-0001 Rev F1Document6 pages1280a4-8430-Ds-0001 Rev F1Stephen LowNo ratings yet

- Huehoco Composite Materials Co., LTD. ANT D 4012 /A277-CN (W98)Document1 pageHuehoco Composite Materials Co., LTD. ANT D 4012 /A277-CN (W98)anbu2810wsNo ratings yet

- B2020-TDC-DEF-005 Dished End Forming R0Document2 pagesB2020-TDC-DEF-005 Dished End Forming R0Ramalingam PrabhakaranNo ratings yet

- Data Sheet For SIMOTICS GP 1LE0143 Low-Voltage MotorDocument1 pageData Sheet For SIMOTICS GP 1LE0143 Low-Voltage MotorkayakurbanoNo ratings yet

- VENDOR Job #I-5206 Vendor Doc. #P.O. #M.R. Nº: I-5206-PC 7500038310 3640-NN-MR-052Document20 pagesVENDOR Job #I-5206 Vendor Doc. #P.O. #M.R. Nº: I-5206-PC 7500038310 3640-NN-MR-052Daniel EsparzaNo ratings yet

- Hexagon Head Screw ISO 4017 - M8 X 10 - 5.6Document1 pageHexagon Head Screw ISO 4017 - M8 X 10 - 5.6Cbh FastenersNo ratings yet

- 2GPI020-01-SP-02 01-11-2022 BW-05A Rack-09 E-E RP-261 9.53THKDocument4 pages2GPI020-01-SP-02 01-11-2022 BW-05A Rack-09 E-E RP-261 9.53THKMohammed EhsanullaNo ratings yet

- Supplier Corrective Action Report (Scar) : Characteristics Specification Actual RemarksDocument3 pagesSupplier Corrective Action Report (Scar) : Characteristics Specification Actual RemarksdysonNo ratings yet

- FA ReportDocument4 pagesFA ReportBudi ArtantoNo ratings yet

- PRNT 33666Document1 pagePRNT 33666Krishnanunni Karayil UllasNo ratings yet

- Report Visual Inspection: ASME SECTION IX Edition 2001Document3 pagesReport Visual Inspection: ASME SECTION IX Edition 2001RisdiantoNo ratings yet

- Universal: WiresDocument2 pagesUniversal: WiresDeepak PawarNo ratings yet

- NM1 Product ManualDocument11 pagesNM1 Product ManualJorge Antonio Cossio RamirezNo ratings yet

- ST04-2nd Sty Flat SlabDocument11 pagesST04-2nd Sty Flat SlabThaung Myint OoNo ratings yet

- Technical Characteristics 2020 ENDocument1 pageTechnical Characteristics 2020 ENezzularabNo ratings yet

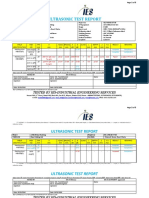

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument3 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- Concrete DeckingDocument8 pagesConcrete DeckingEliasNo ratings yet

- Leaded Surface Mount Technology - SMTDocument14 pagesLeaded Surface Mount Technology - SMTEdson CostaNo ratings yet

- TDS Link Ears and Pins MPIDocument1 pageTDS Link Ears and Pins MPIRanjithNo ratings yet

- Nord Ywnrmh.0Document1 pageNord Ywnrmh.0Navneet RankNo ratings yet

- Sievert Emirates Inspection L.L.C.: Magnetic Particle Testing ReportDocument1 pageSievert Emirates Inspection L.L.C.: Magnetic Particle Testing ReportAvijit DebnathNo ratings yet

- CP.1H20 - BMW G70 AD ESG - Nl.enDocument3 pagesCP.1H20 - BMW G70 AD ESG - Nl.enHafsa BoudguigNo ratings yet

- SEIP For 089-WHB-001: Claus Waste Heat BoilerDocument6 pagesSEIP For 089-WHB-001: Claus Waste Heat BoilerThinh NguyenNo ratings yet

- RS 013 July 2014 (Welder Test Run Sheet Andhika Rolando)Document1 pageRS 013 July 2014 (Welder Test Run Sheet Andhika Rolando)Muhammad Fitransyah Syamsuar PutraNo ratings yet

- Powders: Technical, Application & Safety DataDocument7 pagesPowders: Technical, Application & Safety DataphuongNo ratings yet

- Crown Specialized For Steel Contracting Co. Ltd. Welding Inspection ReportDocument1 pageCrown Specialized For Steel Contracting Co. Ltd. Welding Inspection ReportYasar AliNo ratings yet

- Technical Data Sheet: CN4V2Z - Page 1 / 2Document2 pagesTechnical Data Sheet: CN4V2Z - Page 1 / 2design electricalNo ratings yet

- Powders: Technical, Application & Safety DataDocument7 pagesPowders: Technical, Application & Safety DataphuongNo ratings yet

- Technical Data Sheet: CF6JEQ - Page 1 / 2Document2 pagesTechnical Data Sheet: CF6JEQ - Page 1 / 2Nouh AlsaadiNo ratings yet

- Draw Works Brake Line Links MPIDocument1 pageDraw Works Brake Line Links MPIRanjithNo ratings yet

- Approved Drawing 1 H14 Gel SealDocument1 pageApproved Drawing 1 H14 Gel Sealsabir hussainNo ratings yet

- Optional Service Bulletin OSB 42-134/1 OSB 42NG-073/1: I Technical DetailsDocument7 pagesOptional Service Bulletin OSB 42-134/1 OSB 42NG-073/1: I Technical DetailsSameer KshitizNo ratings yet

- RS 017 August 2014 (Welder Test Run Sheet Yudistira)Document1 pageRS 017 August 2014 (Welder Test Run Sheet Yudistira)Muhammad Fitransyah Syamsuar PutraNo ratings yet

- (D1832 SERIES) : Table 1Document1 page(D1832 SERIES) : Table 1blackhawkNo ratings yet

- Esquema Eletrico Moto E5Document7 pagesEsquema Eletrico Moto E5Bruno CamargoNo ratings yet

- LCM Spec Cbm10063 Golflite BlackDocument7 pagesLCM Spec Cbm10063 Golflite BlackwalterNo ratings yet

- CP J0 AD ESG - Nl.enDocument3 pagesCP J0 AD ESG - Nl.enHafsa BoudguigNo ratings yet

- Technical Data Sheet: CF6JEQ - Page 1 / 2Document2 pagesTechnical Data Sheet: CF6JEQ - Page 1 / 2Nouh AlsaadiNo ratings yet

- Technical Service Report: GR454 Komatsu GD 825 A-2 12797 S6D140E-2 40244Document2 pagesTechnical Service Report: GR454 Komatsu GD 825 A-2 12797 S6D140E-2 40244Yusfian TurnerNo ratings yet

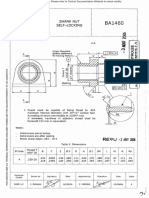

- Shank Nut Self-Locking: REPU-2AOUT2006Document3 pagesShank Nut Self-Locking: REPU-2AOUT2006Renato WatanabeNo ratings yet

- Vernier Calibration 08122020Document1 pageVernier Calibration 08122020Nevil Consultancy ServicesNo ratings yet

- Elevator Lifting Ears MPIDocument1 pageElevator Lifting Ears MPIRanjithNo ratings yet

- Report-1683-1 B1 25mm 14 10 2020Document7 pagesReport-1683-1 B1 25mm 14 10 2020sakthi velNo ratings yet

- SEIP For 086-V-001: Amine Acid Gas KO DrumDocument6 pagesSEIP For 086-V-001: Amine Acid Gas KO DrumThinh NguyenNo ratings yet

- Tela Pultrusión EMK450Document1 pageTela Pultrusión EMK450elbadelcarmensegoviaNo ratings yet

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- PET BottlesDocument1 pagePET BottlesDKNo ratings yet

- Effects of Thermal Treatment On Mechanical Properties and Grain Size of En8 SteelDocument5 pagesEffects of Thermal Treatment On Mechanical Properties and Grain Size of En8 SteelAjeeth KumarNo ratings yet

- PRV C 101 Data SheetDocument1 pagePRV C 101 Data SheetDevit FitriyantoNo ratings yet

- Swaging Process Swaging Process: Homework #2 Authored By: MASA FUADDocument11 pagesSwaging Process Swaging Process: Homework #2 Authored By: MASA FUADMasa FuadNo ratings yet

- Hydro SafetyReliefValves Series15002500Document12 pagesHydro SafetyReliefValves Series15002500HGuruGuruHNo ratings yet

- Ball GrindingDocument10 pagesBall Grindingmahreza189No ratings yet

- نسخة من 232.3R-14 Report on High-Volume Fly Ash Concrete for Structural ApplicationsDocument24 pagesنسخة من 232.3R-14 Report on High-Volume Fly Ash Concrete for Structural ApplicationswalidkcNo ratings yet

- Crusher Wear Parts Selection Guide: Jaws, Cones & ImpactorsDocument14 pagesCrusher Wear Parts Selection Guide: Jaws, Cones & Impactorsgildemeister gerencia100% (2)

- Sika Sprayed Concrete Handbook IndexDocument2 pagesSika Sprayed Concrete Handbook IndexbunkunNo ratings yet

- Archicentre Cost Guide Final v3 Aug15-2Document6 pagesArchicentre Cost Guide Final v3 Aug15-2awal7607No ratings yet

- MN 2Document52 pagesMN 2dbb2r6w8d5No ratings yet

- China (GB) USA UK Japan France Germany Russia Old New Astm BS JIS NF DIN ????Document2 pagesChina (GB) USA UK Japan France Germany Russia Old New Astm BS JIS NF DIN ????payara111No ratings yet

- Mix Design Is 10262 2009Document7 pagesMix Design Is 10262 2009Hossen Ali MollahNo ratings yet

- Composite Counter-Weight Application in Washing Machine: Institute of Science and TechnologyDocument115 pagesComposite Counter-Weight Application in Washing Machine: Institute of Science and TechnologyHassanNo ratings yet

- Jabatan Pengairan Dan Saliran Malaysia: Lampiran FDocument5 pagesJabatan Pengairan Dan Saliran Malaysia: Lampiran FWan ApaiNo ratings yet

- FEIN MF 14-180 Construction Cutter.Document4 pagesFEIN MF 14-180 Construction Cutter.RameetNo ratings yet

- Welding ShopDocument10 pagesWelding ShopAsifJavedNo ratings yet

- Columna Flexible para Pozos de AguaDocument4 pagesColumna Flexible para Pozos de AguaMIGUELNo ratings yet

- PWHT of Socket Weldded ValvesDocument6 pagesPWHT of Socket Weldded Valvesdnageshm4n244No ratings yet

- Bulk Deformation Processes in MetalworkingDocument20 pagesBulk Deformation Processes in MetalworkingKevin Mo KorirhillaNo ratings yet

- Module 5 - Pipe Cutting and JoiningDocument14 pagesModule 5 - Pipe Cutting and JoiningKrizia InteligandoNo ratings yet

- AFNOR NF Cu-B2 NF A51-050Document2 pagesAFNOR NF Cu-B2 NF A51-050dneprmt1No ratings yet

- Wickes PlasterDocument4 pagesWickes Plasterstewuk65No ratings yet

- ACI 334.3R-05 Construction of Concrete Shells Using Inflated Forms - MyCivil - IrDocument13 pagesACI 334.3R-05 Construction of Concrete Shells Using Inflated Forms - MyCivil - IringetabascoNo ratings yet

- BricksDocument12 pagesBricksLalith Koushik GanganapalliNo ratings yet

- Welding Joint Design and Welding Symbols123Document5 pagesWelding Joint Design and Welding Symbols123JACKMAAAANo ratings yet

- 02 Bayset Sec2.WaterproofingmembrainsDocument39 pages02 Bayset Sec2.WaterproofingmembrainsKha PhucNo ratings yet

- 10 - Cost-Analysis - 2 0Document13 pages10 - Cost-Analysis - 2 0J-red MondejarNo ratings yet

- Studies of Some Thermoplastic Resins Note - DR Akinsiku PDFDocument12 pagesStudies of Some Thermoplastic Resins Note - DR Akinsiku PDFGlory Usoro100% (1)