Professional Documents

Culture Documents

B2020-TDC-DEF-005 Dished End Forming R0

Uploaded by

Ramalingam PrabhakaranOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

B2020-TDC-DEF-005 Dished End Forming R0

Uploaded by

Ramalingam PrabhakaranCopyright:

Available Formats

ARC ENERGY INDUSTRIES

St No.114, Section N Block 10, Lot 6.

Jubail, Saudi Arabia. 35729.

TECHNICAL DELIVERY CONDITION

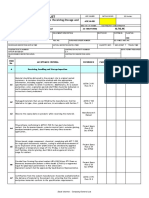

Form No.: QM-F-34 Rev. No: 00 Effective Date: 9/27/2020

Name of Material : Dished End Forming Client : For Demonstration

Tag No. : 001 Job No : ARC – ASNB – 1

Document No. : B2020 – TDC – DEF – 005 Doc. Rev. No : 00

1. SCOPE

This Technical delivery condition covers the requirements of Air receiver vessel Dished Ends fabrication.

2. DESIGN CODES

The following codes in their latest edition including their addenda at the time of fabrication shall form the

basis for fabrication, inspection, testing and acceptance of dished ends.

(a). Construction - ASME Boiler and Pressure Vessel code Sec. VIII, Div-1, Edition 2019.

(b). Materials - ASME Boiler and Pressure Vessel code Section II, Edition 2019.

3. GENERAL FABRICATION

The completed Dished Ends shall meet the requirements given in the drawing and as applicable codes.

Forming of heads shall be carried out by machine by cold forming in such a way to preserve the

specified material properties and to produce a regular finish.

Dished Ends type is Torispherical (refer attached DWG no. B2020-101-500-001_sht.3 of 5)

Material will be free issue from ARC Energy with MTC.

Dished Ends designed for only internal pressure.

Dished Ends layout is to check for centerline, height, and other dimensions as per drawing.

Dished Ends should be seamless construction without center hole.

Thickness specified are minimum, after forming and fabrication.

UG-79 (d) shall be complied

(2) The reduced weld thickness, at any point, shall not be less than the design thickness of the

component.

(3) The reduction in thickness shall not exceed 1/32 in. (1 mm) or 10% of the nominal thickness of

the adjoining surface, whichever is less.

The preparation of edges to be welded shall be done by machining, chipping, grinding, cold

shearing, Oxy-acetylene flame cutting or a combination of these.

Chipping shall be followed by grinding to a smooth and regular finish.

Oxy-acetylene flame cutting done in any circumstances shall be followed by machining or grinding

to eliminate any discoloration of material affected.

Tolerance as per UG-81. Vendor need to submit their documents before manufacturing.

Vendor need to confirm the thickness reduction percentage on the dished ends forming.

Copyright© Arc Energy Industries Page 1 of

2

ARC ENERGY INDUSTRIES

St No.114, Section N Block 10, Lot 6.

Jubail, Saudi Arabia. 35729.

TECHNICAL DELIVERY CONDITION

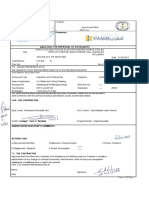

Form No.: QM-F-34 Rev. No: 00 Effective Date: 9/27/2020

Name of Material : Dished End Forming Client : For Demonstration

Tag No. : 001 Job No : ARC – ASNB – 1

Document No. : B2020 – TDC – DEF – 005 Doc. Rev. No : 00

Vendor need to confirm the blank diameter.

UG-79 (c) When the vessel shell section, heads, or other pressure boundary parts are cold formed

by other than the manufacturer of the vessel, the required certification for the part shall indicate

whether or not the part has been heat treated (see UCS-79, UHA-44, UNF-79, and UHT-79).

4. INSPECTION AND TEST

The ARCEI shall be responsible for performing all the inspection and visual inspection and testing required

as per this specification.

The stages of inspection shall be as per ASME.

Visual inspection to be carried out with customer representative.

Magnetic particle / Dye penetration examination shall be carried out on the outside and inside

surface including edges of heads in knuckle zone, after forming for detection of cracks.

5. PACKING

Larger diameter equipment of small thickness shall be provided with an adequate number of struts

positioned inside the equipment to prevent ovality effect while being handled.

These struts shall not be removed until the equipment’s is placed in position at job.

Edge preparation to be protect from the physical damage.

Ensure the wooden blank for the dished ends bottom side for safe transportation.

6. SHIPEMENT

All dispatches of equipment shall be done in accordance with the relevant terms of the purchase order.

Rev No. Description Prepared Approved Date

REVISION STATUS

Prepared By: Approved By: Accepted By:

Details:

(Design Engineer) (Engineering Manager) (AI)

Name: M. Azarudeen R. Prabhakaran

Signature:

Date: 27.09.2020 27.09.2020

Copyright© Arc Energy Industries Page 2 of

2

You might also like

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- 2.procedure For Fabrication and ErectionDocument13 pages2.procedure For Fabrication and Erectionanon_106345234100% (2)

- Itp Signage Rev.01Document8 pagesItp Signage Rev.01moytabura96No ratings yet

- Abu Dhabi aviation fuel depot cathodic protectionDocument11 pagesAbu Dhabi aviation fuel depot cathodic protectionRamesh GanapathyNo ratings yet

- Final Design Report PDFDocument63 pagesFinal Design Report PDFCHANDAN VATSNo ratings yet

- B2020-TDC-SR-006 Shell Rolling R0Document2 pagesB2020-TDC-SR-006 Shell Rolling R0Ramalingam PrabhakaranNo ratings yet

- Purchase Specification For Sludge DryerDocument84 pagesPurchase Specification For Sludge DryerNguyễn LinhNo ratings yet

- RFP - 2023 02 16 17 14 06Document53 pagesRFP - 2023 02 16 17 14 06Barun kumar paridaNo ratings yet

- BMW Technical Guideline Corrosion ProtectionDocument5 pagesBMW Technical Guideline Corrosion ProtectionJiahui WuNo ratings yet

- Glass and GlazingDocument8 pagesGlass and GlazingphilipyapNo ratings yet

- B2020 TDC PP 003 - Pipes - R2Document2 pagesB2020 TDC PP 003 - Pipes - R2Ramalingam PrabhakaranNo ratings yet

- Comparison Sheet - DUCTDocument2 pagesComparison Sheet - DUCTSavad AlwyeNo ratings yet

- 6684-PIP-G00-EB-0006 - 000 - 02 - Technical Specification For Coating $ WRDocument8 pages6684-PIP-G00-EB-0006 - 000 - 02 - Technical Specification For Coating $ WRMuthu AlaguRajNo ratings yet

- b2020-Tdc-Fas-004 Fasteners r3Document2 pagesb2020-Tdc-Fas-004 Fasteners r3Ramalingam PrabhakaranNo ratings yet

- Saudi Aramco Tent Structure SpecificationsDocument5 pagesSaudi Aramco Tent Structure SpecificationsphilipyapNo ratings yet

- De-119951 Monel Sheathing InstallationDocument8 pagesDe-119951 Monel Sheathing InstallationJithuJohn100% (1)

- Geogrid ReinforcementDocument5 pagesGeogrid ReinforcementphilipyapNo ratings yet

- Sealant and CaulkingDocument8 pagesSealant and CaulkingphilipyapNo ratings yet

- Scope of Work For Canopy Replacement of DRS/MRS: 1.0 GeneralDocument9 pagesScope of Work For Canopy Replacement of DRS/MRS: 1.0 GeneralDevang PatelNo ratings yet

- IMI Group Requirements PCB Suppliers v2016.1Document10 pagesIMI Group Requirements PCB Suppliers v2016.1sudar1477No ratings yet

- OPSS - PROV 2452 Nov18Document4 pagesOPSS - PROV 2452 Nov18kakagoNo ratings yet

- 560 000 TS M 296aDocument29 pages560 000 TS M 296awesqui100% (1)

- BP12A 088000 Glazing D00Document21 pagesBP12A 088000 Glazing D00Chrill DsilvaNo ratings yet

- Icf MD Spec 252 Cast Steel Side Buffer ArrgtDocument17 pagesIcf MD Spec 252 Cast Steel Side Buffer ArrgtDipak Kumar ChatterjeeNo ratings yet

- BP12A 074313 Aluminium Cladding and Roofing D00Document26 pagesBP12A 074313 Aluminium Cladding and Roofing D00Chrill DsilvaNo ratings yet

- MS-Fabrication of Tower MemberDocument17 pagesMS-Fabrication of Tower MemberShubham PatelNo ratings yet

- GGG-SPC-PIP-0013 - Rev 02Document25 pagesGGG-SPC-PIP-0013 - Rev 02oleg safaniukNo ratings yet

- Saic-N - 2013Document2 pagesSaic-N - 2013SUNIL RAJPUTNo ratings yet

- Portable Containers Booklet R3Document28 pagesPortable Containers Booklet R3abhi6784No ratings yet

- Structural Steel InspectionDocument3 pagesStructural Steel InspectionDarren LiewNo ratings yet

- Sheet Membrance Water ProofingDocument6 pagesSheet Membrance Water ProofingphilipyapNo ratings yet

- B2020-TDC-VF-009 Vessel Fabrication R0Document5 pagesB2020-TDC-VF-009 Vessel Fabrication R0Ramalingam PrabhakaranNo ratings yet

- Volume Ii: Specifications (Water Proofing) : Issue: FINAL, 14th FEB 2013Document11 pagesVolume Ii: Specifications (Water Proofing) : Issue: FINAL, 14th FEB 2013Ahmad SaadeldinNo ratings yet

- 01 9240 Facility Operation - Asset TaggingDocument2 pages01 9240 Facility Operation - Asset TaggingMarius de WetNo ratings yet

- Jacking Procedure PDFDocument14 pagesJacking Procedure PDFmanish pathrabeNo ratings yet

- JPKT 00 P 1 012 Rev 0 Specification For Field Joint CoatingDocument11 pagesJPKT 00 P 1 012 Rev 0 Specification For Field Joint Coatingrohitbhat2345No ratings yet

- Particular Spec For Geocell - Industrial Plots - East RailwayDocument4 pagesParticular Spec For Geocell - Industrial Plots - East RailwayThameem SharaafNo ratings yet

- Sign TSDocument16 pagesSign TSAjay SinghNo ratings yet

- G3ir 1000 55 SP 9002 - R1 PDFDocument40 pagesG3ir 1000 55 SP 9002 - R1 PDFRamu NallathambiNo ratings yet

- New College Durham STEM Anodizing SpecDocument4 pagesNew College Durham STEM Anodizing SpecjohnNo ratings yet

- TDC-STD-PP012, Rev.02 (SA-234 Gr. WP11,12 and 22)Document1 pageTDC-STD-PP012, Rev.02 (SA-234 Gr. WP11,12 and 22)Tanpreet SinghNo ratings yet

- 22009-Mar-cv-0107 (Raised False Flooring and Their Accessories)Document28 pages22009-Mar-cv-0107 (Raised False Flooring and Their Accessories)ADNAN ZIADNo ratings yet

- 2 66kV Isolator R3 Jan13Document33 pages2 66kV Isolator R3 Jan13akhilesh205No ratings yet

- Demo UdsDocument15 pagesDemo UdsvesselengineerNo ratings yet

- Attachment 5 - Painting and Coating System Including Colour CodeDocument54 pagesAttachment 5 - Painting and Coating System Including Colour CodeVan Anh0% (1)

- JP For Structural WorksDocument4 pagesJP For Structural WorksRajeev KumarNo ratings yet

- Zamil Sample CalculationsDocument108 pagesZamil Sample CalculationsAshraf KhalifaNo ratings yet

- 44AC9100-000-V.02-0110-A4 - Rev B - GENERAL SPECIFICATION FOR INSULATIONDocument51 pages44AC9100-000-V.02-0110-A4 - Rev B - GENERAL SPECIFICATION FOR INSULATIONAvinash ShuklaNo ratings yet

- Saic D 2024Document9 pagesSaic D 2024Md ShariqueNo ratings yet

- Tendring SpecificationDocument98 pagesTendring SpecificationGopalNo ratings yet

- 560 000 TS M 296eDocument8 pages560 000 TS M 296ewesquiNo ratings yet

- D-01 NocDocument29 pagesD-01 NocRochdi Sahli100% (1)

- Afic M 001Document2 pagesAfic M 001Basir AhmadNo ratings yet

- Saudi Arabian Oil Company: GEN-E0004 A Construction Specifications J95Document4 pagesSaudi Arabian Oil Company: GEN-E0004 A Construction Specifications J95moytabura96100% (1)

- Inspection Test Plan ITP Painting WorksDocument4 pagesInspection Test Plan ITP Painting WorksMichael AntipuestoNo ratings yet

- MS-TCC-2200-020-00001 - 6 Insul.Document96 pagesMS-TCC-2200-020-00001 - 6 Insul.ronald mirabelNo ratings yet

- 075216Document15 pages075216Engr KamalNo ratings yet

- The Dow Chemical Company Engineering Specification Process Containment K9S-1010-01 Ol2K 04-JAN-2005 Page 1 of 7Document7 pagesThe Dow Chemical Company Engineering Specification Process Containment K9S-1010-01 Ol2K 04-JAN-2005 Page 1 of 7maheshNo ratings yet

- SAUDCO INSPECTION CHECKLIST FOR SMALL TANKSDocument4 pagesSAUDCO INSPECTION CHECKLIST FOR SMALL TANKSAnonymous S9qBDVkyNo ratings yet

- b2020-Tdc-Fl-002 Flanges r4Document2 pagesb2020-Tdc-Fl-002 Flanges r4Ramalingam PrabhakaranNo ratings yet

- b2020-Tdc-Fas-004 Fasteners r3Document2 pagesb2020-Tdc-Fas-004 Fasteners r3Ramalingam PrabhakaranNo ratings yet

- B2020-TDC-PL-014 Plates 3304 R0Document1 pageB2020-TDC-PL-014 Plates 3304 R0Ramalingam PrabhakaranNo ratings yet

- B2020-TDC-FIT-013 Coupling Plug R1Document2 pagesB2020-TDC-FIT-013 Coupling Plug R1Ramalingam PrabhakaranNo ratings yet

- b2020-Tdc-Gas-012 GasketsDocument1 pageb2020-Tdc-Gas-012 GasketsRamalingam PrabhakaranNo ratings yet

- B2020-TDC-VF-009 Vessel Fabrication R0Document5 pagesB2020-TDC-VF-009 Vessel Fabrication R0Ramalingam PrabhakaranNo ratings yet

- ToleranceDocument1 pageToleranceRamalingam PrabhakaranNo ratings yet

- Mitered Bend Calculator (8!6!2012 Release)Document3 pagesMitered Bend Calculator (8!6!2012 Release)Haleem Ur Rashid BangashNo ratings yet

- 007 E7018 Electrodes R0Document1 page007 E7018 Electrodes R0Ramalingam PrabhakaranNo ratings yet

- Mitering Formula Example For 6" Concrete Wall:: Integraspec®Document2 pagesMitering Formula Example For 6" Concrete Wall:: Integraspec®Ramalingam PrabhakaranNo ratings yet

- 008 ER70S-6 Electrodes R0Document2 pages008 ER70S-6 Electrodes R0Ramalingam PrabhakaranNo ratings yet

- B2020-TDC-PL-010 Plates A36 R1Document2 pagesB2020-TDC-PL-010 Plates A36 R1Ramalingam PrabhakaranNo ratings yet

- B2020-TDC-FIT-013 Coupling Plug R1Document2 pagesB2020-TDC-FIT-013 Coupling Plug R1Ramalingam PrabhakaranNo ratings yet

- Checklist for Bearing DrawingsDocument1 pageChecklist for Bearing DrawingsRamalingam PrabhakaranNo ratings yet

- BN DS A3 1Document1 pageBN DS A3 1lusioNo ratings yet

- Checklist - Damper - Non Pressure Parts Drgs.Document2 pagesChecklist - Damper - Non Pressure Parts Drgs.Ramalingam PrabhakaranNo ratings yet

- Checklist for Baffle Arrangement DrawingsDocument1 pageChecklist for Baffle Arrangement DrawingsRamalingam PrabhakaranNo ratings yet

- Checklist - HRSG Ducting - Non Pressure Parts Drgs.Document3 pagesChecklist - HRSG Ducting - Non Pressure Parts Drgs.Ramalingam PrabhakaranNo ratings yet

- Checklist - Expansion Joint - Non Pressure Parts Drgs.Document3 pagesChecklist - Expansion Joint - Non Pressure Parts Drgs.Ramalingam Prabhakaran100% (2)

- Checklist - Hoppers - Non Pressure Parts Drgs.Document2 pagesChecklist - Hoppers - Non Pressure Parts Drgs.Ramalingam PrabhakaranNo ratings yet

- Checklist For Structural General Arrangement DrawingsDocument2 pagesChecklist For Structural General Arrangement DrawingsRamalingam PrabhakaranNo ratings yet

- Checklist - Fuel Firing - Non Pressure Parts Drgs.Document4 pagesChecklist - Fuel Firing - Non Pressure Parts Drgs.Ramalingam PrabhakaranNo ratings yet

- Checklist for Casing DrawingsDocument3 pagesChecklist for Casing DrawingsRamalingam PrabhakaranNo ratings yet

- Checklist - Hoist and Pulley Block - Non Pressure Parts Drgs.Document2 pagesChecklist - Hoist and Pulley Block - Non Pressure Parts Drgs.Ramalingam PrabhakaranNo ratings yet

- Checklist - Civil - Drgs.Document2 pagesChecklist - Civil - Drgs.Ramalingam PrabhakaranNo ratings yet

- Checklist - HRSG Inlet Duct - Non Pressure Parts Drgs.Document2 pagesChecklist - HRSG Inlet Duct - Non Pressure Parts Drgs.Ramalingam PrabhakaranNo ratings yet

- Checklist - Duct Detailing - Non Pressure Parts Drgs - 01Document2 pagesChecklist - Duct Detailing - Non Pressure Parts Drgs - 01Ramalingam PrabhakaranNo ratings yet

- Checklist For Piping Arrangement DrawingDocument2 pagesChecklist For Piping Arrangement DrawingRamalingam PrabhakaranNo ratings yet

- Fleet Welding Intermediate SMAW Stick Welding V1 05092014Document70 pagesFleet Welding Intermediate SMAW Stick Welding V1 05092014Maxcy LeoNo ratings yet

- Welding NOTESDocument5 pagesWelding NOTESAnonymous utfuIcnNo ratings yet

- Superparflam STDocument20 pagesSuperparflam STAlper SakalsizNo ratings yet

- DocumentDocument53 pagesDocumentKedarcharan BiswalNo ratings yet

- Above Ground Piping ProcedureDocument4 pagesAbove Ground Piping Proceduremusthafa_11No ratings yet

- CTS FitterDocument37 pagesCTS Fitterrajum465100% (1)

- IHT Instruction Manual M4000 MAN-CAP Rev08 EDocument76 pagesIHT Instruction Manual M4000 MAN-CAP Rev08 EraiNo ratings yet

- Digital Arc Voltage Height ControllerDocument58 pagesDigital Arc Voltage Height ControllerJosé I. Cárcamo S.No ratings yet

- Thermal Cutting ProcessesDocument18 pagesThermal Cutting ProcessesLương Hồ VũNo ratings yet

- Oxyacetylene Ablation Testing of Thermal Insulation MaterialsDocument6 pagesOxyacetylene Ablation Testing of Thermal Insulation Materialsjun floresNo ratings yet

- HSE Plan For RSPL ProjectDocument10 pagesHSE Plan For RSPL ProjectSaibabu SiripurapuNo ratings yet

- Notes of Workshop TechnologyDocument96 pagesNotes of Workshop TechnologySanjay PoudelNo ratings yet

- Mb900 Trouble GuideDocument427 pagesMb900 Trouble GuideCarlos Chzs100% (10)

- Hazard Identification Plan: Al Jouf Bulk Plant Saudi Arabian Oil Company-Saudi Aramco BI-10-00610-0001Document7 pagesHazard Identification Plan: Al Jouf Bulk Plant Saudi Arabian Oil Company-Saudi Aramco BI-10-00610-0001Darius DsouzaNo ratings yet

- Welding PrincipleDocument61 pagesWelding PrincipleRishu GroverNo ratings yet

- TRA # 102 For Installation of Piping and Pipe SupportsDocument5 pagesTRA # 102 For Installation of Piping and Pipe SupportsDarius DsouzaNo ratings yet

- CATALOG Uniweld-Products TYPE17-2Document13 pagesCATALOG Uniweld-Products TYPE17-2Máy cầm tay Hoàng TrungNo ratings yet

- Opening and closing gas cutting equipmentDocument11 pagesOpening and closing gas cutting equipmentJebaraj VNo ratings yet

- Victor Tip Charts: Acetylene Cutting Tip ChartDocument3 pagesVictor Tip Charts: Acetylene Cutting Tip ChartahmedNo ratings yet

- Welding+process Abbreviations+and+full+namesDocument1 pageWelding+process Abbreviations+and+full+namesmario fisgaNo ratings yet

- Afloat Shopping Guide Section 1 OverviewDocument318 pagesAfloat Shopping Guide Section 1 OverviewMatthaios SkantrzourakisNo ratings yet

- Boilermaker ResumeDocument5 pagesBoilermaker Resumebcr57nbx100% (2)

- Manufacturing ProcessesDocument10 pagesManufacturing ProcessesHasnain AshrafNo ratings yet

- Selection & Reference Information: Cutting Orifice Reference Chart - Cutting Tip SizeDocument5 pagesSelection & Reference Information: Cutting Orifice Reference Chart - Cutting Tip SizecarlosNo ratings yet

- CWI Module 3Document2 pagesCWI Module 3Basil M. Ikhleif100% (1)

- Welding Practice ExamDocument21 pagesWelding Practice Examaeroberti75% (4)

- KSEW Internship ReportDocument17 pagesKSEW Internship ReportOwl AppleKingNo ratings yet

- 008-MS For Prefabrication of CS, TT & CN Pipe Spools PDFDocument23 pages008-MS For Prefabrication of CS, TT & CN Pipe Spools PDFKöksal PatanNo ratings yet

- FBA Flash Back ArrestorDocument2 pagesFBA Flash Back ArrestorPaige JonesNo ratings yet

- Report Welding PoliDocument15 pagesReport Welding PoliSyahzlan IskandarNo ratings yet