Professional Documents

Culture Documents

Small Power Device Commissioning

Uploaded by

Ali AK0 ratings0% found this document useful (0 votes)

31 views44 pagesProcedure for Commissioning of Small Power device

Original Title

Small Power device Commissioning

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentProcedure for Commissioning of Small Power device

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

31 views44 pagesSmall Power Device Commissioning

Uploaded by

Ali AKProcedure for Commissioning of Small Power device

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 44

vats GEABONTOO

hee ery

Seen en ‘Bower ceHrRL,

TTL

aaa San SSEEST =

-TadrialStness Poca) Cat | sme oe Fa

Err ate Eo cten | “tates

irons Mittin

Cisne Soars lines ete ek

cota Dose : Secor FaEaaTVE— Te

ae

ewes Cletnct Meats CO sine Don

Ce esta MFA: steko! CF: kanerbmton C-REY: nue arRetetin

cw: ae Gein

aja

ta

(LA es

(sot tern trons cme i

Tsering srr

‘eure (Ce reereate on)

Coe serra wh conman emcee n-ne eres

"Sa my pnt et esc et

ee poe an a TT

1D -cxttenes He Neon FoRRATIE

ae

caren! C-satil M-tnt Coe Dove

a

“fod Steer re aig Conse oT Sal Po DoE

Ping Boamet Carpe Vein =

=r

can manta Srna

1 tmntecont CT-HA ttt DF: ttc oon—I-REY- tnd or Rtn

(Le typos entiinrt)

(Dt teat Comme erin ei

oy

geet connate oon

Sao ny peepee ec)

lst

lmtp

Dt-tehlomtan ony

Bie cae

sea cnn tok

ca U [a

oe

—— ot

= —

S88 eet s.smsrwcao. (Y7)_.20))

oor a or oe z 2 Fal

SS Se a

si

"SEE 51TH ORE] —

aye aq es ue par0N pyoyeasuoiadwo> e fq pafer/pavodsu oq | OF s

21 pes 0180/9300 otenbope 3 VOIR 35H

SEDER PONDS uDUaVES pOUTOWN SHA UP or :

= nine oun avowajdwos ©

po orsunucn or :

‘taunp poydivo> 2a eus puE pe. ®

oso | MUMP PIO? 29 HEE PLE paION

londunap Ravessuier-%6P=>P41| ayy yy ONINOISSININOD Td, O5Ie 9pNU|

or :

spenuoy]

ayn u von wondiasop an Uo pased -ONINOISSIAINOD

aujepas _‘,SNYBL 40 NOUINIG, AMM

‘oueisqns 0 2ueayuais Aue oney ousoop—weweres | oF

ue adoossapunanusans pue aves eee 7

asap | enuesans sum rod an poppe pue poion | #4 ~ .AALDITEO 'B 34005 "T, ose1 pue usmey|

owoRTOE

no suounues ey | oe

‘ORT TT/90

=FF nt uedne5 WORST WBPON 7 TOeE0a

Toneiaven wedieg

eusse9—94 afepe4)sn90 Jomog NewS J BUOHRAUIDD PE

Baworsuon aida oy wowsies poe rasa nao 11D

(409) WYO NOLLISOdSIG LNAOD

peoing Soo gery tunojougaet 10960)

oor hepen eran Aare

:

4 a |

| ‘ue Bunso1uopuadapuy poouayadea pue payenD,

‘20v0

ham a3

senoxdde pue Manas sossuodasatduies® | oF

sus pue Buns e 2 |

payduo> oq es ue panoy | 22U0wED cL OHd eran tJ

°

oso |

anos 2q eys pu poIon ° ‘or

e209

ayo 1 pao Ca

pera | jowoo 29 reus pue sion z 6

| oyduo> oq es pue pot0N - 8

aso. ®

or

* 1

Jo 1S] spHaid suowennbss Wwauidmbs 40} ainpeaoie-

oso

j303 Uo BunOM UUM TAPROOT | oF

oysue> aq es pue patON

peso % ssoype ‘Nid Avessanau wergo-| °

Syeway/omes jopenven) suersoesg suowey FERETT | on:

ve (uorenvon) suo ‘evonsmes | “OS

unejo.nee 16360

=m t aureus smnewaraiday penuo) | suey sev0nods |

‘80 Way — uewens 2q su Her my

a saimeua sau sono

‘sroe/rT feo seq : ‘DD ‘Wid ~ #82089 nqjus i

xoz/r/0 2180 ames wen sme

— HOG RI PERSE PU PET

wownod a ypung/30W Ie Buworsunuo> |Z

PO |, soud payduioo aa yeye PUR BONN fee 7

Zou ons Japun es 3

soo ot

1 Jos 38} PadDg Pu Pe

«D4 pur 21 J pnd poe PRIN Zuo}des uy sequinu souassjas uy apinoiat | ©

DvD

“aaa

= persis oq yes pur pion | sasoudinbe pus 90 Run up ® -

Too RFR PRM POET T "FORT UTSTEED I PUTA VPM oe

peop Sou vanes ryomanioadeoigiwegepjemnpurt| oF *

420un poiesogee 22s dL Bue BOON “T v0

aug 10u5 6500:9A+-0OeG ad F784

_erondde 0} doo auto panwans oq eys suOUTOOP

sueueyimes (bonenuea) wotsa ‘suse ‘eemmes | 8S

—ommemer S ohenaliaie

curve ana vow yenesoetg reve vavceoet ean Hommes

{explo ase pene sp 2 nat

‘5uouue 6024) swowuey sie pvaidey =e | [2

motemenaes Sa) i Ses

Jo fall ba &

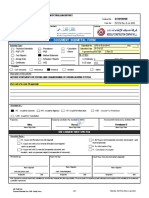

Qatar Petroleum

is

CONTRACT No.: 618108100

CONTRACT TITLE: -FIT OUT FOR PODIUM AT QPD

DOCUMENT TITLE:

METHOD STATEMENT FOR PRECOMMISSIONING AND

COMMISSIONING SMALL POWER DEVICES (PACKAGE 6 -

BASEMENT CARPARK VENTILATION)

(Rc:

ie

Seman gatsanas

‘rb ngnaorig buena

@ pA ChE ea

BxveotCATL

Po Bor23, Aaa Tower 1 Feo

ensinonastoncom

‘paroarea20 | 2 Tesued For Approval “eo [NA | 88

zariorats | 1 Tseued For Comments ‘BD | NA | SB

zaoan1 | 0 Teeued For Comments =I |_NK_| 58

Date [Rev | Description Prepared | Checked” [Approved] Appa. GP.

Document No, ‘aPD-9-£19-0017 Page: 1 oft

Document Te

Deca, | QPD-0-19.0017

[METHOD STATEMENT FOR FRE-COMMISSIONING AND -

COMMISSIONING OF SMALL POWER DEVICES (pacKAGE | Rv 2

66 BASEMENT CARPARK VENTILATION) Date anata

Page 20f28

Table of Contents

4. SCOPE & OBJECTIVE: 4

2. REFERENCES: 5

3. DEFINITIONS AD ABBREVIATION. 6

4. HEALTH & SAFETY HAZARDS: a

General Safty Guietnes 10

Requted PersoralProtsctve Equipment forthe Tasks 10

5. _ RESPONSIBILITIES! SUPERVISION. COMMISSIONING TEAM a

5. _PRE-COMMISSIONING, TESTING AND COMMISSIONING PRELIMINARIES. 13

Test Notiteation 8

Decess Cont 13

PROCEDURE! METHOD TO BE EMPLOYED. 13

TA Pre-commissioning: 13

Praliminary Chek and Veriieations 13

7.2. PSAT (PRE-CONMISSIONING). “

7.24 Interna Visual Procedure: “

7.22 Exteral Visual Procedure: “

7.23 Procedure for Inspection & Testing of Panel Boards. 14

1.24 Procedure for Measurement of Insulation & Continuity Resistance: 18

1.25 Teste an Earth Resistance 6

173 Small power test procedure: 15

134 Polaiy Test 18

732 Procedure (ELCBIRCBO-Elctrical Check). 46

733 Procedure (ELCBIRCBO-Mechanical Check) 18

7.34 Earth aut Lop Impedance (Z5)/ Prospective Fault Curent (PFC). aw

735 Residual Curent Device Trp Test (Live Test). w

736 Function Test (Live Test) w

737 Trining.. 7 set

WORKING HOURS: 18

[MANPOWER REQUIREMENT: 18

40. MATERIAL REQUIREMENT: 18

‘Vi. PLANT & EQUIPMENT REQUIREMENT: 18

Decent Tie

METHOD STATEMENT FOR PRE-COMMSSIONING AND

CCOMHSSIONING OF SMALL POWER DEVICES (PACKAGE

{6 BASEMENT CARPARK VENTILATION)

Rev

ate

Page

‘apD.9-10.0017

2

2ayoor020

ot

12, QC APPROVAL AND OTHER DOCUMENTARY REQUIREMENTS:

43, SUPPORTING DOCUMENTATION:

+4, DISTRIBUTION:

15, OTHERINFORMATION:

46, MAIN CONTRACTORS SAFETY ENGINEERS APPROVAL

47, ATTACHMENTS,

APPENDIX 1- RISK ASSESMENT,

19

19

19

20

20

2

Pocee tee Decne. | GPD8E19.007

McTHOD STATEMENT FOR FRE-COMMISSIONING AND

‘COMMISSIONING OF SMALL POWER DEVICES (PACKAGE

{6 BASEMENT CARPARK VENTILATION)

ev. 2

Date 2aronr020

Page| 40t2t

41. SCOPE & OBJECTIVE:

‘The Purpose of this document is to provide a uniform and systematic procedure for

‘conducting the PreCommissioning and Commissioning of Low Voltage-Small Pawer

‘devices for project Fit out At Podium — Qatar Petroleum District (Package #6 —

Basement Car Park Ventlation)

More over this document will define the methods to be adopted to ensure thatthe works

Conducted at site ate in compliance withthe relevant documents and the methodology

Undertaken are in accordance with QCS 2014, Approved shop drawings, Project

Spectfications and manufacturer's recommendation, taking inlo consideration safe

practices compliant with the Project Safety Plan, and associated safety procedures.

‘The inspection and testing of the works will be as per the Project Quality Plan, its

associated Quality Procedures and relevant Inspection and Test pian.

Only approved commissioning procedures shall be used to cary out the commissioning

activities. "Visual shecks shall be carried out to confi the correciness of the

instalation and the equipment is free of damage. Functional tests shall be carried out

‘on all components to verfy conformance to the manufacturers data,

Purpose & Scope:

This Procedure iste define the guidelines which shall be used by the T and C team to

censure that all actives are planned, Organized, uniform, and systematic procedure for

‘conducting the testng and commissioning process of the Low Voltage-Small Power

‘vices in accocdarce withthe contract and testing plan for projec, Fit out At Podium —

(Qatar Petroleum District (Package #8 — Basement Car Park Ventlation).This document

deserbes the testing and commissioning procedure for Low Voltage-Small Power

devices are to ensure a safe and efficient preparation of the system and to make the

system run as per the programmed schedule and in accordance with the project

specification.

‘The scope of this document is to provide the implementation of the commissioning

process regarding specific systems beina commissioned. Commissioning includes

performance testing to demonstrate that Low Voltage-Small Power devices mest the

Contract performance of the system installation per manufacturer's recommendation,

Industry accepted slandaré and project speciation.

Objective:

“The objective of this document i to confim that Low Voltage-Small Power devices are

fully operational and meets all specifed design intent through series of test and

adjustments.

This T & C Procedure to be read in conjunction with the relevant inspection and test

plan (ITP) with reference to Project Specifications, Quality Procedures of QCS 2014

‘and other related standards.

Desument Te! Deca. | QPD-9-E10.0017

[METHOD STATEMENT FOR FRE-COMMISSIONING AND

‘COMMISSIONING OF SMALL POWER DEVICES (packace | 2

66 BASEMENT CARPARK VENTILATION) Date 2avoarze29

Page Sef2t

2. REFERENCES:

CS 2014 Section 21 Part | Qatar Construction Specification-2014

46810 _|

Bs7671 Wiring regulations 17th edition

Cisse ‘Chartered Insitute of Bulding Service Engineers

BSRIA Building Services Research and Information Associatio

NFPA ‘National Fre Protection Association

‘acEwe ‘Gatar General Electricity & Water Corporation

‘@Po-s-04-0007 Health, Safely, & Environment (HSE) Plan

‘QPD-9-04-0002 ‘Construction Environmental Management Plan

(CEMPL

P-STD-0-003 8.004 | Qatar Petroleum standards

‘GPD-8-04-0005 Emergency response Plan

‘aPD-9-04-0004 Logistic Ptan| -

(PD-9-04-0006 Project Qualty Plan

‘OSHA ‘Occupational Safety and Health administration

Base Design ‘As per Contract

‘GAIGC Manual ‘Quality assurance and Qualiy control manual

HSE Standards Health Safely Environmental Standards

‘oPD: ‘Revision of Detaled design of Firout works at

Projet Specticaion | Petroleum District

Document Transmitals | Material Submittal Approvals

{or Approved Material

ae MAR ref QPD-6-MAR-<-0003,

‘Document Transmials for | Pre-Gualicalon Approval re

‘Approved Pre-Quaifation

‘Approved | (QP D-9-PAD-MG-0069

Document Transmitals | Approved for Construction drawings

(or diferent Packages)

Documents Transmitals | Approved Shop drawings

for Approved shop

drawings Submittals

Document Te

Doctie | aPD-8-E10-0017

METHOD STATEMENT FOR PRE-COMIMISSIONNG AND

CComMuSSIONING OF SMALL POWER DEVICES (PACKAGE | Sv 2

66 BASEMENT CARPARK VENTILATION) Dato: 2aroae20

Page | 6ot2t

3, DEFINITIONS AND ABBREVIATION

‘ap Qatar Petroleum

app ‘Qatar Petroleum District

BS Bish Standard

“GPPS Gata petroleum public spaces

OPPF Gata petroleum public ft out

ee Trternaional Electrotechnical Commission

ENEC European Nowe Elocical Gertiication

80 Diatraiton board

oy Eira bw votage

Ww iio vet

A Commissioning Authoriy

OF ‘Commissioning Engineer

om - Comnissioning Manager

rs Comnissioning Supervisor

or ~ | Commissioning Technician

TP Inspection Test Plan

‘AEB-QRC ‘Arab Engineering Bureau-Qatar Registered Consultant

‘CONTRACTORING | Medgulf Construction Company W.L.L

‘MEP (QMEP Contracting

‘SNC-UFMD ‘SNC-Lavalini Facity Management

EHS ES Envienmental Health, Safety and Security

BS British Standards

FAT Factory Acceptance Test

ik Inspection Request

AFC “Approved for Construction

PRC Project management Consultancy

[Becument Tie

[METHOD STATEMENT FCR PRE-COMMISSIONING AND

‘COMMISSIONING OF SMALL POWER DEVICES (PACKAGE

{6 BASEMENT CARPARK VENTILATION)

Rew. 2

Date 2an2020

Page: Tota

‘@coD (atar Civil Defence Department

toro Lock out Tag out

WAR ‘Material Approval Request

PD Project Director

PE Project Engineer

PPE Personal Protective Equipment

Pu Project Managar

‘@wac ‘Quality Assurance/Qualiy Control

acm ‘Quality Control Manager

‘acs Qatar Construction Standard

FE Fire Fighting

86 Subcontractor

PEAT Partial Stand-Alone Test

SAT ‘Sand Alone Test

frac “Testing & Commissioning

RAM Risk Assessment Matix

ia Installation Test

[coc Certificate of Completion

DEFINITION OF TERMS

| PROJECT

Revision of Detaled Design of Fit out works at Oatar

Petroleum District (PD)

‘VENDOR

Firm that supplies equipment, materials andlor

services for contractor as approved agents in accordance

with the terms of the Purchase Order.

CHECKLIST

Verification checkists that are developed and used diring

all phases of commissioning process to vey that the QP

requirements are being achieved

PRE-COMMISSIONING

“The Pre-commiesioning is one of the constuction adtviies

that involves the verfeation of functional operabiily of

tlements within te system to achieve a state of readiness fo

the Commissioning and Start-up operation,

Deco, | QPD-919.0017

I

ecient TE eal

[METHOD STATEMENTFOR PRE-COMMISSIONING AND |

COMMISSIONING OF SMALL POWER DEVICES packacE | °° 2

{6 BASEMENT CARPARK VENTILATION) Oe peas

Page Bof2t

‘Tho Testing of complete aystems under operational ot

CommissioNING —_ | simulated aperational cations inorder to bring fhe

Tarvare to. tte of Ready un

A fim that manufactures equipment or materials ia

MANUFACTURER | accordance with the recognized industry Standards, Codes

and Project Specifications

4, HEALTH & SAFETY HAZARDS:

4-1 HEALTH AND SAFETY KNOWLEDGE DISSEMINATION

+ HSE Site Safety inductions

‘+ Prozask briefing, Toolbox tak (TBT) and Risk assessment mat (RAMS) to

be briefed / communicated to the workforce prior to commencenent of the

activity

Safety toolbox talks

+ Envionmental toolbox taks

‘+ HSE training records / Toolbox attendance register

‘+ Intemal Safety Awareness courses

‘+ HSE Buletin / HSE Site Notice Boards

‘+ HSE Personne! site instructions

+ Site Engineers, Site Supervisors and Site Foreman wil ensure safe work

rmattod is adopted,

‘+ Emergency Procedure: All running machines shall be switched off before

leaving the ste

4.2 WORK PRE-COMMENCEMENT MANDATORY HSE ACTIVITY

+ Obtein correct PTW,

+ Discuss RA with work crew.

+ Carry out toolbox taks before start of each working day or new task Ensure

only trained /cetifed personnel are assigned on the job

‘+ Preuask briefing, TBT and RAMS to be briefed / communicated to workforce

priorto commencement ofthe activity

‘+ Ensure only trained / certified persons from approved third-party entties are

assigned tothe job.

[Decument

= ec N

[METHOD STATEMENTFOR PRE-COWMISSIONING AND

[COMMISSIONING OF SMALL POWER DEVICES (pacKAGE | *°¥

66 BASEMENT CARPARK VENTILATION) Date

Page:

‘aPD.9.£160017

2

areona20

80f21

4.3 MANDATORY PPE

+ Safa boots

+ Safety Helmet

+ High viswtiy Vest

+ Safety Gloves

+ Safety Glasses

+ Ear Plugs

+ Chemical Respiratory Cartidge Masks

+ DusthMask

+ Full 3ody Harness,

4.4. EMERGENCY PROCEDURE

Client / Consultants-approved Site Emergency Procedure shail be followed by the

‘contractor during the execution ofthis work.

4.5 PRE-EMERGENCY PLANNING AND AWARENESS

+ Emergency procedures to be communicated to all assigned employees for

this scope of work before commencement of activity.

+All communications to be documented and made avalable for the clint

whenever requested

+ Copies of emergency procedure to be kept at site for and available for

relerence at any point during the work

4 ACTIONS IN THE EVENT OF A FIRE

‘+ Step 1 = Raise the Alarm. Anyone discovering a ite should raise the alarm

immediately

‘+ Stop 2 ~ Evacuate. Evacuation should be prompt

makng thelr way to the designated assembly point,

‘+ Step 3~ Get to the Assembly Point

‘and calm, vith everyone

“+ Follow all the client consultants approved Fire Emergency Procedure and

Fe Dil Steps.

Docurent Te ‘Boe Ne,

[METHOD STATEMENT FOR PRE-CONMISSIONING AND

COMMISSIONING OF SMALL POWER DEVICES (PacKAce | R=

6 BASEMENT CARPARK VENTILATION) | ome

Page

(oPD-2-£18-0017

2

2a1o2020

s00t24

‘+ Ensure only trained / certified personnel are assigned on the job

‘+ Scaffolé to be used must be tagged and inspected by a competent scafiokd

supervisor / inspector prior to usage.

“+ Ensure LOTO procedure is observed before conducting the multi meter lest

‘on the equipment

‘+ Make sure all employees are Safety Inducted before they can work onsite

“+ Make sure employees take the right equipment with them on visits. Check

thay have been trained and know how to use it

“+ Keep available, records of hazards on particular sites.

people are notified.

“+ Make sure a supply ofthe right equipment is available.

1+ Helmets, Safety boots, Safety goggles, High visibilty vests, face masks,

‘overalls should be appropriate and in good condition,

‘+ Consider the risks of manual handling before going to the site and look atthe

materials being used or stored

‘+ Adequate Ilunination shall be set up at the work area and ensure the

requirec Lux available as per QCS 2014 during night shit, and at the dark

areas required during daytime.

‘+The lifting area will be baricaded, and appropriate signs fixed to warn and

avoid the unauthorized entry.

+ Copies af driversfoperator’s license vehicle's registration and security passes

{be submitted to Company safety department before commencing the work.

‘+ All mable construction plant shal be tested and certified by Third Party por

to mobilzation to site, a8 required,

“+ Ample and unobstructed passage shall aivays be maintained in and around

the truck loading and iting space

‘+ All equipment movement at job site must be contolld by third party certited

SlingeriSignaller (Rigger)

‘+ Trained Competent and authorized Supervision present always to ensure

Workers are performing their duties safely

Required Personal Protective Equipment fo the Tasks

Task related PPE for specific activities:

Make sure all relevant

Decumant TH

[METHOD STATEMENT FOR PRE-COMMISSIONING AND

‘COMMISSIONING OF SMALL POWER DEVICES (PACKAGE

(0PD-8-£16.0017

66 BASEMENT CARPARK VENTILATION) 2aeane20

tt 0f21

+ Safety boots

+ Safety Helmet

+ High Visiity Vest

+ Safety Gloves (Shockproof)

+ Safely Glasses

+ EarPlugs

+ DustMtask

+ Full Body Hames QCS 2014, NEPA & QCD

5. RESPONSIBLITIES/ SUPERVISION. COMMISSIONING TEAM.

‘COMMISSIONING MANAGER:

‘+ To ensure that all commissioning activities are carried out ir liaison with

‘supplier / vendor to the satisfaction of MG / AEB-QRC/ AP.

‘+ Raisng non-conformance or corrective action and adhere to safey procedure

+ Carry out a punch ist walk down and liquidate punch lis items as required

MEDGULF REPRESENTATIVE:

‘+ To vorfy the task, conducted by MEP contractor and ensure full compliance to

Site Testing and Commissioning Procedure

+ Veritcation of documentation

‘AEB-QRG/ CP REPRESENTATIVE:

‘+ Advise punch lis items

‘© Witness of testing & verification caried out during commissioning

COMMISSIONING ENGINEER / REPRESENTATIVE:

‘+ Allworks performed in accordance with this procedure

+ To oversee the works personnel to ensure they adhere to safely procedures

and folow AEB-ORC/ OP HSE standards and requirements

‘Ensure that all works are cartied according to approved project specification

‘and project construction drawings

‘+ Co-adination with vendor, main contractor and consultant for smooth

‘unctoning of commissioning,

‘+ Safed correct test equipment handling

‘+ Check and liquidate punch list tems

‘+ Complete commissioning reports and preparation the handover dossier

‘Decument Te Decne | aPD-ee180017

[METHOD STATEMENT FOR PRE-COMMISSIONING AND

Rev. 2

‘COMMISSIONING OF SMALL POWER DEVICES (PACKAGE

66 BASEMENT CARPARK VENTILATION) Dat: 2aron2020

Page: ott

‘SAFETY OFFICER / REPRESENTATIVE:

‘+ Allapplicable safety and environmental measures are implemented during the

period of construction

‘+ RAs performed and signed by all personnel

‘QA/OC ENGINEER/REPRESENTATIVE:

‘+ Allqality issues are adhered to as defined by the contract,

‘+ The preparation and approval of any quality contol procedure and inspection

test plans (ITP) undertake any inspections or tests as defined by the relevant

ITP and approved documents

VENDOR ENGINEER / REPRESENTATIVE:

‘+ Responsible for the commissioning of the vendor supplied ecuipment and

interfaces from the vendor supplied equipment tothe rest of the project.

‘+ Ensure that all the works are carried out according to vendor commissioning

procedure

‘+ Ensure proper safety is maintained.

TECHNICIANS

‘+ Responsible for ensuring that the work as outined in the Site T&C Procedure

's performed safety and al safeguards & controls are complied wih

‘+ Responsible for preparing the equipment/ system for testing or activites as

cuted in this Site T&C Procedure

‘+ Responsible for executing the testslactivties as outlined in the Site T&C

Procedure and as instructed by the commissioning engineer.

‘THIRD PARTY INSPECTION (TPIh

‘+ Responsible forthe supervision ofthe on-going construction actvtes.

‘+ Guiding the construction team for the correct installation prosess as per

‘manufacturer recommendations

“+ Ensure the pre and final commissioning is carried out under the supervision of

the qualified commissioning team,

‘+ Veriying the pre & final commissioning of the components meet the design

requirements

‘+ TPI should witness and sign the pre and final commissioning inspection

reports and other related commissioning documents.

Doooment Te

METHOD STATEMENT FOR PRE-COMMSSIONING AND

‘COMMISSIONING OF SMALL POWER DEVICES (PACKAGE

(6 BASEMENT CARPARK VENTILATION)

2ao22020

ta0t2t

+ Ensuring the process of commissioning is carried out in line with the client

requirements and standard procedures.

6, PRE-COMMISSIONING, TESTING AND COMMISSIONING PRELIMINARIES

TEST NOTIFICATION

+ All activities shall be witnessed by a Third Party and a Representative from

MG, AEB-ORC.

+ The AEB-ORCI GP will be given opportunity to witness by providing at least

‘one (1) days’ notice period prior to testing inspection.

+ Notation of test willbe given in due time to the AEB-ORC! QP contact point,

that may, or may notattend the test.

ACCESS CONTROL,

+ All employees entering the construction area will do so using access areas,

provided,

+ All operatives wil have the adequate traning as required by the Project

Management

‘All employees will attend the Medgulf Health and Safety Induction prior to entering the

area of operation

7. PROCEDURE! METHOD TOBE EMPLOYED

7.1 Pre-commissioning:

iminary Cheeks and Verifications

‘+ Otain the necessary work permit from the concerned authority as required

‘+ The concemed partes who wil witness the test shall be notied through IR.

(inspection Request Form.)

Ensure thatthe Distibution Board rating, type and size of breakers conform to

‘the specifications and drawings.

Ensure the Mechanical Completion Dossier and certicate is avaiable prior to

re-commissioning

‘+ Ensure the Category’ punch listing is cleared.

“The surrounding of te testing area shal be cordoned off and the access shall

be restricted to the authorized personnel only.

“The safety warning sign boards shall be provided.

Ensure that all test equipment is made available atthe test area and with valid

‘albration sticker and cericates

Proper ventilation provided.

Decuria Tae

Doctie | aPD-e-E19.0017

METHOD STATEMENT FORFRE.cOMMISSIONING AND |

COMMISSIONING OF SMALLPOWER DEVICES (PACKAGE | 2

{6 BASEMENT CARPARK VENTILATION) ae eae

Page saot2t

*+ Upstream shouki be ready fr powering the downstream,

+ Fire suppression equipment should be in place

7.2PSAT (PRE-CCMMISSIONING)

7.2: Internal Visual Procedure:

+ Verity the instalation 1s completed, verifed and approved by Engineer/Client

representat

+ Very all corductors are properly marked with identification color codes, Le. (ted

yellow, blue phase markers and black neutral marker) and circuit labeling,

+ Check all eath bonding straps have been fied

‘+ Verity earth connection to all current carying components within the assembly,

‘+ Check cable insulation and end cable lug jacket isnot tear/damage.

+ Eneure that dust, corroded, waste materials cumulated in the device box are

remaved before commencing the lve tes.

‘+ Ensure that here i no timming of cable strands to ft into cable lug. Proper cable

lug and end eap cable jacket size shall be used

+ Ensure that respective latest Single Line Diagram and Load schedule are provided

in the envelope located inside the Distribution Board

‘+ Ensure that here is no sweating/condensation occurs in the DB,

7.2.2 Extomal Visual Procedure:

“+ Verity condition of the paint work

“+ Verity assembly nameplate label ited as per specication,

= Verify al functional unit identifying labels havo beon fied

“+ Verity circuit abeling ited as per specication,

“Verity circuit ayout arrangement match inthe plan layout drawing

“+ Verity incoming feeder cable identiiation tab

“+ Verity all doors and covers ft correctly

“+ Verity cablelwiresidevices identification completed

7.2.3 Procedure for Inspection & Testing of Panel Boards

“+ Check all device cirult labeling details as per the approved drawings.

“+ Check the installation and termination of cable for proper workmanship.

Document TH

[METHOD STATEMENT FOR PRE-COMMISSIONING AND

CCONMISSIONING OF SMALL POWER DEVICES (PACKAGE

66 BASEMENT CARPARK VENTILATION)

ate 2are2n020

180f21

7.2.4 Procedure for Measurement of Insulation & Continuity Resistance:

Conduct a centinuity check on all phasesiground and neutral with a multi meter to

‘encure the busbar conductors are continuous throughout the length ofthe run

‘Test Equipment: Multi-Function Meter

Conduct an insulation resistance test with an insulation resistance tester at S00VDC to

ensure thatthe systom I free ffom short circuits and grounds (phase-to-ground phase-

toneutral and phase-to-phase). I should be noted that readings vary inversely with the

length of run and width or numberof bars per phase,

8) Confirm the heaithiness of the outgoing circu

1») Check the continuity of individual circuit from Distribution Board to load devices.

©) Check wih an Ohmmeter that there is na electrical connection between the phase

lor between phases and ground, Record test results from approved test frm.

4) Set the test equipment as per insulation rated voltage of the cable. Record test

results in the approved test forms.

©) Measure Insulation Resistance of outgoing cable from Distribution Board to

‘outgoing bad devices using Calibrated Megger.

1) Repeat procedure (b,c& d) forall outgoing cccuits.

8) Measure the R1+R2, R1-R1, RN-RN and CPC-CPC, (see procedure at Secton 6.1)

1h) Terminate all cable onthe terminals wth proper tightness.

7.2.5 Tests on Earth Resistance

Instrum rth Clamp Meter or Mult

‘8, Checked continuity ofthe protective conductor or a separate protective conductor

fre connected corractl par for energization

Using the Earth Clamp meter check the resistance value of the protective conductor

land record result inthe approved test frm.

Acceptance value should be less than 1 ohm as per QCS2014 & BS 7671

‘unetion

7.3 Commissioning Procedure for Small power device

‘+ Ensure branch circuit breaker ie OFF. In measuring the resistance of (RIAR2, R1-

RI, RN-RN and CPC-CPC).

‘+ Measure resistances in Ring and Ratial Ccult wings as per BS 7671

7.344 Polarity Test:

“+ Polarity test is conducted at the field device (power sockets).

acura TH

Deca | QPD.9-t0.0017

[METHOD STATEMENT FOR PRE-COMMISSIONING AND

‘COMMISSIONING OF SMALL POWER DEVICES (PacKAGE | Fev 2

6 BASEMENT CARPARK VENTILATION) Date 2aroanc20

Pa 1wot2t

+ Make sure branch circuit to be tested is power ON.

+ Plugin Polaty Instrument Test and connect test leads of the Mult-Function Meter

‘an the device to verity the termination of phase and neutral a the socket,

+ Rectily ifthe phase or vice-versa connected wrong terminal point

+ Repeat procedures for al the remaining outgoing circus,

7.3.2 Procedure (ELCBIRCBO-Electrical Check)

Instrument Usee: Muli:Eunction Meter / Polarity Tester

‘+ Make sure that the power Is ON and DB is energized

+ Connect the test cables to the ELCBIRCBO under test

+ Set the tester to desired settings for Idn and Sxldn and apply the test butte tothe

itp tet and nate the value for each setting

+The breater should tip faster when applying 5 times of current.

1+ Record the ELCBIRCBO Operating Time on the approved tes form.

‘+ Repeat procedure forthe next outgoing branch circuit breaker which tobe tested

sent Used: Polarity Tester

‘+ After the wring devies such as socket outlets has been energized, plug the polarity

tester unt ino the 240V socket outlet under test

“+ Turn on the polarity tester and read the indication, elther "Correct wiring” or ‘reverse

wiring”

“+ Ifthe reading is “Correct wiring”, proceed to lve test otherwise, rectify the wiring

and retes the polaity unlit gives a reading of "Corect wiring”

+ Below is he photo of a polaiy tester plugged in power socket outlet under fet.

7.3.3 Procedue (ELCBIRCBO-Mechanical Check)

‘+ Make sur that the main power & controls are OFF

“+ Push breaker handle to ON/OFF positon for checking operation are working

properly

DosumentTWe

[METHOD STATEMENT FOR PRE-COMMISSIONING AND

‘COMMISSION

734

735

736

b.

4

a7

Doctie | aPD-8-E19-0017

ING OF SMALL POWER DEVICES (PacKace | 2

JASEMENT CARPARK VENTILATION) Date ‘2aroarc20

Page srot2t

Record the result on the test frm

Repeat procedure forthe next branch circuit breaker which to be tested

Earth Fault Loop Impedance (2s) / Prospective Fault Current (PFC)

‘Switch ON the power supply.

Testing stould be done atthe last point ofthe outgoing circuit loop connection

Disconnect the protective earth cable on the device terminal

Connect tst lead between the incoming line of each phase, neutral and to earthing

conductor.

Perform the test by selecting loop impedance (Zs) inthe multifunctional reter for

teach phace and compare the result.

Record the highest result value taken from the test instrument.

Reconnect the main earth conductor tothe main earth terminal ater performing the

test

Repeat procedure forthe next outgoing branch circuit breaker which o be tested.

Residual Current Device Trip Test (Live Test)

Mutttuncton tester fs connected atthe end ofa ve circuit

RCD fs tepped using a multiplier of x1 of the RCD current rating at 0° test current,

phase

Record the tip tine

RCD is troped using a multiplier of x6 of the RCD current rating at 180° test current

phase

Record the trip time

Function Test (Live Test)

Test MCB breaker switch whether ittum on and off

Check the Function Test coluran

‘Test the RCD triptest button

Ifthe RCD tum off, check the Function Test column.

Training

‘Tradesmen performing the installation and testing work will be experionced

technicians. If deemed necessary specific teamindlviduals will undergo futher

training and awareness programs for this activity by the Production/Qualty

‘Assurance departments,

‘Toolbox iaks wil provide general training and awareness for each activity and

also in Health and Safety matters and precautions

Document Ti

ETHOD STATEMENT FOR PRE-CONMISSIONING AND

‘COMMISSIONING OF SMALL. POWER DEVICES (PACKAGE

66 BASEMENT CARPARK VENTILATION)

Doce, | QPD-9-E19.0017

Date 2avonre020

Page: 10821

8. WORKING HOURS:

Site Working Hours:

Start Time: 7:008M to 12.00PM & 12:30PM to 17:30PM

Lunch Hours 12:00PM to 12:30PM

9, MANPOWER REQUIREMEN

+ Project Manager

‘+ Testing and Commissioning Manager

‘+ Commissioning Engineer

“+ Interface Coordinator

‘+ Vendor Engineer/Representative

‘+ Site Engineer Electrical & ELV

+ Safety Ofcer

+ QC EngineerManager

‘+ Technicians! Helpers

410. MATERIAL REQUIREMENT:

{As per project specification, approved shop drawings and material submittal,

111, PLANT & EQUIPMENT REQUIREMENT:

+ 500 VOC Calibrated Megger

* Calbraed Digtal Mutimeter

Torque Wrench

+ Digital Earth Clamp

+ Polarity tester (for measuring current polarity)

++ Toolbor with portable hand tools (screw drivers, measuring tape, wire marking

ferrules, cutter, combination pier ete.)

"+ Electrical Hand Gloves

‘+ Warning Sign boards & Warning Tapes

Document Ti: Doce | GPD-8-E160017

METHOD STATEMENTFOR PRE-COMMISSIONING AND | _ —

‘COMMISSIONING OF SMALL POWER DEVICES (PACKAGE 2

{6 BASEMENT CARPARK VENTILATION) avez

190t21

Note: The test cetiicates, instrument manufacturer details, scale ad full-scale

‘accuracy, date of calibration date & name of last calibration company will be

provided prior to actualT& inspection and wll not proceed any Testing and

‘commissioning activities without above mentioned documents.

12.Q¢ APPROVAL AND OTHER DOCUMENTARY REQUIREMENTS

‘+ To ensure work to be carried out in full compliance with approved Method

Statement and as per the project quality standards.

‘+ Allinspection works shall be carried out in accordance with specifications. Work

‘shall be caried out by the Q-MEP site team under the guidance ofthe Electrical

Engineer and shall futher be checked and approved by QNQC

‘+ In-Process works shall be monitored for quality of workmanship and installation

against approved shop drawings by the relevant supervisor,

‘+ Allworks shall be inspected for conformance to specification

‘+The inspection formats shall be used in accordance with the requirements of the

‘main contracting

‘© Check the works as per approved drawing

13, SUPPORTING DOCUMENTATION:

“This MS to be readin conjunction with below referenced document

‘© Approved Method of statements

‘Approved Drawings (AFC)/As-Bult Drawings

+ Approved Material Submitals

414, DISTRIBUTION:

Copies of tris MS will be circulated fo the folowing fo Information & acto

Project Manager

‘+ Testing and Commissioning Manager

+ Interface Manager

+ Interface Coordinator

* Corstruction Managers

‘Decument Te boone

| METHOD STATEMENT FOR PRE-COMMISSIONNG AND |.

‘COMMISSIONING OF SMALL POWER DEVICES(PACKAGE | Fev

66 BASEMENT CARPARK VENTILATION) Date 2aioana20

Page 200121

+ Site Engineers

‘+ Safety Manager

© QAQC Manager

415. OTHER INFORMATION:

Eneure that ll the activites have been caried out to sult the site conditions.

46. MAIN CONTRACTORS SAFETY ENGINEERS APPROVAL

Permits

‘Work Permit shall be obtained from prior to star the work and endorsed as per permit

requirements. The following permits are required for the execution ofthis method

statement:

‘+ Cliont Approval to proceed

‘+ Environmental Permit

“+ Intemal Work Permit

= LoTo

AT7.ATTACHMENTS

+ Risk Assessment (RA) anc Checklists

Document Tie

oc No, | aPDe-e19.0017

[METHOD STATEMENT FOR PRE-COMMISSIONING AND -

CCONIMISSIONING OF SMALL POWER DEVICES (PACKAGE | 1

6 BASEMENT CARPARK VENTILATION) oe anzaae

Page: | 2tof2t

APPENDIX 1- RISK ASSESMENT and CHECKLISTS

SROpIETETON (3007 WORSE way SORIA TON BBO WONTON BSTexa) BUSSE

zoz/zo/veoie0 ago se ssn 009 :0N woo ‘on vit

‘SENINOHNOD

3 ¥

‘NTEVEOW COOH SNISYRONT

svouiado-nincrDoueWanawiven0 4a. Sree

SISATYNY owVZVH Sor

‘swouwzd0- sundsDOwd TWiNaMULMVas -¥BINI

= enrol sys

Sa RN GT

sd an

soma peso oy aimamsepared

te

Jone pasa spo ah) 9

posing ea

Ayes $4 poddens / pamoes Ajzadoud are speo| aunsuy “¢

me

vac eo xj 09a KEN ANITA “y oun

wonder

post

reo wuspaty agen oubanse SHG IHFNN HF) a pu ag

empains ‘nouns gE a8 aINPY “Z cm Sao «| TRON,

ND anoaadina ‘us uy wo weNsOPeG "7 ane

Q pepe dea open et anu orem | so uopebaneary

vonwising | tevxe | _Younppoedann ita t| meoxe | Jowmmmoiaar amen 1) wate

5

mung po viv Sos

mr sao

mod sop ya ee OD “6

situ owe or

SNoUWaadO-J4NG;DOWs WINGHULNVEIO-WBINT

nnn ee

+ wosyuadns Jo 001 “9 |

ypruosg

ays Sa u

sumo > 7

sup ast sss QMO aMamseg “¢

‘wusog suosid paenpzomne 6 |

oso no pots ar soptanse orssod ye ansea*Z 7

9 =a

ie pms ‘nu a pawn, *Z

‘a oy sso pazuogneun saul oy antes ea say sor

wossindng | tev | Mowat pu asin rowsgd sae “t| INeOX 098 payOAUCOKN “L| yo suomMseUY

Jpuuosg

ayes Sa

siio 9 *

soupy as

€ mm

soy wom wooed

pps qs 3280105.

z ounssu,

| weoxe se ayperg 00g t| Suypuer reuue

| josnyepeytaget hw taon Bee

SISATUNY GVZvH GO

= eee

SNOUMaMO-2uNG;DOUE TWINBMLNYEIO-WBLNI Re Tr

RouoRouo Jo 9909 ur asoud

‘uopeyfusuo sup Sums 0 1d da peau,

9 Plowees “appe|axnionpueD ¢

wosusdnsJoxpe7 Ҥ

‘somianae

Suyuosstut pe Buysor m0 Suto

‘1 panojpe ame siaou9 30 suo,

wroduoo /pozrome Kuo ams ¢

popuodsns

a

safstapeonnms on oon eee “© satay

ees ee

bree peomne sapeccicteamaret ie (ee oe

“sopianaewovasod pt

ve asad s} Uo

1)

doa anstty “9

280 J0 soutaue we podondip pur pourgo

‘are stud a woos pazrBieus amnsty “Ss

0% spo 205 poops

us ayes apo s vase canst ‘wora,duio9

SIskrwNy auvevH aor

© | wee mmeremmernn | AR SHEAR

spar Ba PEN *F

Weoxt

youre pozioua yo uonsodsus rons Burp

youd 9p wos aounsipsyeadaudde doy -g

uose20}

ps0 J0 outa e podoydsip pun pourago

ad Ano woot porious amstiy g

SISATWNY aUvZvH Gor

ae

| snoueago-sunasooue WiNaVLNve20 LN SS

ERE POOH OT PROTEUS SLA PL

1 pros om uo suosiad om Jo tanTYY “1

‘uonwurpioo9 yuoussour

prey = suas Jodeud pawenpr009

T1699 0 Oyas Jo oUBHOY “OF

“syespuny 210 woo] op ou suosiog “6

sanow $1 a80q8,YO 98 94001 NSH“

"ase 30% punas

‘souls Suze pu siouseg apisoid “9

ployeos ausiaduionv 4a paisnds

pun pod oq is posn 901 POKES “¢

“ays avenbope

wo gus pon st op SuppoM “Ie,

soBrsAudn09

oud 9g ut woe SUE

‘papcadsns pamnoosu “11

opm press

wo BdsoyesN04 004 ‘OT

espns

‘sano 29 001 FEUDS 6

poy-oaiparsadsuy

ou pIeHES “8

oy uo sito

np pregos Fagen,

sonia pean poqsu, ‘pone

"01389 00) ~SPIOEDS

Jouurtasou sappy “9

uopaoroud a8p9 ON. “s

SISKIWNy aWVZvH Gor

es

aS NGG STWADOAN GL TTA, - woureueu 9989200 “9

suounsu Buns}

pounpou /ayesun jo asp. °¢

Jounosing + suoumasuy

97s 5 syjon pomba jo Sddns-2080 lose 02 uns papparsqas

steps y _umpmuypoyatoduton Kg pasn 99 O1.9RBIWY “¢ se poBeURP OSE “F

SuPY ASH se 88ou a BunsauU09

WO (Comes sBK0d yoSULEP a ang ONO

Syoqno0ye TenpIsOL

WL HOY

poopasosien 1] “Sounnsny

opting | Tevx IN-oxr L501

sodar wou ou un spr ues

‘9p 0} poms ate seusnur popusdans

Sb poy a 0

stony popesdsnsSumpuns-2a SU 91

nq unm sn po4n8

xn on 20 wo Sue on 08 OC's

| somos stsfoesone nyo sua wo,

SISkIVNY ouvaH gor

T ere

© soememmccimnonen | RL STRAP

SUIS a TOT

2orauu ap Buonpuoo agaq pass23q0

syamposead ino 8 no yoo] ag2 ans aE)

{S21 2)eu]NT

sp Buppuouo> a0yoq paioydwuoo

‘ry a00‘aaoge asugd 1s 208m.

‘90 WALLY saudi agp uo swaUNSAEpE

autnbasJo/pue iasso00u fp ans,

Weoxp

Sepa prpumsgas

0 podeusep 30257)

ay peounseta

eo1240 SHON

SL HHMI

~ swoumst |

1 91 10350,

SouaRiaw9 Jo

seo uy asoy sip Sams oy sud da poasy

‘ue patgopr ave syxa CousRiowe amu

sn zgsinBunx>

ay yo a@pqmoury waiadusoo a0

anny 9 suerruyoy stonodsur aunt

‘wone>o] 38 a}ge,2AE

{ag yeouoyo 20g says any amu,

{ser sod pease oye por unse1p

‘Suunp postaednsun Ayre Bast Jo eae

bU95 20 yusuadbo 32) Su 9882] 308 OC,

‘dup 20198

20pm ga sou a

‘398 Jo donor 0} sod pa

sqreou wouudinbo 40 sjoo ets ue "EY

‘SB 's 04 -syeuoqeu oxnonpuo amnsuo

ew spa] s0 241s oeIUOD YS rOAY

woud

‘Bunsay yo ae pao,

sais fq wo

sy ounsisd aaponpuo

L

SISATUNY awWE¥H BOF

©

en.

ereeana yD

ny

wossiazdns | TeXe

“da Hujuorsyaion-asod je ANS “Z

paarosqost ampaoaxd Loran ams aN “I | oxy

tou amp20034 OLOT

supedoy uonsadsu,

1] sod / 210d

PASS A pur HoTAIG aT TO

in uayen 29 0 sey ase Fuso so RU

‘u pats samstous jonuos xp 1°21 parenpuC>

‘Atysag aaq S11 Je paypoaidde s 5159)

‘3 en ans 9¥bu ‘PowBadas9q 01 pou ase

‘uyso)s98Fou1 op ose Sur 30531 AION.

ssoup oquans9[9 pur 9120919

oy suonmesaid Sages jaeus8 ap anrasqQ “¢

‘2p Bumseour uays Su0[0d 9p 2419800“

Snag ae amseour oy Bunducne 210329

20} pots st rea a UO 2

prom 309) TVEIND

uoucba

Bunsoryoos pezuowmneun

sts Aq wo

say eupsiadaapanpuod

owaBeubw 21909 1004

swouimnsur Buns

aggpow /yestn Jo 259,“

Feauosieg

ayes

a80a109 wou

SISATUNY GaVZvH Gor

©

SNOUWHEUO- 3UNOEDOW WANSHULNWERO -¥BLNE

me

sroreoeR

ipauosieg Troup dum wo pajoug ame ON AMS “= Sao SOp oT FAO TT

ae va poze

sone som np ut oom Spuounion a

ayaa suosiad ga} Ie 0 poreoqunutiog

wemaog sryomssessy yon PawaHar an INSU “Z 6

sonsiodas

Bou wonvagmoap sSm10q WH “8

7 en 8 so yp

2 Suquen yy papi pur Sop, Spmpor -z| SMT aan

wwoystatadng | T-VXE_ OLOTOW Plone 01 are aalopyion TTY “I | W=OXt | ONINIVALOLOTON “9 | _punory Sun0% | OL

Fos. a9 pews <0

womxinbs 20 sjo0 peu / PIMPS

presses

0 eppeyaanenpue9 8

‘wonmap009 SgO IIS 0

ipawoisg 2009 SOWIS ON. “$

ages 64 paworfo iow smoussessy

eos enL REMY “y

Spy ASH

wom ©

aesisodes

uy | z

ino | _

- “Sskava auvev gor

] BS rere

| __sMounadosanaroueWenuivan an era

sou WOISALERS TI

uwone>o}

201 Jo save 7 poeydsyp pus pourego

‘am syed Ane woos pozrBious asus

smu a0 Surouoxsn09 oy sora dn pass

pus pouuopt are sy Sousfious amstry

semana p08.

ones Buump weasosgo pu e814 2g

‘opwaruan 3004 “61

suonipuos ox dum 81

es

ae “nines

a —— nt

ants a

———

0} umpxoud aso] ur sym sno FuyAaeD woes SORRT EL

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Lighting Control SystemDocument48 pagesLighting Control SystemAli AK100% (1)

- Central Battery SystemDocument48 pagesCentral Battery SystemAli AKNo ratings yet

- Lighting FixturesDocument42 pagesLighting FixturesAli AKNo ratings yet

- Crown Light CommissioningDocument41 pagesCrown Light CommissioningAli AKNo ratings yet