Professional Documents

Culture Documents

Operating and Installation Instructions: Pressure Reducing Station Ari-Presys (Type PRS)

Uploaded by

behnam fallahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Operating and Installation Instructions: Pressure Reducing Station Ari-Presys (Type PRS)

Uploaded by

behnam fallahCopyright:

Available Formats

Operating and installation instructions

Pressure reducing station

ARI-PREsys® (Type PRS)

(Illustration example)

Contents

1.0 General information on operating 5.5 Safety valve.................................................................2-9

instructions .......................................................... 2-2 6.0 Putting the valve into operation / Operation... 2-10

2.0 Notes on possible dangers ................................ 2-2 7.0 Care, maintenance and taking

2.1 Significance of symbols ............................................. 2-2 out of operation.................................................. 2-11

2.2 Explanatory notes on safety information .................... 2-2 8.0 Troubleshooting ................................................ 2-11

3.0 Storage and transport ........................................ 2-3 9.0 Troubleshooting table ...................................... 2-12

4.0 Description .......................................................... 2-3 10.0 Dismantling ..................................................... 2-13

4.1 Scope of applications ................................................. 2-3

11.0 Disposal............................................................ 2-13

4.2 Operating principles.................................................... 2-4

12.0 Warranty / Guarantee ...................................... 2-13

4.3 System arrangement - Pressure reducing station ...... 2-5

4.3.1 Parts ........................................................................ 2-5

4.4 Technical data - remarks ............................................ 2-6

4.5 Marking ...................................................................... 2-6

5.0 Installation ........................................................... 2-7

5.1 General notes on installation ...................................... 2-7

5.2 Requirements at the place of installation.................... 2-7

5.3 Control line, flow restrictor, water seal pot

of the pressure reducing valve..................................... 2-8

5.4 Strainer ...................................................................... 2-9

Rev. 0040901000 3616 englisch

Operating and installation instructions

ARI-Pressure reduction station

1.0 General information on operating instructions

These operating instructions provide information on mounting and maintaining the pressure

reducing station. Please contact the supplier or the manufacturer in case of problems which

cannot be solved by reference to the operating instructions.

They are binding on the transport, storage, installation, start-up, operation, maintenance

and repair.

The notes and warnings must be observed and adhered to.

- Handling and all work must be carried out by expert personnel or all activities must be

supervised and checked.

It is the owner’s responsibility to define areas of responsibility and competence and to

monitor the personnel.

- In addition, current regional safety requirements must be applied and observed when

taking the fittings out of service as well as when maintaining and repairing them.

The manufacturer reserves the right to introduce technical modifications at any time.

These Operating Instructions comply with the requirements of EU Directives and are only

valid in connection with the plant specification sheets. The operating an installation

instructions of all components must be observed.

2.0 Notes on possible dangers

2.1 Significance of symbols

ATTENTION !

... Warning of general danger.

Non-compliance with operating instructions is dangerous!

Read the operating instructions before installation, operation,

maintenance or disassembly and adhere to them strictly.

2.2 Explanatory notes on safety information

In these Operating and Installation Instructions dangers, risks and items of safety

information are highlighted to attract special attention.

Information marked with the above symbol and “ATTENTION!” describe practices, a failure

to comply with which can result in serious injury or danger of death for users or third parties

or in material damage to the system or the environment. It is vital to comply with these

practices and to monitor compliance.

All other information not specifically emphasised such as transport, installation, operating

and maintenance instructions as well as technical data (in the operating instructions,

product documentation and on the device itself) must also be complied with to the fullest

extent in order to avoid faults which in turn can cause serious injury to persons or damage

to property.

Page 2-2 Rev. 0040901000 3616

Operating and installation instructions

ARI-Pressure reduction station

3.0 Storage and transport

ATTENTION !

- Protect against external force (like impact, vibration, etc.).

- Components such as actuators, handwheels, hoods must not be used to take

external forces, e.g. they are not designed for use as climbing aids, or as

connecting points for lifting gear.

- Suitable materials handling and lifting equipment should be used.

See plant specification sheet for weights.

- At -20°C to +65°C (valid for empty systems.)

4.0 Description

4.1 Scope of applications

The pressure reducing station are used for „pressure regulation of liquids, steam, gases

and vapours in the procedure and process technic as well as in the plant manufacture“.

ATTENTION !

- Refer to the plant specification sheet for applications, limits on use and

possibilities.

- Certain media require or preclude the use of special materials.

- The plant is designed for standard operating conditions. If conditions exceed

these requirements, e.g. aggressive or abrasive media, the operator should

state the higher requirements when ordering.

- Valves made from cast iron are not authorised for use in systems subject to

TRD 110.

The information complies to the Pressure Equipment Directive 2014/68/EU.

It is the responsibility of the system operator to ensure compliance.

The special markings on the pressure reducing station and its components must be taken

into account.

Refer to the plant specification sheet to see which materials are used in standard versions.

Please contact the supplier or the manufacturer if you have any questions.

Rev. 0040901000 3616 Page 2-3

Operating and installation instructions

ARI-Pressure reduction station

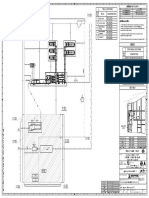

4.2 Operating principles

The pressure reducing station is a direct acting proportional regulator for regulating the

pressure of fluid, gas and vapour media of Fluid Group II pursuant to Pressure Equipment

Directive 2014/68/EU. No auxiliary energy is needed.

In a pressureless state the valves (pos. 4 and 6) before and behind the pressure reducing

valve are fully open, the bypass valve (pos. 8) is closed. The media passes through the

plant from the inlet to the outlet. The pressure behind the pressure reducing valve is

converted to the actuator over the control line (see Fig. 1).

For operating pressures above the allowable actuator temperature, for media (e.g. water for

steam) a water seal pot is inserted in the control line.

The downstream pressure is converted over the actuator diaphragm of the pressure

reducing valve in a force working in the disc closing direction. The spring force is attained in

the spindle over a pin and coupling and is opposed through the diaphragm force, therefore

works in the disc open direction. When both forces are equal, the valve is balanced, and the

downstream pressure is maintained constant.

When the downstream pressure is altered the disc either „opens“ or „closes“.

Page 2-4 Rev. 0040901000 3616

Operating and installation instructions

ARI-Pressure reduction station

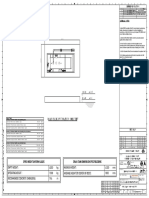

4.3 System arrangement - Pressure reducing station

19

Bypass pipe

9 2

8

10

3

4 5 6

7

1 15

Control line

11

16

17

13

14 18

12

Fig. 1

4.3.1 Parts

Pos. Designation

1 Pressure reducing valve ARI-PREDU

2 Safety valve ARI-SAFE

3 Separator

4 Stop valve ARI-FABA-Plus

5 Strainer

6 Stop valve ARI-FABA-Plus

7 Water seal pot

8 Stop valve with regulating plug, cap and lead-sealing FABA-Plus

9 Upstream manometer P1

10 Downstream manometer P2

11 Stop valve ARI-FABA-Plus

12 Sight glass

13 Ball float steam trap ARI-CONA S

14 Stop valve ARI-FABA-Plus

15 Stop valve ARI-FABA-Plus

16 Stop valve ARI-FABA-Plus

17 Sight glass

18 Bimetallic steam trap ARI-CONA B

19 Orifice plate

Material, dimensions, size (nominal diameter, etc.) see plant specification sheet.

Rev. 0040901000 3616 Page 2-5

Operating and installation instructions

ARI-Pressure reduction station

4.4 Technical data - remarks

for

- Principal dimensions,

- Material, capacity, etc. refer to plant specification sheet.

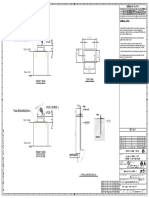

4.5 Marking

Inlet DN/PN

* Upsteam

pressure Outlet DN/PN

* Downstream

CE-marking

pressure

Notified body

Medium

max. perm. temp.

Capacity of the plant

in kg/h or kW

Serial Number Before taking the system in use

Weight of the

and recurrence testing observe

total plant Year of manufacture the operating instructions.

* PS1 = max. permissible upstream pressure

(Set pressure of the safety valve for the upstream system)

* PS2 = max. permissible downstream pressure

(Set pressure of the safety valve for the downstream part. Part of the pressure reducing station)

Fig. 2: Marking of the plant

Address of manufacturer: refer to item 12.0 Warranty / Guarantee

According to the Pressure Equipment Directive appendix 2, table 7 and table 2 the

pressure reducing station is only allowed to be CE-marked category I.

Page 2-6 Rev. 0040901000 3616

Operating and installation instructions

ARI-Pressure reduction station

5.0 Installation

5.1 General notes on installation

The following points should be taken into account besides the general principles governing

installation work:

ATTENTION !

- Remove flange covers if present.

- The interior of the pressure reducing station must be free from foreign particles.

- Note installation position with reference to flow, see mark on the pressure

reducing station.

- Steam line systems should be designed to prevent water accumulation.

- Lay pressure reducing stations so, that damaging transverse, bending and

torsional forces are avoided.

- Protect pressure reducing stations from dirt during construction work.

- Connection flanges must mate exactly.

- Connecting bolts for pipe flanges should be mounted preferably from the

counter flange side (hexagon nuts from the valve side).

At DN15-32: If valves should be mounted directly to valves, the upper flange

connecting bolts should be preferably executed with studs and hexagon nuts on

both sides.

- Components such as actuators, handwheels, hoods must not be used to take

external forces, e.g. they are not designed for use as climbing aids, or as

connecting points for lifting gear.

- Suitable materials handling and lifting equipment should be used.

See plant specification sheet for weights.

- In case of a damaged diaphragm of the pressure reducing valve dangerous

media (hot condensate, steam etc.) can escape out of the vent hole (screw

plug), so connect with a pipe to a safe place.

- We have intended to use a safety valve with an open bonnet for steam. the

possibility of danger through steam escaping must be observed.

- Planners / construction companies or operators are responsible for positioning and

installing the pressure reducing station.

- The stations are designed for application, not influenced from weather.

- For application outside or in adverse environments like corrosion-promoting conditions

(sea water, chemical vapours, etc.), special constructions or protective measures are

recommended.

- Before installing the pressure reducing station rinse and clean the total system otherwise

the seat / disc of the valves will be damaged and the control hole will be blocked.

- Centre packings between the flanges.

5.2 Requirements at the place of installation

The place of installation should be easily accessible and provide ample space for

maintenance and removing the actuator.

Refer to a system sample under point 4.3 where the pressure reducing station with all

components is shown. The pressure reduction should be near to the users.

When isolating of the piping, do not isolate the spring room, the actuator, the water seal pot

and the control line.

Rev. 0040901000 3616 Page 2-7

Operating and installation instructions

ARI-Pressure reduction station

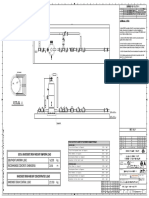

5.3 Control line, flow restrictor, water seal pot

of the pressure reducing valve

ATTENTION !

-

- Install water seal pot for temperature in excess of 100C (NBR-diaphragm) or

130C (EPDM-diaphragm).

- The existing water seal pot must be filled complete (steam, with water) until the

water runs out of the bleed plug from the actuator (see Fig. 3).

can be filled with the help of the supplied funnel.

- Only when the pressure reducing valve in the pressure reducing station shows

unstable working, the supplied flow restrictor must be built in between actuator

and control line.

Funnel

Fill hole

Connection R 3/8

Adjusting plate

Water seal pot

Weld screw

(e.g. Ermeto AS 10-PL)

Actuator Control line

Ventilation

plug Flow restrictor (only by unstable working!)

G 1/4 / G 1/4

Plug

to bleed water

90°-screw

(e.g. Ermeto WE 10-LLR)

R 1/4

Fig. 3

Page 2-8 Rev. 0040901000 3616

Operating and installation instructions

ARI-Pressure reduction station

5.4 Strainer

ATTENTION !

-

A strainer is installed before the pressure reducing valve, with the sieve sideways

(with the medium steam) to avid the collection of condensate.

The strainer must be cleaned from time to time.

5.5 Safety valve

The safety valve must be installed with an outlet pipe, so that if media should flow, it is

purged safety. The piping must be dimensioned that the permissible back pressure doesn’t

exceed 10% of the set pressure. When 10% is exceeded consult the manufacturer.

ATTENTION !

-

The system part behind the pressure reducing valve (downstream pressure

side), the control line and actuator is protected against excess pressure. The

necessary safety valve is dimensioned so that by max. possible upstream

pressure, by fully open pressure reducing valve, the max. possible capacity must

be blown of by the safety valve.

The set pressure must be conform to the system part with the lowest nominal

pressure. An adequate distance must exist between the set downstream

pressure and the safety valve set pressure (min. 25% x P2).

The bypass valve in the system is secured against misuse through a lead seal.

Before using the bypass valve, close the stop valves before and behind the

pressure reducing valve.

If not secured that the open bypass line works parallel to the pressure reducing

valve, the capacity rating for the safety valve must include the extra capacity.

The manufacturer must be consulted in case a necessary change of valve is

needed.

Rev. 0040901000 3616 Page 2-9

Operating and installation instructions

ARI-Pressure reduction station

6.0 Putting the valve into operation / Operation

ATTENTION !

- The operating safety ordinance (in germany: BetrSichV) must be observed.

- Before the test pressure of the system is done, the ball float steam trap CONA

S, the safety valve and the pressure reducing valve must be protected.

- Before putting the valve into operation, check material, pressure, temperature

and direction of flow.

- Regional safety instructions must be adhered to.

- Residues in piping and valves (dirt, weld beads, etc.) inevitably lead to leakage.

- Touching the valve when it is operating at high (> 50°C) or low (< 0°C) media

temperatures can cause injury.

Affix warning notice or protective insulation as appropriate!

- The water seal pot is available for media temperatures over 100 C (NBR-

diaphragm) or 130C (EPDM-diaphragm).

- The water seal pot is completely filled (by steam with water) and the actuator is

bleeded by the plug (see Fig. 3).

Before putting a new plant into operation or restarting a plant after repairs or

modification, always make sure that:

- All works has been completed!

- The valves are in the correct position for its function.

- Bypass valve closed and sealed.

- Safety devices have been attached.

- Valves 14 and 16 must be closed before and during the working system.

The operation is then as follows:

- Open manometer valve.

- Open valves (pos. 11 and 15).

- Close valves pos. 14 and 16).

- If present open the stop valve in the control line.

- Slacken spring by turning adjusting plate (pos. 17) to the left.

- Open valves (pos. 6 behind the pressure reducing valve).

- Now open slowly the stop valve (pos. 4 heat up the piping) then open until the full P1

pressure is reached.

- Pressure reducing valve closes by min. P2 rise.

- Now pre-tension spring by turning adjusting plate (pos. 17) to the right (size 19 spanner -

clockwise) until the desired downstream pressure is obtained (for possible downstream

pressure see type plate on the plant), if downstream pressure is too high, slacken spring

by turning adjusting plate (pos. 17) to the left (anti clockwise).

- To set the pressure reducing valve, the flow must exist.

- Now the pressure reducing valve is ready for use.

ATTENTION !

-

- Squashing of finger between the spring coils and in the area of the pin in the

head piece when the valve lift is moving.

- When in use high flow noise can occur.

Page 2-10 Rev. 0040901000 3616

Operating and installation instructions

ARI-Pressure reduction station

- In case steam exists on the P2 side please contact the manufacturer.

-

- In no case is steam hammer allowed in the system.

- The bypass valve is only allowed to be opened when the stop valves,

downstream, upstream are closed (manual service).

- Manual operation only under supervision.

- When no flow is required, the stop valve before the pressure reducing valve

must be closed.

- The pressure reducing station is only allowed to be used acc. to the given data.

See plant specification sheet. (Correction to new data, consult manufacturer.)

7.0 Care, maintenance and taking out of operation

The operating safety ordinance (in germany: BetrSichV) must be observed.

Regional safety instructions must be adhered, too.

Before the test pressure of the system is done, the ball float steam trap CONA S, the safety

valve and the pressure reducing valve must be protected.

Maintenance and maintenance-intervals have to be defined by the system operator

according to the requirements.

ATTENTION !

- To blow down, the valves 14 and 16 are allowed to be shortly opened only with a fitted

protection piping.

Danger through steam exit!

- Before taking out of operation observe point 10.0!

Taking out of operation in reverse order,

see point „6.0 Putting the valve into operation / Operation“.

8.0 Troubleshooting

In the event of malfunction or faulty operating performance check that the installation and

adjustment work has been carried out and completed in accordance with these Operating

Instructions.

ATTENTION !

It is essential that the safety regulations are observed when identifying faults.

If malfunctions cannot be eliminate with the help of the following table

“9.0 Troubleshooting table”, the supplier or manufacturer should be consulted.

Rev. 0040901000 3616 Page 2-11

Operating and installation instructions

ARI-Pressure reduction station

9.0 Troubleshooting table

ATTENTION !

- read point 10.0 and 12.0 prior to dismantling and repair work !

- read point 5.0 and 6.0 before restarting the plant !

Fault Possible cause Corrective measures

No flow Flange covers not removed Remove flange covers

Little flow Dirt sieve clogged Clean / replace sieve

Piping system clogged Check piping system

Kvs value of valve unsuitable Fit valve with higher Kvs value;

Consult manufacturer

Downstream pressure Seat/disc leakage of the pressure Change valve or, if necessary,

rises quickly when the reducing valve, very dirty seat/plug

users are turned off Control line or flow restrictor blocked Clean control line or flow restrictor

Diaphragm of the pressure reducing Change diaphragm

valve is defect

Vent plug of the pressure reducing Open hole in the vent plug screw

valve is blocked

Valve in the control line closed Open valve in the control line

Actuator of the pressure reducing Loosen lock nut. Tighten actuator;

valve is not fitted proper Fix lock nut

Bypass line not closed proper Close bypass line

Pressure reducing valve defect Change pressure reducing valve

Media comes out of the Diaphragm leaking Change diaphragm

vent plug hole of the

pressure reducing valve

Flange broken Damage during transport Change damaged part

Flange bolts not evenly tightened Change damaged part

Transfer of unsafe forces such as Install free of tension

bending or torsional forces

Downstream pressure Valve sized to small Install valve with larger Kvs-value;

can not be adjusted in the Consult manufacturer

full capacity range Valve setting is wrong Set valve properly

Pressure reducing valve Control line or flow restrictor blocked Clean control line or flow restrictor.

doesn’t regulate Diaphragm defect Change diaphragm.

Control line is connected to the vent Fix control line pipe to the control

plug hole pipe connection

Downstream pressure Flow restrictor not installed Install flow restrictor

unstable

Media exit out of the bon- Pressure reducing valve bellow defect Change pressure reducing valve

net of the pressure reduc-

ing valve (at the spindle

leakage)

Downstream pressure Manometer defect Change manometer

can’t be altered Valve closed in the control line Open valve in the control line

Valve stem of the pres- Valve plug slightly seized owing to Change pressure reducing valve

sure reducing valve solid dirt particles

moves in jerks

Unsafe rise in down- Safety valve or outlet blocked Remove test gag or blind flanges

stream pressure

Page 2-12 Rev. 0040901000 3616

Operating and installation instructions

ARI-Pressure reduction station

10.0 Dismantling

ATTENTION !

The following points must be observed:

- Pressureless pipe system.

- Medium must be cool.

- Plant must be drained.

- Purge piping systems in case of caustic, inflammable, aggressive or toxic

media.

- The operating an installation instructions of all components must be observed.

11.0 Disposal

Disposal of this product or parts of it must be carried out according to the following

guidelines:

Use the local public or private waste collection service.

12.0 Warranty / Guarantee

The extent and period of warranty cover are specified in the "Standard Terms and

Conditions of Albert Richter GmbH & Co. KG" valid at the time of delivery or, by way of

departure, in the contract of sale itself.

We guarantee freedom of faults in compliance with state-of-the-art technology and the

confirmed application.

No warranty claims can be made for any damage caused as the result of incorrect handling

or disregard of operating and installation instructions, datasheets and relavant regulations.

This warranty also does not cover any damage which occurs during operation under

conditions deviating from those laid down by specifications or other agreements.

Justified complaints will be eliminated by repair carried out by us or by a specialist

appointed by us.

No claims will be accepted beyond the scope of this warranty. The right to replacement

delivery is excluded.

The warranty shall not cover maintenance work, installation of external parts, design

modifications or natural wear.

Any damage incurred during transport should not be reported to us but rather to the

competent cargo-handling depot, the railway company or carrier company immediately or

else claims for replacements from these companies will be invalidated.

Technology for the Future.

GERMAN QUALITY VALVES

ARI-Armaturen Albert Richter GmbH & Co. KG, D-33750 Schloß Holte-Stukenbrock

Telephone (+49 5207) 994-0 Telefax (+49 5207) 994-158 or 159

Internet: http://www.ari-armaturen.com E-mail: info.vertrieb@ari-armaturen.com

Rev. 0040901000 3616 Page 2-13

You might also like

- Wheel Loader Liebherr 2plus2 L 550-L 586 - Service ManualDocument165 pagesWheel Loader Liebherr 2plus2 L 550-L 586 - Service ManualAdam Pegiel86% (43)

- Reintjes Marine Reduction Gear Operating ManualDocument72 pagesReintjes Marine Reduction Gear Operating Manualbigcee6496% (24)

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- Maintenance Manual - Varco ST-80 RoughneckDocument42 pagesMaintenance Manual - Varco ST-80 RoughneckCarlos Alberto Perdomo100% (2)

- The Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsFrom EverandThe Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsRating: 3.5 out of 5 stars3.5/5 (14)

- TDS-11SA Service Manual PDFDocument236 pagesTDS-11SA Service Manual PDFBoris Zaslichko88% (33)

- Hibon Blower ManualDocument55 pagesHibon Blower ManualAulia RahmanNo ratings yet

- A300-Service Manual PDFDocument122 pagesA300-Service Manual PDFCarl100% (1)

- Operating manual for liquid ring vacuum pumps and compressorsDocument0 pagesOperating manual for liquid ring vacuum pumps and compressorsCorina PanfilNo ratings yet

- Top Drive ManualDocument236 pagesTop Drive ManualAlex Zaman100% (1)

- Manual - 2389 Hs-Iso-Vac r2Document21 pagesManual - 2389 Hs-Iso-Vac r2Federico QuijanoNo ratings yet

- IHT-M15: Integrated Hydrostatic Transaxle Service ManualDocument48 pagesIHT-M15: Integrated Hydrostatic Transaxle Service ManualJane SmithNo ratings yet

- Suzuki sx4 ManualDocument445 pagesSuzuki sx4 ManualAlexe Victor100% (3)

- Operator’S Guide to Centrifugal Pumps, Volume 2: What Every Reliability-Minded Operator Needs to KnowFrom EverandOperator’S Guide to Centrifugal Pumps, Volume 2: What Every Reliability-Minded Operator Needs to KnowNo ratings yet

- Major Process Equipment Maintenance and RepairFrom EverandMajor Process Equipment Maintenance and RepairRating: 4 out of 5 stars4/5 (4)

- Student Information Maintenance System ProjectDocument4 pagesStudent Information Maintenance System ProjectHarshpreet Singh0% (1)

- CT3701 - Instruction Manual For Gazcon PSA M2-V41 - 1Document32 pagesCT3701 - Instruction Manual For Gazcon PSA M2-V41 - 1Anonymous uTO1WINo ratings yet

- Operating & Installation Instruction PRVDocument16 pagesOperating & Installation Instruction PRVNguyễn SángNo ratings yet

- 2Document17 pages2WormInchNo ratings yet

- Installation and Operating Instructions: Straight Through Control Valves STEVI 448/449Document18 pagesInstallation and Operating Instructions: Straight Through Control Valves STEVI 448/449widuri nirmalaNo ratings yet

- ManualDocument15 pagesManualAndres NavarroNo ratings yet

- Manual Bomba KSB RPK 41 1118Document20 pagesManual Bomba KSB RPK 41 1118elegel1982100% (2)

- TCS Owner's Manual (Rev. 0612-PC-02)Document54 pagesTCS Owner's Manual (Rev. 0612-PC-02)Kito CanadaNo ratings yet

- Universal Excess Pressure Valve SAMSON Type 41-73Document37 pagesUniversal Excess Pressure Valve SAMSON Type 41-73Bata ZivanovicNo ratings yet

- TCR Operation and PartsDocument78 pagesTCR Operation and PartsKito Canada100% (2)

- User Instructions: Flowact - Adaption For Valtek Mark One Installation Operation MaintenanceDocument60 pagesUser Instructions: Flowact - Adaption For Valtek Mark One Installation Operation MaintenanceisctomaslopezNo ratings yet

- TDS1000AInstallationManual 03May28AbridgedDocument20 pagesTDS1000AInstallationManual 03May28Abridgedbwd104No ratings yet

- Operating and Installation Instructions: Disc Check Valves Checko - D DN125-350Document8 pagesOperating and Installation Instructions: Disc Check Valves Checko - D DN125-350sauloNo ratings yet

- Self-Operated Pressure Regulator Installation GuideDocument16 pagesSelf-Operated Pressure Regulator Installation GuideHamilton MaranhãoNo ratings yet

- Operating and Installation Instructions: Automatic Air Vent (PN16 - 40)Document10 pagesOperating and Installation Instructions: Automatic Air Vent (PN16 - 40)thirumurugan sNo ratings yet

- Flow Serve PositionerDocument40 pagesFlow Serve Positionersomucdm6023100% (1)

- Operating and Installation Instructions: Straight Through Control Valves - STEVI 440 / 441, 445 / 446Document20 pagesOperating and Installation Instructions: Straight Through Control Valves - STEVI 440 / 441, 445 / 446widuri nirmalaNo ratings yet

- Datasheet 4140 Pressure Temperature Switch 0119rev12Document14 pagesDatasheet 4140 Pressure Temperature Switch 0119rev12irfanWPKNo ratings yet

- Self-Operated Pressure Regulators: Type 41-23 Universal Pressure Reducing ValveDocument20 pagesSelf-Operated Pressure Regulators: Type 41-23 Universal Pressure Reducing ValveDiego Martínez FernándezNo ratings yet

- T19 0扶梯电气随机文件(默纳克一体机)(英文)Document83 pagesT19 0扶梯电气随机文件(默纳克一体机)(英文)Tora BorgaNo ratings yet

- Operation Manual: & Parts ListDocument62 pagesOperation Manual: & Parts ListanggieNo ratings yet

- (Iom150563 Ed05-2015) (En) Butterfly Check Valve D150 D151 D160 D161 D162 D163Document12 pages(Iom150563 Ed05-2015) (En) Butterfly Check Valve D150 D151 D160 D161 D162 D163Ирина ИринаNo ratings yet

- SM0856BDocument236 pagesSM0856Bsorangel_123No ratings yet

- Manual Ve 15-45 Se-P1 (GB) Rev01Document25 pagesManual Ve 15-45 Se-P1 (GB) Rev01Voştinar IoanNo ratings yet

- Oim UlncDocument38 pagesOim UlncHendi HendriansyahNo ratings yet

- Operating Instructions Back Pressure Regulator Series: BPR: Holter RegelarmaturenDocument19 pagesOperating Instructions Back Pressure Regulator Series: BPR: Holter Regelarmaturenamin100% (2)

- Flow Regulator SAMSON 42-36 ManualDocument28 pagesFlow Regulator SAMSON 42-36 Manualenjiniring sbklNo ratings yet

- Installation and Repair Manual For Compressor G4481/G6204 Lincoln Air Vantage WelderDocument23 pagesInstallation and Repair Manual For Compressor G4481/G6204 Lincoln Air Vantage WelderJamie RobertsNo ratings yet

- Operating and Installation Instructions: Safety Valves SAFEDocument18 pagesOperating and Installation Instructions: Safety Valves SAFEkaka_patoNo ratings yet

- ServiceDocument398 pagesServicemaher mlbaseNo ratings yet

- Revestimiento Tuberia2Document44 pagesRevestimiento Tuberia2jlcegarraNo ratings yet

- Ms KRT 2553 804 10 14Document40 pagesMs KRT 2553 804 10 14sharandeep1112No ratings yet

- Pneumatic Barrel Pumps Model SAF1-YL Und SAF2-YL: Owner Manual Operating Instructions and Service Parts ListDocument17 pagesPneumatic Barrel Pumps Model SAF1-YL Und SAF2-YL: Owner Manual Operating Instructions and Service Parts Listredwan al-mustafaNo ratings yet

- Strainer InstallationDocument10 pagesStrainer InstallationNhuan Pham VanNo ratings yet

- Armstrong Installation43.80 VIL I&ODocument14 pagesArmstrong Installation43.80 VIL I&Osas999333No ratings yet

- Cursor Tier 3 Series I PDFDocument216 pagesCursor Tier 3 Series I PDFChhoan Nhun100% (1)

- Manual Safety Installation Operations Tescom en 123946Document23 pagesManual Safety Installation Operations Tescom en 123946Karikalan JayNo ratings yet

- Lorentz Pump ManualDocument16 pagesLorentz Pump ManualGirish OniyilNo ratings yet

- RTX Iom Alr R01Document13 pagesRTX Iom Alr R01NCNo ratings yet

- Compresor Sullair LS25S-257KWDocument83 pagesCompresor Sullair LS25S-257KWEduardo Saúl Tapia100% (4)

- Kiln Gear Ring Oil Automatic SprayDocument78 pagesKiln Gear Ring Oil Automatic SprayAdi IrpaiNo ratings yet

- Products L4AS Modularc CB 71916 V1 enDocument20 pagesProducts L4AS Modularc CB 71916 V1 enUrsula JohnsonNo ratings yet

- Gascat - Pressure Regulating Valve ManualDocument14 pagesGascat - Pressure Regulating Valve ManualDidik SetyawanNo ratings yet

- Apa-Zhd-Pr-Cal-026 15Document1 pageApa-Zhd-Pr-Cal-026 15behnam fallahNo ratings yet

- Apa-Zhd-Pr-Cal-026 15Document1 pageApa-Zhd-Pr-Cal-026 15behnam fallahNo ratings yet

- Apa-Zhd-Pr-Cal-026 19Document1 pageApa-Zhd-Pr-Cal-026 19behnam fallahNo ratings yet

- Apa-Zhd-Pr-Cal-026 13Document1 pageApa-Zhd-Pr-Cal-026 13behnam fallahNo ratings yet

- Druckminderstation 300 200 eDocument35 pagesDruckminderstation 300 200 ebehnam fallahNo ratings yet

- Binder1 1Document1 pageBinder1 1behnam fallahNo ratings yet

- 9Document1 page9behnam fallahNo ratings yet

- 7Document1 page7behnam fallahNo ratings yet

- AJEAT Vol.7 No.S1 April 2018 Pp. 7 10Document5 pagesAJEAT Vol.7 No.S1 April 2018 Pp. 7 10behnam fallahNo ratings yet

- Vendor List: Gas Pressure Reducing Station TBS 30,000 SCMHDocument2 pagesVendor List: Gas Pressure Reducing Station TBS 30,000 SCMHbehnam fallahNo ratings yet

- 5Document1 page5behnam fallahNo ratings yet

- 8Document1 page8behnam fallahNo ratings yet

- 3Document1 page3behnam fallahNo ratings yet

- 6Document1 page6behnam fallahNo ratings yet

- 2Document1 page2behnam fallahNo ratings yet

- 4Document1 page4behnam fallahNo ratings yet

- Safety Shut Off Valve DatasheetDocument3 pagesSafety Shut Off Valve Datasheetbehnam fallahNo ratings yet

- 1Document1 page1behnam fallahNo ratings yet

- Modeling Biologics, Antibodies & ProteinsDocument2 pagesModeling Biologics, Antibodies & Proteinsthamizh555No ratings yet

- Description and Operation: Unison Industries Component Maintenance Manual Ignition LeadsDocument2 pagesDescription and Operation: Unison Industries Component Maintenance Manual Ignition Leadsmaty englerNo ratings yet

- AHU DetailsDocument2 pagesAHU DetailsamitbslpawarNo ratings yet

- LinuxCBT Squid NotesDocument3 pagesLinuxCBT Squid NotesrajasekarkalaNo ratings yet

- SOP Periodic Balance Check Eccentricity - e - 11793058Document4 pagesSOP Periodic Balance Check Eccentricity - e - 11793058Marcos PerezNo ratings yet

- Electrical Design AnalysisDocument12 pagesElectrical Design AnalysisJerome Virgo Catipay100% (2)

- AN5274 IC Audio Toshiba 21Document7 pagesAN5274 IC Audio Toshiba 21Abu AsyifaNo ratings yet

- Cavpower Filter ListDocument5 pagesCavpower Filter Listshanmuga.chokkaiyanNo ratings yet

- Supply Chain Management-A Key To Sucess in Indian Rural MarketDocument18 pagesSupply Chain Management-A Key To Sucess in Indian Rural MarketVishal BishnoiNo ratings yet

- BHA PROPOSAL FOR SERD-N2 ST WELLDocument1 pageBHA PROPOSAL FOR SERD-N2 ST WELLPinggir KaliNo ratings yet

- Digicoil Parts List: GBC Is An Acco Brands CompanyDocument46 pagesDigicoil Parts List: GBC Is An Acco Brands CompanyMike DonnellyNo ratings yet

- (CHEVROLET) Manual de Taller Chevrolet Sail 2010Document120 pages(CHEVROLET) Manual de Taller Chevrolet Sail 2010Nader Jimenez79% (14)

- Feltest Whitepaper - Correct Felt Permeability (ENG)Document6 pagesFeltest Whitepaper - Correct Felt Permeability (ENG)Engr. Waqar AliNo ratings yet

- Investment Castings, Steel and Alloy, Common Requirements, For General Industrial UseDocument9 pagesInvestment Castings, Steel and Alloy, Common Requirements, For General Industrial UseAngel CamberoNo ratings yet

- Diseño y Calculo de Valvulas MariposaDocument2 pagesDiseño y Calculo de Valvulas MariposaKilo AsaelNo ratings yet

- Presentation-Rock Mechanics PDFDocument35 pagesPresentation-Rock Mechanics PDFRENGANATHAN PNo ratings yet

- RESUME TITLEDocument2 pagesRESUME TITLEYogesh ChaudhariNo ratings yet

- Circular PierDocument48 pagesCircular PierAbhijeet Sahu100% (2)

- Coating, Laminating and Testing CapabilitiesDocument28 pagesCoating, Laminating and Testing CapabilitiesrabiulfNo ratings yet

- LUXATHANE 5160 Polyurethane Finish Product DetailsDocument2 pagesLUXATHANE 5160 Polyurethane Finish Product DetailsshameelNo ratings yet

- Alspa Drive Range - Drives Solutions PDFDocument8 pagesAlspa Drive Range - Drives Solutions PDFRahul AnandNo ratings yet

- Listening Scripts Kls 4Document5 pagesListening Scripts Kls 4dedepamulangNo ratings yet

- 9 Ray Optics and Optical Instruments: SolutionsDocument48 pages9 Ray Optics and Optical Instruments: SolutionsVISHAL SINGHNo ratings yet

- Apega Salary PDFDocument137 pagesApega Salary PDFharshdNo ratings yet

- Edm Electrodes: Function of The ElectrodeDocument8 pagesEdm Electrodes: Function of The ElectrodeTaimur KhalidNo ratings yet

- UT For Duplex Stainless Steel WeldsDocument5 pagesUT For Duplex Stainless Steel WeldsvsnaiduqcNo ratings yet

- Central Office FY 2018Document8 pagesCentral Office FY 2018Malson GutierrezNo ratings yet

- STRESS AND STRAIN CALCULATIONSDocument3 pagesSTRESS AND STRAIN CALCULATIONSSaketh BoggavarapuNo ratings yet